Zwitterionic inorganic-organic monomer polymer drilling fluid treatment agent and preparation method thereof

A drilling fluid treatment agent and amphoteric ion technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of insufficient inhibition of synthetic products, achieve good protection effect, high permeability recovery value, control water The effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

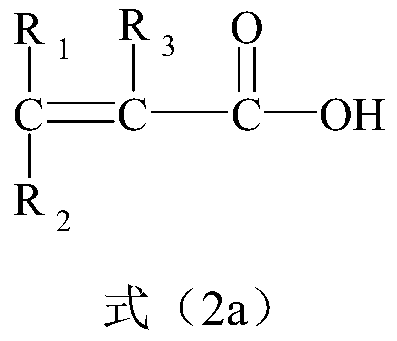

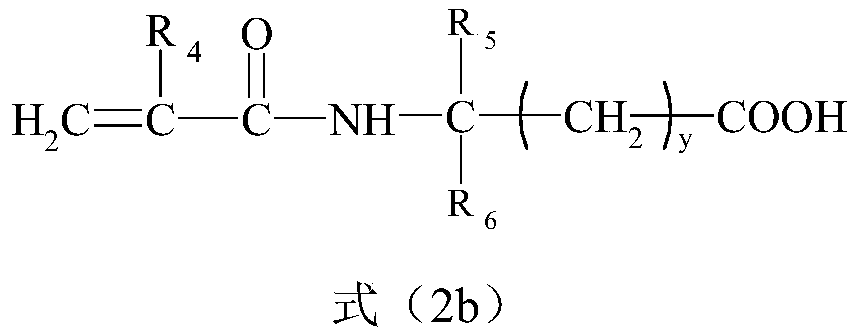

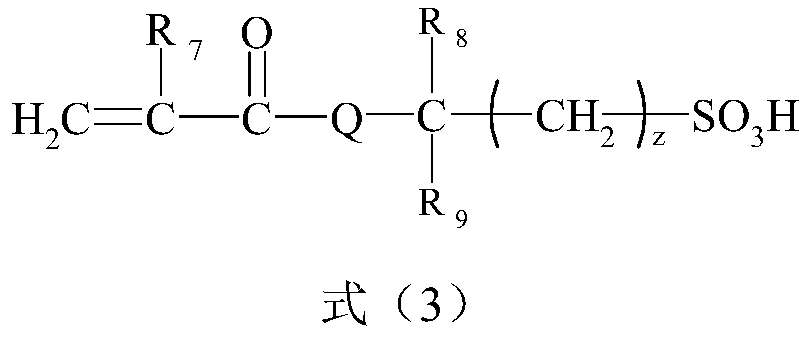

Method used

Image

Examples

Embodiment 1

[0053] (1) 582ml of water and 166.2 grams of lithium magnesium silicate are ground into an inorganic hydrogel with a colloidal mill;

[0054] (2) Add 160 grams of sodium hydroxide and 750ml of water into the reactor, slowly add 1.8 moles of acrylic acid and 2.2 moles of 2-acrylamido-2-methylpropanesulfonic acid at 30°C, and continue Stir for 10-30 minutes. Then add the inorganic hydrogel prepared in step (1) and stir for 0.5 hour. After the stirring time is up, add 5.0 moles of acrylamide and 1.0 moles of 3-methacryloyloxy-2-hydroxypropyltrimethylammonium chloride, and continue stirring for 15 minutes after the addition to obtain a reaction mixture;

[0055] (3) Add the reaction mixture obtained in step (2) into the polymerization tank, stir for 5 minutes, and adjust the pH value of the system to 7 with a 25% mass fraction of sodium hydroxide solution. Nitrogen was passed for 5 minutes, 3.5 grams of ammonium persulfate and 3.5 grams of sodium bisulfite were added, and after ...

Embodiment 2

[0058] (1) 178ml of water and 59.6 grams of lithium magnesium silicate are ground into an inorganic hydrogel with a colloidal mill;

[0059] (2) Add 120 grams of sodium hydroxide and 617 ml of water into the reactor, slowly add 0.5 moles of acrylic acid and 2.5 moles of 2-acrylamido-2-methylpropanesulfonic acid at 28 ° C, add Continue stirring for 25 minutes after completion. Then add the inorganic hydrogel prepared in step (1) and stir for 1 hour. After the stirring time is up, add 6.5 moles of acrylamide and 0.5 moles of 3-methacryloyloxy-2-hydroxypropyltrimethylammonium chloride, and continue stirring for 25 minutes after the addition to obtain a reaction mixture;

[0060] (3) Add the reaction mixture obtained in step (2) into the polymerization tank, stir for 8 minutes, and adjust the pH value of the system to 8 with a 30% mass fraction of sodium hydroxide solution. Nitrogen was passed for 25 minutes, 1.7 g of ammonium persulfate and 1.7 g of sodium bisulfite were added,...

Embodiment 3

[0062] (1) 1800ml of water and 359.6 grams of aluminum-magnesium silicate inorganic gel are ground into an inorganic hydrogel with a colloid mill;

[0063] (2) Add 200 grams of sodium hydroxide and 1556 ml of water into the reactor, slowly add 4 moles of acrylic acid and 1 mole of 2-acrylamido-2-methylpropanesulfonic acid at 20 ° C, add Continue stirring for 20 minutes after completion. Then add the inorganic hydrogel prepared in step (1) and stir for 0.5 hour. After the stirring time is up, add 3.5 moles of nonionic monomer C and 1.5 moles of 3-methacrylamide-2-hydroxypropyltrimethylammonium chloride, and continue stirring for 20 minutes after the addition is complete to obtain a reaction mixture;

[0064] (3) Add the reaction mixture obtained in step (2) into the polymerization tank, stir for 5 minutes, and adjust the pH value of the system to 12 with a 10% sodium hydroxide solution by mass fraction. Nitrogen was passed for 5 minutes, 4.85 grams of ammonium persulfate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com