Production line assembly jig

An assembly line and fixture technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., to achieve the effect of accurate position, easy positioning, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

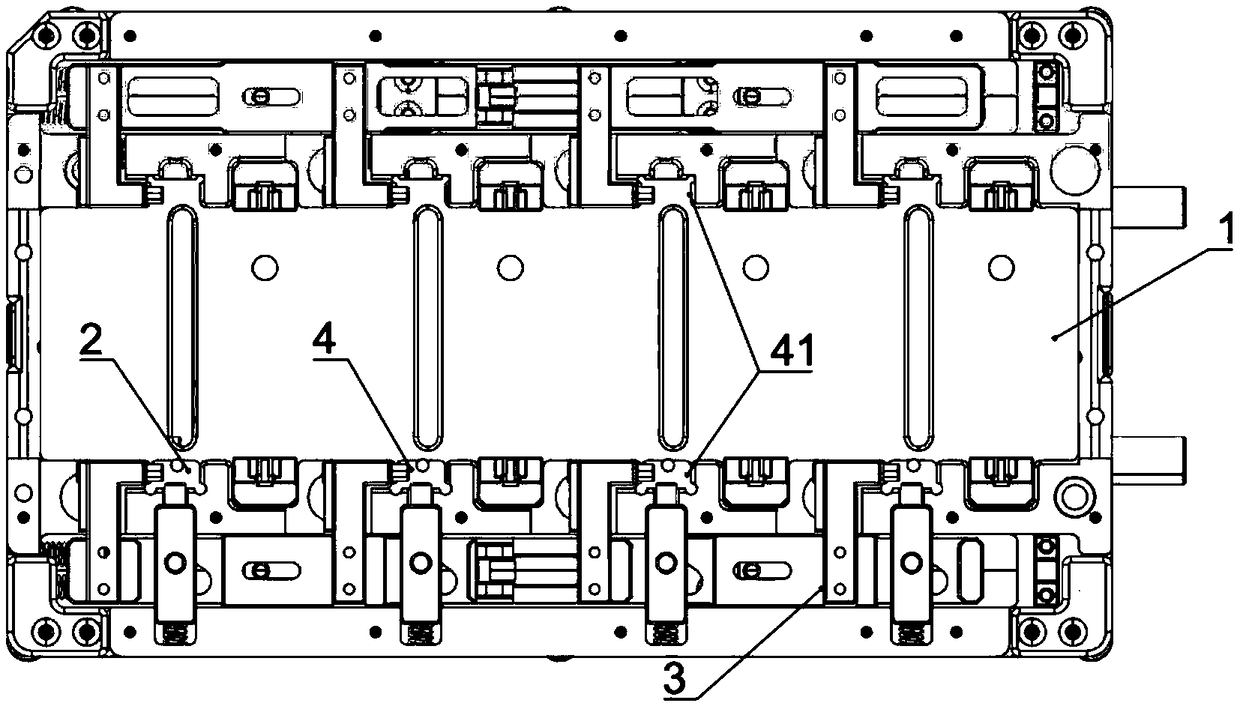

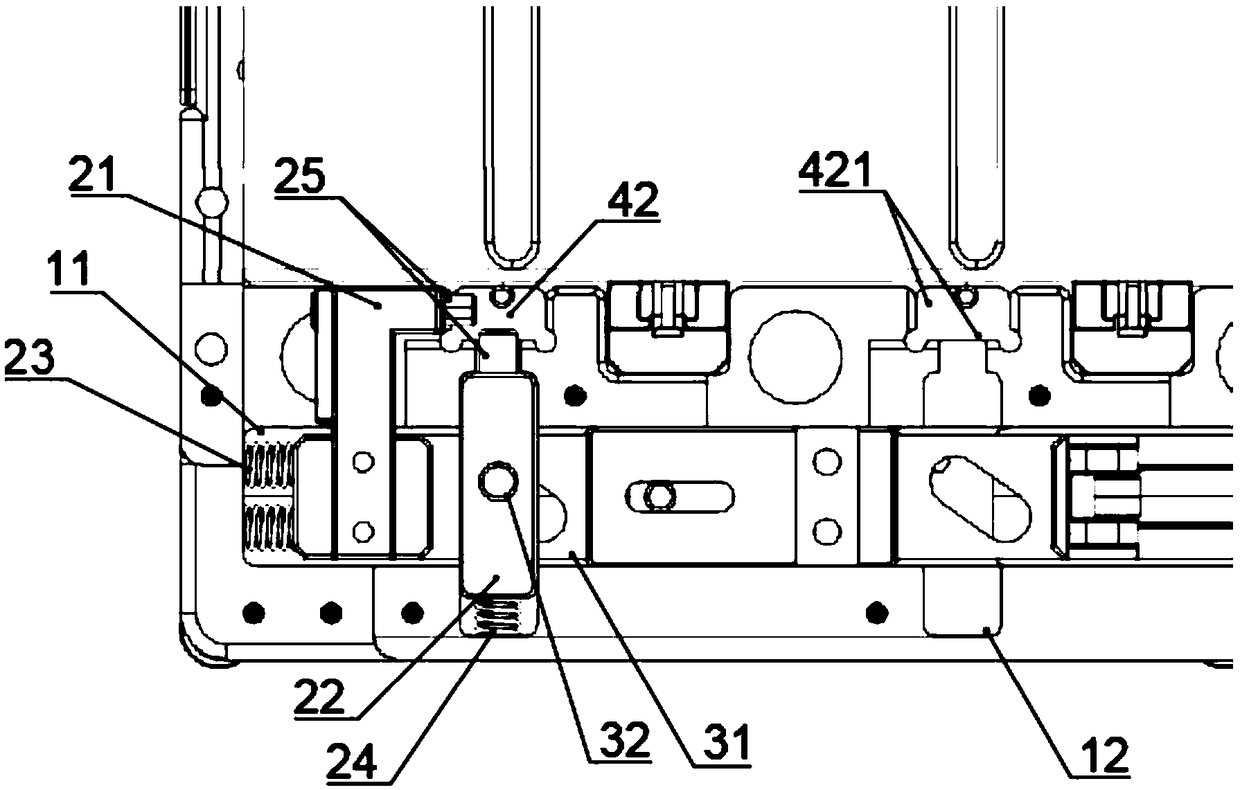

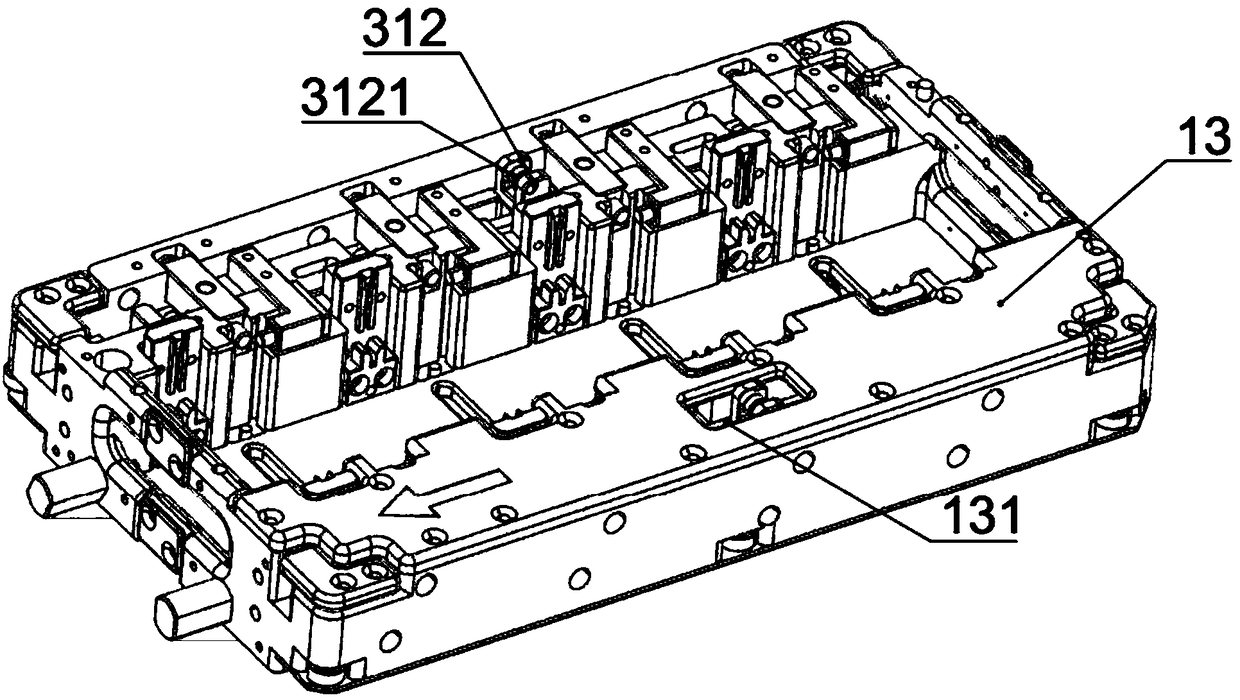

[0043] This embodiment provides an assembly line fixture, its structure is as follows Figure 1 to Figure 4 As shown, it includes a base and several positioning mechanisms and locking mechanisms arranged on the base. The locking mechanism has a locking position for fixing the workpiece and an unlocking position for releasing the workpiece, so that the workpiece placed in the positioning mechanism can be locked at a specific position. Locking is convenient for the positioning of workpieces. It is suitable for assembly line operations. The operating mechanism operates on batches of the same workpieces at the same time, eliminating the trouble of locating the workpieces one by one.

[0044] The locking mechanism 2 in this embodiment includes a traction device 3 and a first locking device 21 connected to the traction device 3 , the traction device 3 is acted by an external force and drives the first locking device 21 to move to an unlocked position or a locked position. At least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com