Drilling fixture for wooden door processing

A drilling jig and wooden door technology, which is applied in wood processing equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as errors, easy rotation of connecting parts, and unstable positioning of jigs, and achieve the effect of precise drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

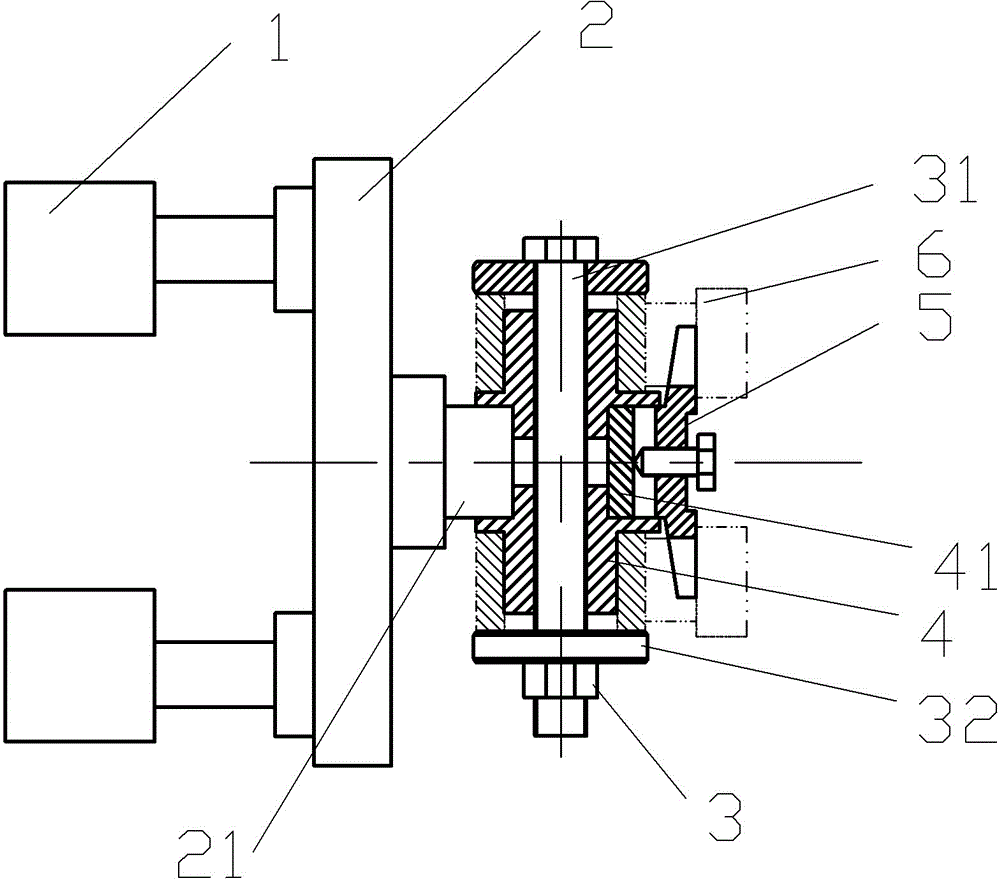

[0012] The reference numerals in the drawings of the description include: hydraulic cylinder 1, base 2, clip seat 21, nut 3, stud 31, washer 32, fixing sleeve 4, spacer 41, anti-rotation block 5, and connector 6.

[0013] The embodiment is basically as figure 1 Shown:

[0014] The drilling jig for wooden door processing includes a base 2 and a clamp seat 21 fixed on the base. There is a fixing sleeve 4 on the upper and lower sides of the base, and the inner hole of the connecting piece 6 is sleeved on the outer circle of the fixing sleeve. Two The fixing sleeves are connected by studs 31, one end of the studs is fixed by a nut 3, and the left ends of the two fixing sleeves are both pressed against the holder, and the two fixing sleeves, the two connecting parts and the holder are formed into a firm whole by the studs, The freedom of movement of the connecting piece is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com