High-temperature water-based drilling fluid and preparation method thereof

A water-based drilling fluid and high-temperature technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as mud cake thickening, high-temperature thickening, and filtration loss increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0034] High-temperature water-based drilling fluid, including: 103 parts by weight of base slurry, 1 part of fluid loss additive I, 1.5 parts of fluid loss additive II, 2 parts of fluid loss additive III, 2 parts of polyethylene glycol, 1 1 part of aminosilanol, 3 parts of potassium chloride, 2 parts of lubricant, 0.6 part of 600-800 mesh calcium carbonate powder, 1.2 parts of 400-500 mesh modified diatomite, and the addition amount is to increase the weight of high-temperature water-based drilling fluid to 1.4g / cm 3barite;

[0035] Wherein, the base slurry includes water, calcareous bentonite, sodium carbonate, and sodium hydroxide with a mass ratio of 100:2:0.15:0.2;

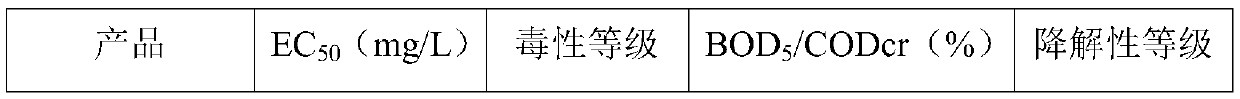

[0036] Fluid loss reducer I is a graft copolymer with corrosive acid as the skeleton;

[0037] Fluid loss reducer II is a composition composed of fluid loss reducer I, 1000-2000 mesh calcium carbonate powder as the core, and medium softening point asphalt as the shell, wherein the softening point of the medi...

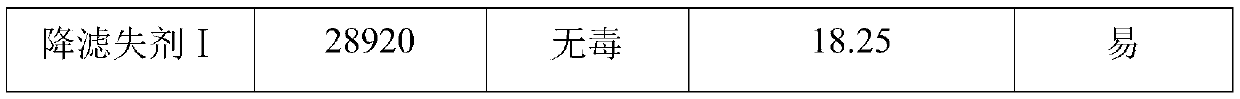

Embodiment 1b

[0040] The preparation method of high-temperature water-based drilling fluid comprises the following steps according to the dosage of :

[0041] S1. Preparation of fluid loss reducer II: Add medium softening point asphalt into the asphalt tank and heat until dissolved, stir and mix evenly, add fluid loss reducer I, 1000-2000 mesh calcium carbonate powder, stir until fully mixed, then cool and grind to 400-500 mesh, that's all;

[0042] S2. Preparation of fluid loss additive III: add high softening point asphalt into the asphalt tank and heat until dissolved, pave to form an asphalt layer with a height (thickness) of 2-3 μm, spread fluid loss additive I evenly on the asphalt layer, Cool and pulverize to 600-800 mesh to obtain half-coated fluid loss reducer I; add asphalt with medium softening point into the asphalt tank and heat until dissolved, add half-coated fluid loss reducer I, stir until fully mixed, cool and grind to 400-500 mesh, that's all;

[0043] S3, in parts by w...

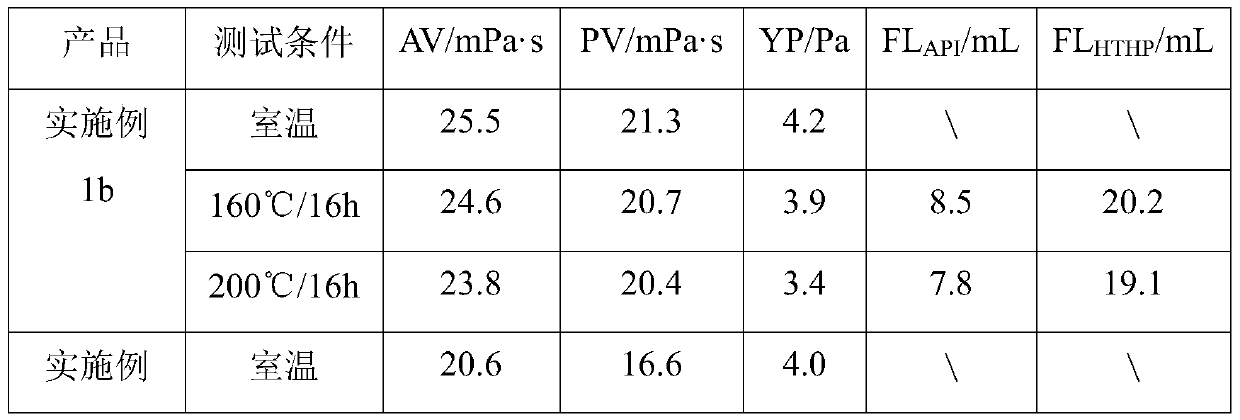

Embodiment 2a

[0048] High-temperature water-based drilling fluid, including: 104 parts by weight of base slurry, 1.5 parts of fluid loss control agent I, 2 parts of fluid loss control agent II, 2.5 parts of fluid loss control agent III, 2 parts of polyethylene glycol, 1.5 parts 1 part of aminosilanol, 5 parts of potassium chloride, 2.5 parts of lubricant, 1 part of 600-800 mesh calcium carbonate powder, 1.5 parts of 400-500 mesh modified diatomite, and the addition amount is to increase the weight of high-temperature water-based drilling fluid to 1.4g / cm 3 barite;

[0049] Wherein, the base slurry includes water, calcareous bentonite, sodium carbonate, and sodium hydroxide with a mass ratio of 100:2:0.15:0.2;

[0050] Fluid loss reducer I is a graft copolymer with corrosive acid as the skeleton;

[0051] Fluid loss reducer II is a composition composed of fluid loss reducer I, 1000-2000 mesh calcium carbonate powder as the core, and medium softening point asphalt as the shell, wherein the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com