Electric lamp

A technology for electric lamps and lamp houses, applied to discharge lamps, gas discharge lamps, circuits, etc., can solve problems such as troublesome cutting operations, pollution, and reduced mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

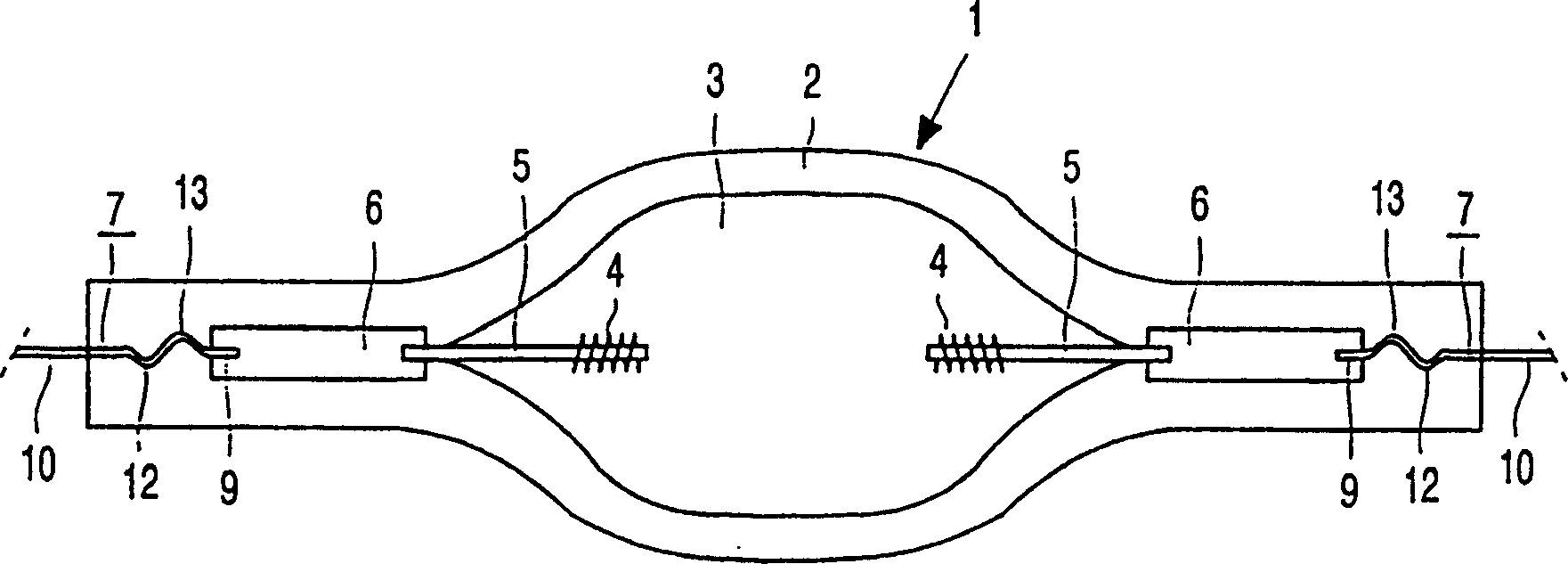

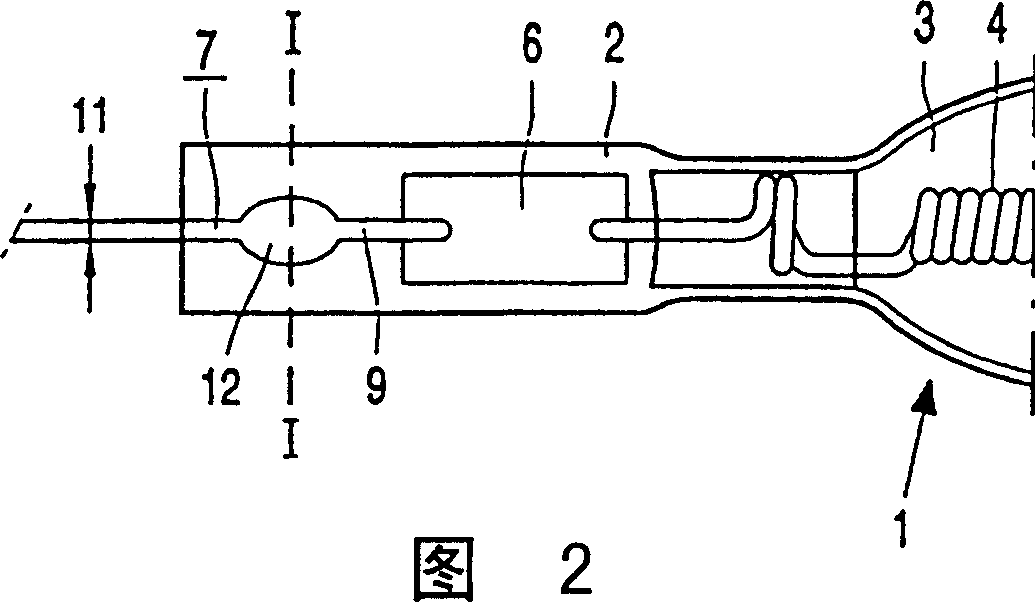

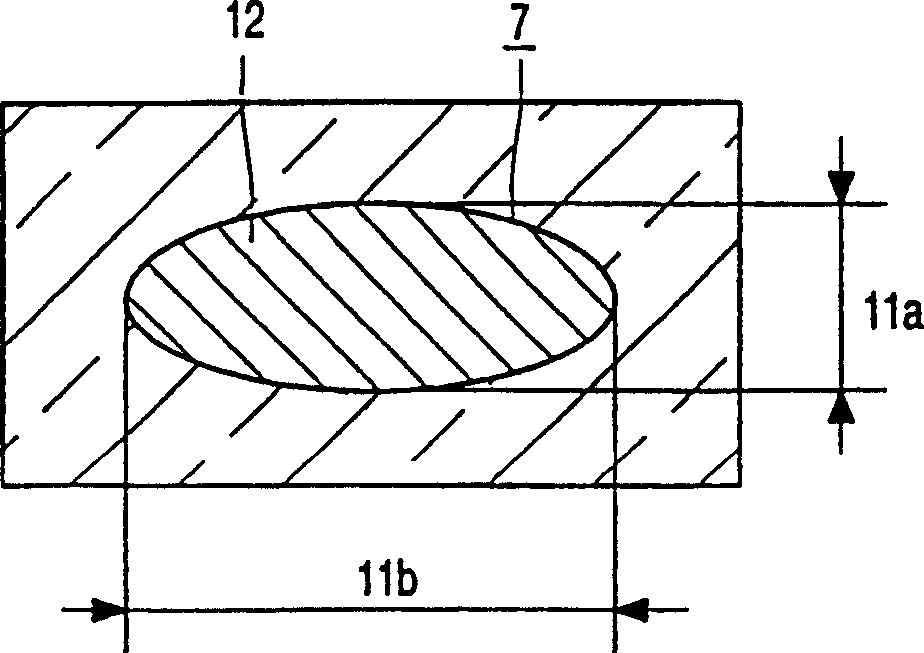

[0015] figure 1 The electric lamp in is a high-pressure gas discharge lamp having a lamp vessel 1 sealed in a vacuum-tight manner and a quartz glass wall 2 of an enclosed space 3 . The electrical element 4, that is, a pair of electrodes 4 in the figure is connected to a corresponding metal foil 6 through a respective inner current conductor 5, and the inner current conductor 5 extends from the wall 2 of the lamp chamber 1 into the space 3. The metal foil 6 is composed of molybdenum containing 0.5% by weight of diyttrium trioxide. figure 1 The middle metal foil 6 is embedded in the wall 2 of the lamp vessel 1 and is connected, ie welded in the figure, to an outer current conductor 7 made of molybdenum. Each outer current conductor 7 connected to a respective metal foil 6 comprises a first end 9 and a second end 10 . The inner current conductor 5 and the electrical element 4 are made of tungsten and may contain minor additions to adjust the grain growth of tungsten, such as 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com