White asphalt for drilling fluid and method for preparing white asphalt for drilling fluid

A technology of drilling fluid and white asphalt, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex preparation process and increased viscosity of drilling fluid, and achieve simple preparation process, good plugging of cracks, The effect of high environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First, add accurately weighed 40kg of paraffin, 20kg of stearic acid, 1kg of alkylphenol polyoxyethylene ether, and 4kg of polyethylene glycol into the reaction kettle, raise the temperature of the reaction kettle to 70°C, and stir at constant temperature for 30 minutes; Add 4kg of polyacrylamide to the kettle, and continue to stir at a constant temperature for 30 minutes; finally add 20kg of light calcium carbonate, and continue to stir at a constant temperature for 0.5 hours; the product is obtained by spray granulation.

Embodiment 2

[0021] First, add accurately weighed 50kg of paraffin wax, 30kg of stearic acid, 2kg of alkylphenol polyoxyethylene ether, and 5kg of polyethylene glycol into the reactor, raise the temperature of the reactor to 80°C, and stir at constant temperature for 20 minutes; Add 4.5kg of polyacrylamide to the kettle, and continue to stir at a constant temperature for 40 minutes; finally add 25kg of light calcium carbonate, and continue to stir at a constant temperature for 2 hours; the product is obtained by spray granulation.

Embodiment 3

[0023] First, accurately weighed 45kg of paraffin, 25kg of stearic acid, 1.5kg of alkylphenol polyoxyethylene ether, and 4.5kg of polyethylene glycol were added to the reactor, and the reactor was heated to 90°C and stirred at a constant temperature for 40 minutes; Add 5kg of polyacrylamide into the above reaction kettle, continue to stir at constant temperature for 20 minutes; finally add 30kg of light calcium carbonate, continue to stir at constant temperature for 1 hour; obtain the product through spray granulation.

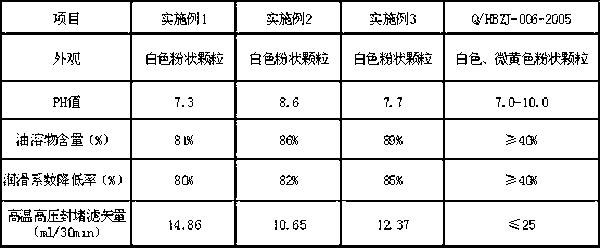

[0024] The comparison of various performance indicators between the white asphalt prepared in Examples 1-3 and Q / HBZJ-006-2005 is shown in Table 1.

[0025] Table 1 Various performance indicators of white bitumen used in drilling fluid

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com