Anhydrous foam generator for shale oil and gas reservoir fracturing as well as application thereof

A foam generator, shale oil and gas technology, applied in chemical instruments and methods, production fluids, wellbore/well components, etc., can solve problems such as difficult to meet the requirements of high-efficiency occurrence of anhydrous foam, prevent clogging of gates, reduce The effect of damaging the formation and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

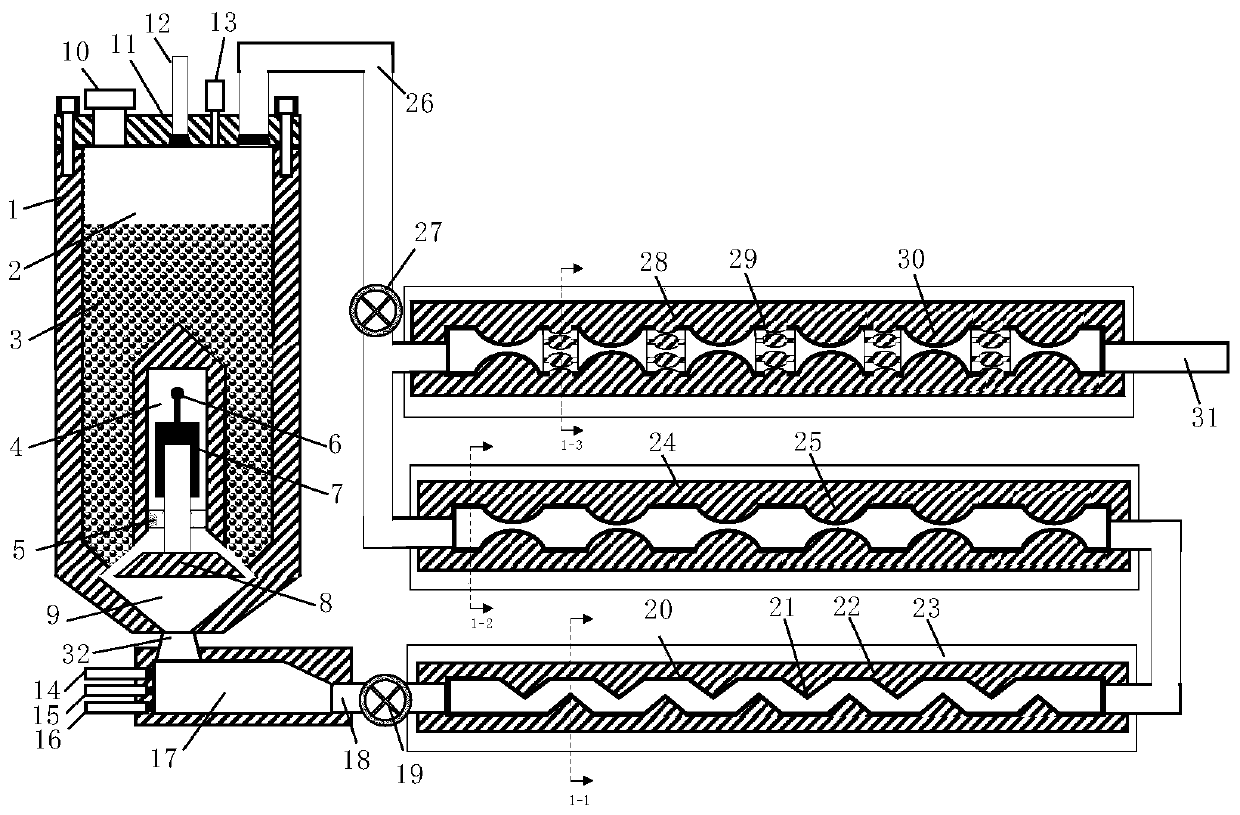

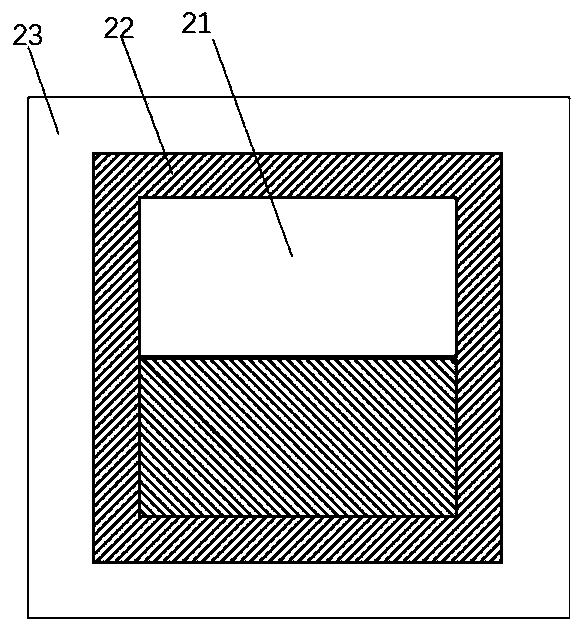

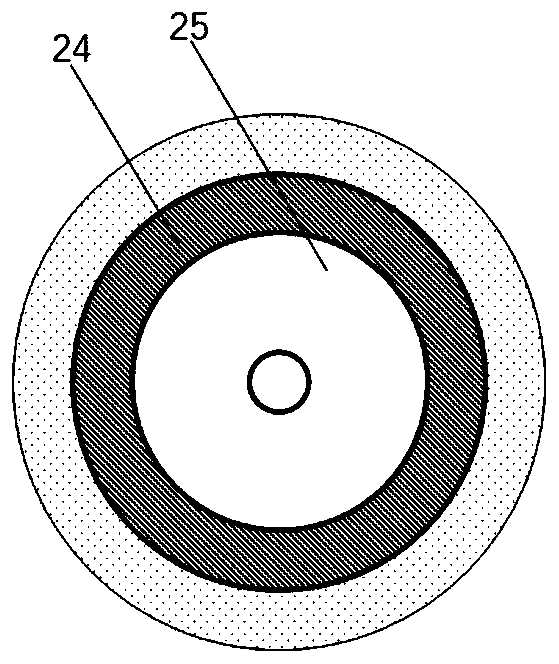

[0062] The structural representation of the anhydrous foam generator for shale oil and gas reservoir fracturing provided by the invention is as follows figure 1 As shown, it includes a proppant storage tank (including a proppant storage tank body 1 and a proppant storage tank inner chamber 2), a high-pressure gas-liquid-solid mixer 17, an anhydrous foam fracturing fluid primary oscillator, an anhydrous foam fracturing fluid Secondary oscillator for fracturing fluid and third-stage oscillator for anhydrous foam fracturing fluid. The top of the proppant storage tank body 1 (the upper cover plate 11 of the proppant storage tank body) is provided with a sand filling port 10, liquid CO 2 The second injection port 12 and the safety valve 13, the bottom is connected with the high-pressure gas-liquid-solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com