Drilling fluid additive, preparation method thereof and drilling fluid

A drilling fluid treatment agent and compound technology, which is applied in the field of drilling to achieve the effects of high yield, simple operation steps and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a kind of preparation method of the drilling fluid treatment agent described in above-mentioned technical scheme, comprises the following steps:

[0040] (1) chitosan, basic compound and alcohol compound are reacted to obtain the first intermediate product; the basic compound is alkali metal carbonate or alkali metal hydroxide;

[0041] (2) reacting the first intermediate product with a chlorocarboxylic acid to obtain a second intermediate product; the number of carbon atoms of the chlorocarboxylic acid is 2 to 11;

[0042] (3) The second intermediate product is reacted with chlorinated monohydric alcohol compound, dibasic alcohol compound and chloroalkyl epoxide to obtain the third intermediate product; the number of carbon atoms of the chlorinated monohydric alcohol compound is 2 to 11; the number of carbon atoms of the dihydric alcohol compound is 2 to 17; the number of carbon atoms of the chloroalkyl epoxide is 3 to 12;

[0043] (4) r...

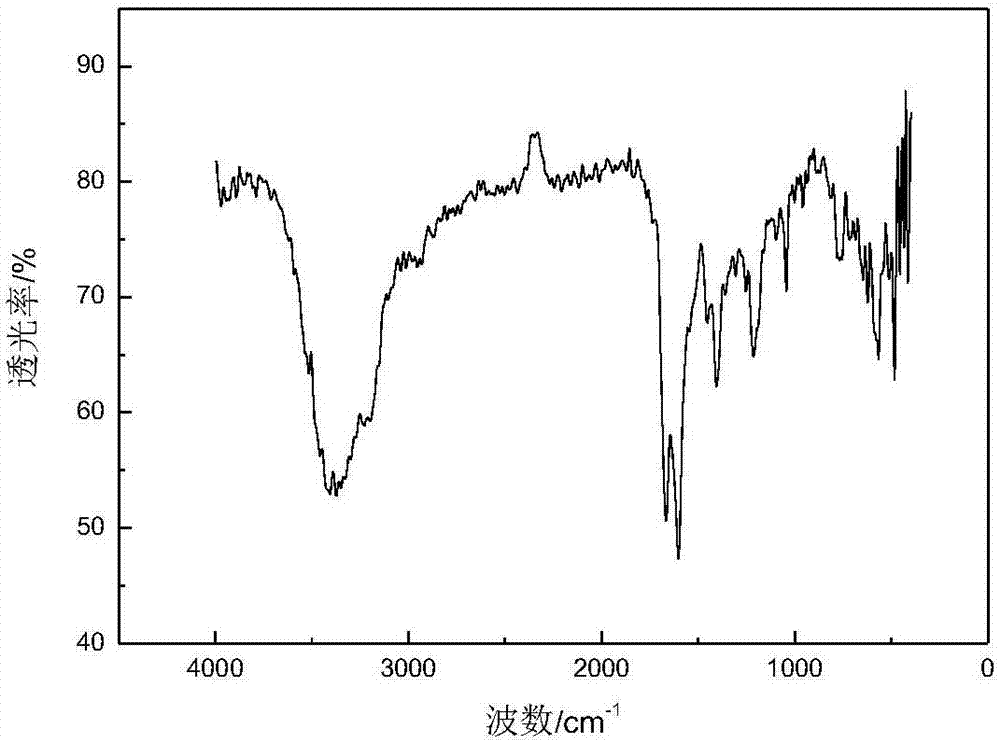

Embodiment 1

[0089] 16 parts by weight of chitosan (number average molecular weight is 200000), 150 parts of water, 20 parts of sodium hydroxide and 40 parts of methanol are stirred and mixed evenly, and carried out alkalization and gelatinization reaction for 0.5 hour at 50 ° C to obtain The first intermediate product; the first intermediate product and 24 parts of chloroacetic acid were stirred and reacted at 55°C for 2 hours to obtain the second intermediate product; 10 parts of chloroethanol, 10 parts of ethylene glycol and 6 parts were added to the second intermediate product Parts of epichlorohydrin were reacted at 95°C for 2 hours to obtain a third intermediate product; 8 parts of ethylenediamine were added to the third intermediate product, stirred and mixed evenly, and the temperature was raised to 60°C for 0.5 hours to obtain a dark red viscous It is a gel-like transparent solid, and the drilling fluid treatment agent can be obtained after drying and removing water, and the produc...

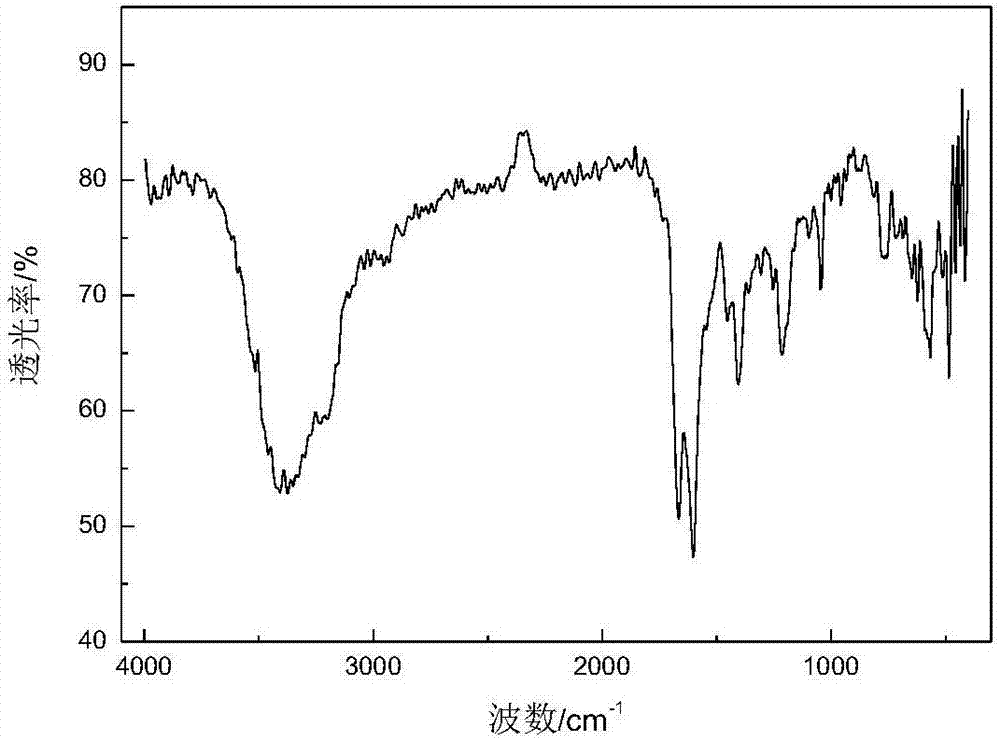

Embodiment 2

[0092] 17 parts by weight of chitosan (the number average molecular weight is 300000), 160 parts of water, 25 parts of sodium carbonate and 45 parts of ethanol are stirred and mixed uniformly, and carried out alkalization and gelatinization reaction for 1 hour at 55 ° C to obtain the first An intermediate product; the first intermediate product was stirred and reacted with 30 parts of chloropropionic acid at 65°C for 2.5 hours to obtain the second intermediate product; 11 parts of chloropropanol, 11 parts of polyethylene glycol were added to the second intermediate product Alcohol 400 and 7 parts of 1,2-epoxychlorobutane were reacted at 110°C for 3 hours to obtain the third intermediate product; 9 parts of diethylenetriamine were added to the third intermediate product, stirred and mixed evenly, and the temperature was raised to After reacting at 70°C for 1 hour, a dark red viscous gelatinous transparent solid was obtained. After drying and removing water, the drilling fluid tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com