Pebble stratum deep and large foundation pit underground diaphragm wall retaining wall slurry and preparation method thereof

An underground continuous wall and stratum technology, applied in chemical instruments and methods, fertilization devices, organic fertilizers, etc., can solve the problem that specific gravity, pH value, viscosity stability are easily affected by groundwater, unfavorable environmental protection, and can not effectively ensure the stability of the tank wall. The performance of slurry wall protection and slurry recycling and reuse rate are improved, environmental pollution and material consumption are reduced, and the tank wall stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

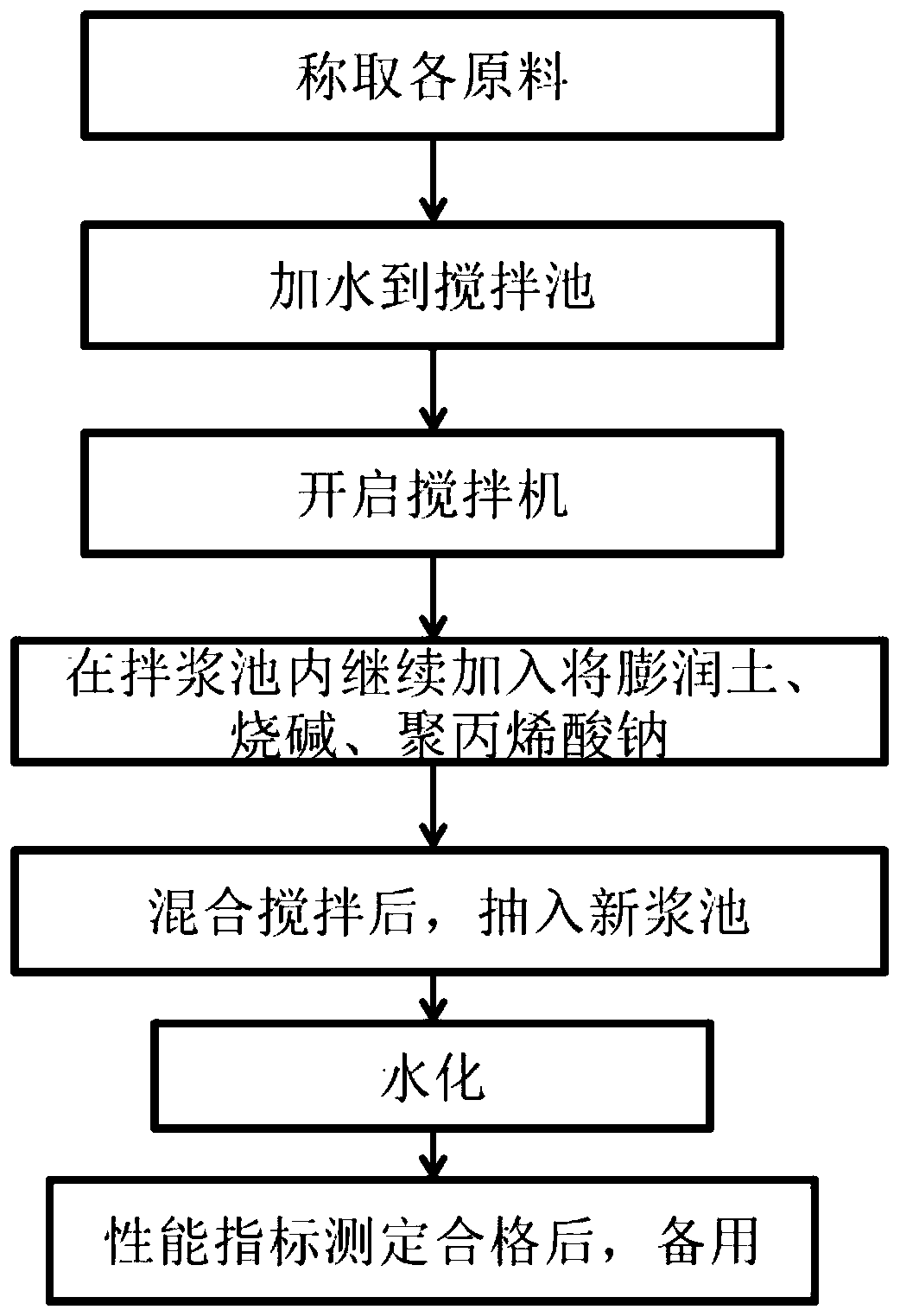

Method used

Image

Examples

Embodiment 1

[0034] The mud for retaining wall of the underground diaphragm wall of a deep and large foundation pit in a round boulder formation includes the following raw materials in parts by weight: 1000 parts of water, 75 parts of bentonite, 3 parts of soda ash, and 0.5 part of sodium polyacrylate.

[0035] Among them, the raw water comes from the groundwater extracted by drilling, pH 6, and used after passing the test; the soda ash is industrial soda ash, which is mixed with raw water, and the pH is 8; the sodium polyacrylate is food-grade sodium polyacrylate used as a thickener.

Embodiment 2

[0037] A kind of slurry for retaining walls of underground diaphragm walls of deep and large foundation pits in round boulder formations in this embodiment includes the following raw materials in parts by weight: 1000 parts of water, 85 parts of bentonite, 5 parts of soda ash, and 1.5 parts of sodium polyacrylate.

[0038] Among them, the raw water comes from the groundwater extracted by drilling, pH 7, and used after passing the test; industrial soda ash is used, and the pH is 10 after mixing with raw water; sodium polyacrylate is food-grade sodium polyacrylate used as a thickener.

Embodiment 3

[0040] The mud for retaining wall of the underground diaphragm wall of a deep and large foundation pit in a round boulder formation comprises the following raw materials in parts by weight: 1000 parts of water, 80 parts of bentonite, 4 parts of soda ash, and 1 part of sodium polyacrylate.

[0041] Among them, the raw water comes from the groundwater extracted by drilling, pH 6.5, and is used after passing the test; industrial soda ash is used, and the pH is 9 after being mixed with raw water; sodium polyacrylate is food-grade sodium polyacrylate used as a thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com