Tire

A tire, tire circumferential technology, applied in off-road vehicle tires, tire parts, tire tread/tread pattern, etc., can solve problems such as vehicle drift and lack of consideration, and achieve improved road performance, high mud performance, and improved The effect of sand road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, one embodiment of the present invention will be described based on the drawings.

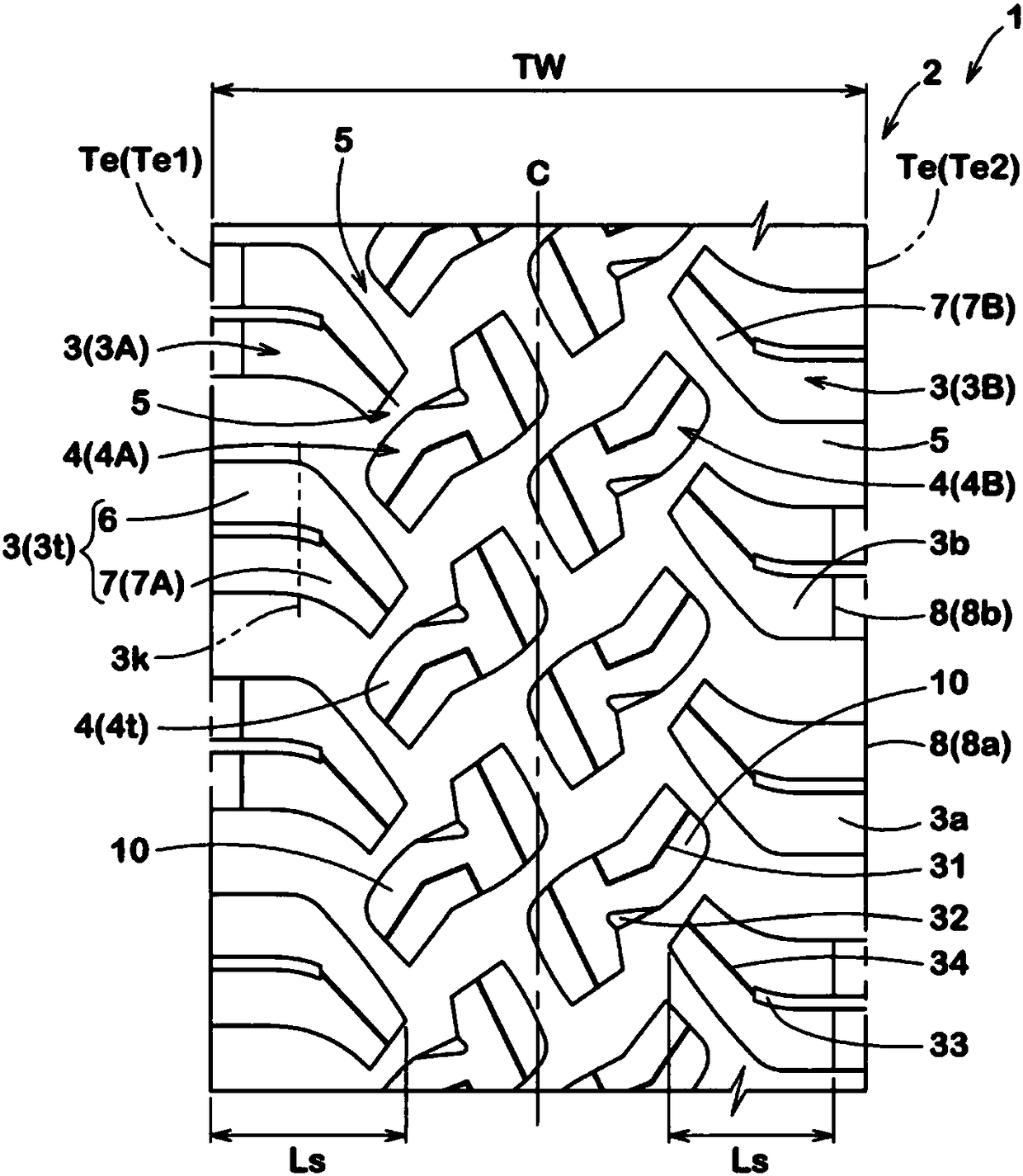

[0029] figure 1 A developed view showing the tread portion 2 of the tire 1 according to one embodiment of the present invention is shown. The present invention can be used, for example, as various tires such as pneumatic tires for cars and trucks, and non-pneumatic tires that do not fill the inside of the tire with pressurized air. The tire 1 of this embodiment is an all-season tire for a four-wheel drive vehicle.

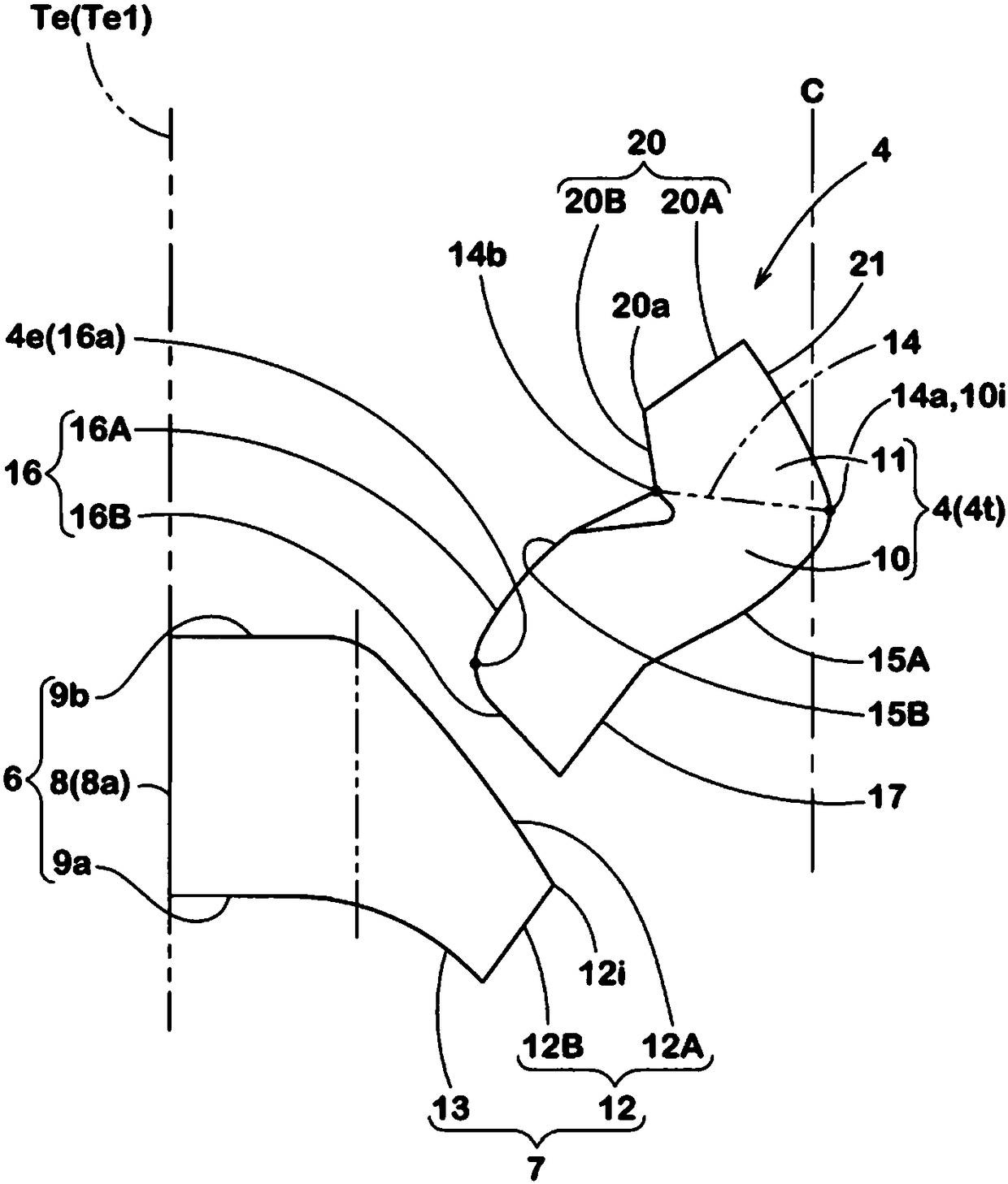

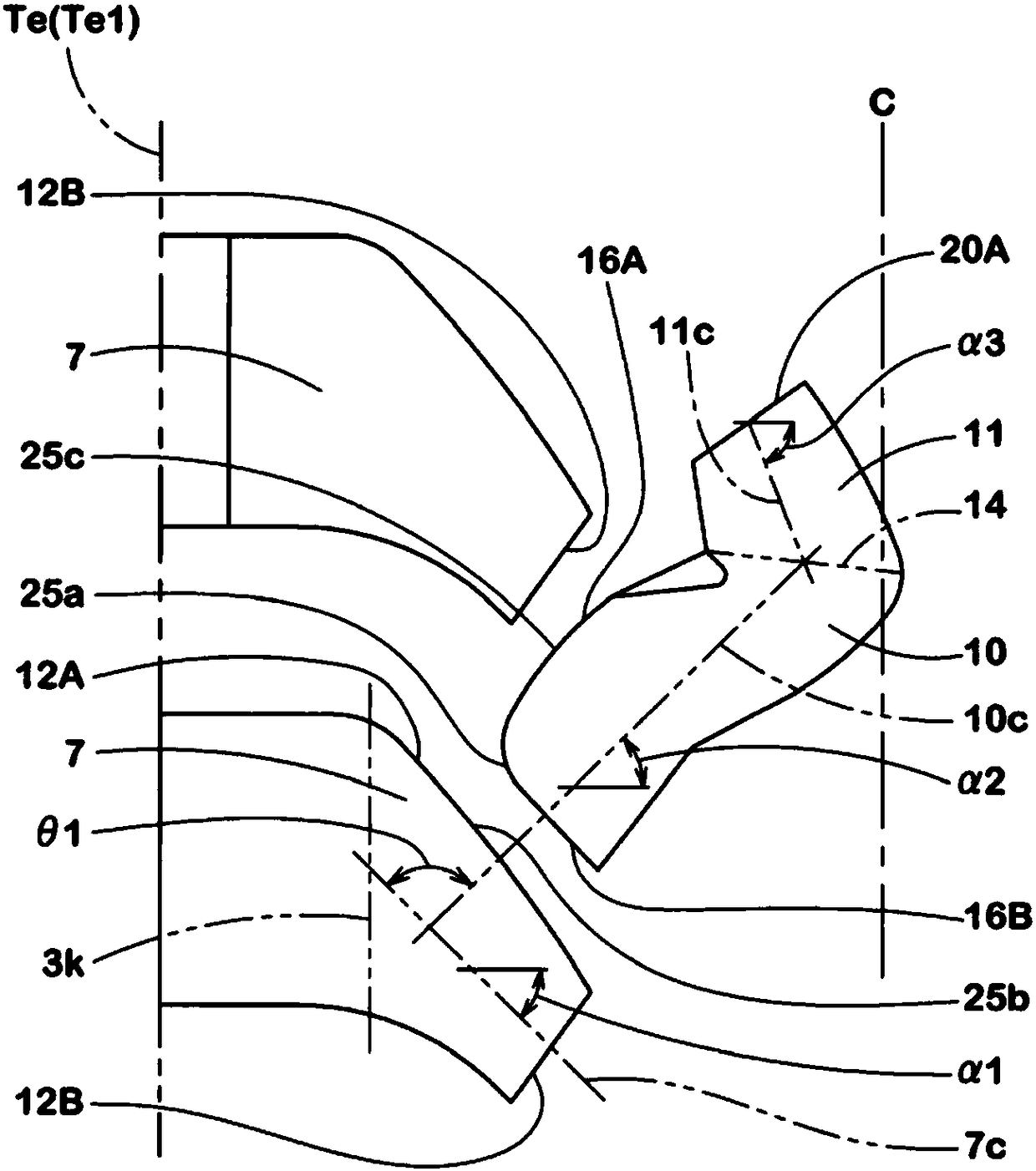

[0030] Such as figure 1 As shown, the tread portion 2 of the tire 1 is provided with a shoulder block 3 disposed on the tread edge Te side and a crown block 4 disposed axially inward of the shoulder block 3 . The tread portion 2 of the present embodiment is provided with grooves 5 extending between the shoulder blocks 3 , 3 , between the crown blocks 4 , 4 , and between the shoulder blocks 3 and the crown blocks 4 .

[0031] The shoulder block 3 of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com