Preparation method of synthetic base drilling fluid

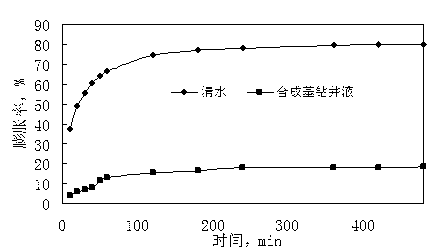

An oil-based drilling fluid and synthetic-based technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of easy collapse, poor inhibition ability, shale hydration expansion, etc. Good rheological properties, low aromatic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

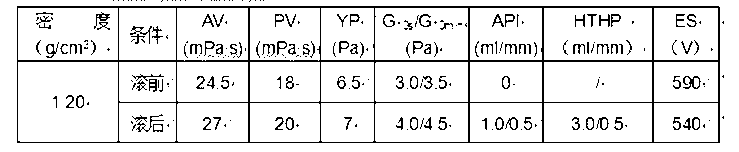

Embodiment 1

[0035] As a preferred application example of the present invention, the main application in the shale gas development of the Changning block in Sichuan is a synthetic base drilling fluid formed from a synthetic base as the main raw material. The formulation of the drilling fluid of the present invention is:

[0036] 70% synthetic base + 3.0% organic soil + 3.0% main emulsifier + 3.0% auxiliary emulsifier + 0.1% wetting agent + 0.9% flow regulator + 2.0% CaO + 10% CaCl 2 Aqueous solution + 5.0% fluid loss agent + 3.0% anti-collapse plugging agent; (among which CaCl 2 The mass concentration of the aqueous solution is 20%).

[0037] The steps to apply this formula to a specific preparation method are as follows:

[0038] a. Under stirring conditions, add organic soil, main emulsifier, auxiliary emulsifier, wetting agent, flow modifier, and quicklime into the synthetic base fluid according to the formula, and stir for 30 minutes;

[0039] b. The preparation mass concentration is 20% CaCl 2...

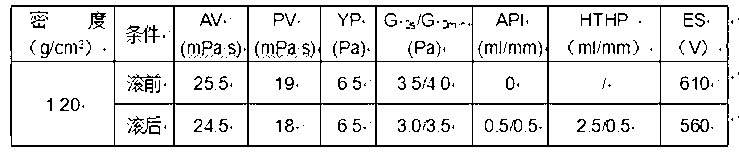

Embodiment 2

[0044] As another preferred application example of the present invention, the main application in the Fushun and Jinqiu blocks of the Sichuan Shell project is a synthetic base drilling fluid formed from a synthetic base as the main raw material. The formulation of the drilling fluid of the present invention is:

[0045] 65% synthetic base+4.0% organic soil+4.0% primary emulsifier+3.0% secondary emulsifier+0.1% wetting agent+0.9% flow regulator+2.0%CaO+12%CaCl 2 Aqueous solution + 6.0% fluid loss agent + 3.0% anti-collapse plugging agent; (among which CaCl 2 The mass concentration of the aqueous solution is 20%).

[0046] The steps to apply this formula to a specific preparation method are as follows:

[0047] a. Under stirring conditions, add organic soil, main emulsifier, auxiliary emulsifier, wetting agent, flow modifier, and quicklime into the synthetic base fluid according to the formula, and stir for 30 minutes;

[0048] b. The preparation mass concentration is 20% CaCl 2 Solution...

Embodiment 3

[0053] As the best embodiment of the present invention, the present invention discloses a method for preparing synthetic-based drilling fluid, which includes the following steps:

[0054] a. Under stirring conditions, by weight percentage, wetting 2.0%~4.0% of organic soil, 3.0%~5.0% of main emulsifier, 2.0%~4.0% of auxiliary emulsifier, 0.1%~0.2% of wetting Adding agent, 0.5%~2.0% flow regulator, 2.0%~3.0% CaO to 60~70% synthetic base, stirring for 30min;

[0055] b. The preparation mass concentration is 20% CaCl 2 Solution to make CaCl 2 completely dissolved;

[0056] c. Under stirring conditions, reduce the weight percentage of 10% to 15% CaCl 2 The solution is slowly added to the synthetic base;

[0057] d. Add 4.0% to 6.0% by weight fluid loss agent and 2.0% to 3.0% anti-collapse plugging agent to the synthetic base under stirring conditions;

[0058] e. Add barite to the synthetic base to achieve the required density and form synthetic base drilling fluid.

[0059] The said anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com