Filtrate loss reduction composition, filtrate loss reducer, and preparation method and application of filtrate loss reducer

A technology of fluid loss control agent and composition, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of abnormal rheology of drilling fluid system, increase of fluid loss, and decrease of electrical stability, etc. Improve high temperature emulsion stability and filtration performance, solve the increase of filtration loss, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

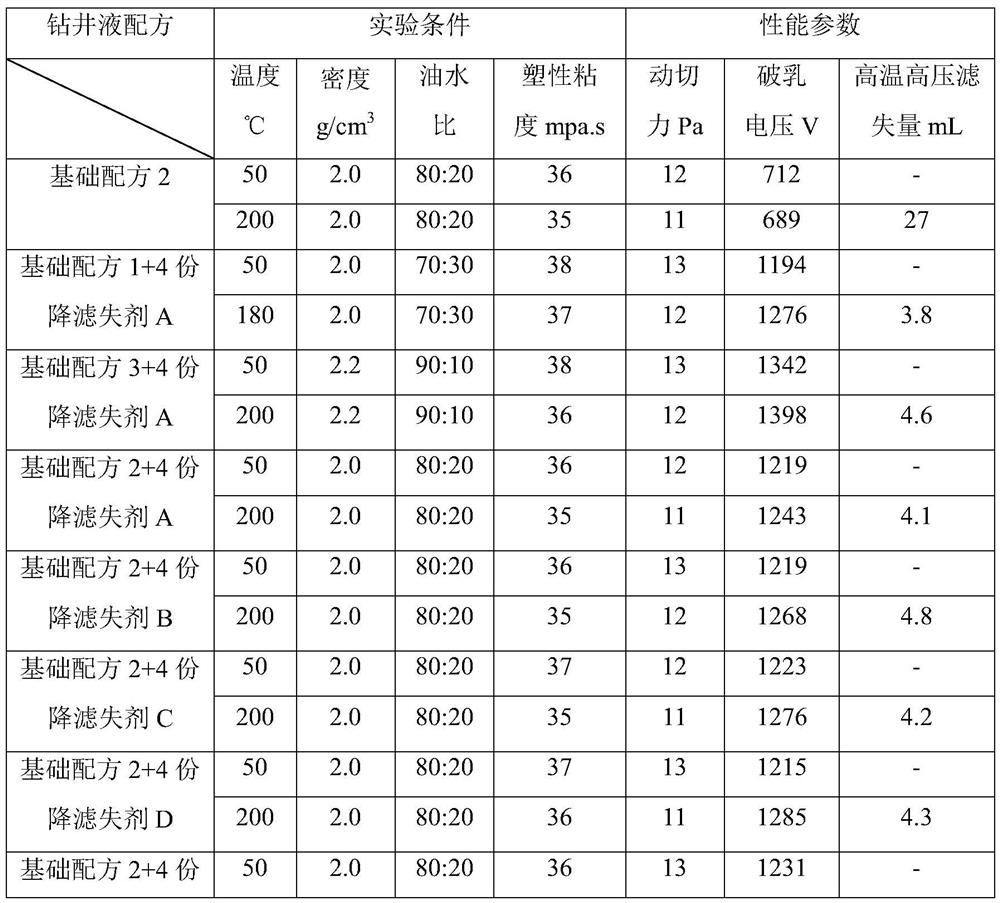

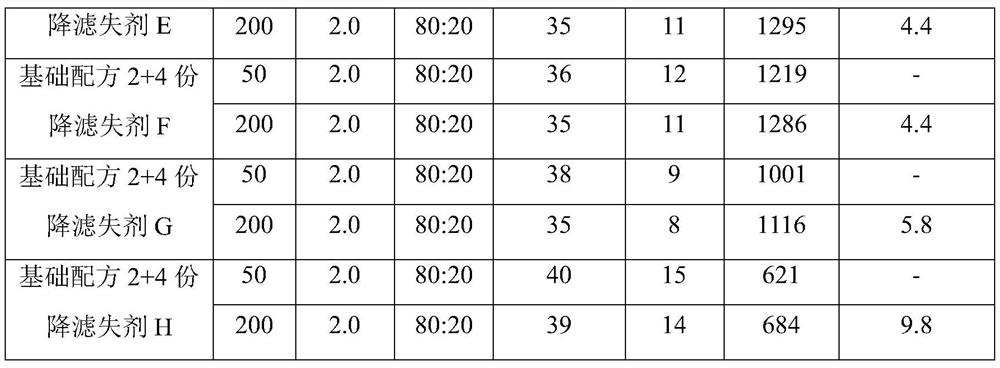

Examples

Embodiment 1

[0035] Firstly, 320 parts of oleic acid and 60 parts of diethylenetriamine were sequentially added into the reactor, and the temperature was raised to 165°C under constant stirring, and the dehydration condensation reaction was carried out for 3 hours to obtain the first post-reaction system. Then add 200 parts of triethylene glycol monobutyl ether and 150 parts of humic acid to the system after the first reaction, and continue to carry out the dehydration condensation reaction at 165 ° C for 3 hours. The finished fluid loss agent is denoted as fluid loss agent A.

Embodiment 2

[0037] Firstly, 160 parts of oleic acid and 50 parts of diethylenetriamine were sequentially added into the reactor, and the temperature was raised to 165°C under constant stirring, and the dehydration condensation reaction was carried out for 3 hours to obtain the first post-reaction system. Then add 180 parts of triethylene glycol monobutyl ether and 100 parts of humic acid to the system after the first reaction, and continue to carry out the dehydration condensation reaction at 165 ° C for 3 hours. The finished fluid loss agent is denoted as fluid loss agent B.

Embodiment 3

[0039] Firstly, 320 parts of oleic acid and 80 parts of diethylenetriamine were sequentially added into the reactor, and the temperature was raised to 165°C under constant stirring, and the dehydration condensation reaction was carried out for 3 hours to obtain the first post-reaction system. Then add 240 parts of triethylene glycol monobutyl ether and 170 parts of humic acid to the system after the first reaction, and continue to carry out the dehydration condensation reaction at 165 ° C for 3 hours. The finished fluid loss agent is denoted as fluid loss agent C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com