Preparation method of cellulose ether and cellulose ether obtained in same

A technology of cellulose ether and cellulose powder, applied in the field of cellulose ether, can solve the problems of poor light transmittance, low filtration loss reduction effect, low water retention rate, etc., and achieves high temperature stability and mildew resistance improvement, preparation method Simple and easy to implement, the effect of filtration reduction effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

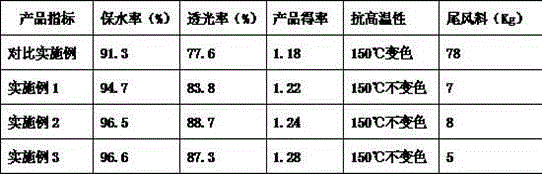

Examples

Embodiment 1

[0019] (1) Preparation of lye: first prepare 7000L of mixed solvent, the mixed solvent is the mass ratio: isopropanol / (isopropanol+toluene)=0.13, add 5000L of mixed solvent, 450Kg For solid NaOH, heat up and stir until the solid alkali is completely dissolved, then cool down to 20±1°C;

[0020] (2) Crushing the refined cotton into cotton powder;

[0021] (3) Add 800Kg of cotton powder into the reaction kettle, spray with the remaining 2000L of mixed solvent while adding cotton powder, and stir for 1.5h at a temperature equal to or lower than 20°C after the addition is complete;

[0022] (4) Add 180Kg propylene oxide and 590Kg methyl chloride to the reactor, and keep warm for 90 minutes when the temperature is raised to 54°C and 87°C;

[0023] (5) Desolventize the material in the reactor for not less than 1.5 hours;

[0024] (6) Add 25Kg of analytically pure acrylic acid: acrylamide = 4:1 mixed solution, 0.025Kg of potassium persulfate, stir for 35min at a temperature not low...

Embodiment 2

[0029] (1) Preparation of lye: first prepare 8000L of mixed solvent, the mixed solvent is the mass ratio: isopropanol / (isopropanol+toluene)=0.19, add 7000L of mixed solvent, 850Kg For solid NaOH, heat up and stir until the solid alkali is completely dissolved, then cool down to 26±1°C;

[0030] (2) Crushing the refined cotton into cotton powder;

[0031] (3) Add 880Kg of cotton powder into the reaction kettle, spray with the remaining 1000L of mixed solvent while adding cotton powder, and stir for 2 hours at a temperature equal to or lower than 26°C after the feeding is completed;

[0032] (4) Add 310Kg propylene oxide and 1000Kg methyl chloride to the reactor, and keep warm for 2 hours when the temperature is raised to 54°C and 87°C;

[0033] (5) Desolventize the material in the reactor for not less than 1.5 hours;

[0034] (6) Add 20Kg of analytically pure acrylic acid: acrylamide = 6:1 mixed solution, 0.02Kg of potassium persulfate, stir for 40min at a temperature not low...

Embodiment 3

[0039] (1) Preparation of lye: first prepare 7500L of mixed solvent, the mixed solvent has a mass ratio of isopropanol / (isopropanol+toluene)=0.16, add 7000L of mixed solvent, 500Kg For solid NaOH, heat up and stir until the solid alkali is completely dissolved, then cool down to 24±1°C;

[0040] (2) Crushing the refined cotton into cotton powder;

[0041] (3) Add 850Kg cotton powder into the reaction kettle, and spray with the remaining 500L mixed solvent while adding cotton powder. After the feeding is completed, stir at a temperature equal to or lower than 24 for 2 hours;

[0042](4) Add 240Kg propylene oxide and 700Kg methyl chloride to the reactor, and keep warm for 90min and 2h when the temperature is raised to 54°C and 87°C respectively;

[0043] (5) Desolventize the material in the reactor for not less than 1.5 hours;

[0044] (6) Add analytically pure acrylic acid: acrylamide = 9:1 mixed solution 10Kg, ammonium persulfate 0.01Kg, stir at a temperature not lower than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com