Polymer filtrate reducer and preparation method thereof

A technology of fluid loss reducer and polymer, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low molecular weight and unsatisfactory, and achieve simple operation, stable product quality, and no pollution to the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

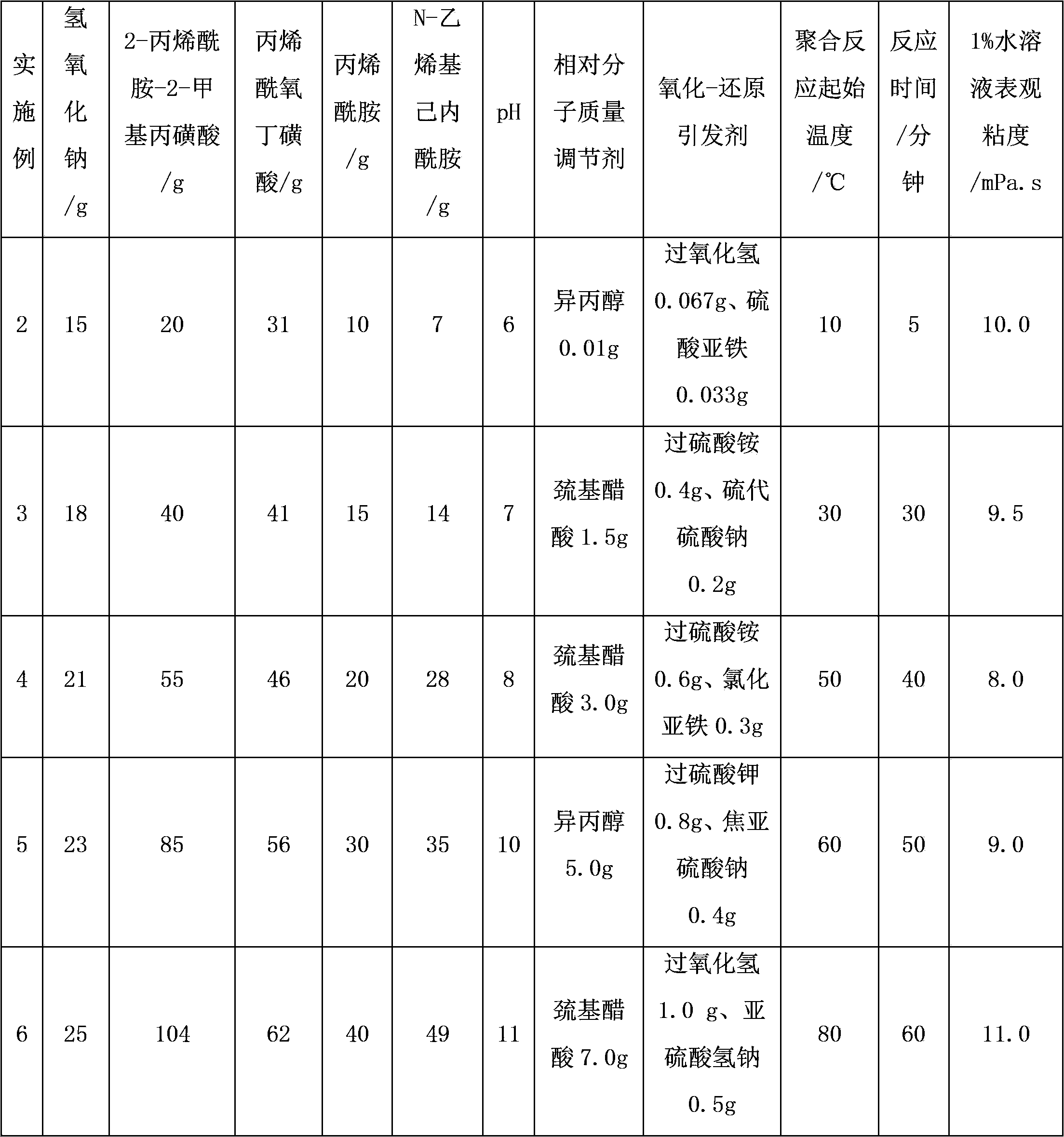

Examples

Embodiment 1

[0019] Add the required amount of water into the reaction flask with a stirrer, then add 25g of sodium hydroxide, and after it dissolves, mix the acidic monomer, 2-acrylamide-2-methylpropanesulfonic acid 90g, acryloyloxybutyl 40g of sulfonic acid, stir until completely dissolved; then add 35g of acrylamide and 25g of N-vinylcaprolactam, stir to dissolve, and adjust the pH value of the system to 7.5 with a mass fraction of 20% to 45% sodium hydroxide aqueous solution; The reaction mixture of the above-mentioned monomers was transferred to a polypropylene plastic container, and 5 g of relative molecular mass regulator isopropanol, 0.5 g of oxidation-reduction initiator potassium persulfate, and 0.25 g of sodium sulfite were added accordingly under stirring, and the mixture was stirred evenly and left to stand React for 20 minutes, the initial temperature of the polymerization reaction is 10°C, and finally obtain a porous elastomer, which is crushed, dried, and pulverized to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com