Well clean-up sand washing device and method

A technology of well washing and sand flushing, which is used in earth-moving drilling, wellbore/well components, cleaning equipment, etc. The effect of liquid speed and strong sprinting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

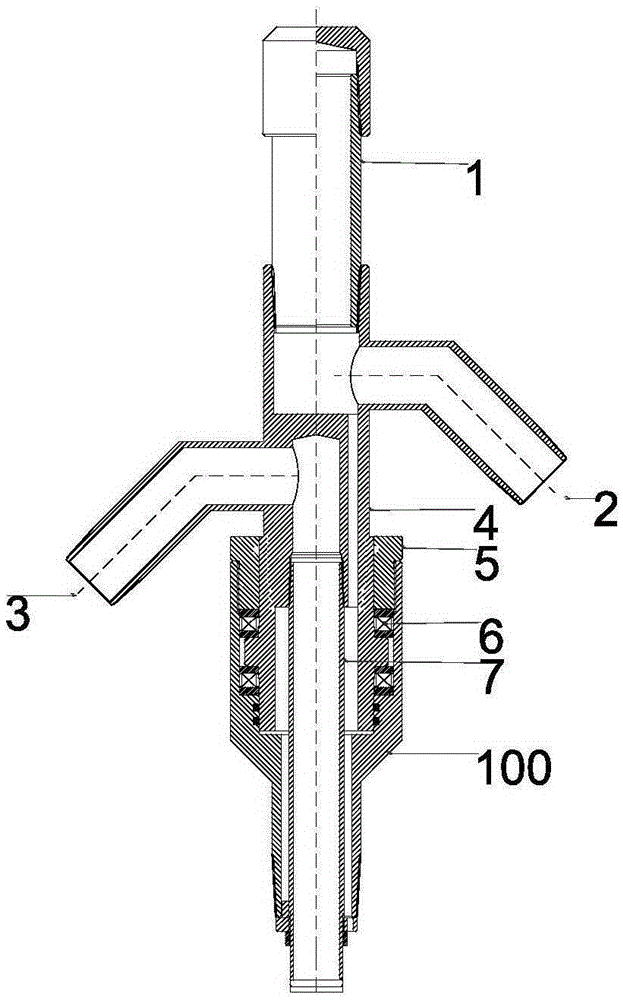

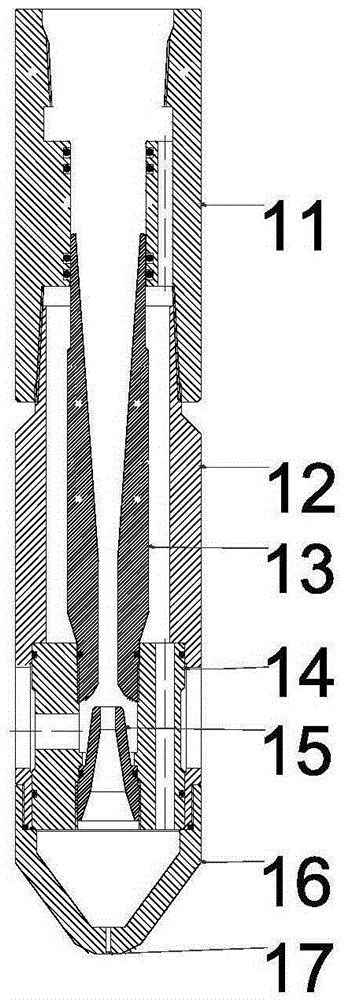

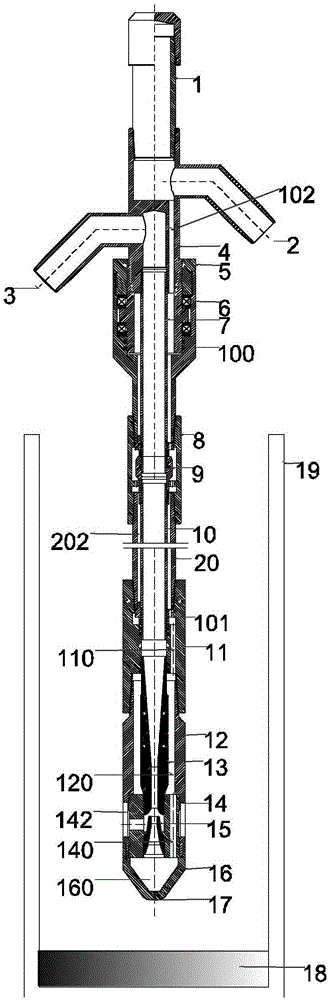

[0020] Example: such as Figure 1-3 As shown, the present invention provides a specific embodiment of a well washing and sand washing device, which includes a faucet, a double-layer concentric oil pipe whose top is connected to the water faucet, a well washing device connected to the bottom end of the double-layer concentric oil pipe, and a water source Water source well casing 19 on the well. Wherein the water source well casing pipe 19 bottom deposits sand 18.

[0021] The faucet includes the lifting sub-joint 1 located above, the multi-flow joint 4 connected with the lifting sub-joint 1, the well flushing inlet 2 connected with the high-pressure pump truck pump and connected with the multi-flow joint 4, connected with the multi-flow joint 4 and located in the washing The well-flushing outlet 3 below the well inlet 2, the faucet joint cap 5 stuck on the side of the multi-flow joint 4, the pressure-bearing bearing 6 that is in contact with the faucet joint cap 5, is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com