Camshaft drilling device

A technology for drilling devices and camshafts, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as the influence of processing efficiency, the amplification of processing errors, and the complexity of clamping and positioning operations , to avoid positioning interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

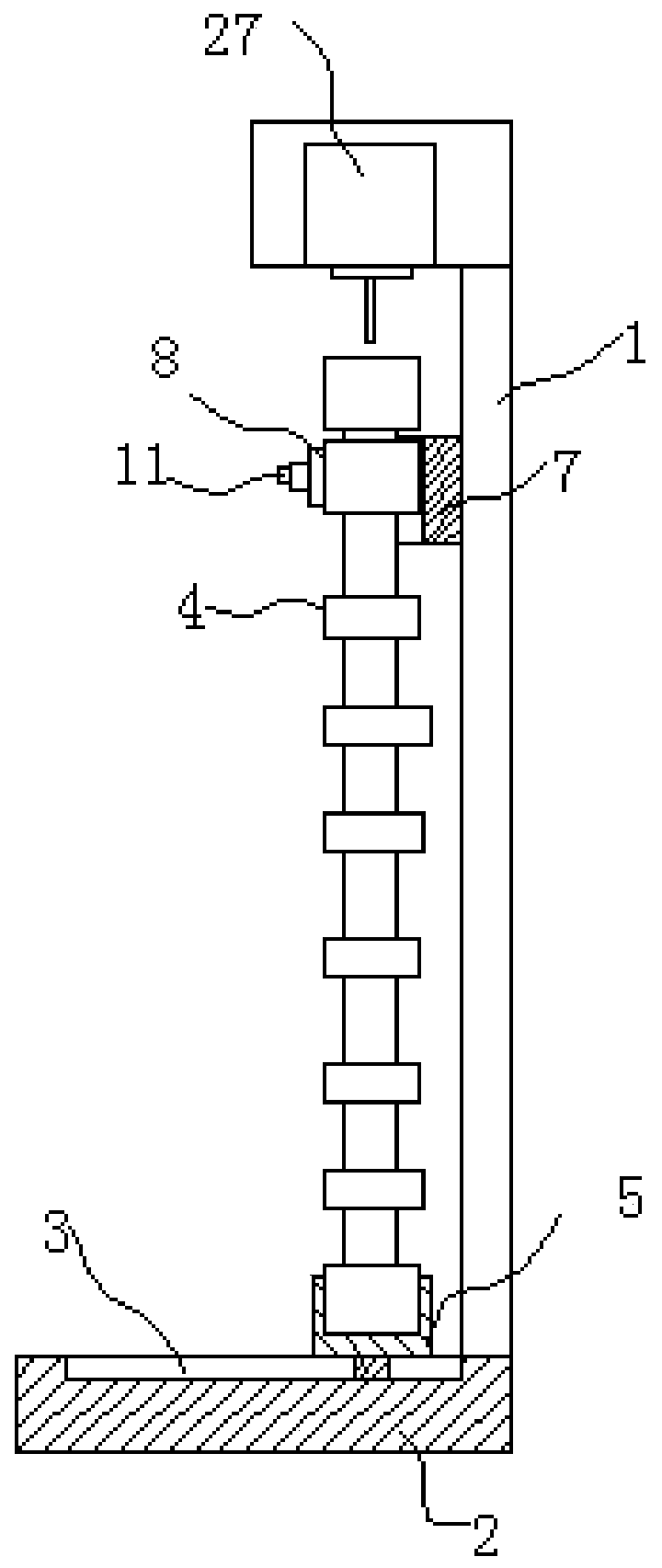

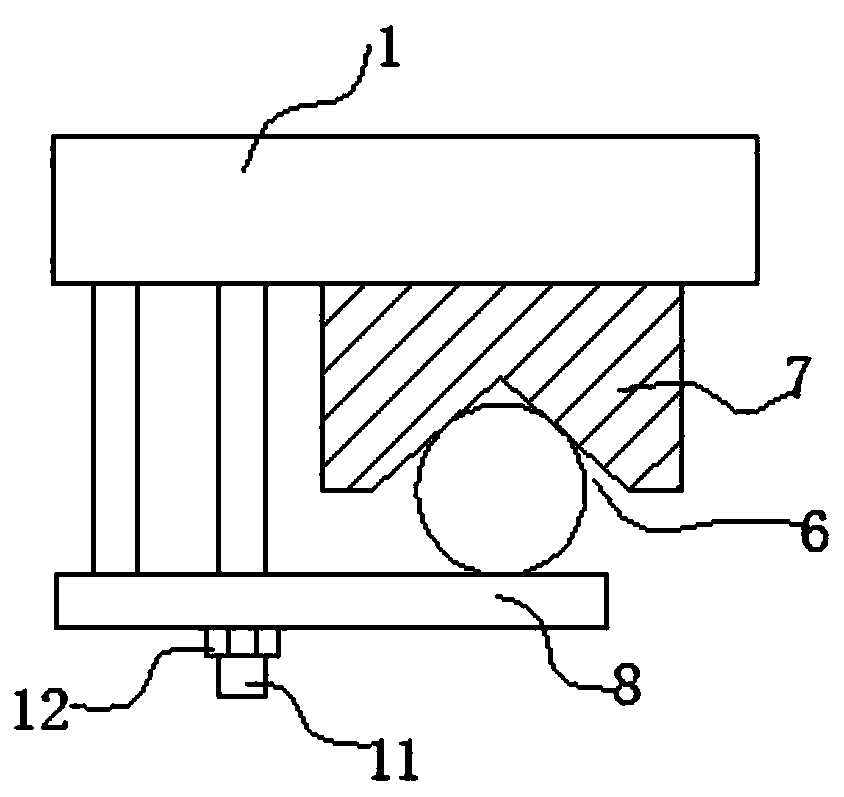

[0017] Such as Figure 1 to Figure 2 As shown, a camshaft drilling device includes a frame 1, the lower end of the frame 1 is fixedly mounted with a base 2, and the upper surface of the base 2 is provided with a guide groove 3 extending transversely or longitudinally. A positioning sleeve 5 sleeved on the lower end of the camshaft 4 is movably installed in the guide groove 3, and the inner peripheral surface of the positioning sleeve 5 is close to the outer peripheral surface of the camshaft 4 and is in clearance fit with the lower end of the camshaft 4. , the frame 1 is also provided with a camshaft positioning device located above the positioning sleeve 5 , and the frame is also provided with a drilling device 26 located above the upper end of the camshaft 4 . The drilling device 27 can be a working head of a vertical drilling machine, and the column of the vertical drilling machine is fixedly connected with the frame. The camshaft locating device is positioned above the lo...

Embodiment 2

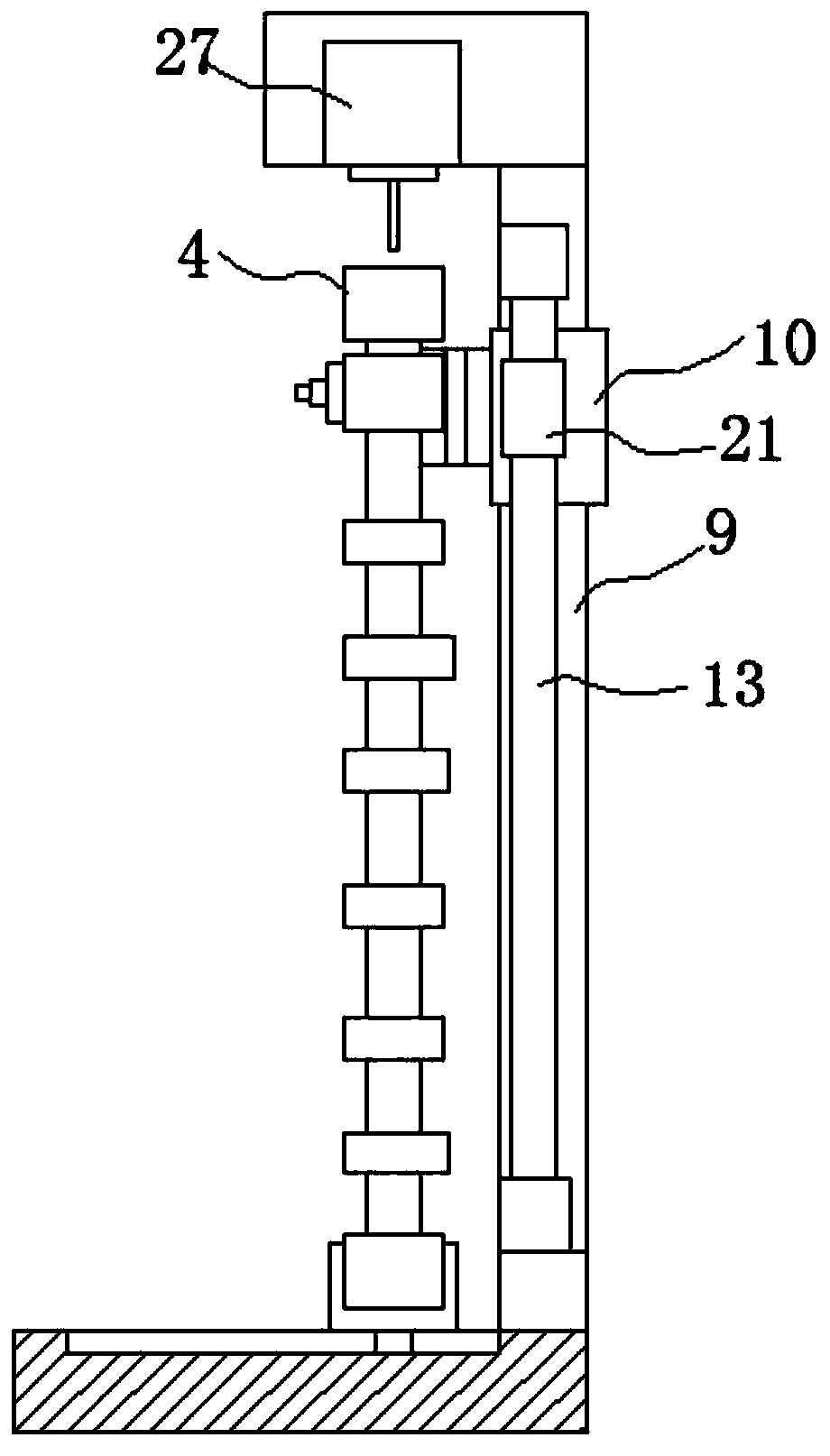

[0019] Embodiment two: if Figure 3 to Figure 6 As shown, the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the frame is also provided with a vertically extending vertical guide column 9, and the vertical guide column 9 is movably installed with The guide sleeve 10, the positioning seat 7 is fixedly installed on the guide sleeve 10, and the stud is fixedly installed on the positioning seat 7. In this embodiment, the vertical guide column can double as the frame.

[0020] The bottom plate 23 of the positioning sleeve 5 is provided with a guide block movably installed in the guide groove 3, the guide block includes a left block 14 and a right block 15, and the bottom plate of the positioning sleeve is provided with a guide block along the The strip guide hole 16 that the widthwise direction of guide groove extends, described left block 14 and the right block 15 that can move along described strip guide hole are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com