Cationic polymer densifier, fracturing fluid and preparation method thereof

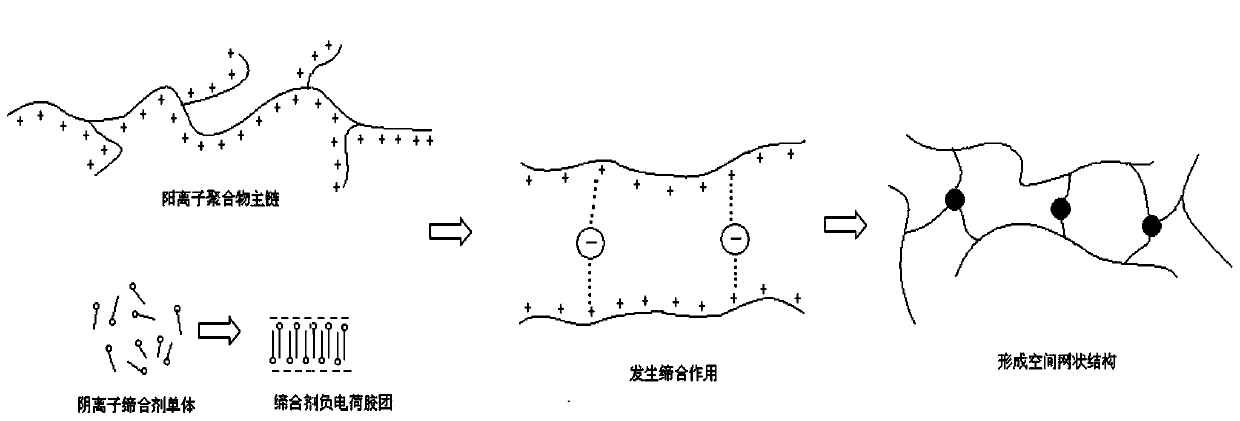

A cationic polymer and anionic associative agent technology, applied in the field of oil drilling, can solve the problems of high pump injection friction, large amount of residue, unfavorable deep well construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Use an appropriate amount of deionized water to dissolve AM, 10% DMDAAC, 4% urea and 4% sodium bicarbonate in sequence with a mass fraction of 30%;

[0037] 2) Add 0.05% of the mixture of sodium bisulfite and ammonium persulfate and 0.04% of 2,2'-azobisisobutylamidine dihydrochloride, accounting for the total mass of AM and DMDAAC, at 40°C under the condition of nitrogen protection , reacted for 20 minutes, and when the temperature of the system rose to 90°C, continued to react for 1.5 hours to obtain a solid polymer;

[0038] 3) Cut the polymer product into 1cm 3 The left and right cubes are stirred in kerosene containing 2wt% Span-80 to make it further broken;

[0039] 4) Dry the pulverized product at 70° C., and then pulverize it into a 60-mesh powder.

Embodiment 2

[0041] 1) Dissolve AM, 12% DMDAAC, 5% urea and 5% sodium bicarbonate in sequence with an appropriate amount of deionized water;

[0042] 2) Add 0.05% of the mixture of sodium bisulfite and ammonium persulfate and 0.04% of 2,2'-azobisisobutylamidine dihydrochloride, accounting for the total mass of AM and DMDAAC, at 45°C under the condition of nitrogen protection , reacted for 20 minutes, and when the temperature of the system rose to 96°C, continued the reaction for 1 hour to obtain a solid polymer;

[0043] 3) Cut the polymer product into 1cm 3The left and right cubes are stirred in kerosene containing 2wt% Span-80 to make it further broken;

[0044] 4) Dry the pulverized product at 70° C., and then pulverize it into a 60-mesh powder.

Embodiment 3

[0046] 1) Use an appropriate amount of deionized water to dissolve AM, 11% DMDAAC, 4.5% urea and 4.5% sodium bicarbonate in sequence with a mass fraction of 33%;

[0047] 2) Add 0.055% of the mixture of sodium bisulfite and ammonium persulfate and 0.045% of 2,2'-azobisisobutylamidine dihydrochloride, accounting for the total mass of AM and DMDAAC, under nitrogen protection conditions at 43°C , reacted for 20 minutes, and when the temperature of the system rose to 93°C, continued the reaction for 1 hour to obtain a solid polymer;

[0048] 2. the preparation of fracturing fluid (in the following each embodiment, described polymer thickener is all obtained by embodiment 1):

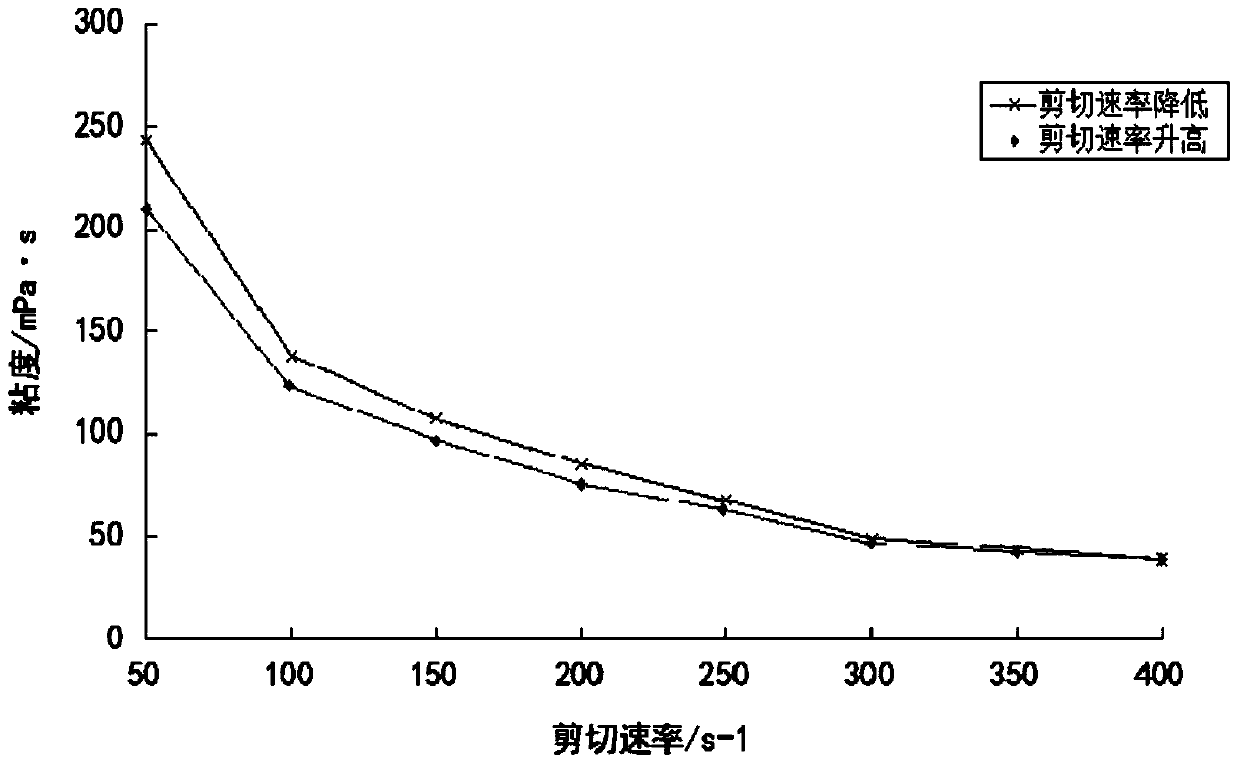

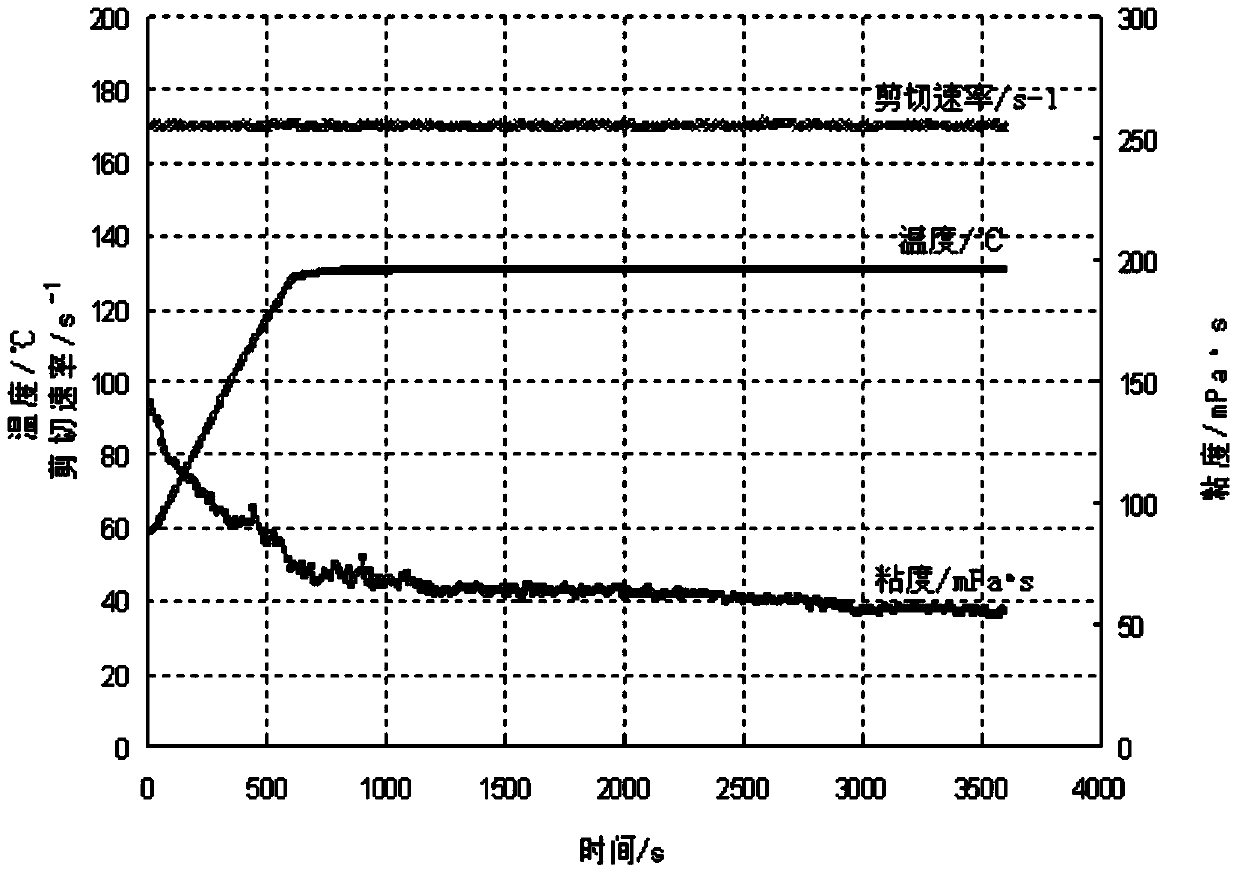

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com