Crosslinking fluid loss agent preparation method

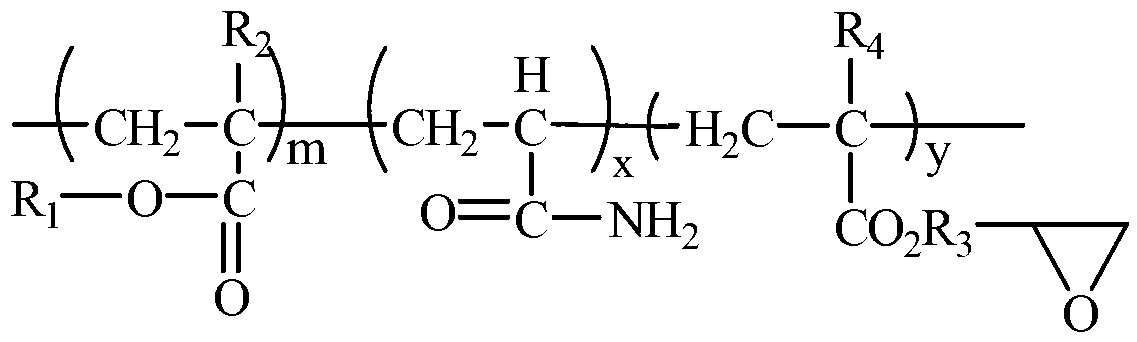

A technology of fluid loss reducer and cross-linking monomer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as poor temperature resistance, and improve viscoelastic performance, temperature resistance, and adsorption capacity Strong, good polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

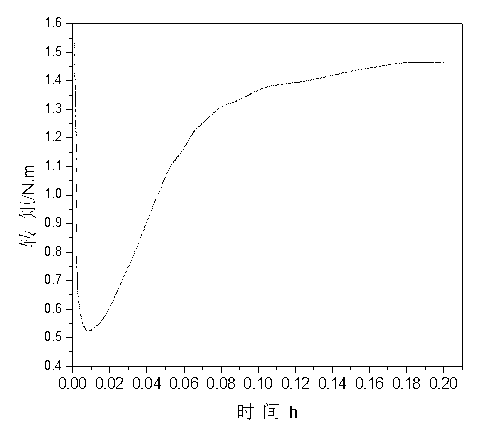

Method used

Image

Examples

Embodiment 1

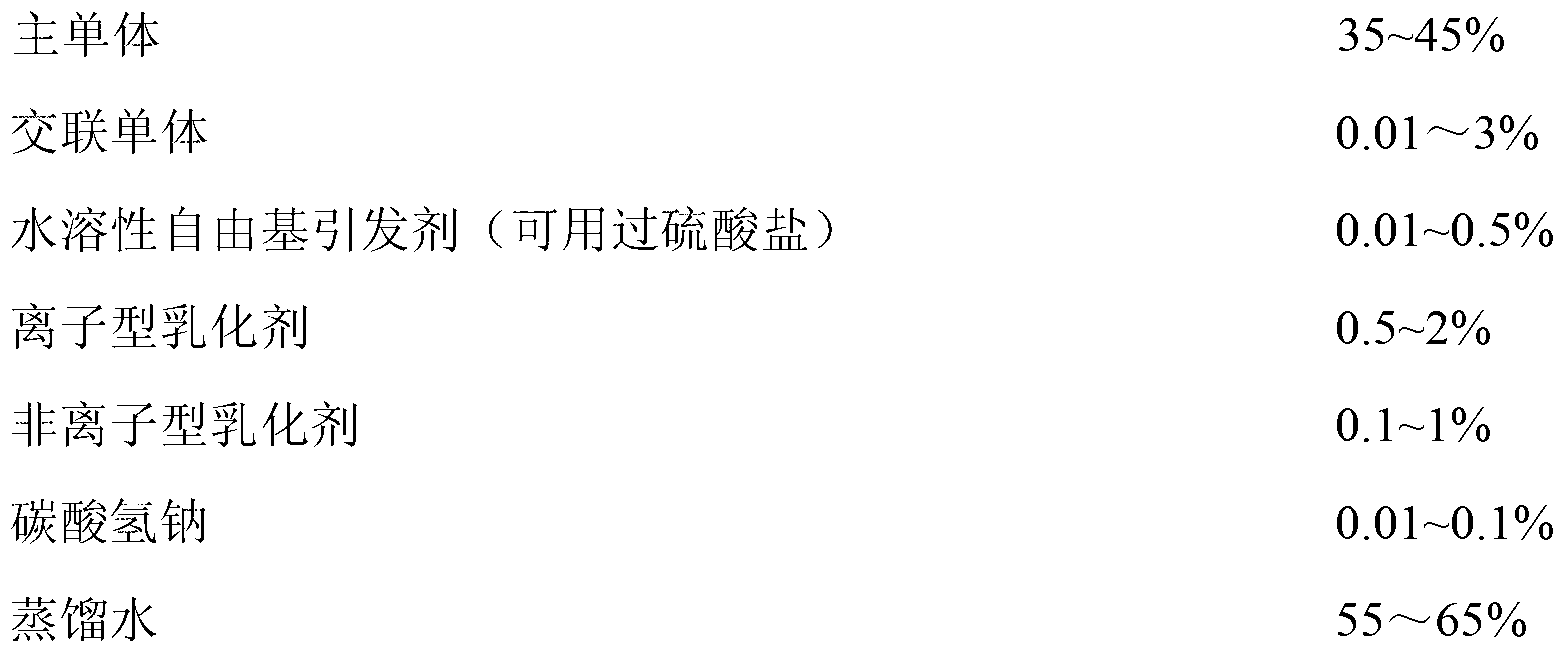

[0028] In the present embodiment, adopt following mass parts raw material:

[0029]

[0030] The process steps are as follows:

[0031] 1. Mix the purified 3 / 4 butyl acrylate, 1 / 4 methyl methacrylate, 1 / 4 cross-linking monomer and compound emulsifier evenly, then add it to a three-necked bottle, and stir it quickly with a stirrer for 30 minutes to prepare a pre-emulsion .

[0032] 2. Heat the three-necked bottle with the pre-emulsion in a water bath. When the temperature reaches 70°C, nitrogen gas is introduced. After 10 minutes, 2 / 3 of the initiator is slowly added dropwise and stirred at a constant speed. The stirring speed is controlled within 100r / min. After keeping blue for a period of time, add the remaining monomer and initiator dropwise, and react at constant temperature for 2 hours. After cooling, add sodium bicarbonate solution dropwise to adjust the pH value to 6-7, and discharge to obtain fluid loss reducer FL-0.

Embodiment 2

[0034] In this example, except that the cross-linking monomer GMA accounts for 1% of the monomer content, the total amount of monomers remains unchanged, and the other three main monomers are reduced in the same proportion, and the mass percentages of other raw materials are the same as in Example 1 .

[0035] In this example, the process steps of preparing the fluid loss control agent FL by emulsion polymerization are the same as those in Example 1 to obtain the fluid loss control agent FL-1.

Embodiment 3

[0037] In this example, except that the cross-linking monomer GMA accounts for 3% of the monomer content, the total amount of monomers remains unchanged, and the other three main monomers are reduced in the same proportion, and the mass percentages of other raw materials are the same as in Example 1 .

[0038] In this example, the process steps of preparing the fluid loss control agent FL by emulsion polymerization are the same as those in Example 1 to obtain the fluid loss control agent FL-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com