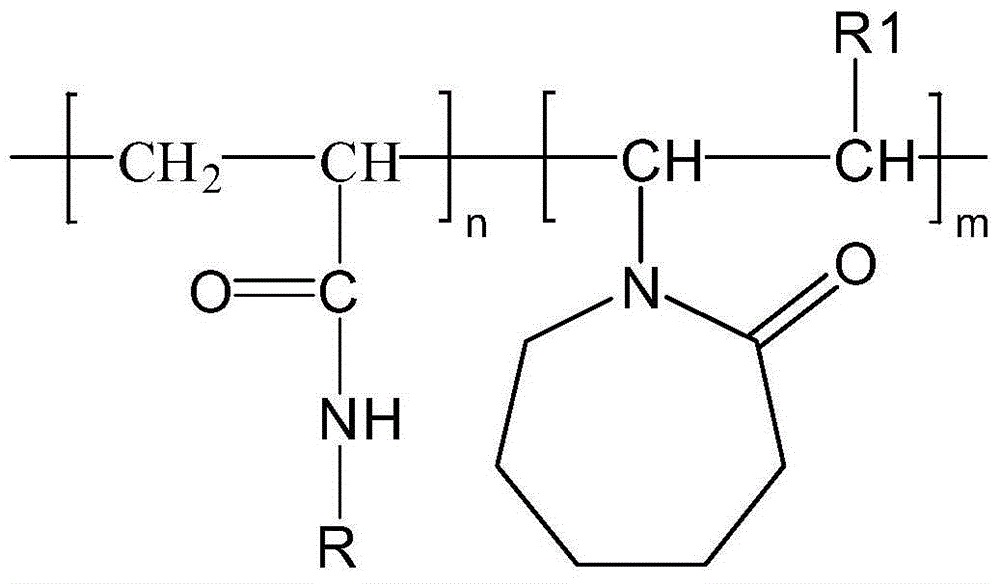

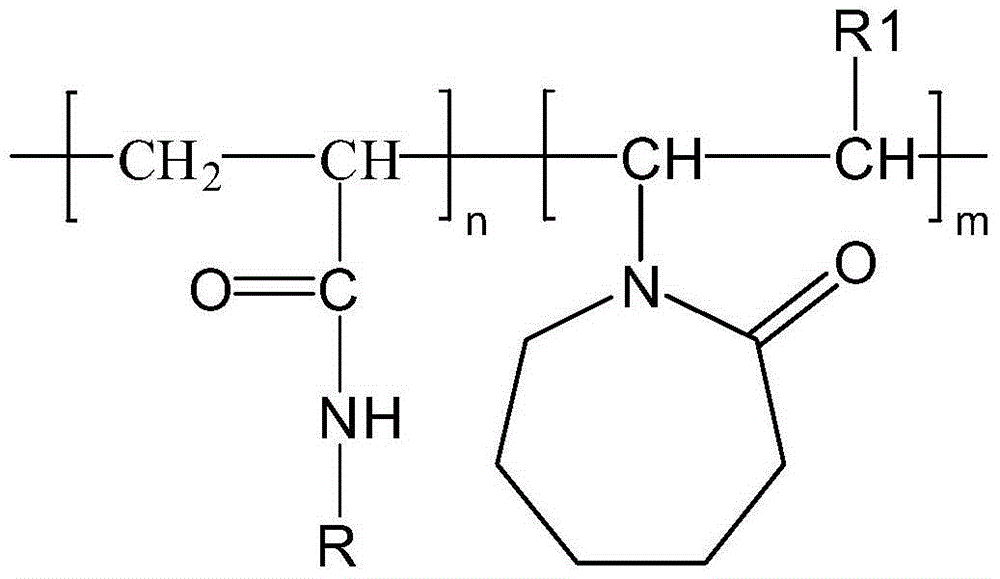

Drilling fluid filtrate reducer with natural gas hydrate inhibiting effect

A technology of fluid loss control agent and inhibition effect, which is applied in the field of copolymers of N-alkenyl caprolactam and N-substituted acrylamide, which can solve the problems of complex treatment agents and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The preparation of the copolymer used in the present invention follows the traditional chemical method: adding activated carbon to the monomers respectively, utilizing its adsorption to remove the polymerization inhibitor, and then filtering to obtain pure monomers. Add the two monomers, the initiator ammonium persulfate and solvent water into a four-necked bottle, seal it, replace the air with nitrogen, heat to 60°C, and keep it under nitrogen protection during the reaction for 3 hours. A viscous product is obtained, which is vacuum-dried and pulverized to obtain a copolymer powder.

[0013] The test of the hydrate inhibition performance of fluid loss control agent mainly includes reaction kettle, constant temperature air bath, magnetic coupling stirring and pressure and temperature measurement system, vacuum pump, data acquisition system, etc. The reaction kettle is a stainless steel kettle with a volume of 1.02 liters, and the maximum working pressure can reach 35MPa...

Embodiment 1

[0016] Both R and R1 are H, and the copolymer is synthesized according to n:m=1, and the weight average molecular weight is controlled at 1,000,000. The copolymer is configured into a 200g aqueous solution according to a mass concentration of 0.5%, and it is loaded into a reactor with stirring, and the experiment starts The pressure is 8.5MPa, the experimental gas is the mixed gas provided by Foshan Gas Plant (91.86% methane, 5.04% ethane and 3.1% propane), the reaction temperature is maintained at 4.0°C, and no hydrate is formed within 4000 minutes. With this concentration of copolymer drilling fluid, the test fluid loss is 8ml.

Embodiment 2

[0018] R is a methyl group, R1 is a methyl group, and the copolymer is synthesized according to n:m=0.5, and the weight average molecular weight is controlled at 400,000. The copolymer is configured into a 200g aqueous solution according to a mass concentration of 1%, and is loaded into a stirred reactor. The initial pressure of the experiment was 10MPa, the experimental gas was the mixed gas provided by Foshan Gas Plant (91.86% methane, 5.04% ethane and 3.1% propane), the reaction temperature was maintained at 4.0°C, and no hydrate was formed within 5000 minutes. The tested fluid loss of the copolymer drilling fluid containing this concentration is 5ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com