Biomass synthetic base drilling fluid and preparation method thereof

A biomass and synthetic-based technology, applied in the field of drilling fluids, can solve the problems of difficult biodegradation and low environmental acceptability of synthetic-based drilling fluids, and achieve the effects of good ecological safety, excellent environmental protection properties, and efficient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

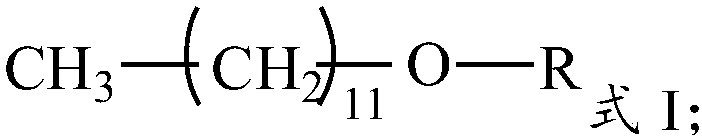

[0066] Add 1 mol of lauryl alcohol, 0.5 mol of chloropentane, 0.5 mol of potassium hydroxide and 0.025 mol of polyethylene glycol 400 catalyst into a reaction kettle with a stirring, condensing and heating device, stir and mix evenly, at 100°C, 300rpm The reaction was carried out at room temperature for 24 hours, and the temperature was lowered to room temperature to obtain the biomass base liquid product.

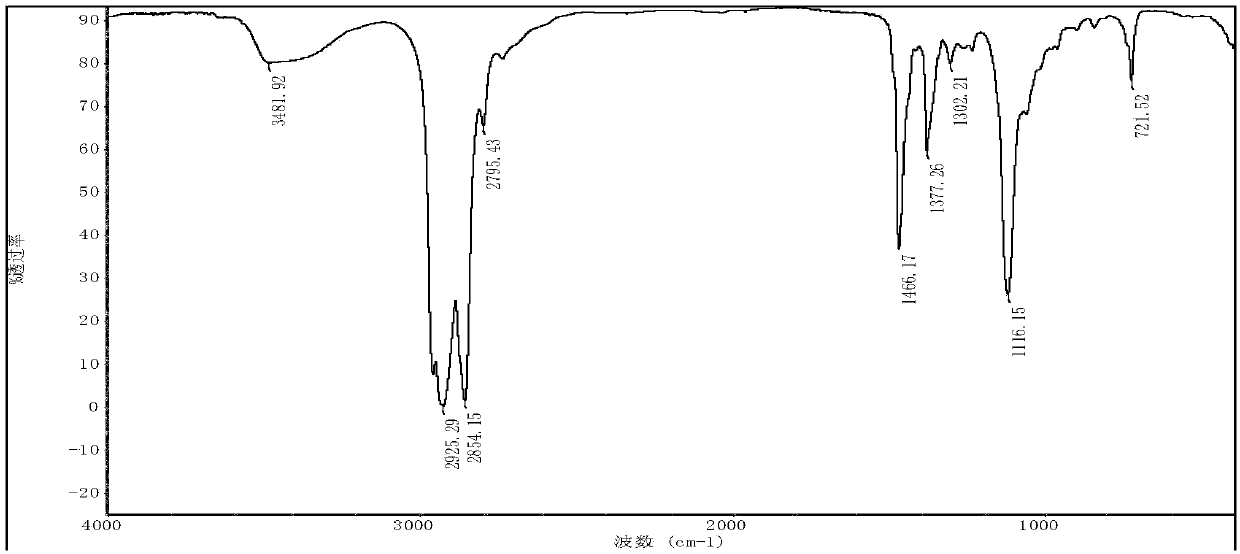

[0067] The biomass base liquid product prepared in Example 1 of the present invention is carried out infrared spectrum detection, and the detection result is as follows: figure 1 as shown, figure 1 For the infrared spectrogram of the product prepared in Example 1 of the present invention, by figure 1 It can be seen that the product prepared in Example 1 of the present invention is pentyl lauryl ether, and its structural formula is: CH 3 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -O-CH 2 -CH 2 -CH 2 -CH 2 -CH 3

Embodiment 2

[0069] Add 1 mol of lauryl alcohol, 1.5 mol of n-chlorohexane, 1.5 mol of potassium hydroxide and 0.25 mol of polyethylene glycol 600 catalyst into a reaction kettle with a stirring, condensing and heating device, stir and mix evenly. After 12 hours of reaction, the temperature was lowered to room temperature, and the biomass base liquid product was obtained.

[0070] According to the method described in Example 1, the product prepared in Example 2 of the present invention is tested, and the test result is that the product lauryl hexyl ether prepared in Example 2 of the present invention has the structure: CH 3 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -O-CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 3

Embodiment 3

[0072] Add 1 mol of lauryl alcohol, 1 mol of n-heptane chloride, 1.2 mol of sodium hydroxide and 0.15 mol of polyethylene glycol 600 catalyst into a reactor equipped with a stirring, condensing and heating device, stir and mix evenly, at 140°C and 400rpm After 20 hours of reaction, the temperature was lowered to room temperature, and the biomass base liquid product was obtained.

[0073] According to the method described in Example 1, the product prepared in Example 3 of the present invention was tested, and the test result was that the product prepared in Example 3 of the present invention was lauryl heptyl ether, and its structure was: CH 3 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -O-CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 2 -CH 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com