Patents

Literature

252results about How to "Precise drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

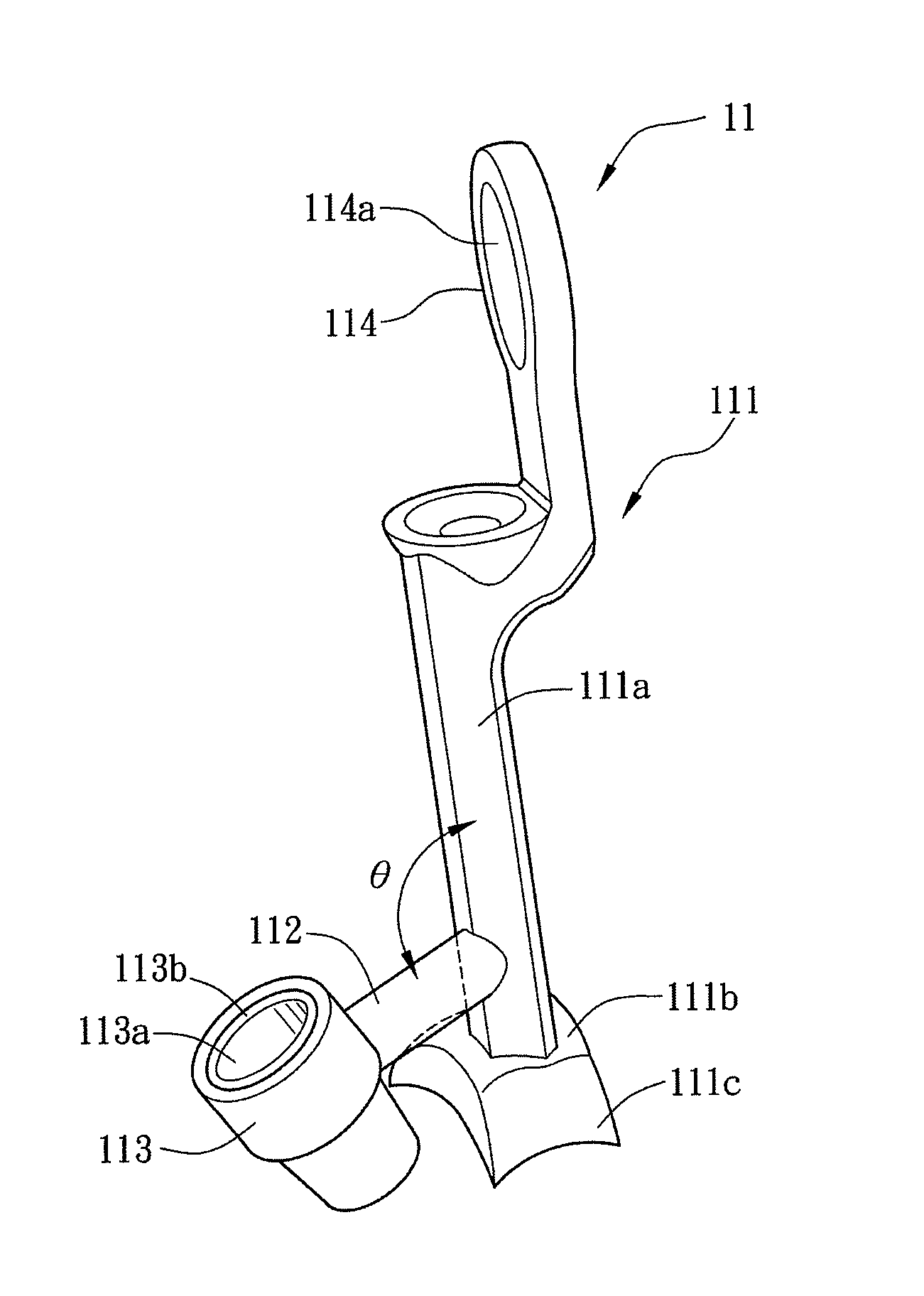

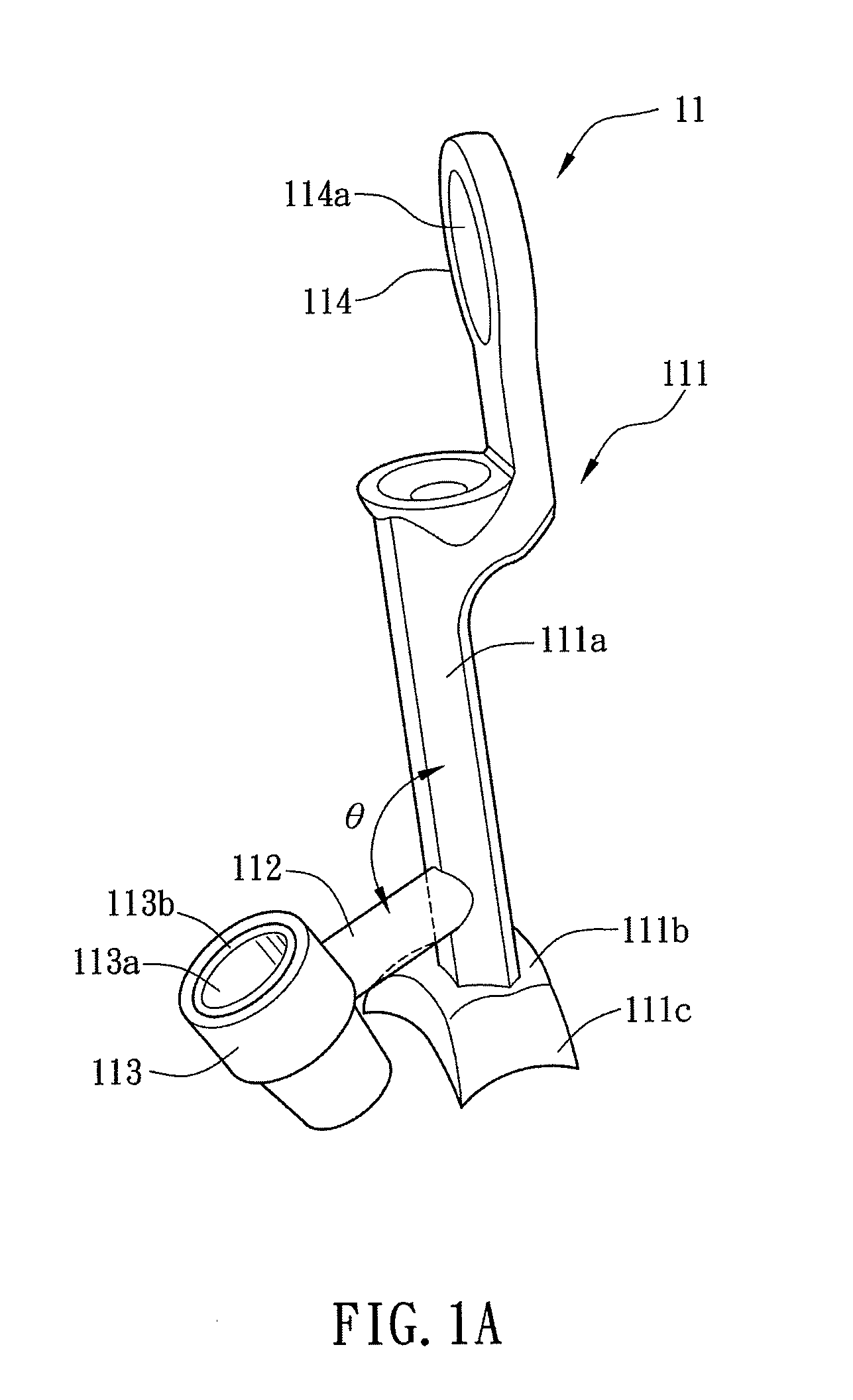

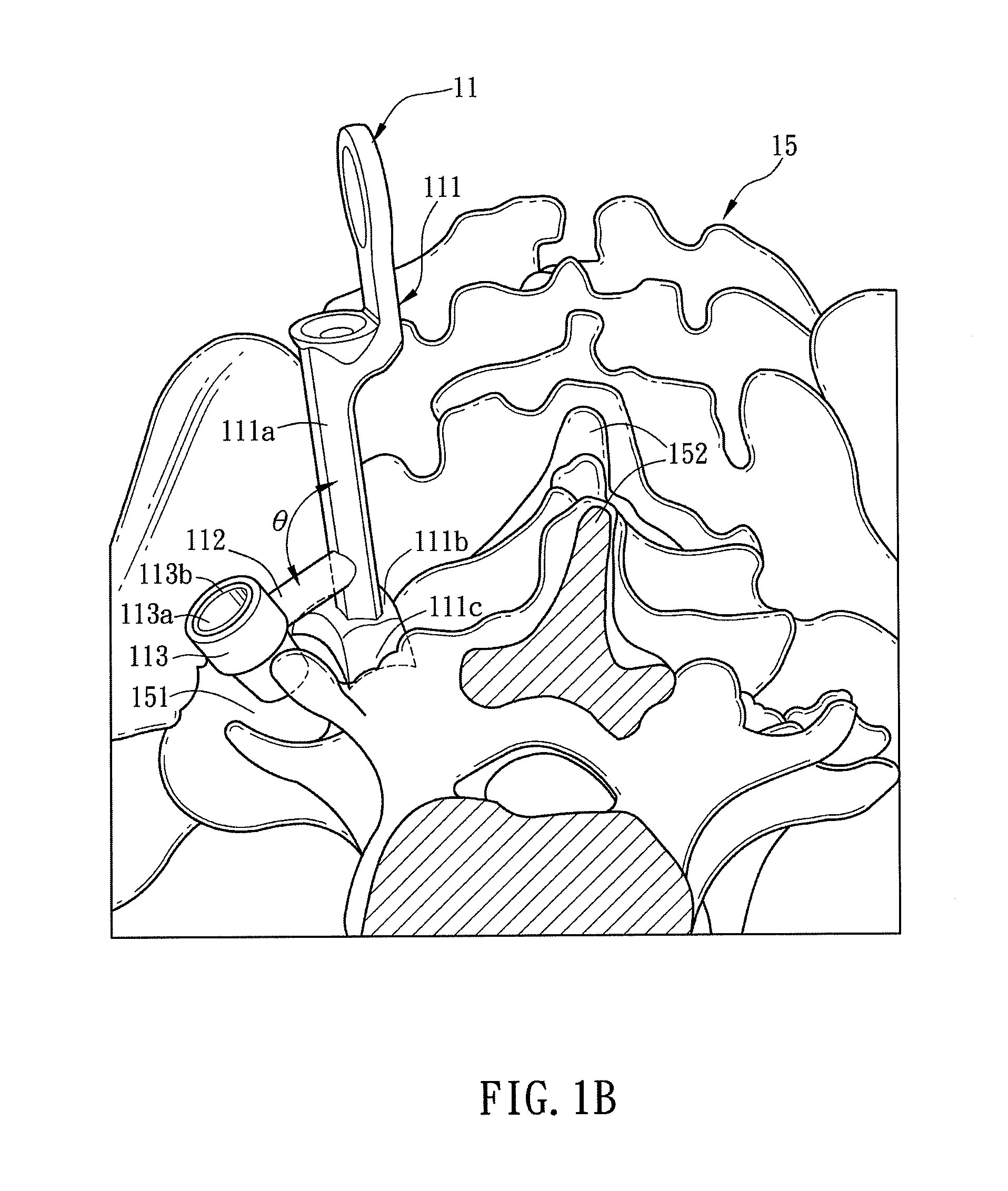

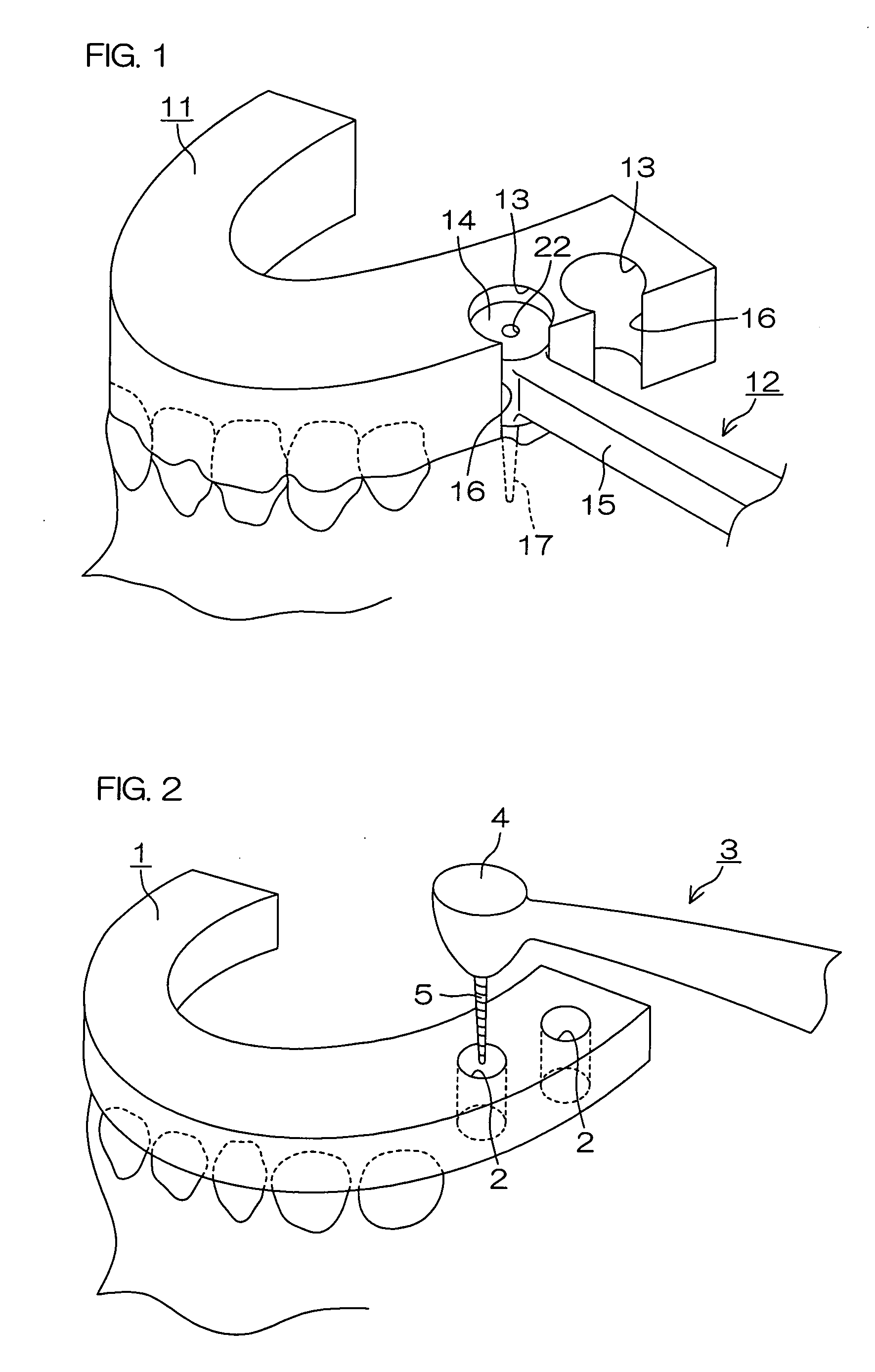

Method for spinal drilling operation and guiding assembly

InactiveUS20120245587A1Enhance precision and stabilityIncrease precisionProsthesisOsteosynthesis devicesVertebraBiomedical engineering

A method for spinal drilling operation is disclosed. The method includes the steps of disposing a guiding element on a vertebra; mounting an auxiliary element on a locating part of the guiding element; mounting a k-pin on the auxiliary element; locating the k-pin and removing the auxiliary element from the locating part; mounting a cannular driller having a holding part and a drilling part through the k-pin; and rotating the holding part to drive the drilling part for a reaming process. A guiding assembly for spinal drilling operation is also disclosed. Accordingly, the spinal drilling process can be conducted easier and more precisely.

Owner:NAT CHENG KUNG UNIV

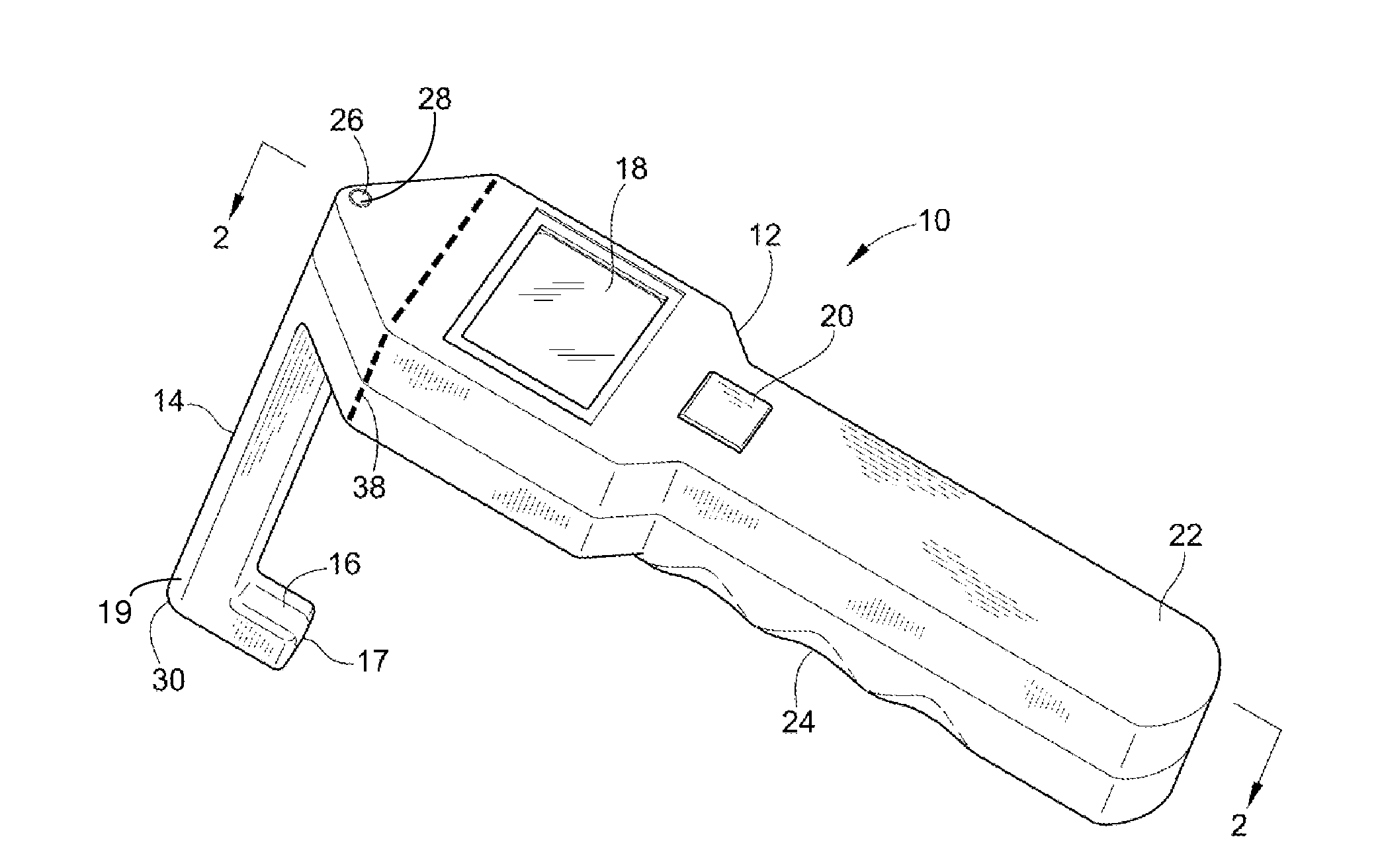

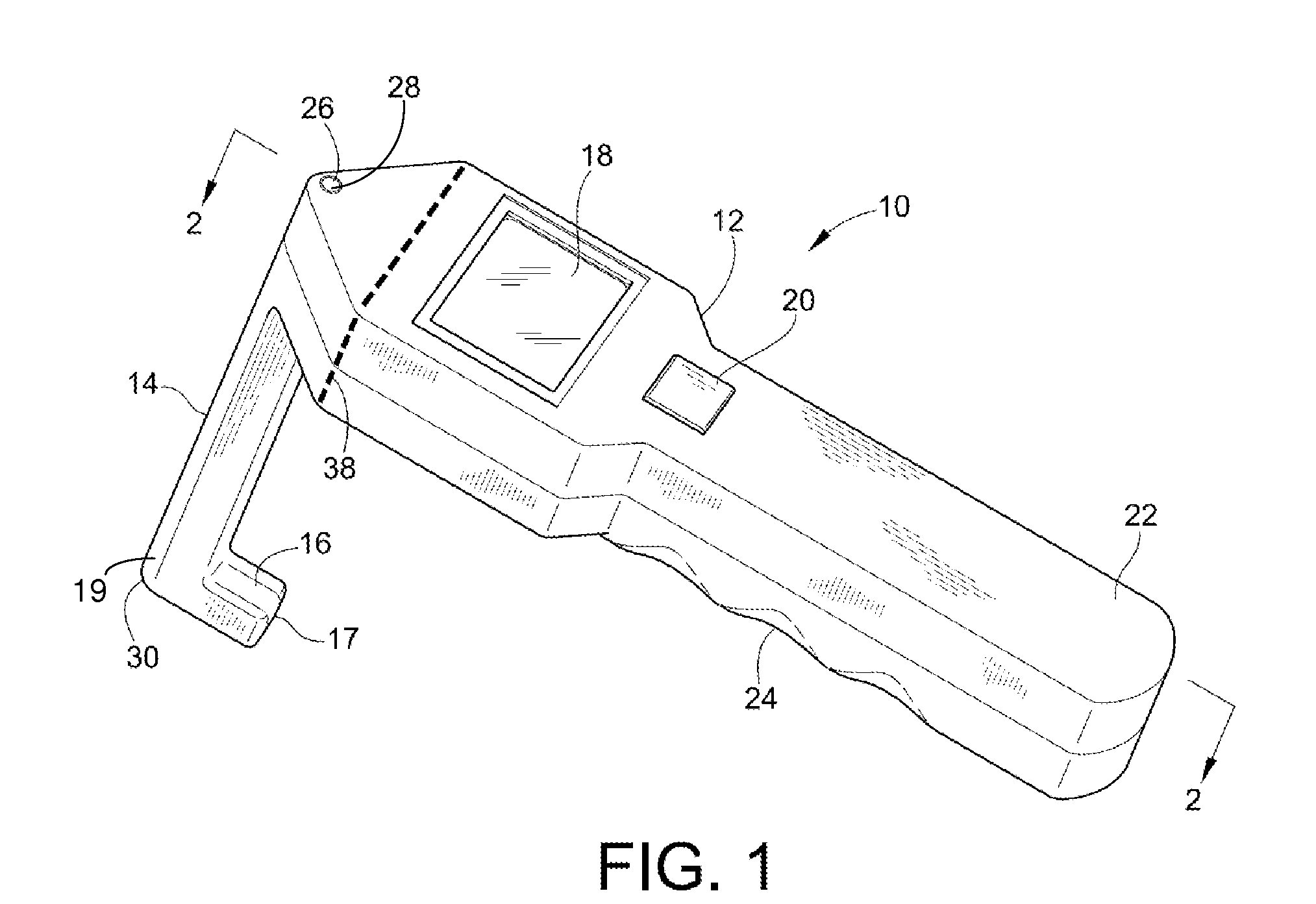

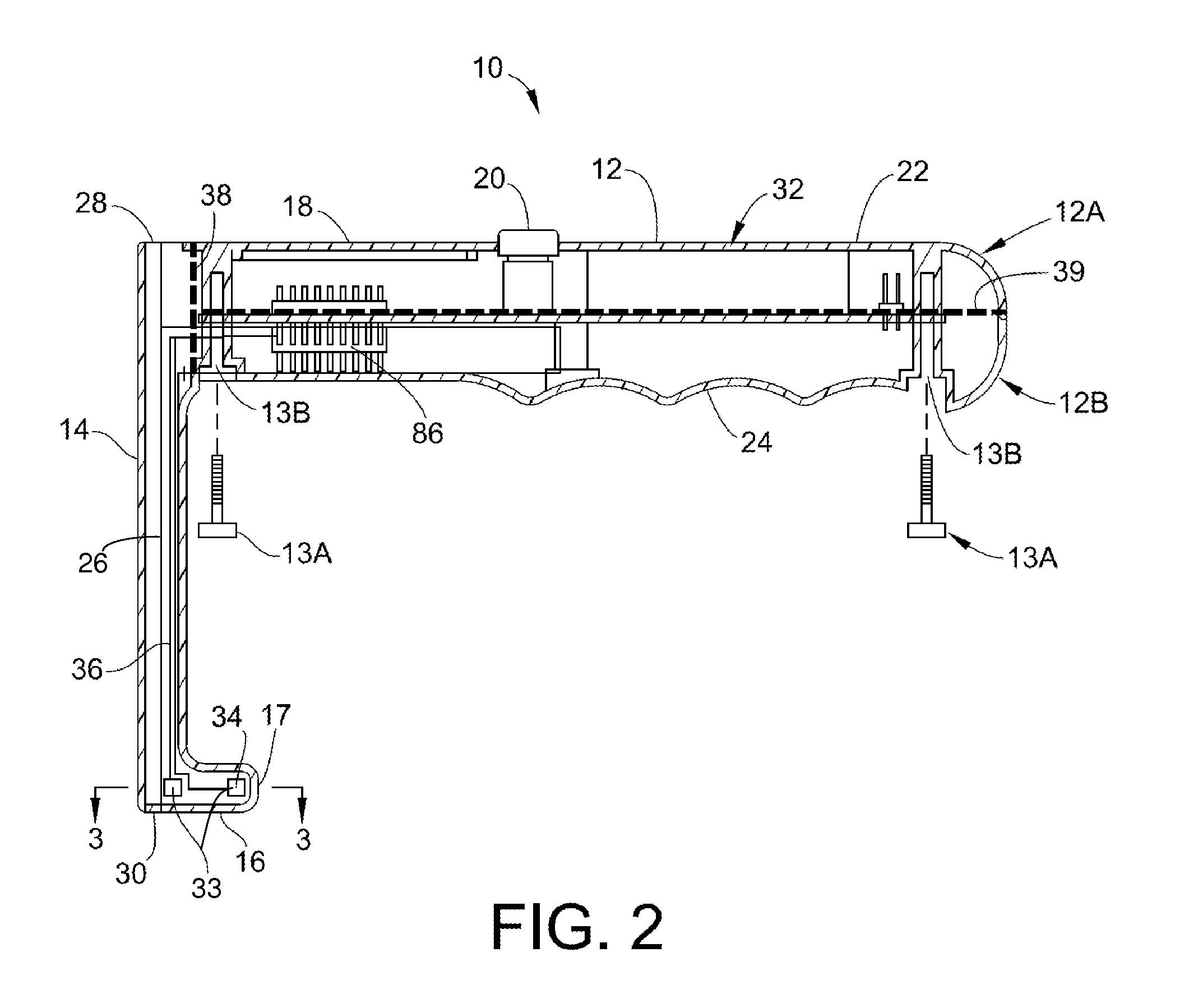

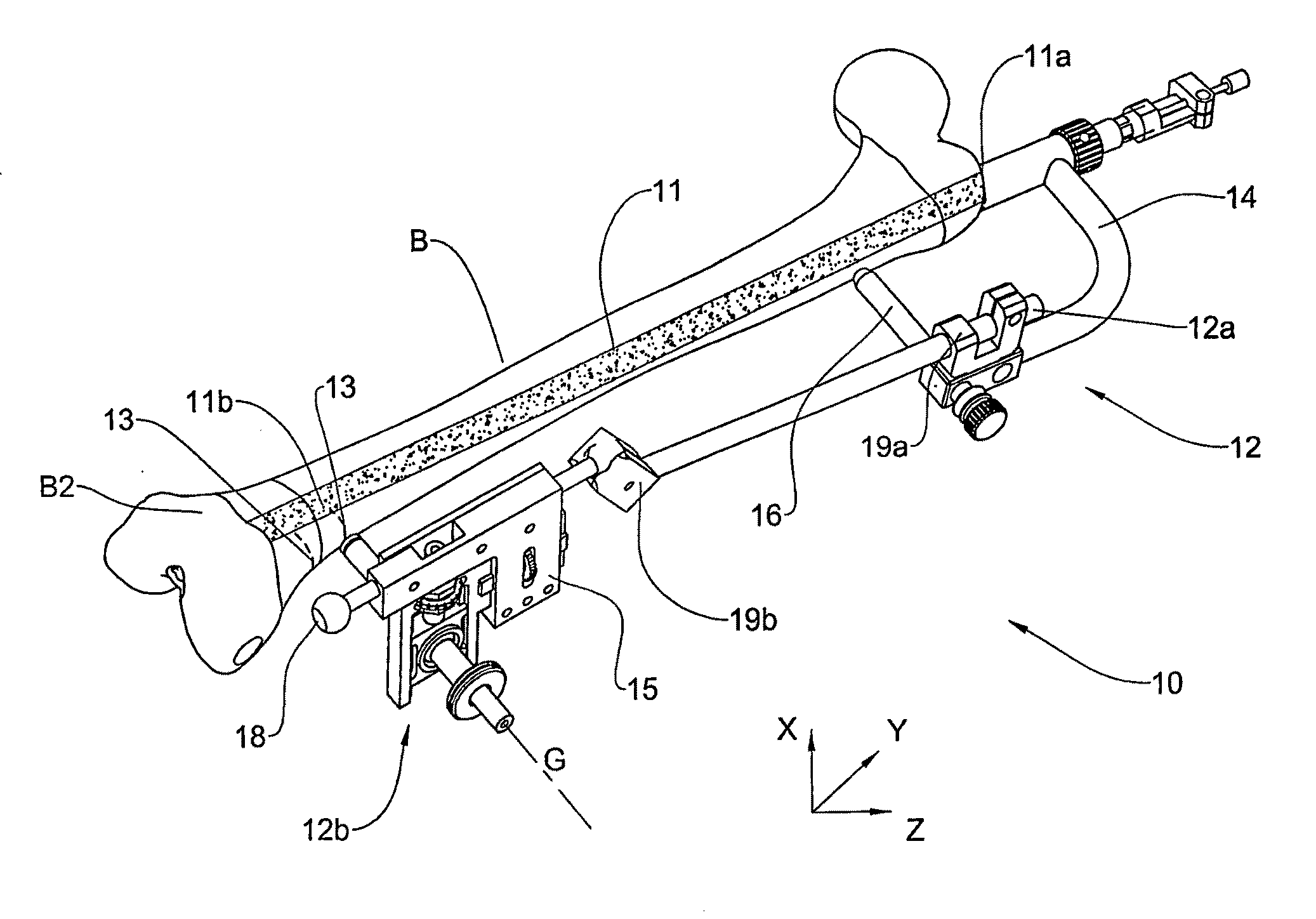

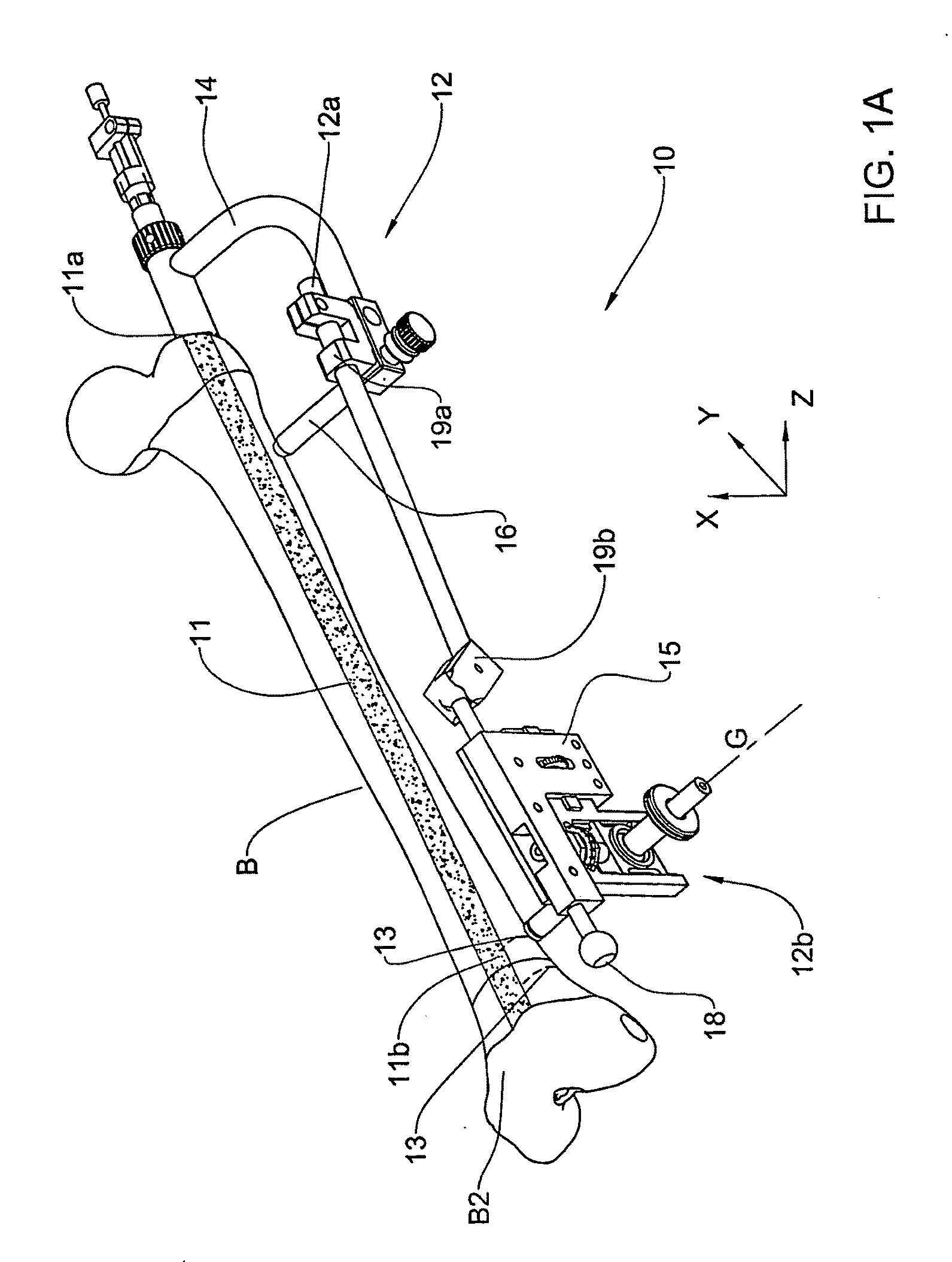

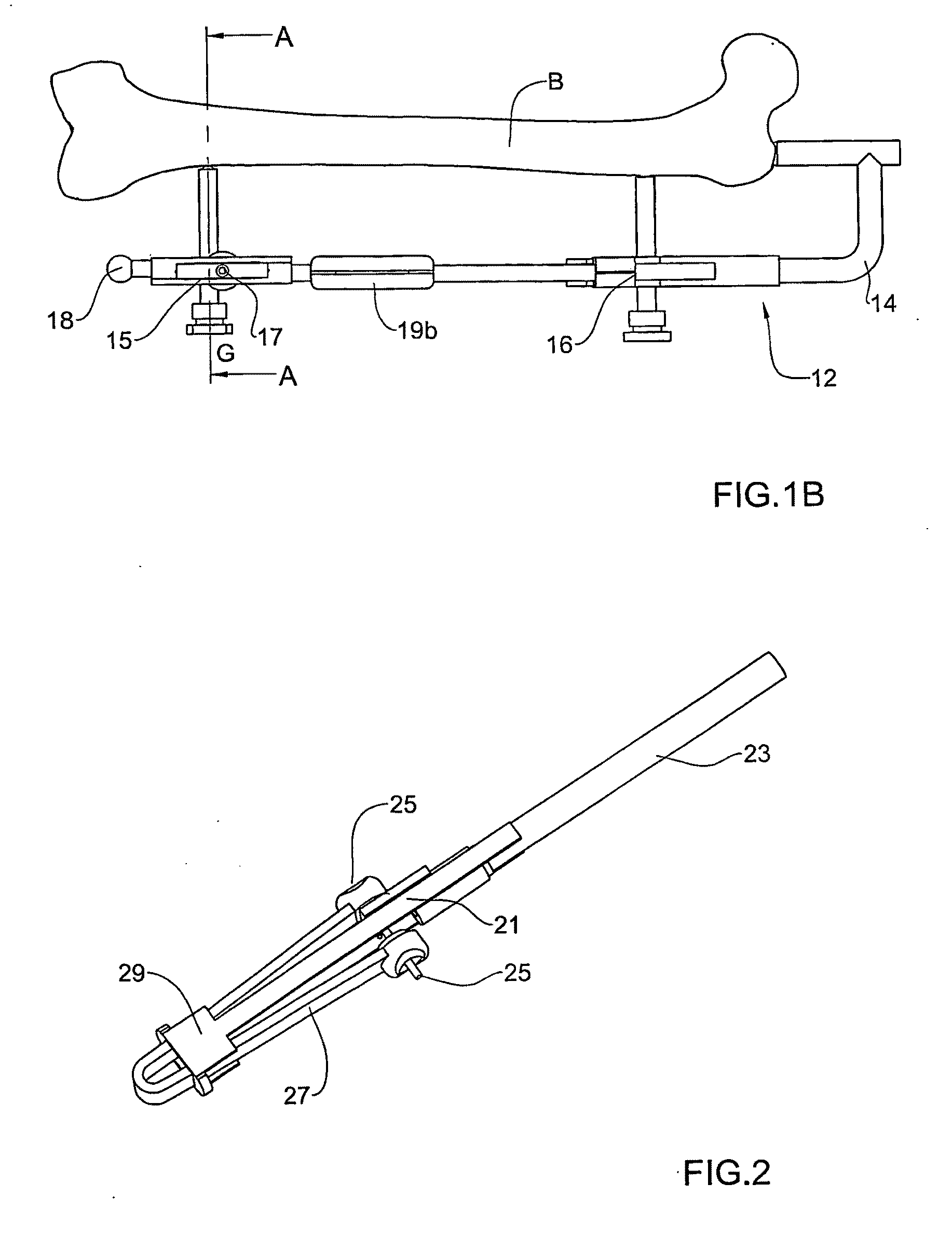

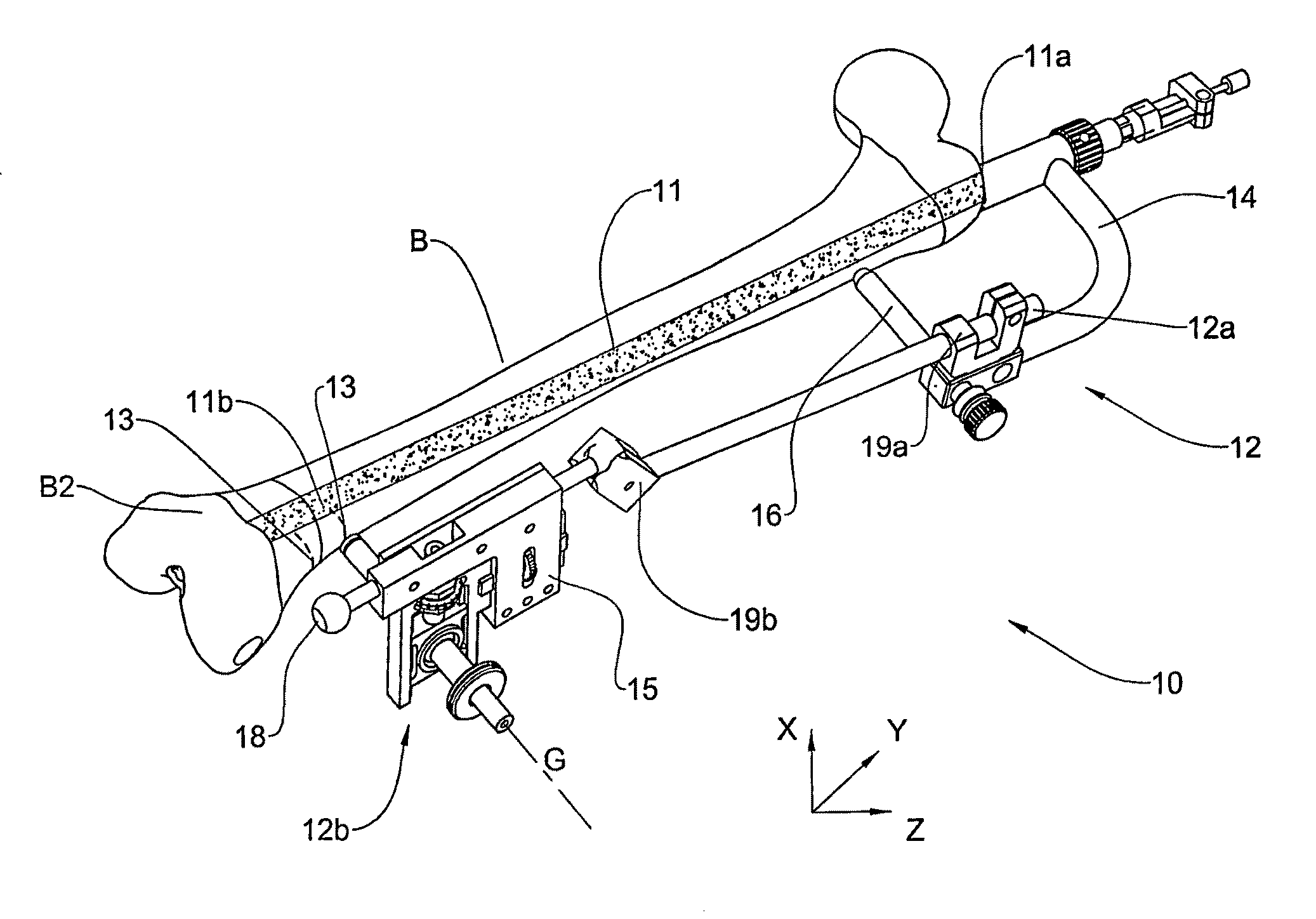

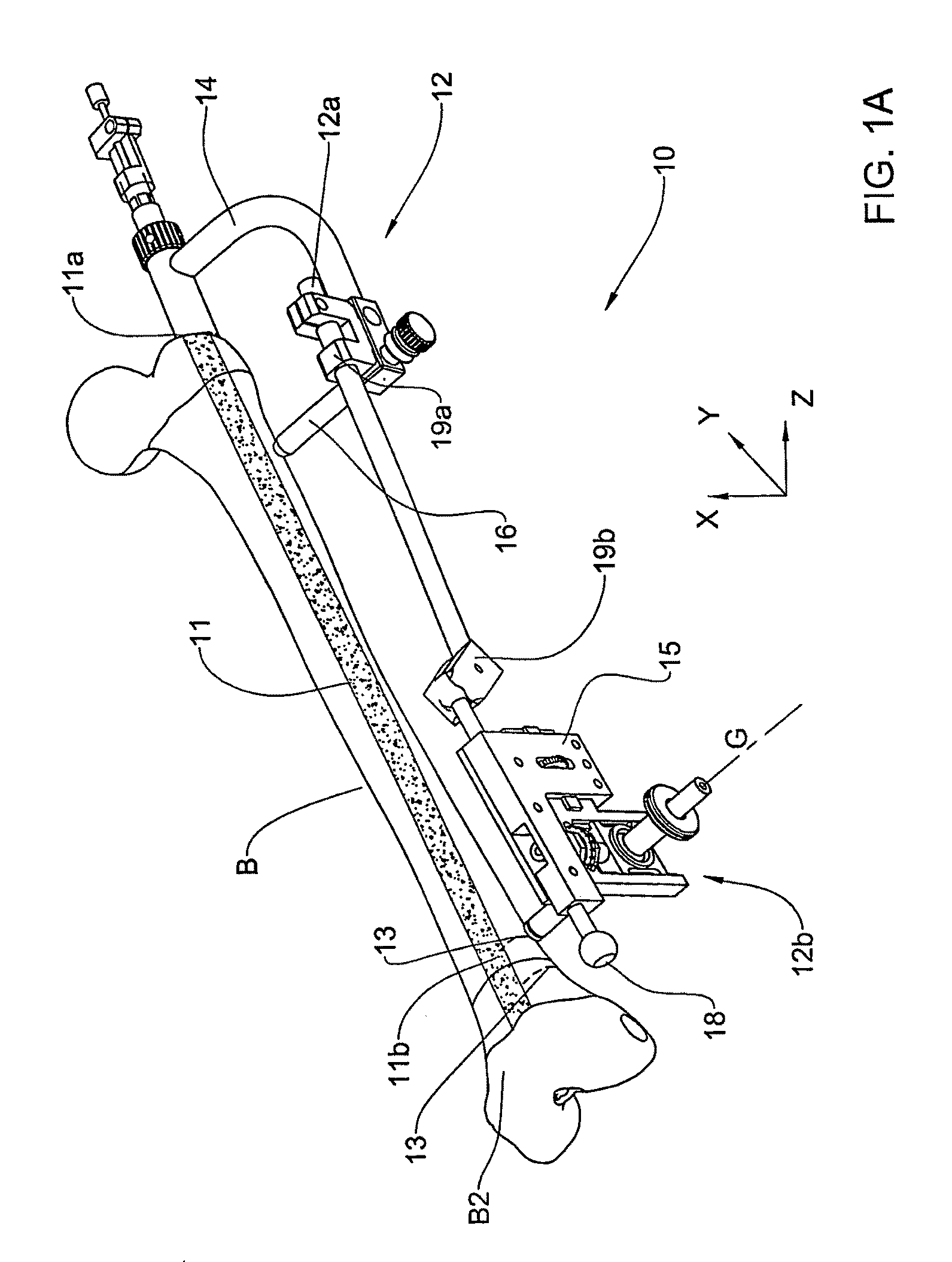

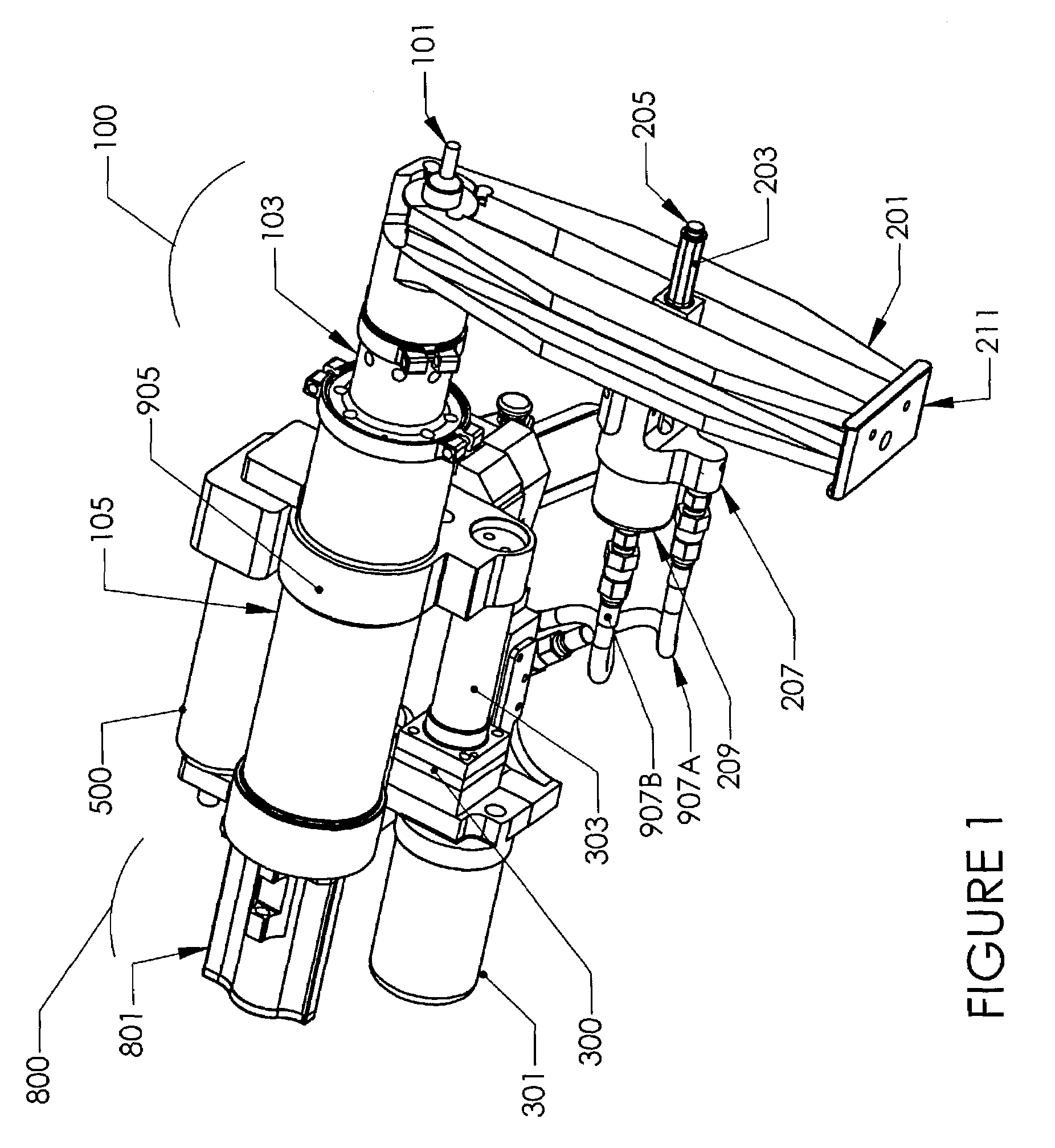

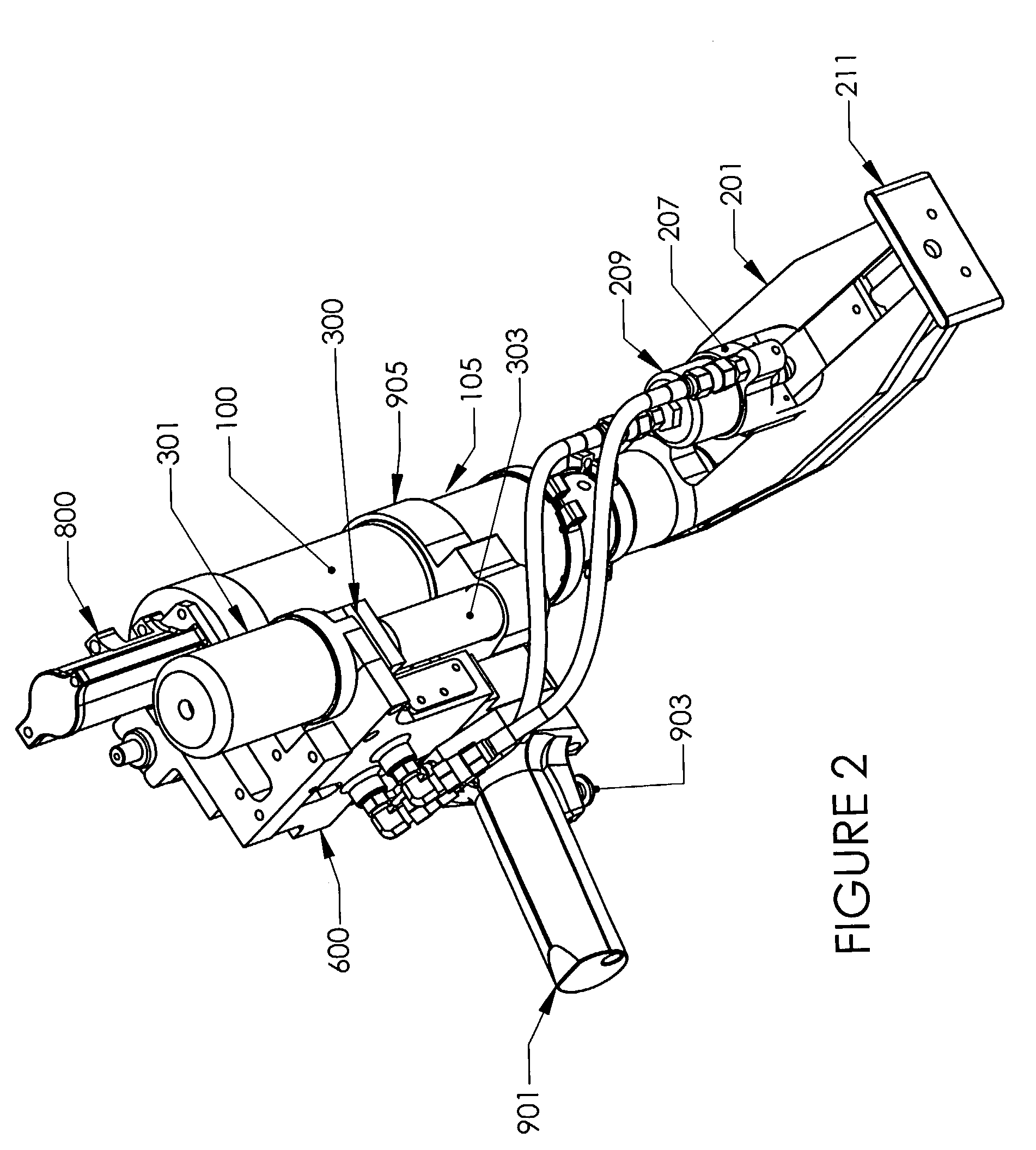

Intramedullary nail targeting device

InactiveUS20100249782A1Precise positioningMinimize degree of freedomInternal osteosythesisJoint implantsSensor arrayIntramedullary rod

An intramedullary nail targeting apparatus for targeting and drilling screw openings in the intramedullay nail is provided herein. A preferred version of the targeting apparatus includes a magnetic targeting device, a nail extension for connecting to an intramedullary nail, and a magnet member, preferably in a “bucking configuration,” for affixing to the intramedullary nail at a defined position relative to the screw openings in the nail. The nail extension includes a targeting arm with one or more bores which align with the screw openings in the nail when the targeting arm is aligned with the intramedullary nail. The magnetic targeting device includes a support member with a sensor array that extends through one of the bores on the targeting arm to target the magnet member, thereby aligning the targeting arm with the intramedullary nail. A second bore on the targeting arm can then be used for drilling through the bone at the position of an aligned screw opening. Methods for using the targeting apparatus for targeting and drilling screw openings in intramedullary nails or openings in bone plates are also described herein.

Owner:DURHAM ALFRED A

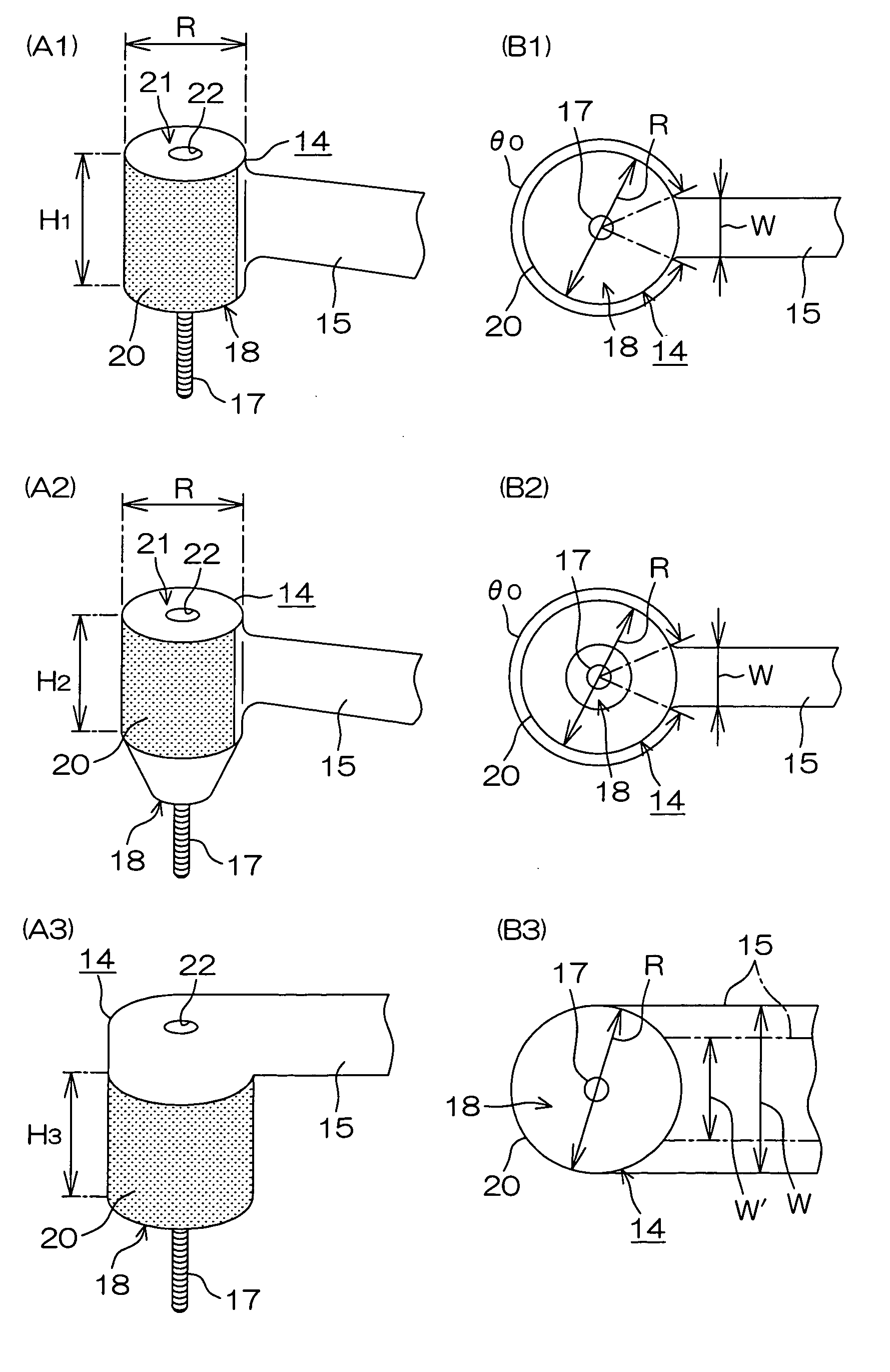

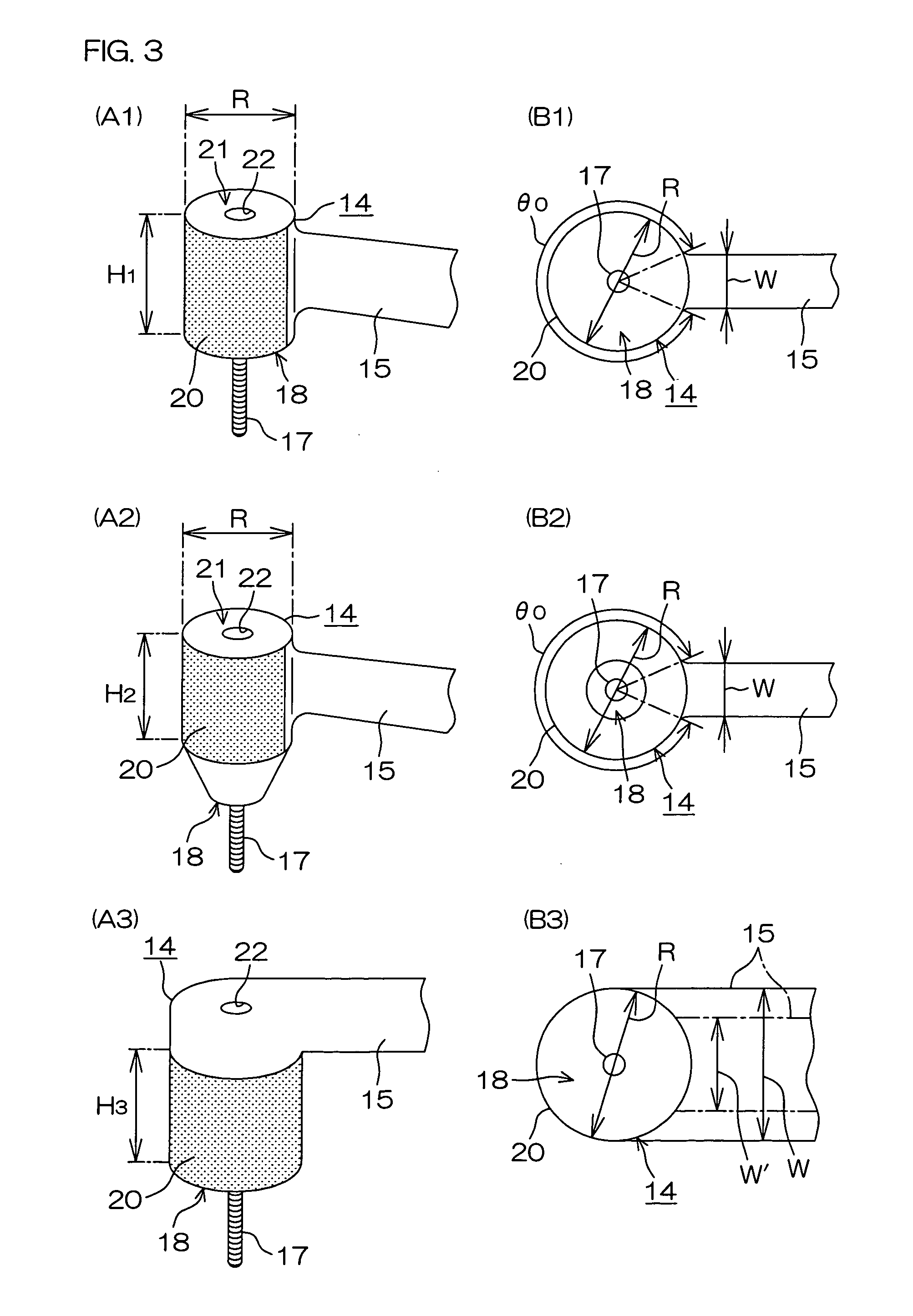

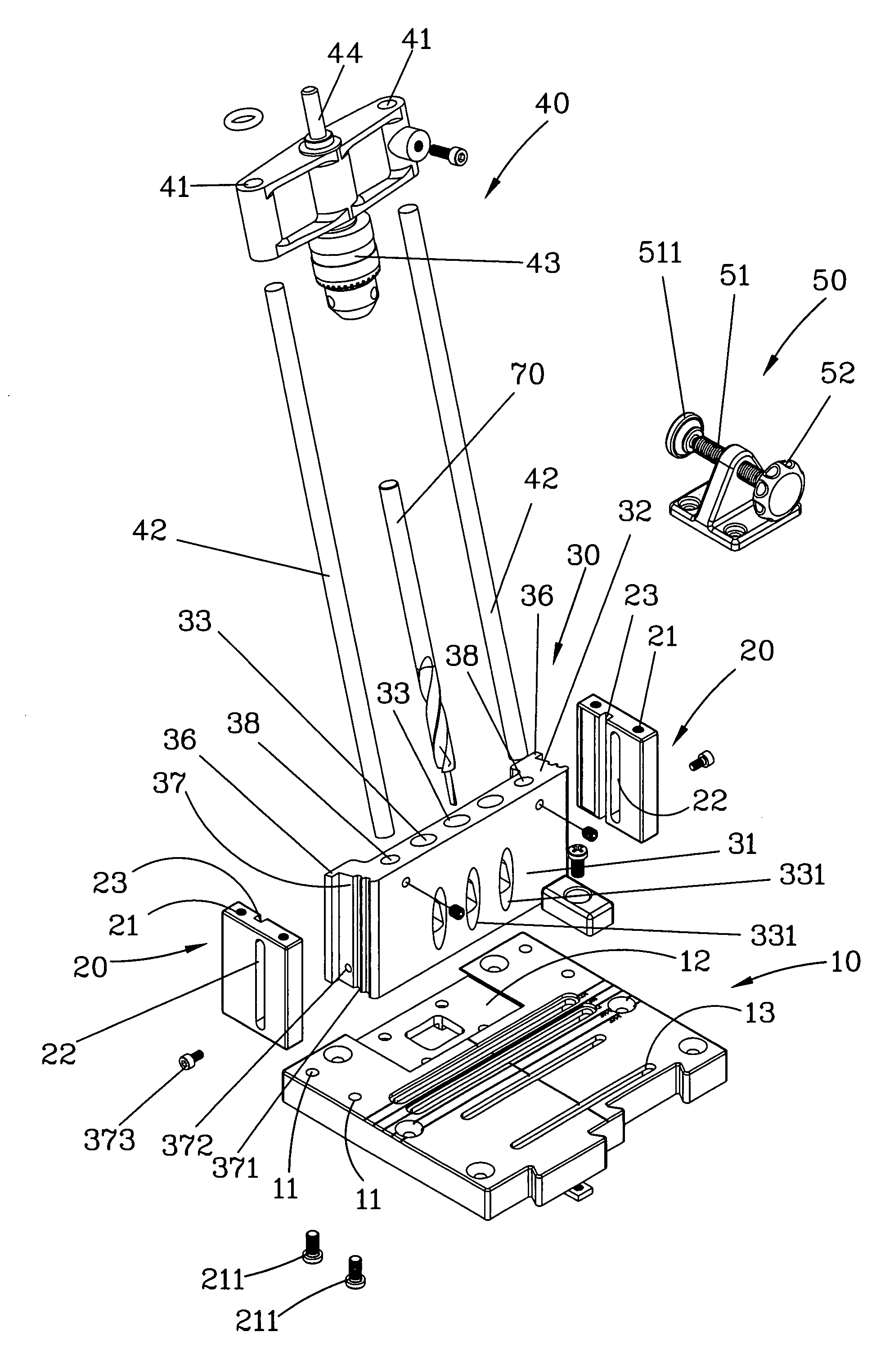

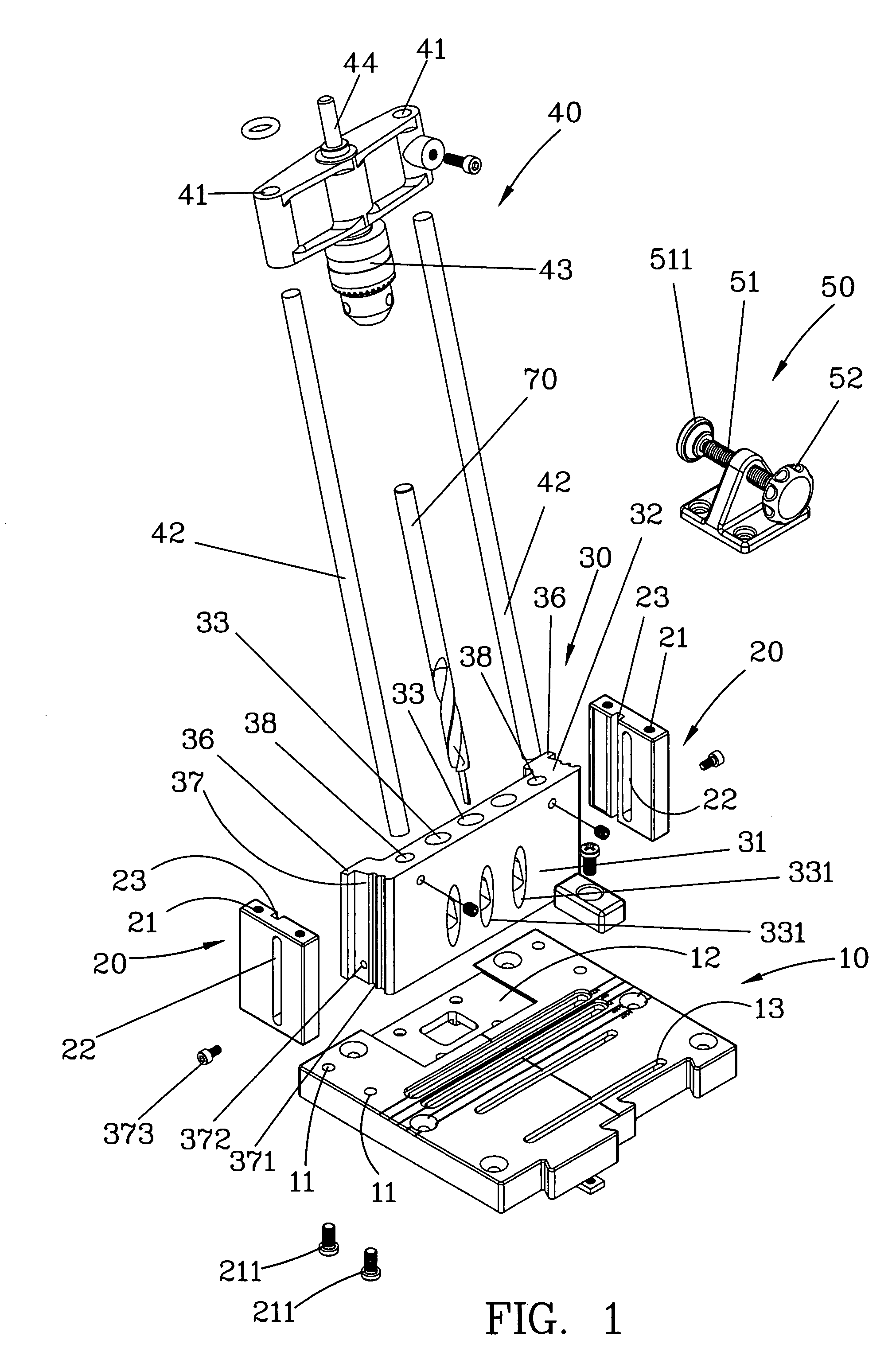

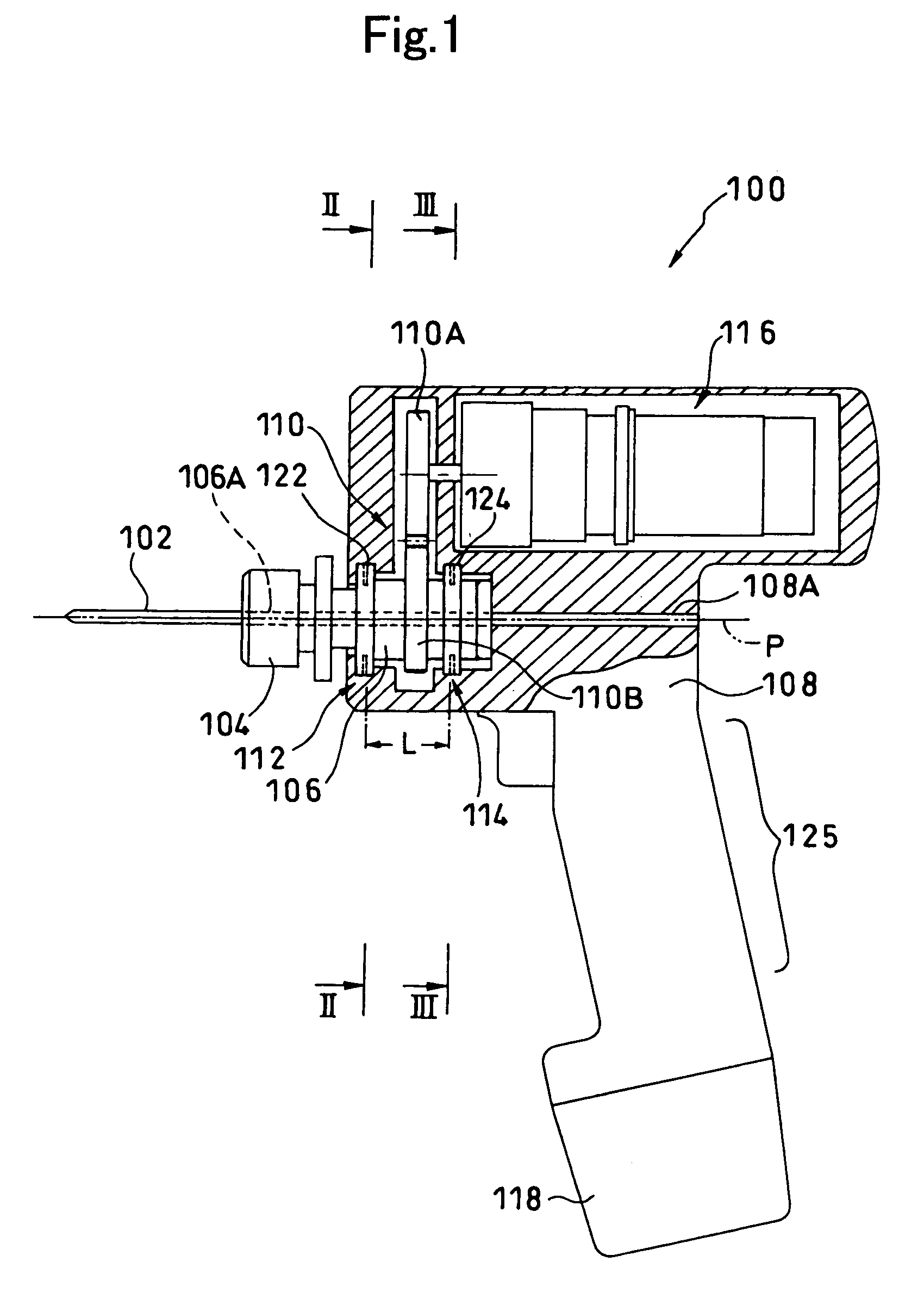

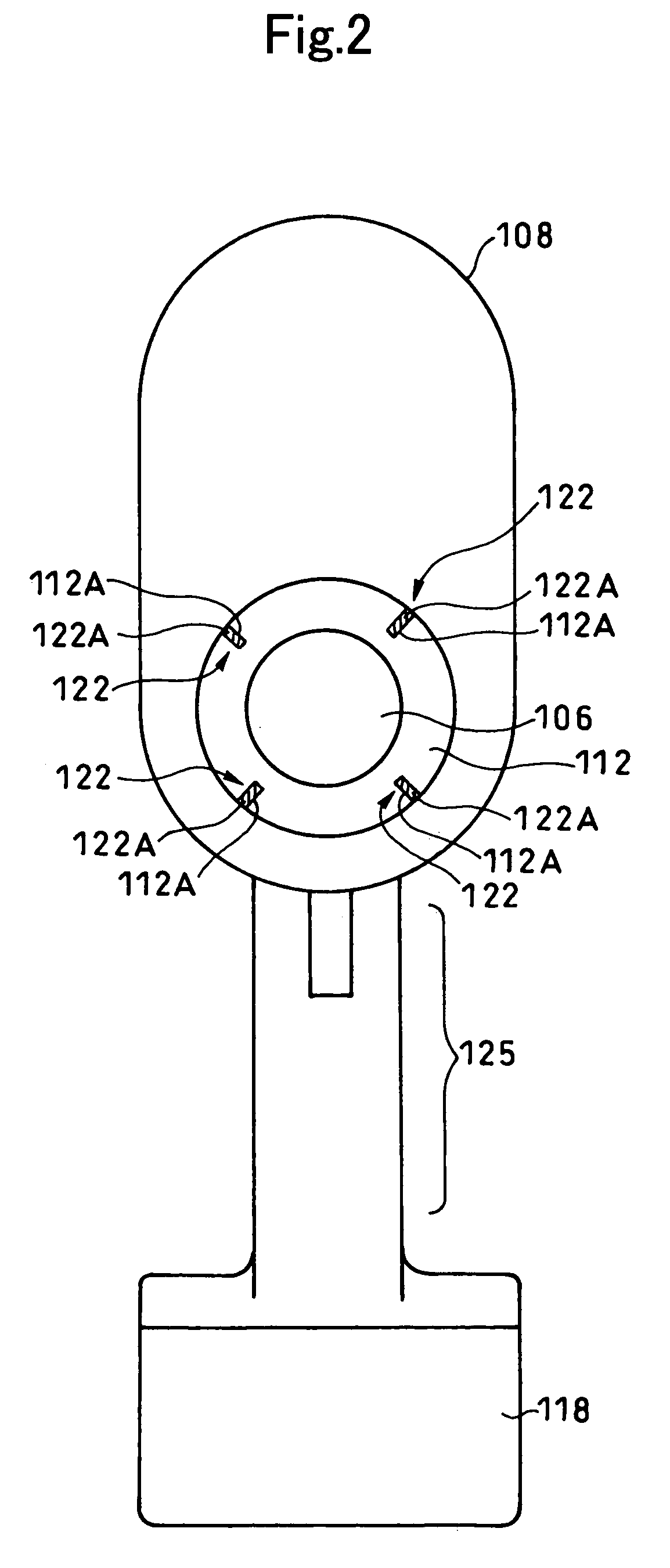

Implant erecting drill toll, hand-piece, adaptor for the hand-piece, and surgical guide

InactiveUS20100185201A1Precise drillingEnsure correct executionBoring toolsProsthesisBiomedical engineeringDrill bit

An inventive implant handpiece (12) includes a head (14) having a round outer peripheral surface (20) which is concentric with a center axis of a drill bur (17) and has a predetermined length (H1 to H3) as measured axially of the drill bur (17). A surgical guide (11) has a guide hole (13) having a round inner peripheral surface to be opposed to the round peripheral surface (20) of the head (14). Since a drilling operation is performed with the head (14) fitted in the guide hole (13), the head (14) can be reliably uniquely guided to form an implant implantation hole as desired. Thus, the present invention provides an implant handpiece capable of accurately drilling a hole for formation of an implant implantation hole, and a surgical guide capable of guiding this handpiece.

Owner:IMAGNOSIS

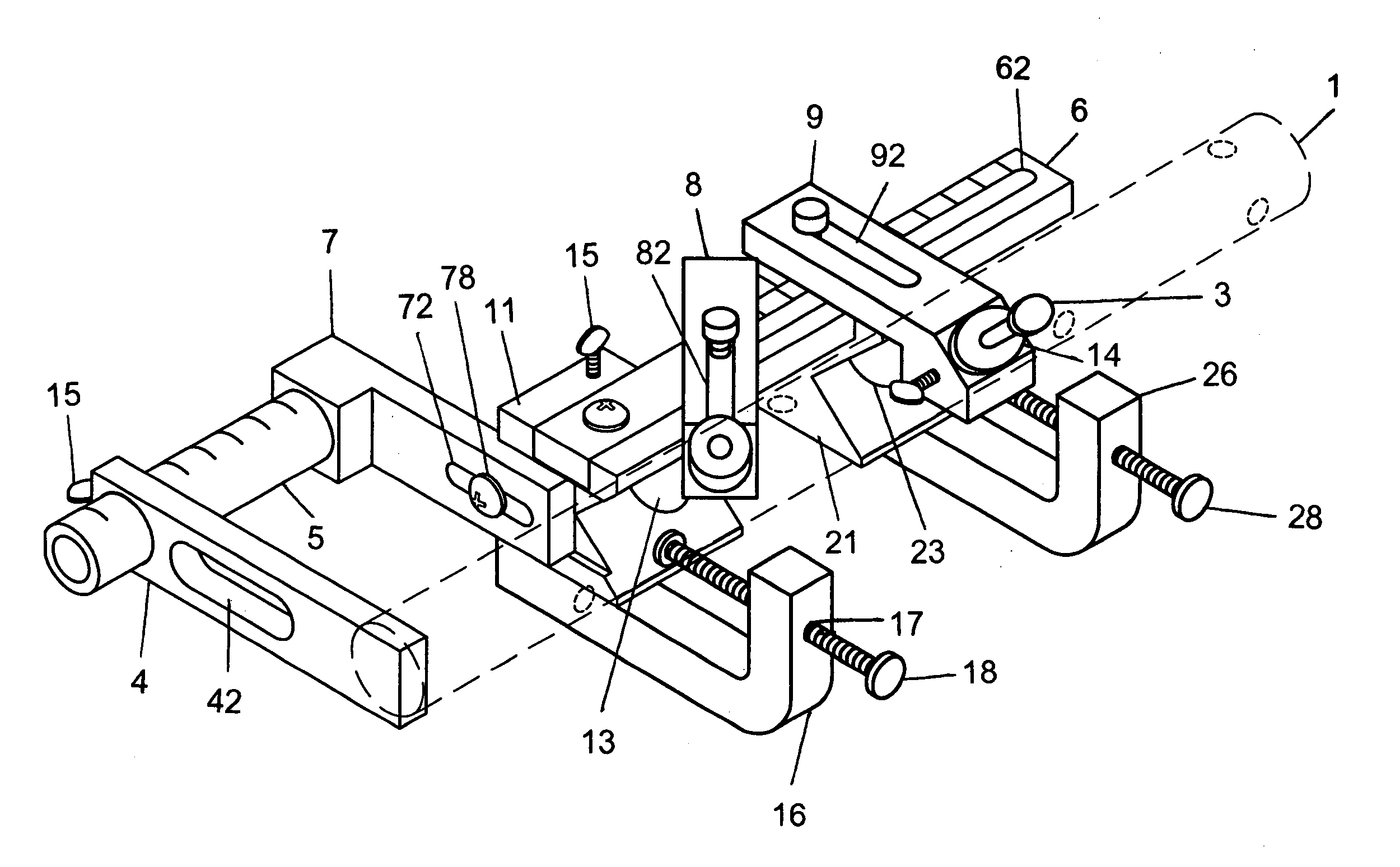

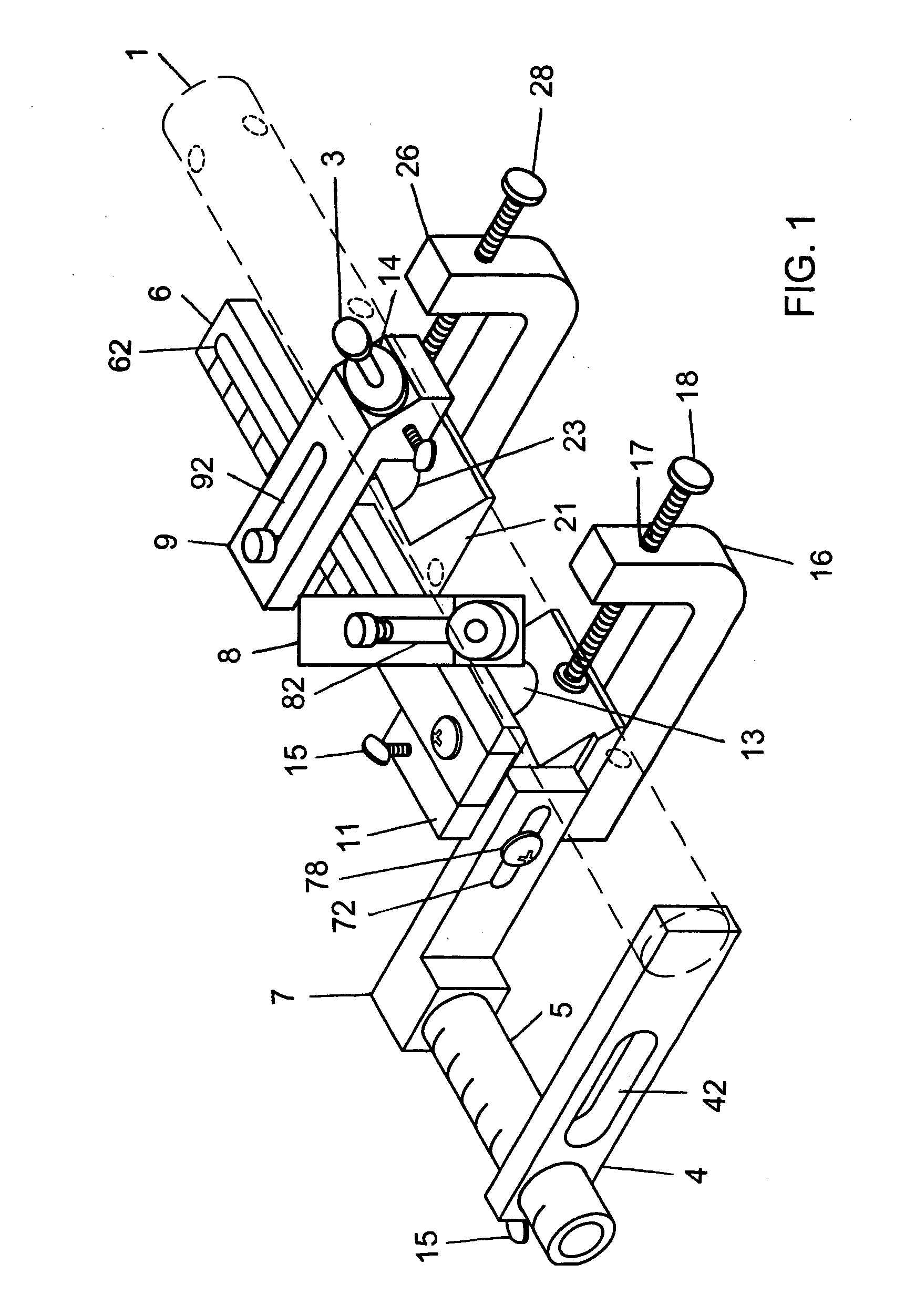

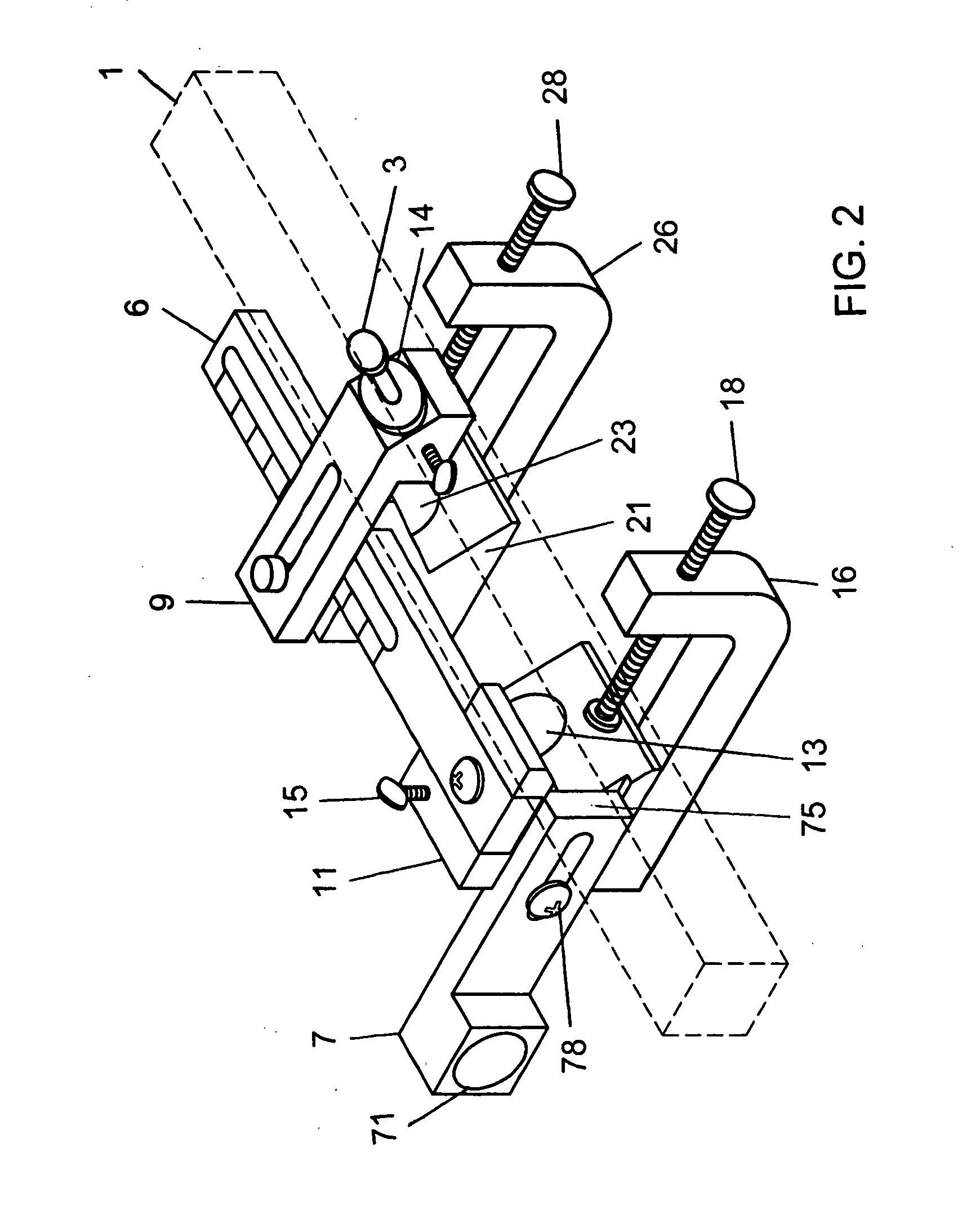

Fixturing device for drilling workpieces

InactiveUS20060233620A1Easy to manufactureEasy maintenanceThread cutting machinesDrill jigsEngineeringMechanical engineering

A fixturing device for holding a workpiece with a longitudinal axis is disclosed. The fixturing device includes a first v-block with holding surfaces that intersect each other at an intersection and form a v-shape. The first v-block has a hole formed therein with a center axis that is substantially perpendicular to the longitudinal axis of the workpiece and intersects the intersection of the holding surfaces. A clamping arm mounted to the first v-block for clamping the workpiece in the first v-block. A second v-block that is similar to the first v-block is also provided. A clamping arm is mounted to the second v-block for clamping the workpiece to the second v-block. A cross-member adjustably attaches the first v-block to the second v-block. At least one drill bushing is removably disposed in one of the hole in the first v-block and the hole in the second v-block.

Owner:HERRICK RICHARD

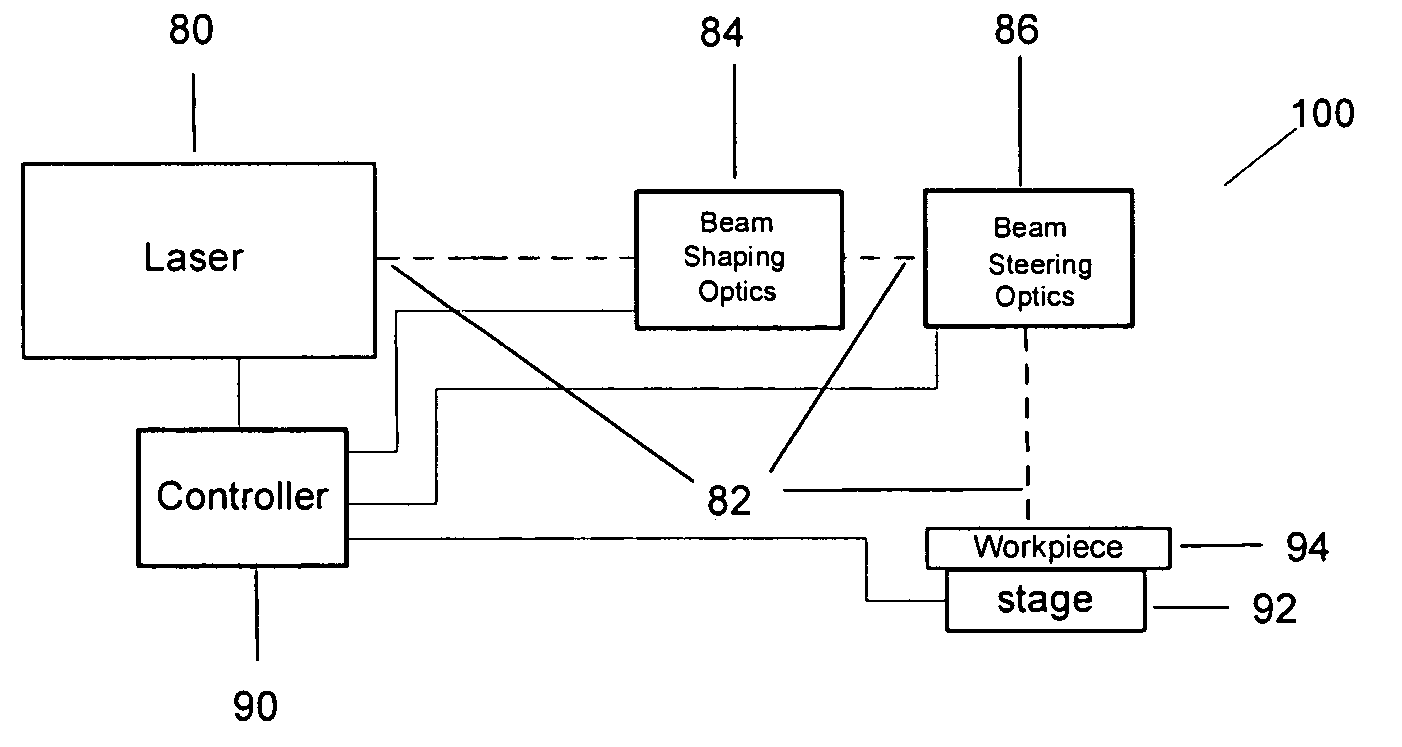

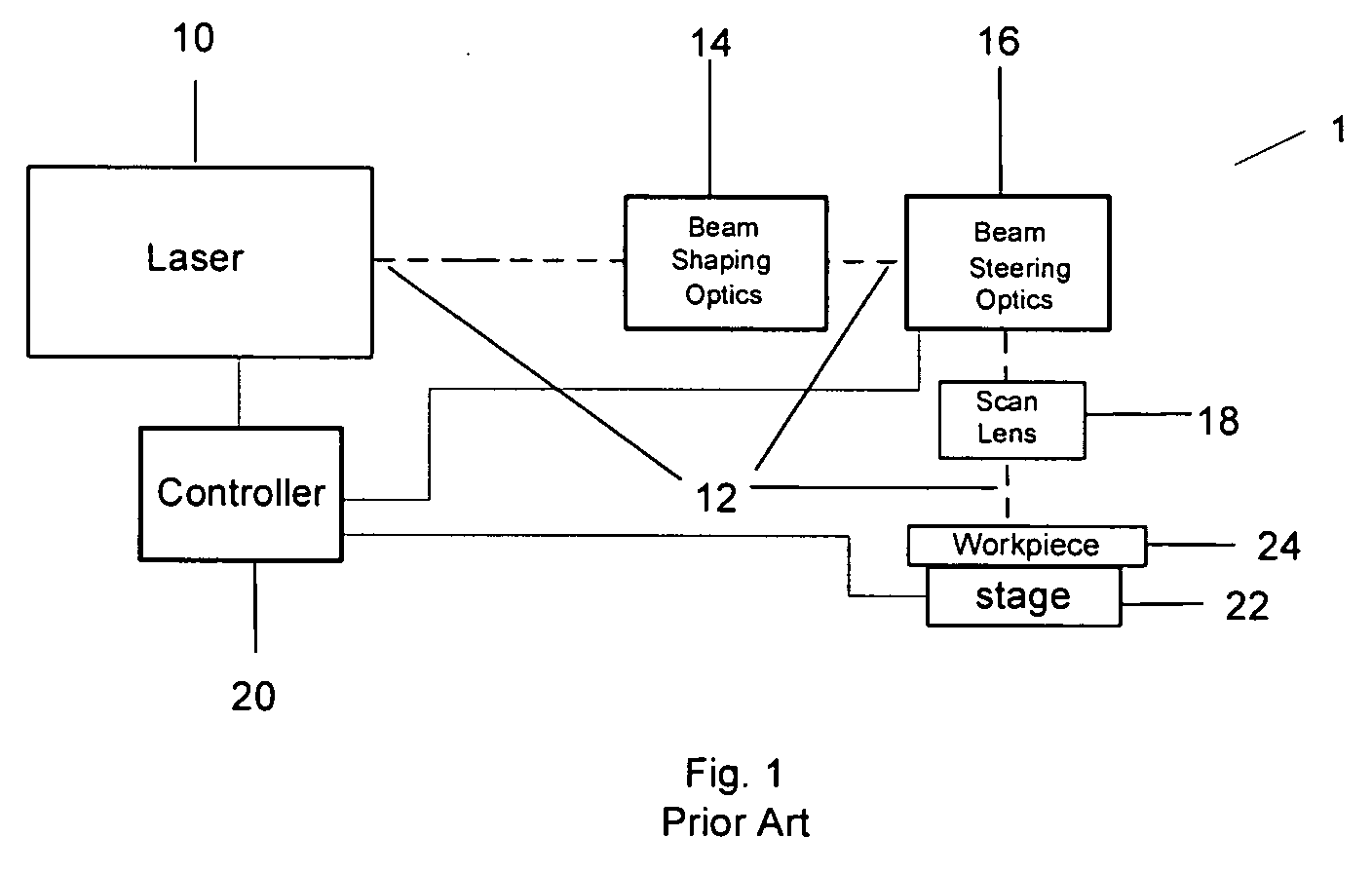

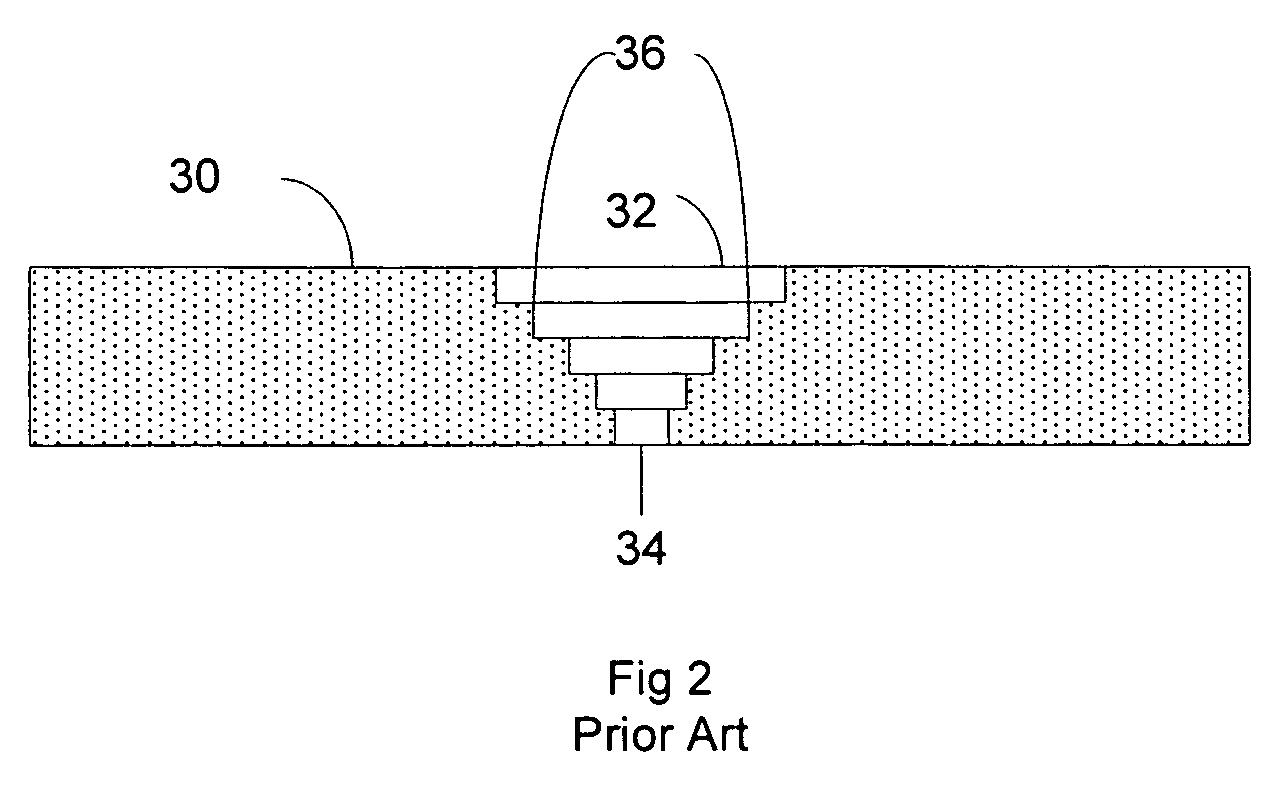

Method and apparatus for laser drilling holes with gaussian pulses

ActiveUS20090242528A1Increase path lengthDifficult to maintainWelding/soldering/cutting articlesLaser beam welding apparatusSurface finishOptoelectronics

An improved method and apparatus for drilling tapered holes in workpieces with laser pulses is presented which uses defocused laser pulses to machine the holes with specified taper and surface finish while maintaining specified exit diameters and improved system throughput. A system is described which can also drill holes with the desired taper and surface finish without requiring defocused laser pulses.

Owner:ELECTRO SCI IND INC

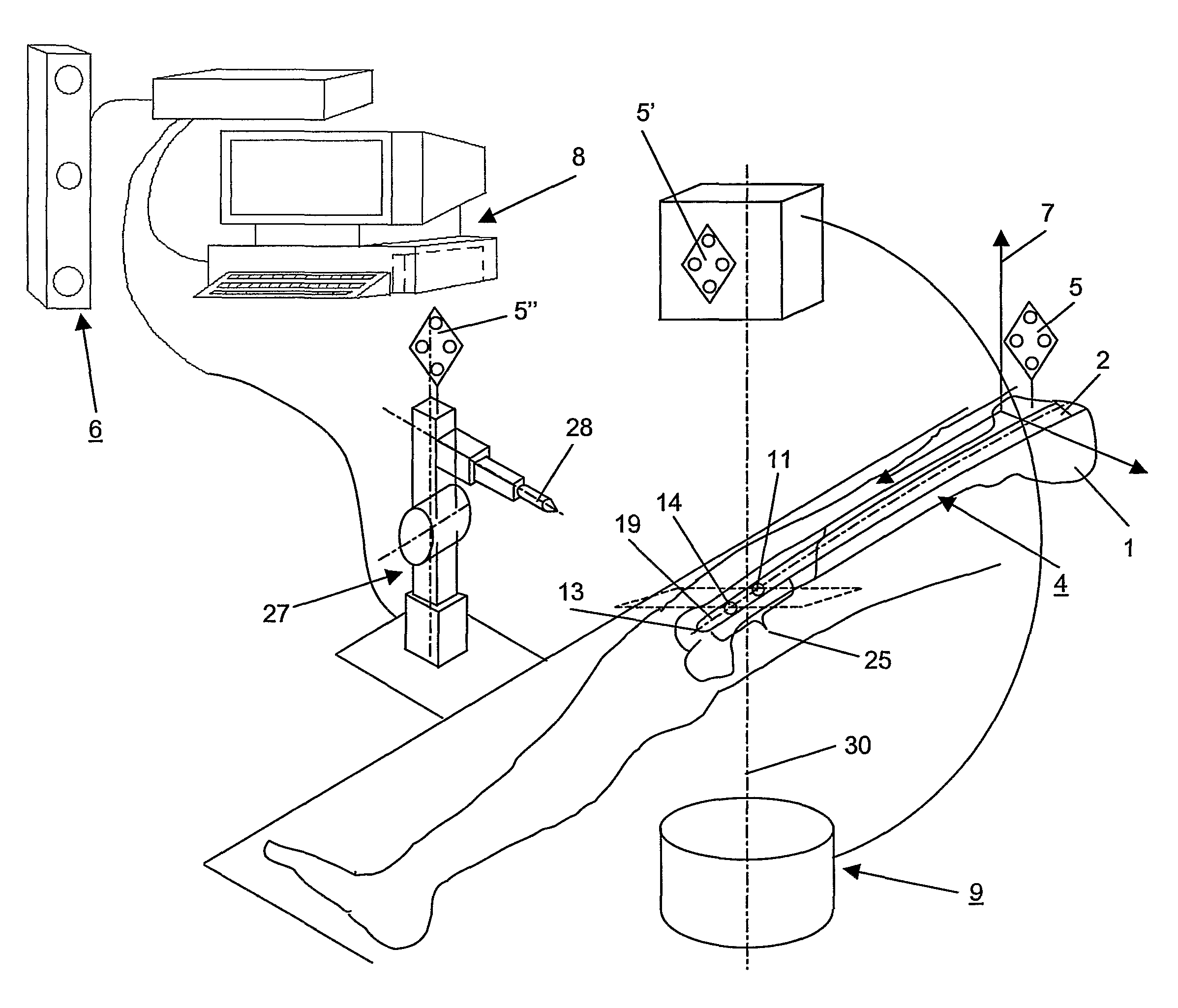

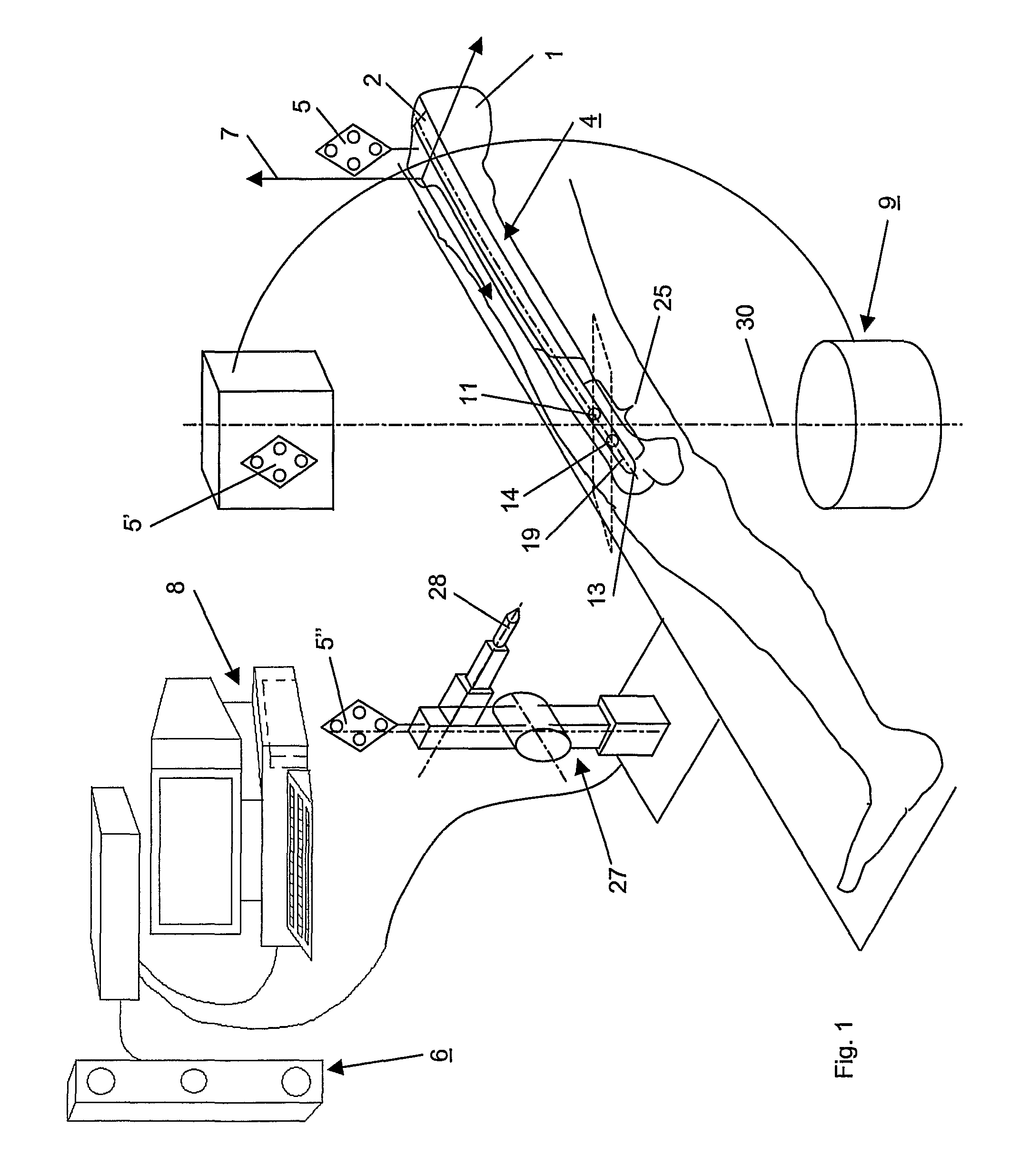

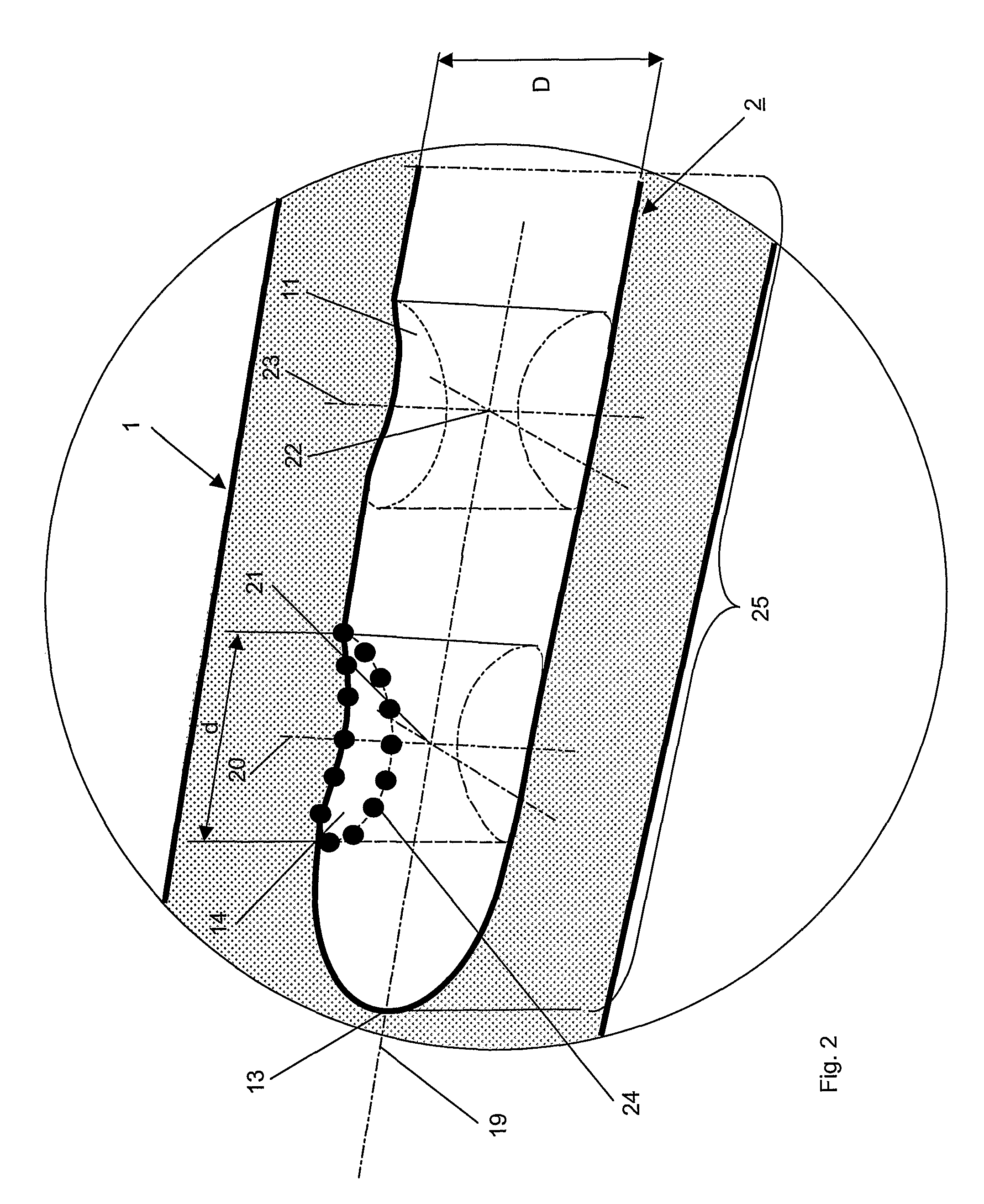

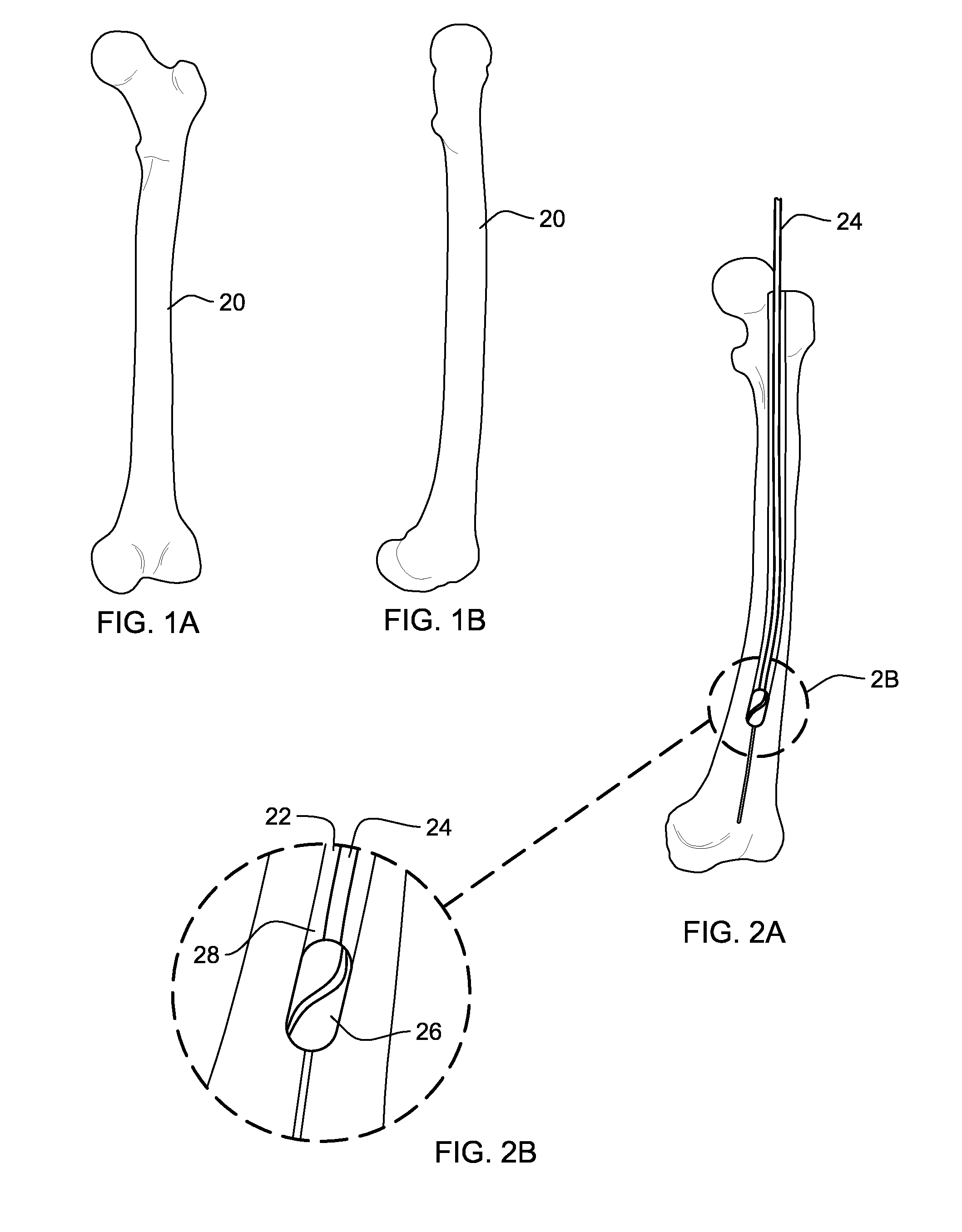

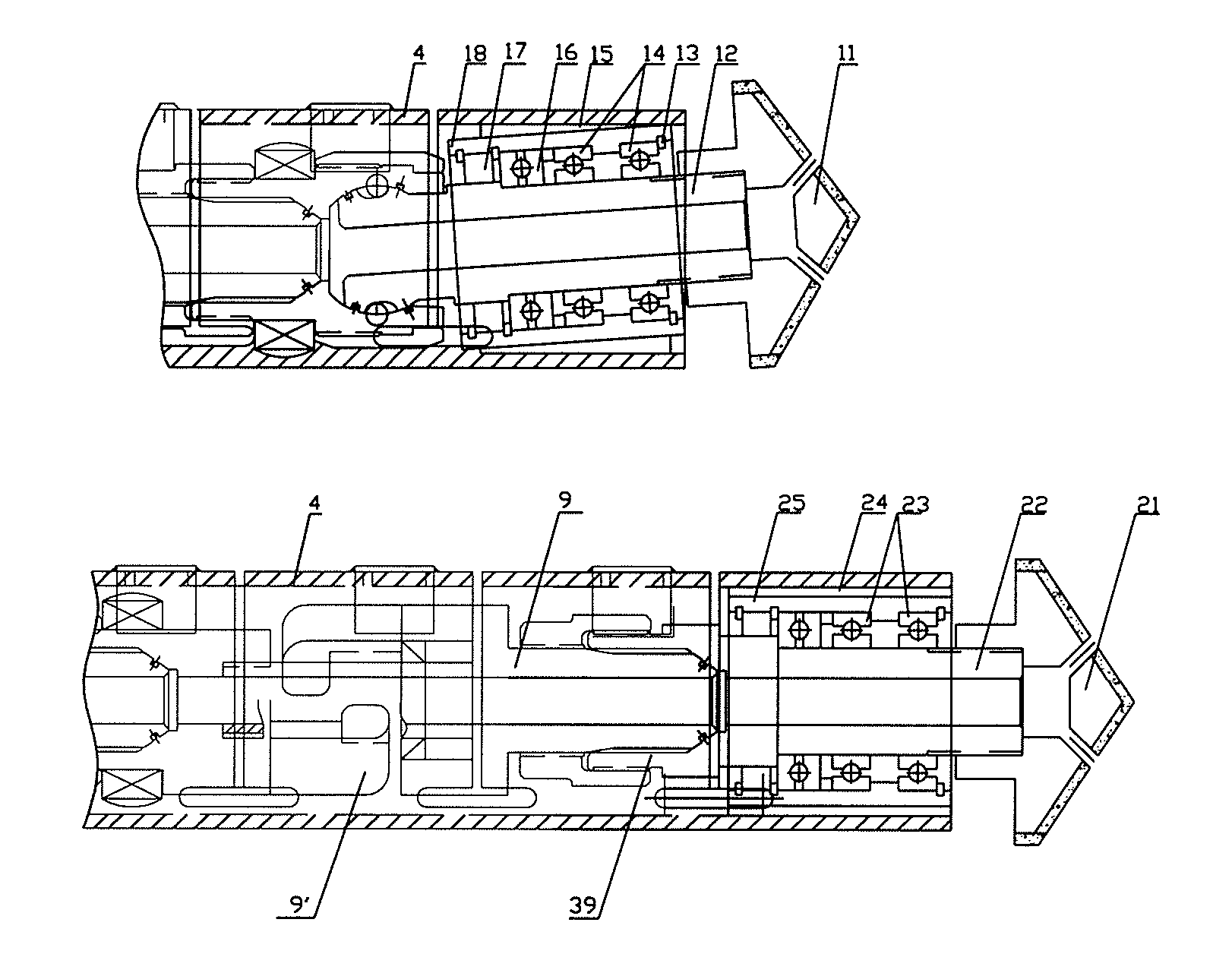

Method and Device for Computer Assisted Distal Locking of Intramedullary Nails

ActiveUS20080281334A1Minimizes X-ray exposurePrecise drillingDiagnosticsSurgical navigation systemsOptical axisSingle image

A method for computer assisted localization of the distal locking holes (11; 14) of an implanted intramedullary nail (2) having a nail axis (19) and a first and second distal locking hole (11; 14) by A) acquiring one single image IM of the distal end section (25) of said intramedullary nail by means of an X-ray device (9) whose optical axis (30) is oriented essentially perpendicular to the nail axis (19) but irrespective to the orientation of the distal locking holes (11; 14); and B) calculating the position of the first and second hole axis (23; 20) of the first and second distal locking hole (11; 14) with respect to a three-dimensional coordinate system A-COS (7) of the implanted intramedullary nail (2).

Owner:AO TECH AG

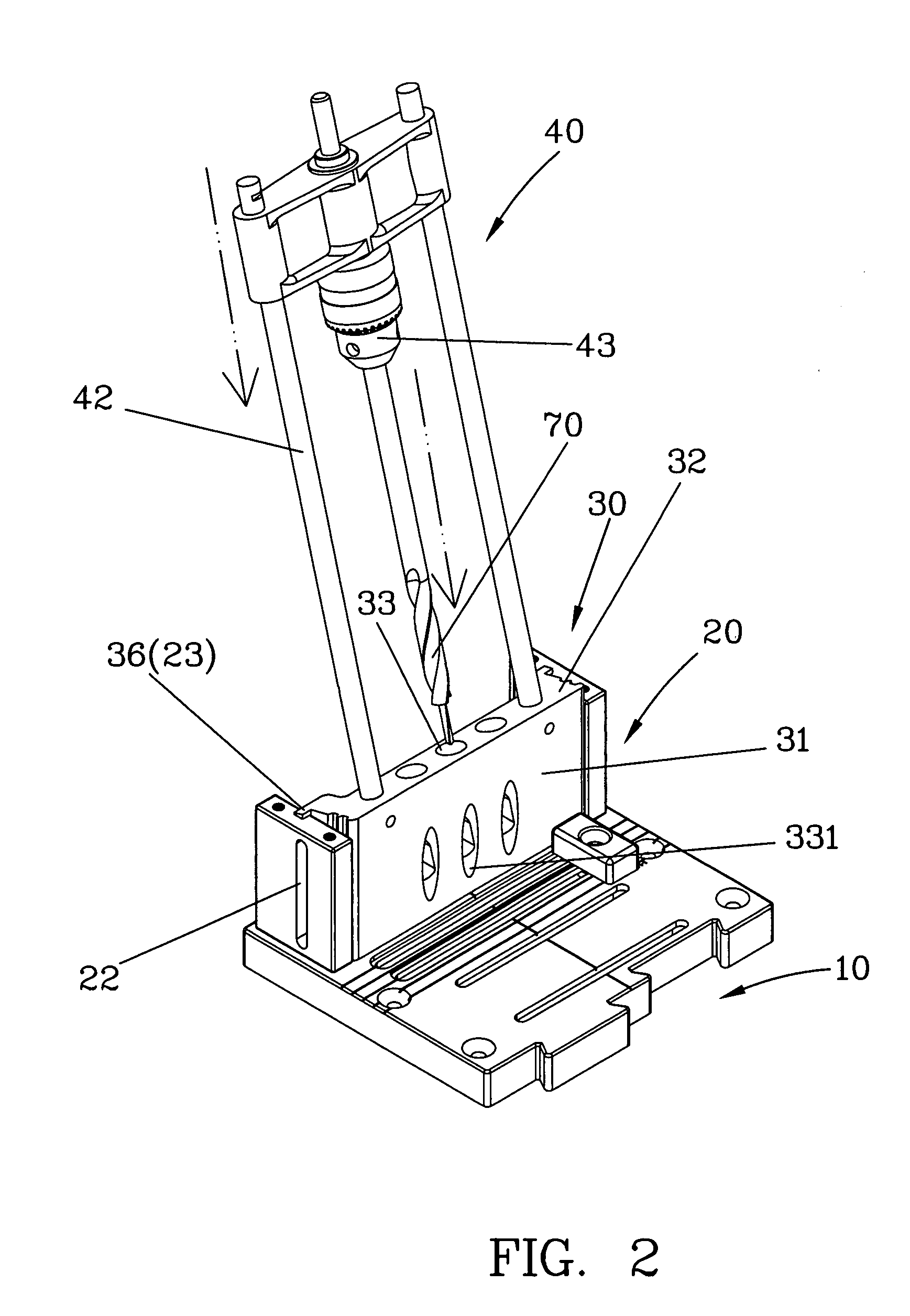

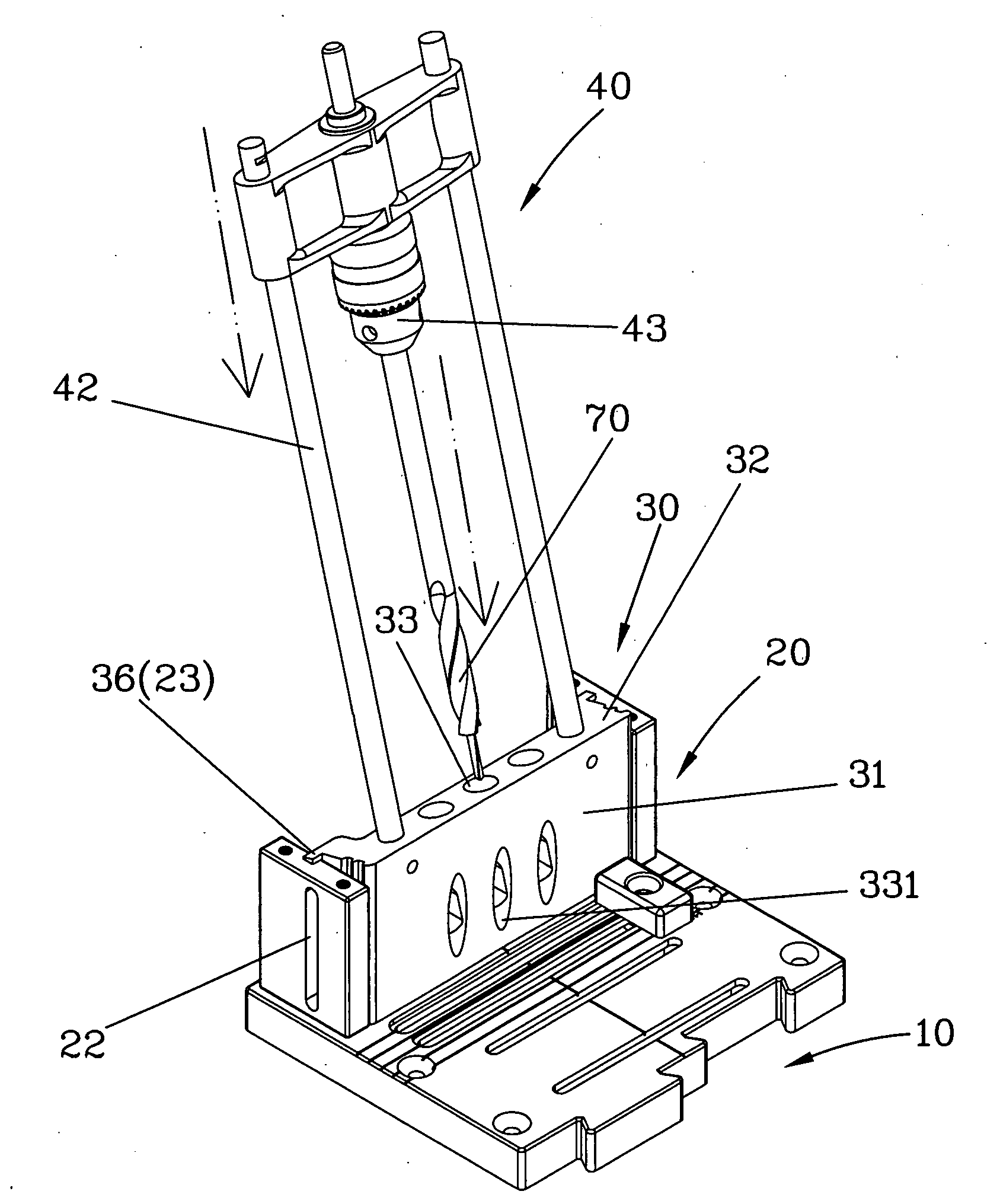

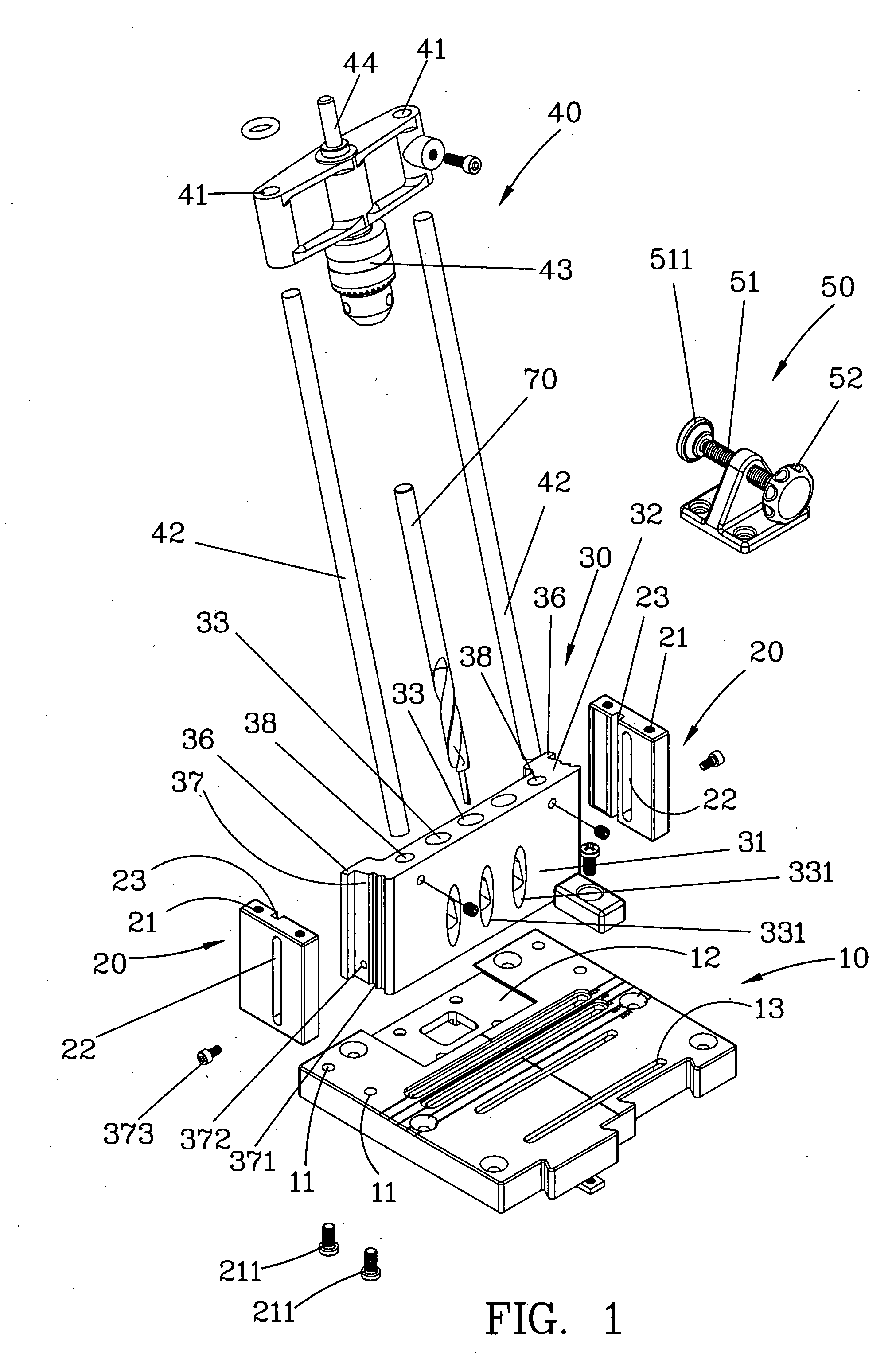

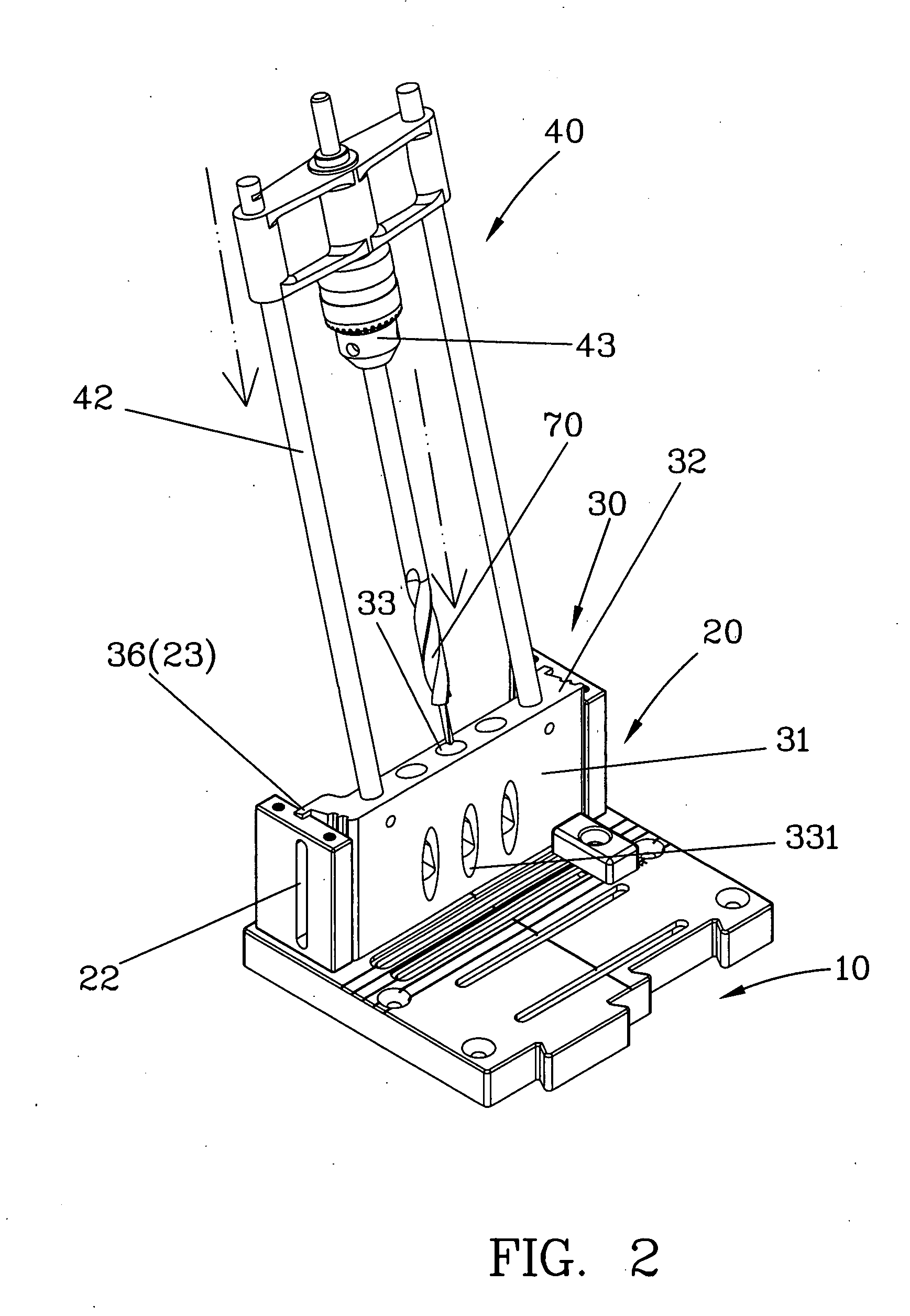

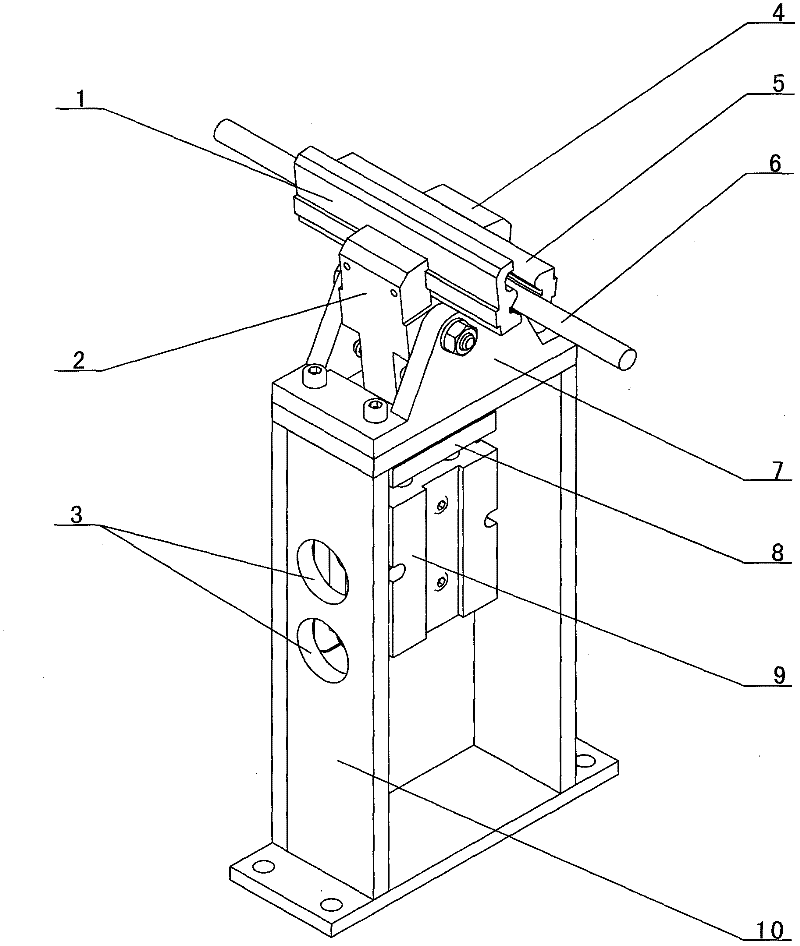

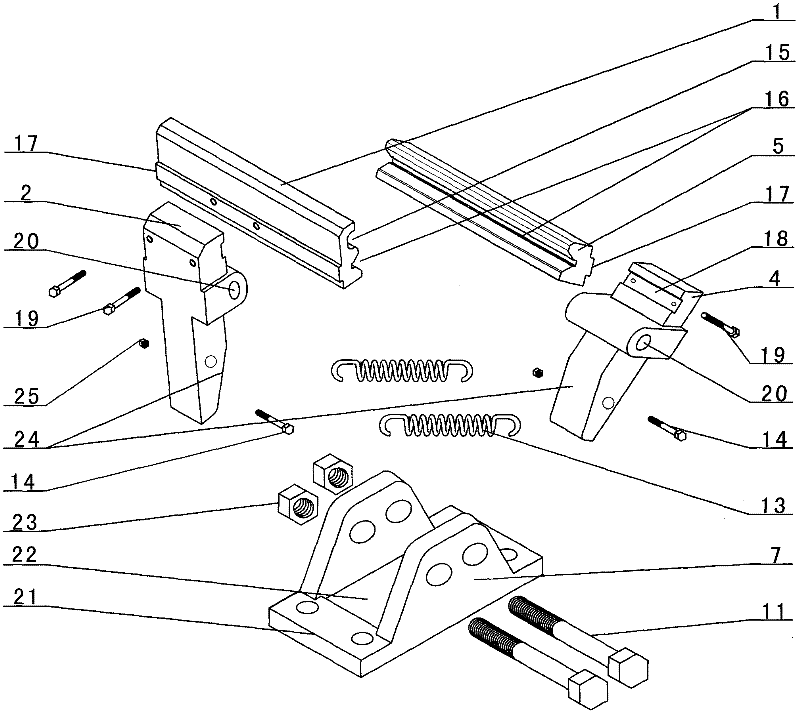

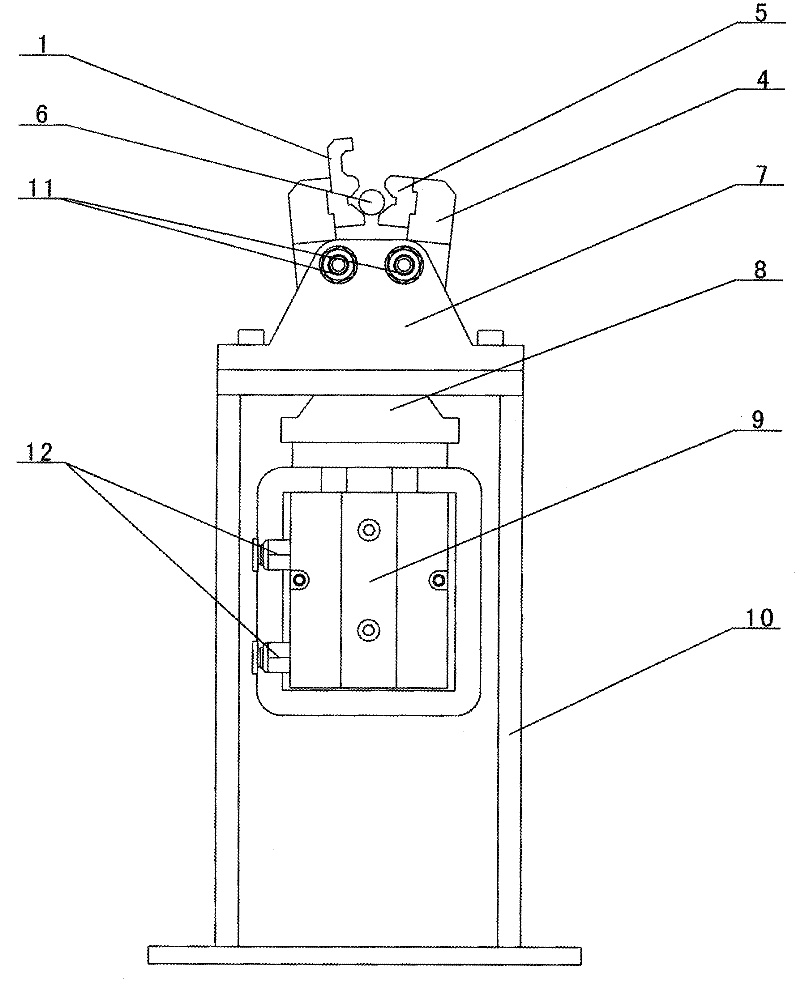

Upright inclined-hole drilling jig

InactiveUS7597513B2Quick adjustment positioningGood effectDrilling/boring measurement devicesThread cutting machinesParallel plateEngineering

An improved upright drilling jig comprises two parallel panels parallelly mounted on a leveled base platform, and an inclined-hole drilling jig slidably disposed between the sides of the parallel panels in a manner that it can be vertically adjusted. A sliding saddle is slidably mounted at the top of the inclined-hole drilling jig through two axial bars. The rear side of the drilling jig is concavely constricted to form a bow jumper area and disposed with a discharge concavity in a manner approaching a clamping end plane. The discharge concavity has a chip hole inside that communicates with a guide axle hole. Such arrangement can achieve optimum performance of inclined hole drilling of woodwork.

Owner:CHIANG VANCE

Upright inclined-hole drilling jig

InactiveUS20080226406A1Quick adjustment positioningGood effectDrilling/boring measurement devicesThread cutting machinesParallel plateEngineering

An improved upright drilling jig comprises two parallel panels parallelly mounted on a leveled base platform, and an inclined-hole drilling jig pivotally disposed between the sides of the parallel panels in a manner that it can be vertically adjusted. A sliding saddle is slidably and pivotally mounted at the top of the inclined-hole drilling jig through two axial bars. The rear side of the drilling jig is concavely constricted to form a bow jumper area and disposed with a discharge concavity in a manner approaching a clamping end plane. The discharge concavity has a chip hole inside that communicates with a guide axle hole. Such arrangement can achieve optimum performance of inclined hole drilling of woodwork.

Owner:CHIANG VANCE

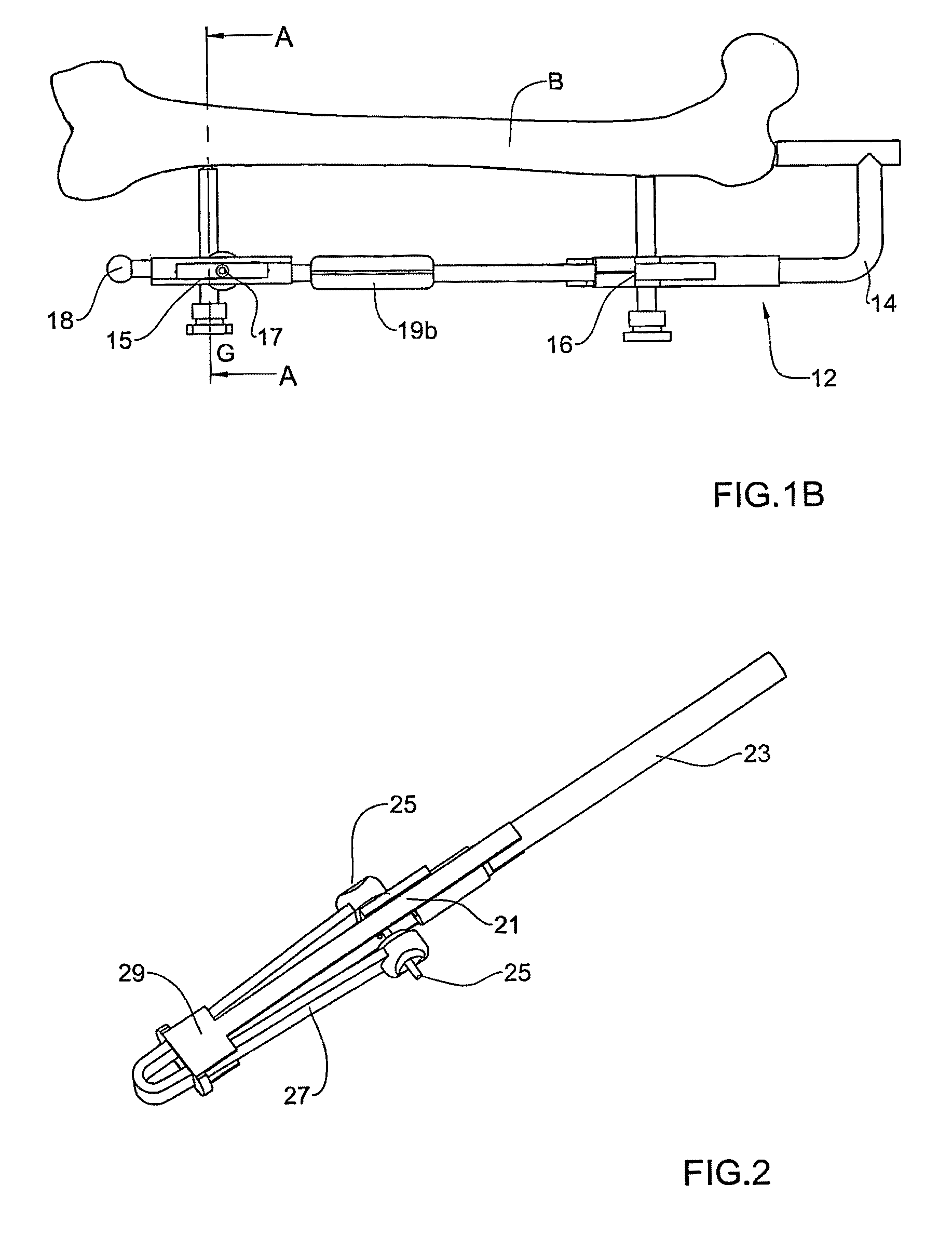

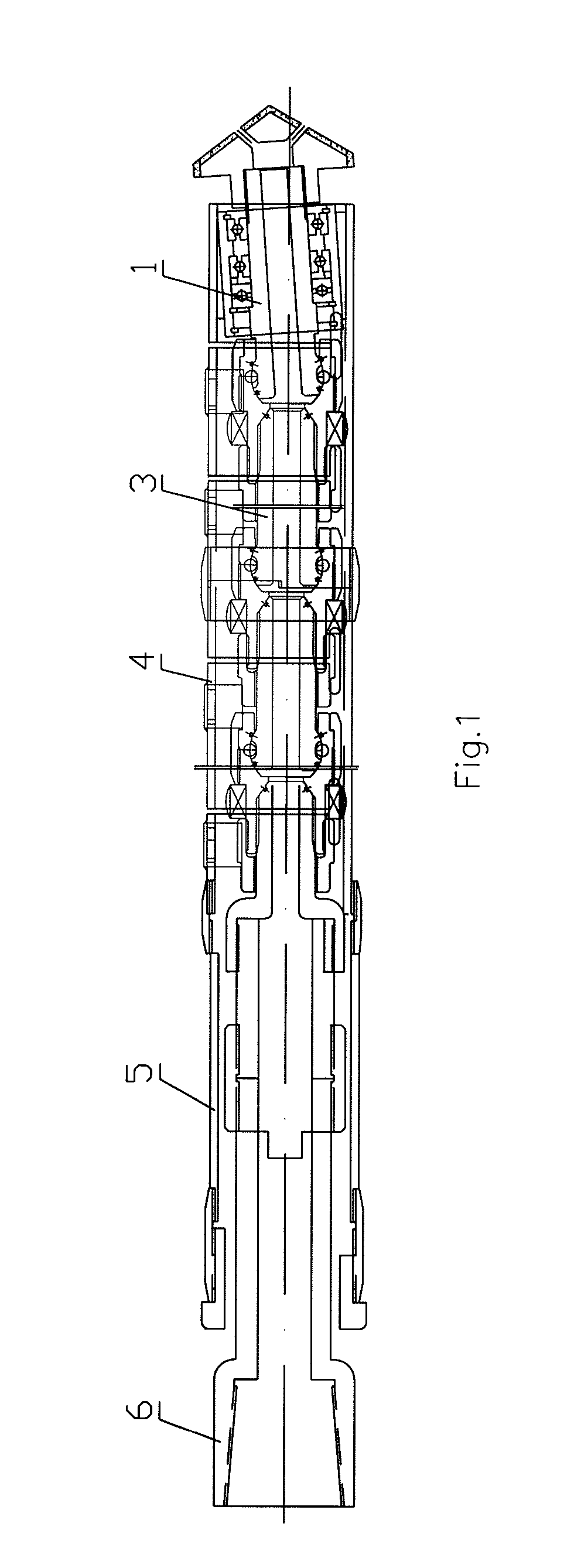

System and Method for Locating of Distal Holes of an Intramedullary Nail

InactiveUS20090306665A1Avoid radiationPrecise drilling of holes through the boneDiagnostic markersJoint implantsX ray imageBiomedical engineering

Systems and methods for use with a hollow intramedullary nail having a proximal end, a distal end and at least one distal hole formed in the nail's wall adjacent said distal end and having a hole axis, for detecting a location of said distal hole when the nail is implanted into a intramedullary canal of a bone. The system includes a jig adapted for being mounted on said bone so as to constitute a bridge between the proximal end of said nail and a distal end of said bone, and having a positioning head with a guiding axis oriented generally perpendicular to the nail longitudinal axis, adapted for receiving therein at least a drill bit so that the drill bit's axis is aligned with said guiding axis, the positioning head being movable to bring said guiding axis into different spatial positions with respect to said hole axis. The system may further include at least one of the following: a disposable member insertable into said nail and having a nail light source for emitting light along said distal hole axis so as to create an illuminated spot on an outer surface of said bone, said nail light source is of a kind providing collimated light and, said member further includes means for positioning an axis of a collimated beam created by said light along said hole axis; viewing optics mountable in said positioning head along said guiding axis for viewing said illuminated spot; an alignment pin having a pin proximal end, a pin distal end, and a pin axis, and being adapted for mounting in said positioning head so that said pin axis is aligned with said guiding axis and so that the pin distal end faces towards the bone, where the pin further includes reference marks on its outer surface, visible in X-ray images.

Owner:L R S ORTHO

System and method for locating of distal holes of an intramedullary nail

InactiveUS8231629B2Avoid radiationPrecise drilling of holes through the boneDiagnostic markersNon-surgical orthopedic devicesIntramedullary rodMedicine

Owner:L R S ORTHO

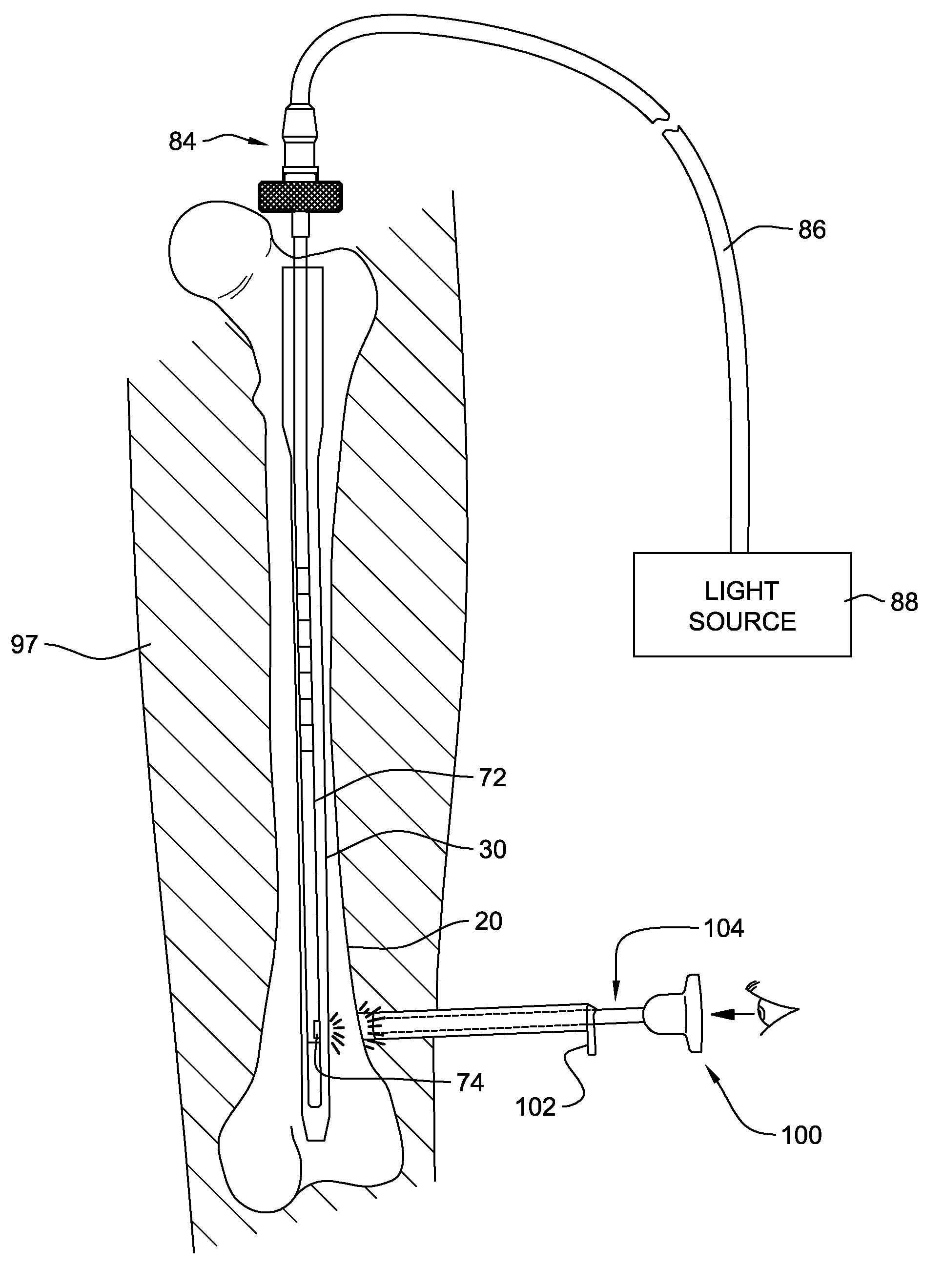

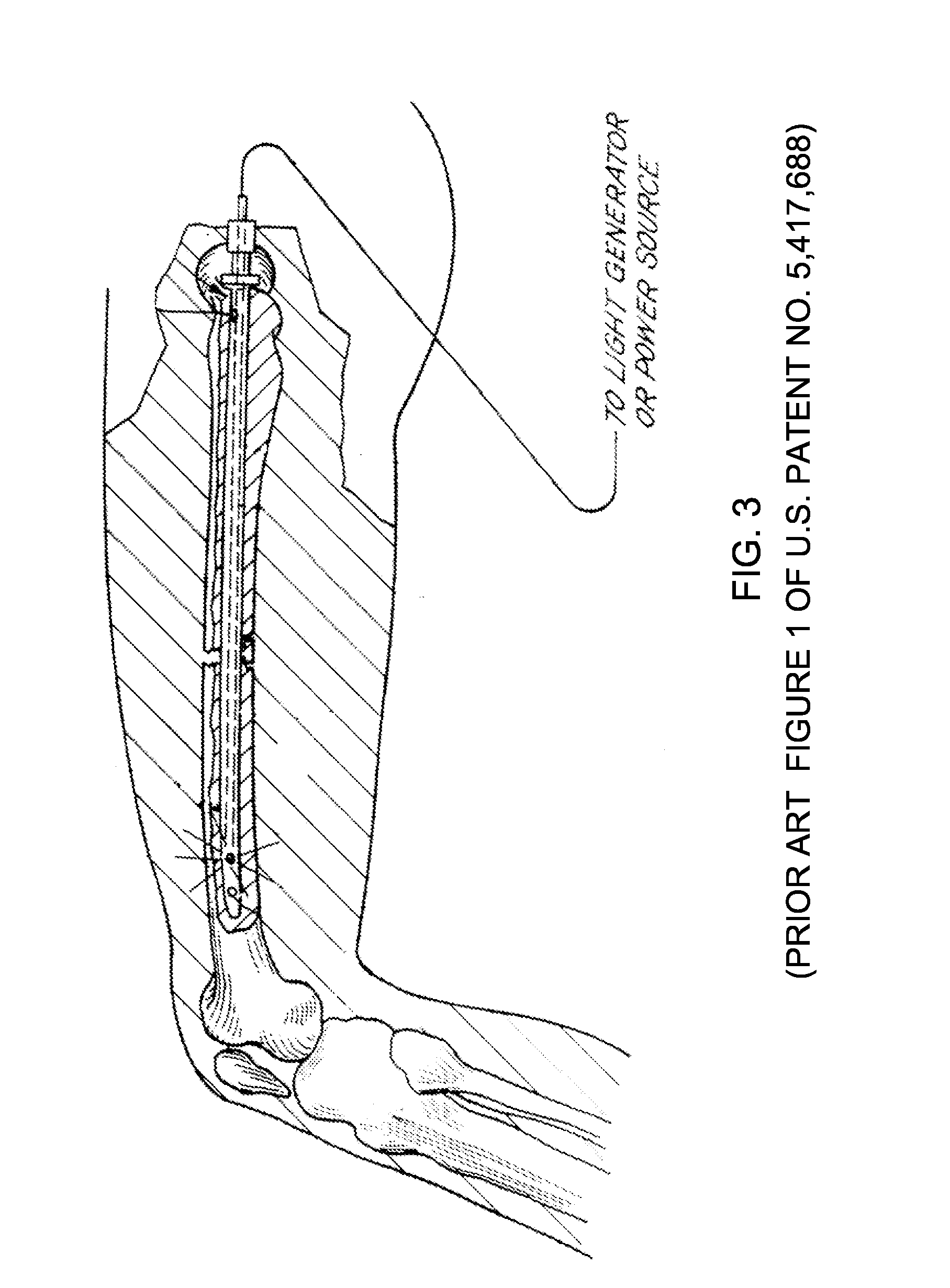

Intramedullary transillumination apparatus, surgical kit and method for accurate placement of locking screws in long bone intramedullary rodding

InactiveUS20070270864A1Accurate locationImprove accuracy and precisionSurgeryCatheterNon-ionizing radiationSurgical operation

Apparatus, including a surgical kit, for use with a surgical drill, in the repair of bones using an intramedullary nail insertable into a patient's bone, comprising a rod like device for insertion into the intramedullary nail, the device having a light source emitting electromagnetic non-ionizing radiation in the infrared or visible portions of the electromagnetic spectrum, and the device being positionable so that the light source emits the radiation through a distal transverse hole of the intramedullary nail; and a surgical instrument for exposing an exterior surface of a portion of the bone illuminated by the radiation for view by the surgeon. The surgeon can detect the radiation on the exterior surface of the bone and align the surgical drill to the radiation passing through the transverse hole of the intramedullary nail, permitting accurate drilling of a hole through the bone and passage of the drill through the transverse hole of the intramedullary nail.

Owner:GURTOWSKI JAMES P

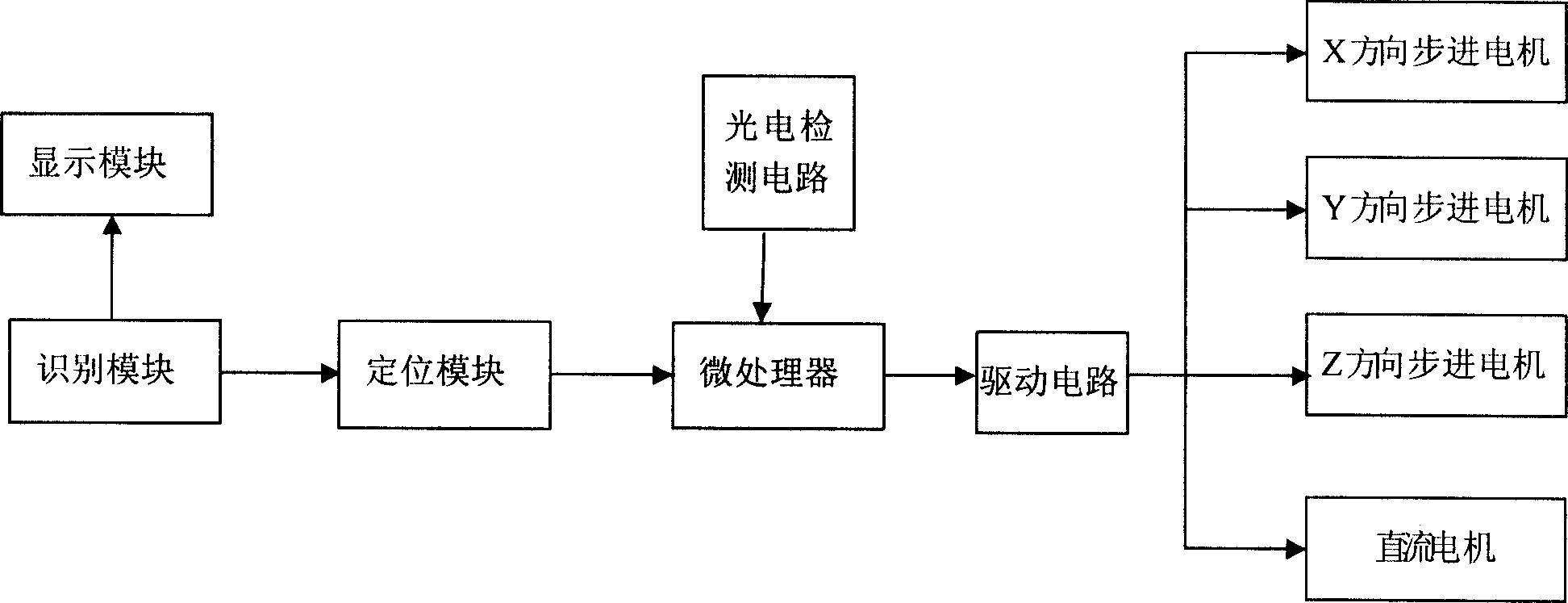

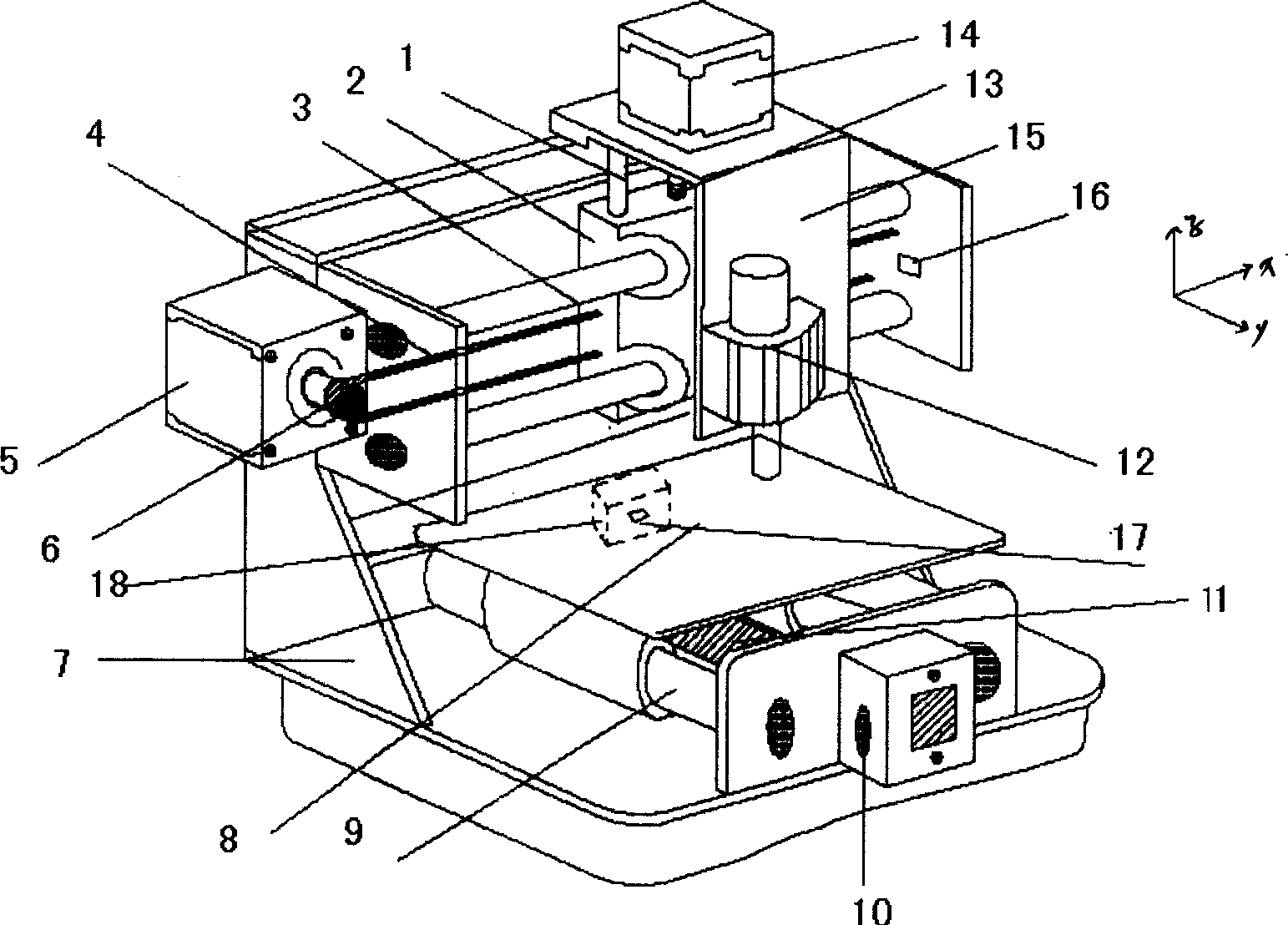

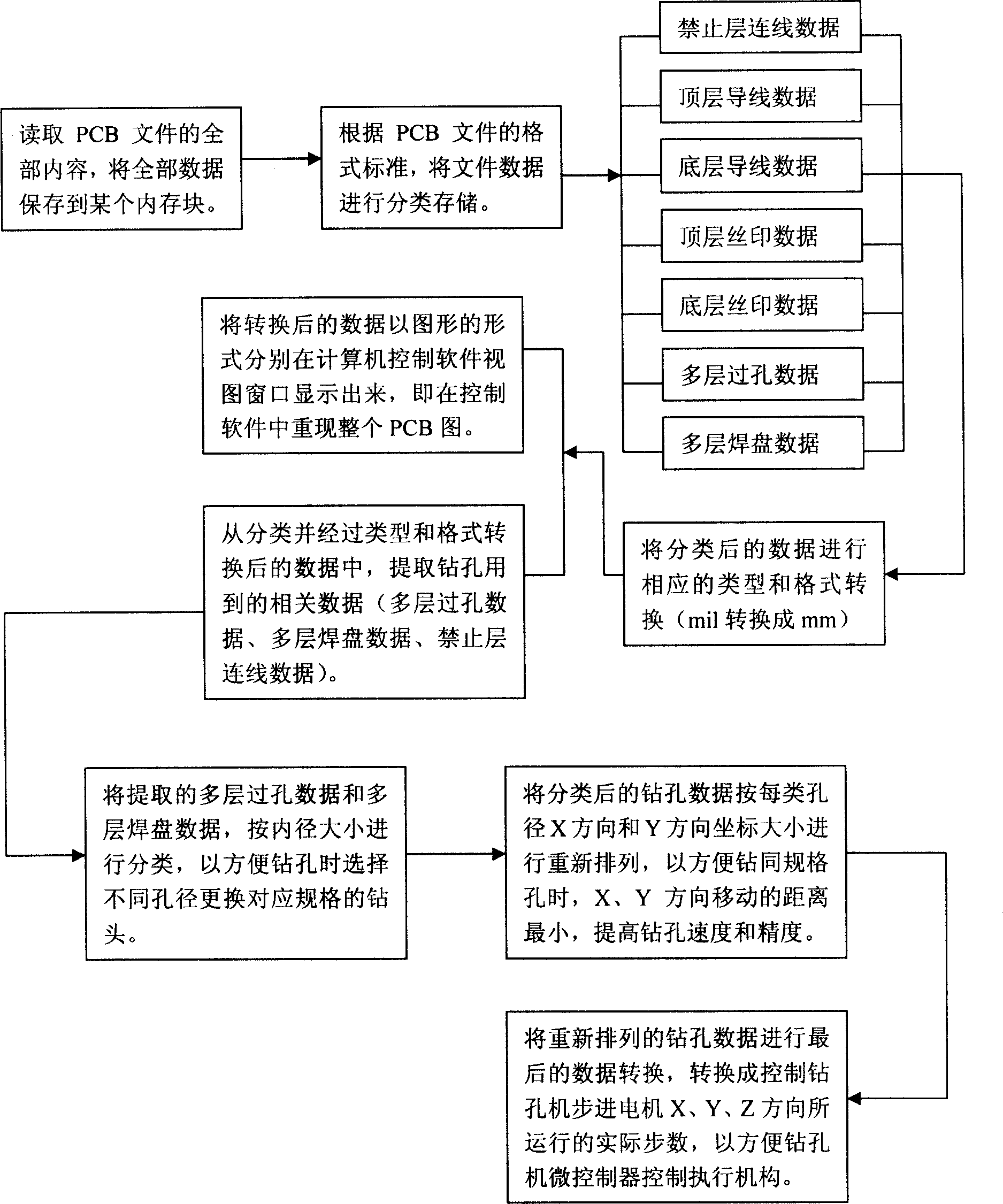

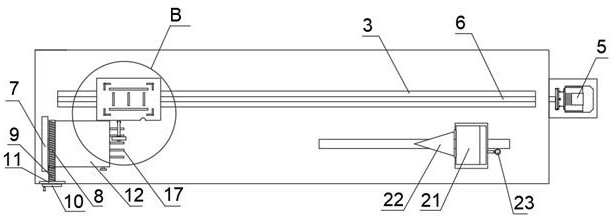

Circuit board automatic drilling machine

InactiveCN1730212ANot easy to damageReduce volumeBoring/drilling machinesEngineeringDrilling machines

The invention discloses a circuit board automated drilling machine, which comprises foundation, operating platform, x-direction motion mechanism, bidimensional motion mechanism, y-direction motion mechanism, continuous current dynamo, drill, recognition mould, display mould, locating mould, microprocessor and driving circuit. The invention has the following settings: operating platform locating on y-direction; the upper of operating platform locating x-direction motion mechanism, bidimensional motion mechanism, continuous current dynamo and drill fixed on foundation; recognition connecting with display mould, storage mould and locating mould and recognizing drill data in PCB document; locating mould processing drill hole data and sending it to microprocessor; and microprocessor controlling drive circuit and driving x-direction motion mechanism, bidimensional motion mechanism, y-direction motion mechanism and continuous current dynamo to complete drilling. The invention has the advantages of simple structure, low cost, small bulk, accurate drilling and stably operating.

Owner:HUNAN CREATE SCI & TECH

Horizontal type numerical control glass drilling machine

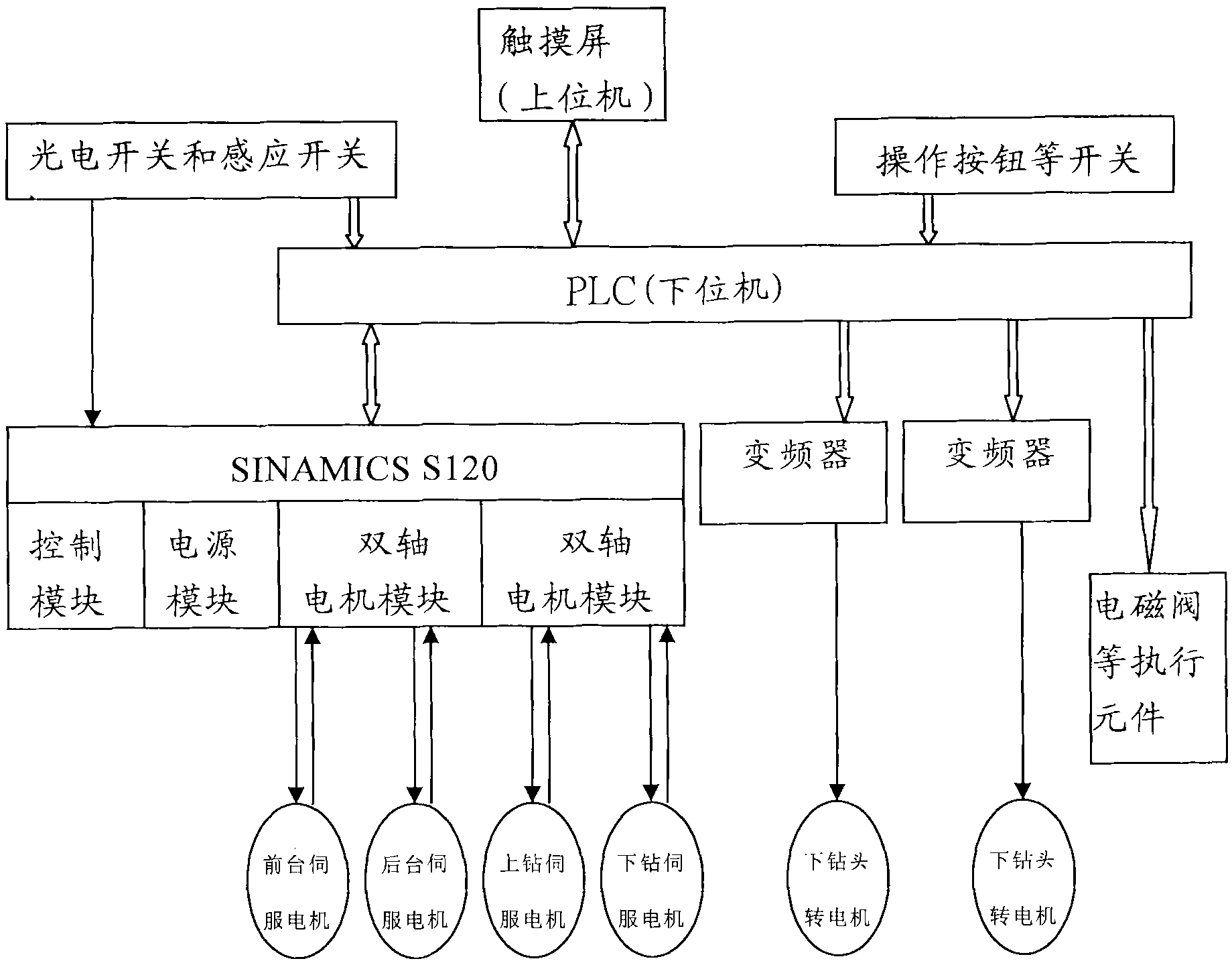

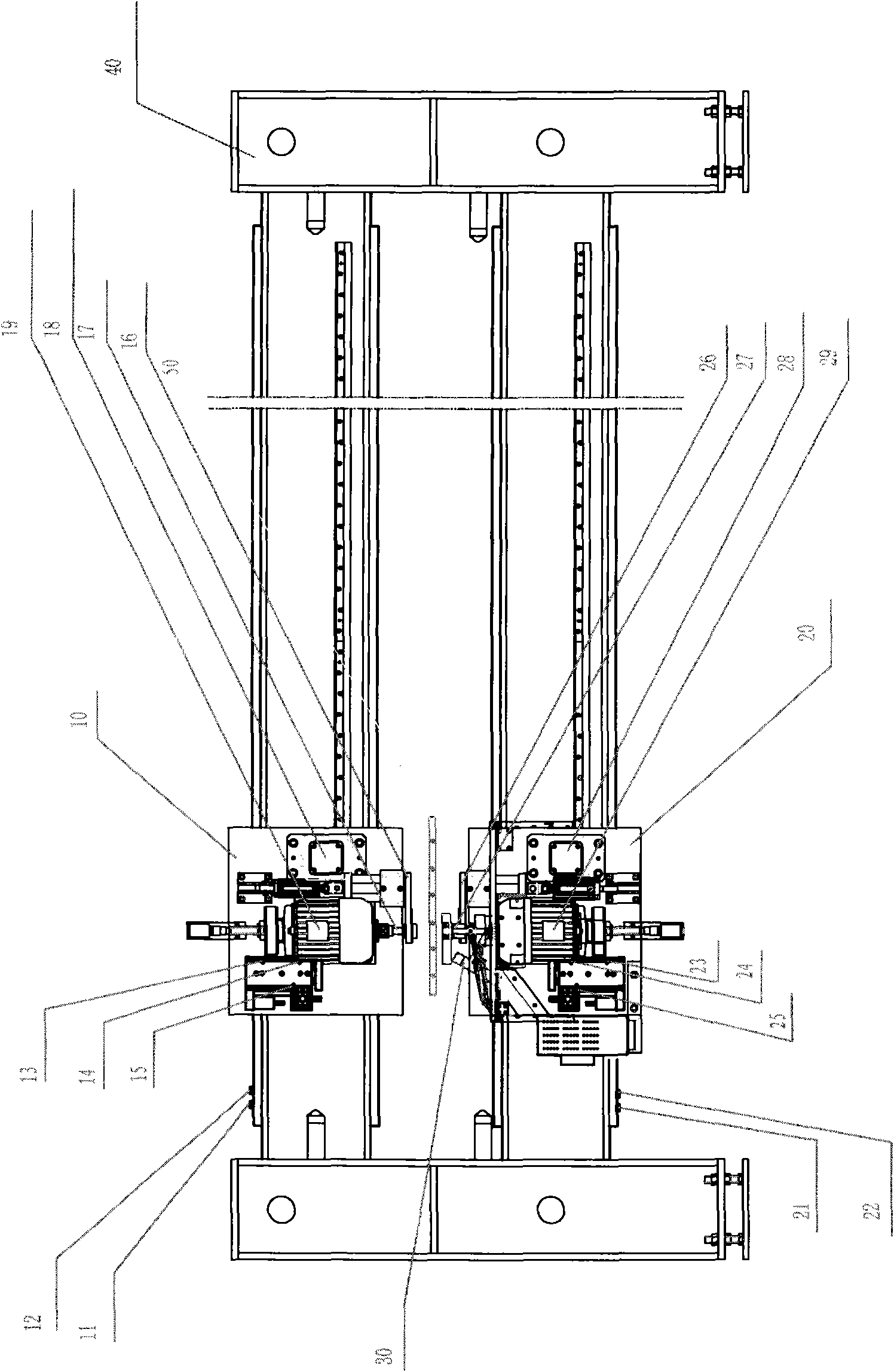

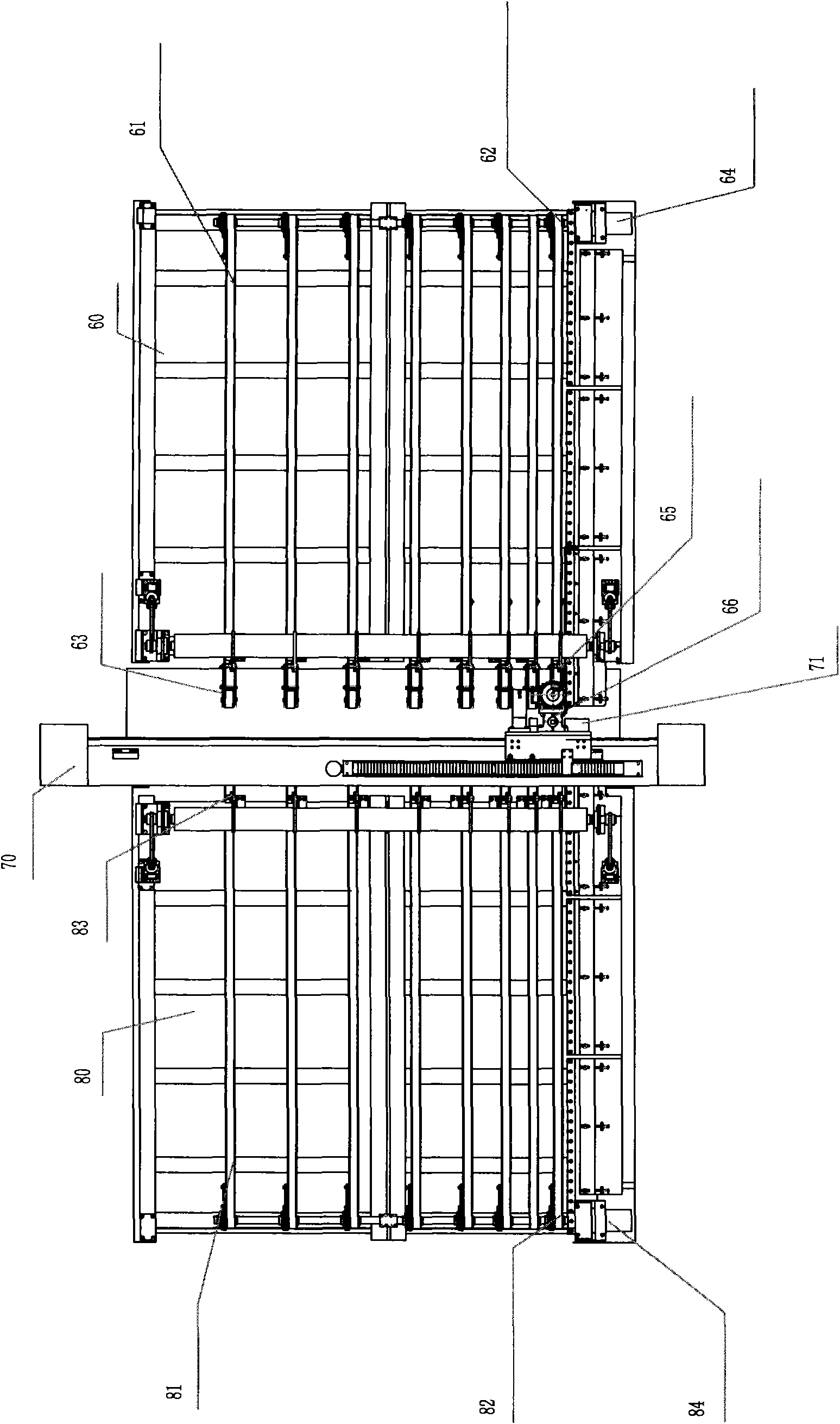

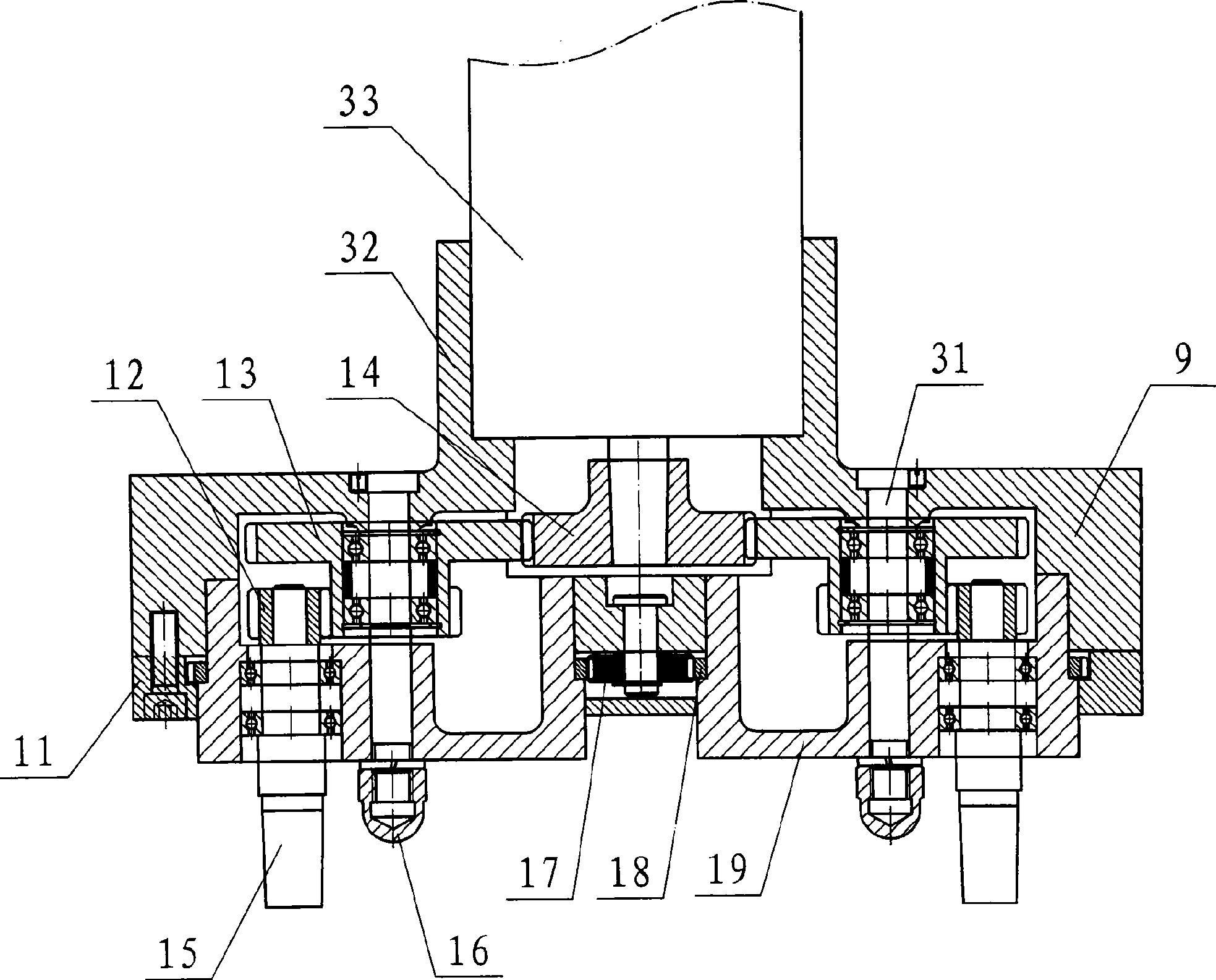

ActiveCN101863085APrecise DrillingEasy loadingGlass severing apparatusStone-like material working toolsDrill bitMechanical system

The invention relates to a horizontal type numerical control glass drilling machine, the mechanical system of which comprises a front processing table, a rear processing table, a portal drilling frame, an upper drilling assembly and a lower drilling assembly. The front processing table comprises a horizontal jack horse and a plurality of front processing table conveyer belts. The front processing table conveyer belts are driven by a front processing table servo motor. A glass-in-front-processing-table sensor, a glass speed reduction sensor and a glass-in-place sensor are also arranged. The rear processing table comprises a horizontal jack horse and a rear processing table conveyer belt. The rear processing table conveyer belt is driven by a rear processing table servo motor. A glass-out-of-rear processing table sensor is also arranged. The portal drilling frame is arranged between the front processing table and the rear processing table. Two longitudinal guide rails are installed on the portal drilling frame. The upper drilling assembly and the lower drilling assembly are movably connected with the two longitudinal guide rails. The upper drilling assembly and the lower drilling assembly respectively comprise a drilling frame, a drill bit, a drilling frame servo motor and a drill bit rotating motor. The glass-in-place sensor is also arranged. The control system of the horizontal numerical-control glass drilling machine comprises a central control unit, low-voltage electrical elements, a multi-shaft driving device and a frequency converter and is used for controlling the mechanical system.

Owner:上海北玻玻璃技术工业有限公司

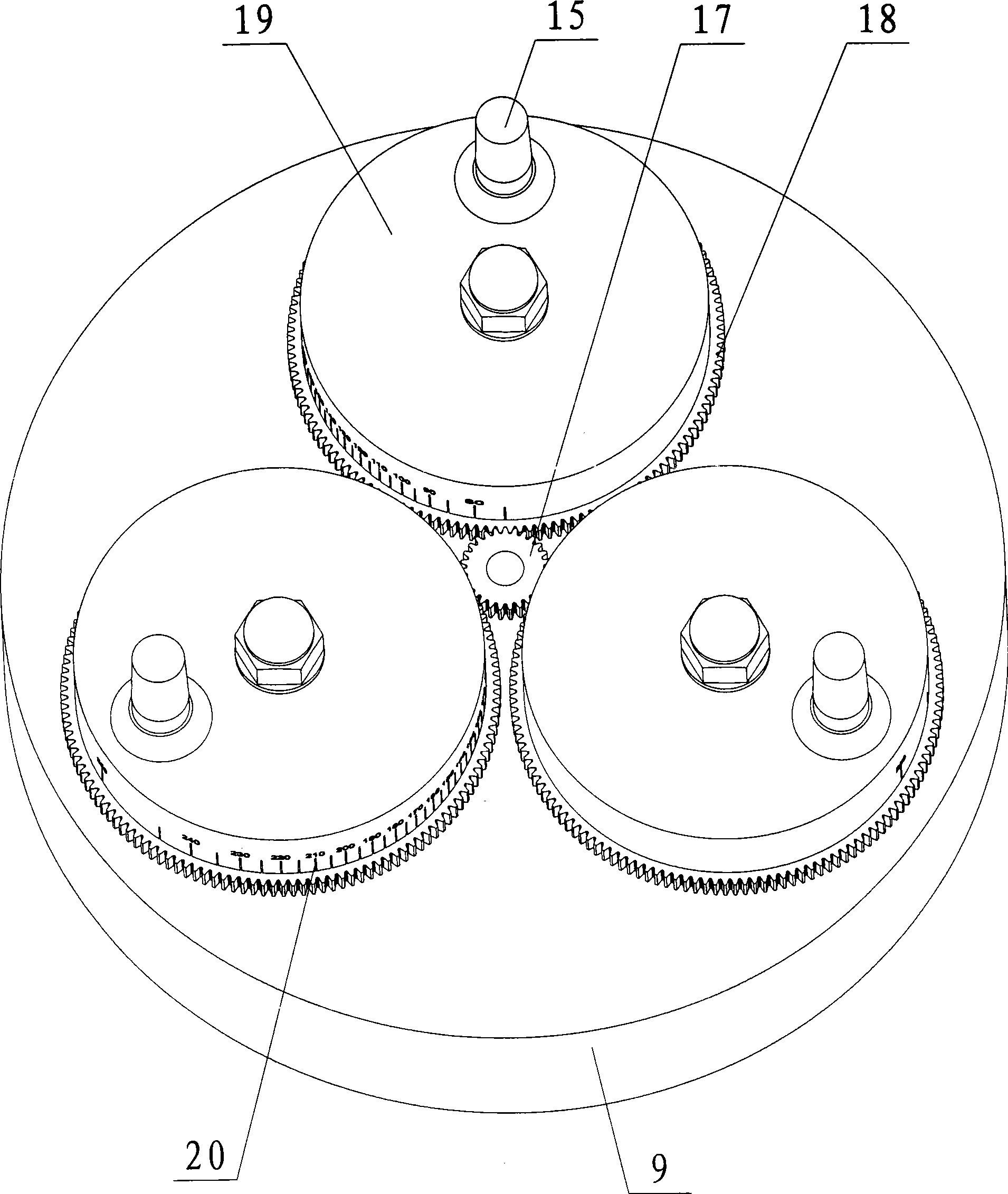

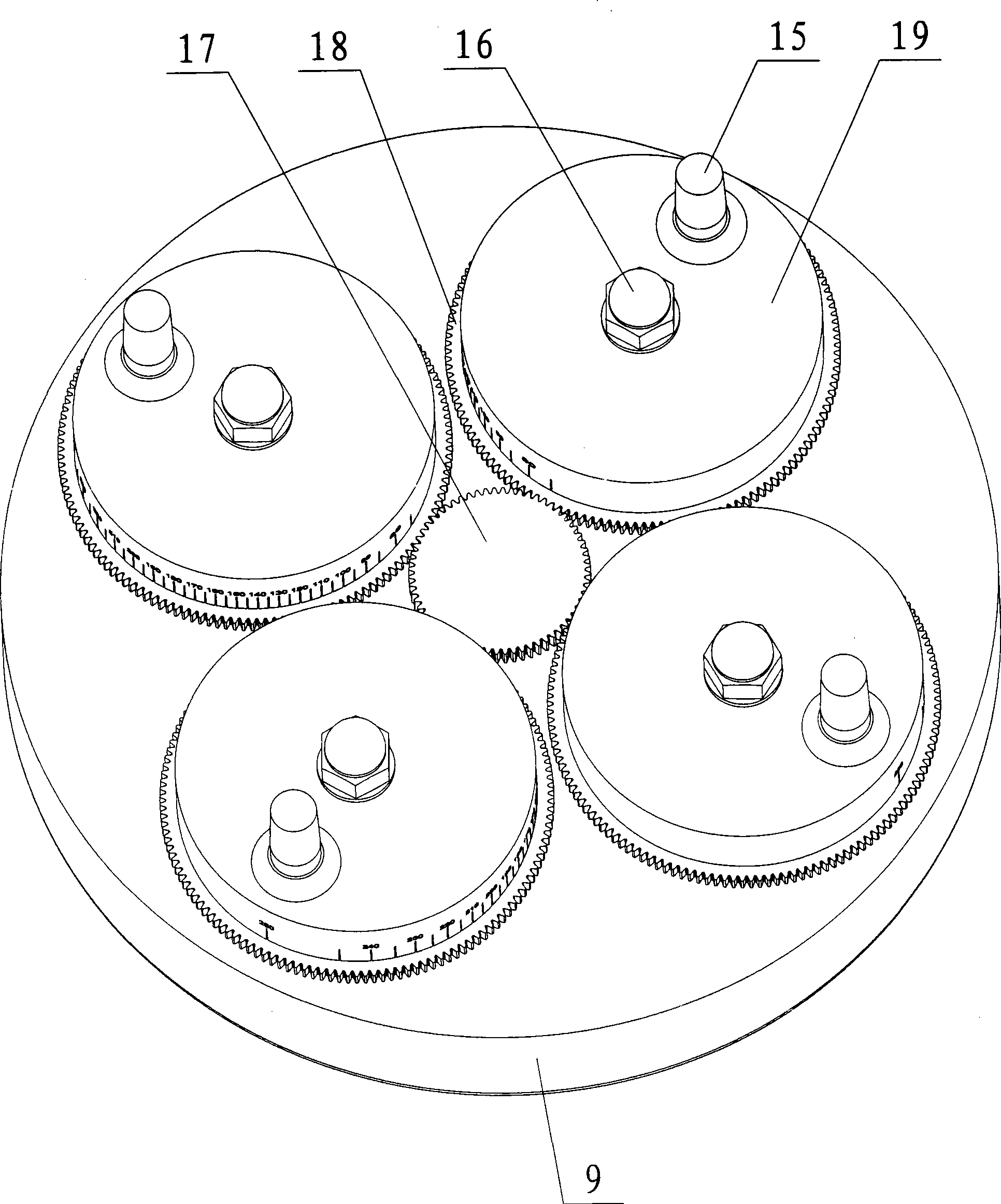

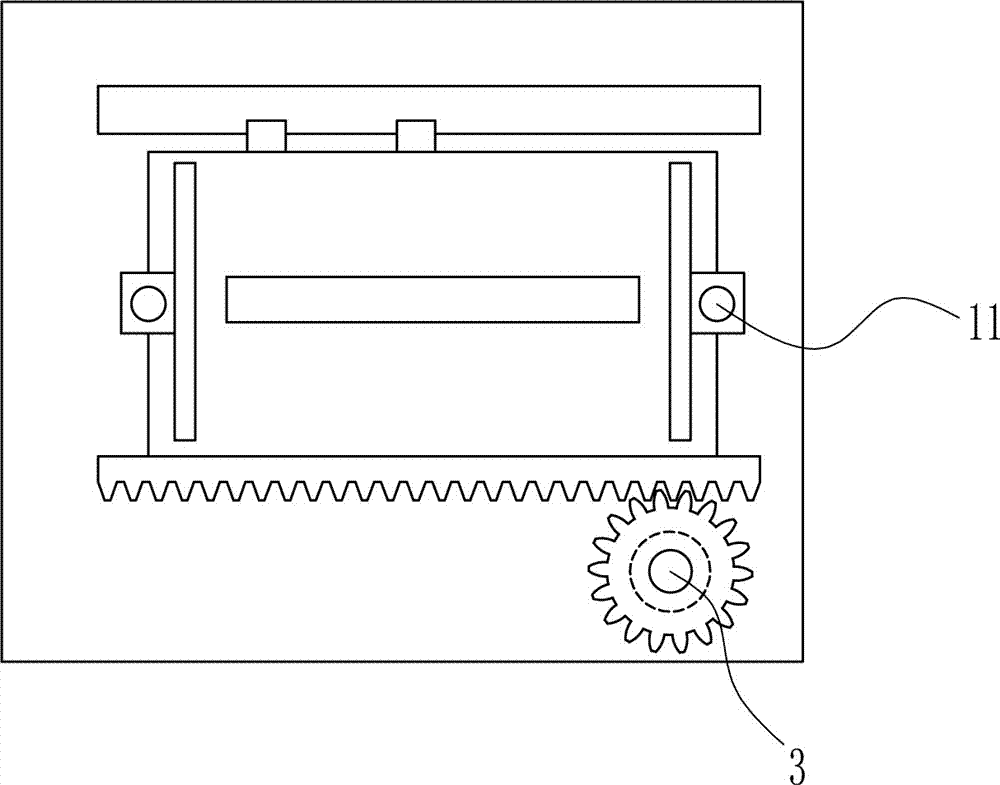

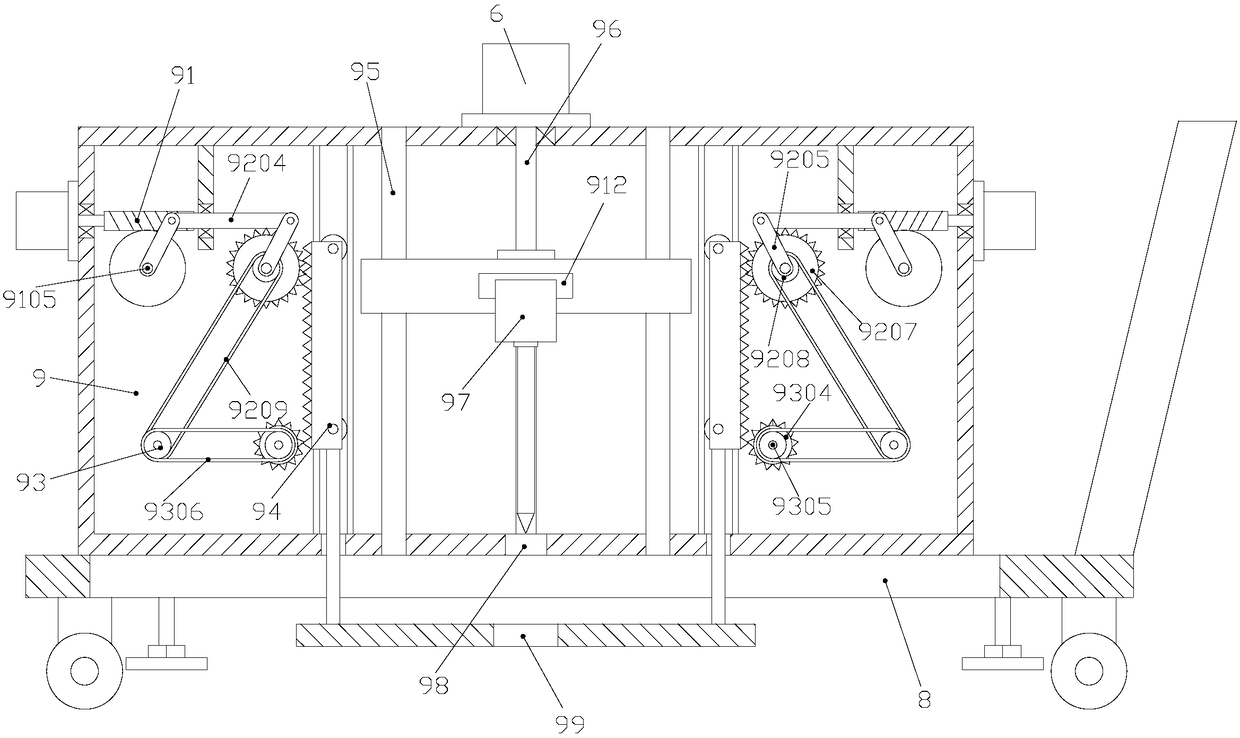

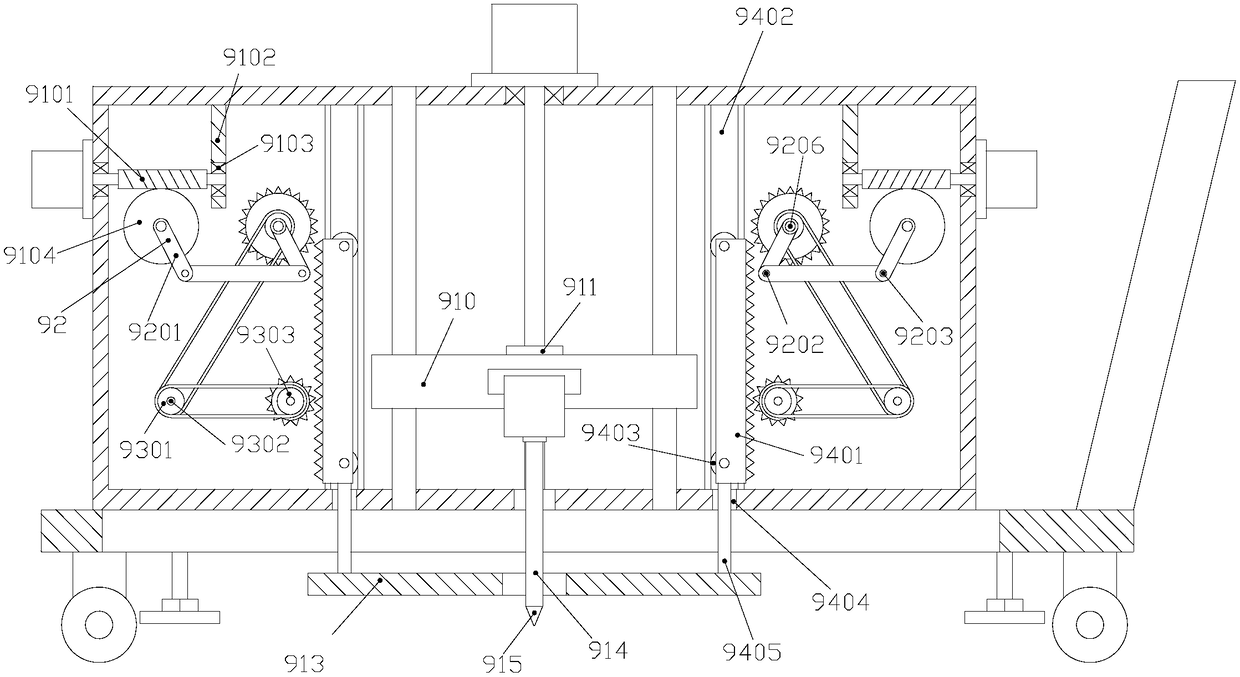

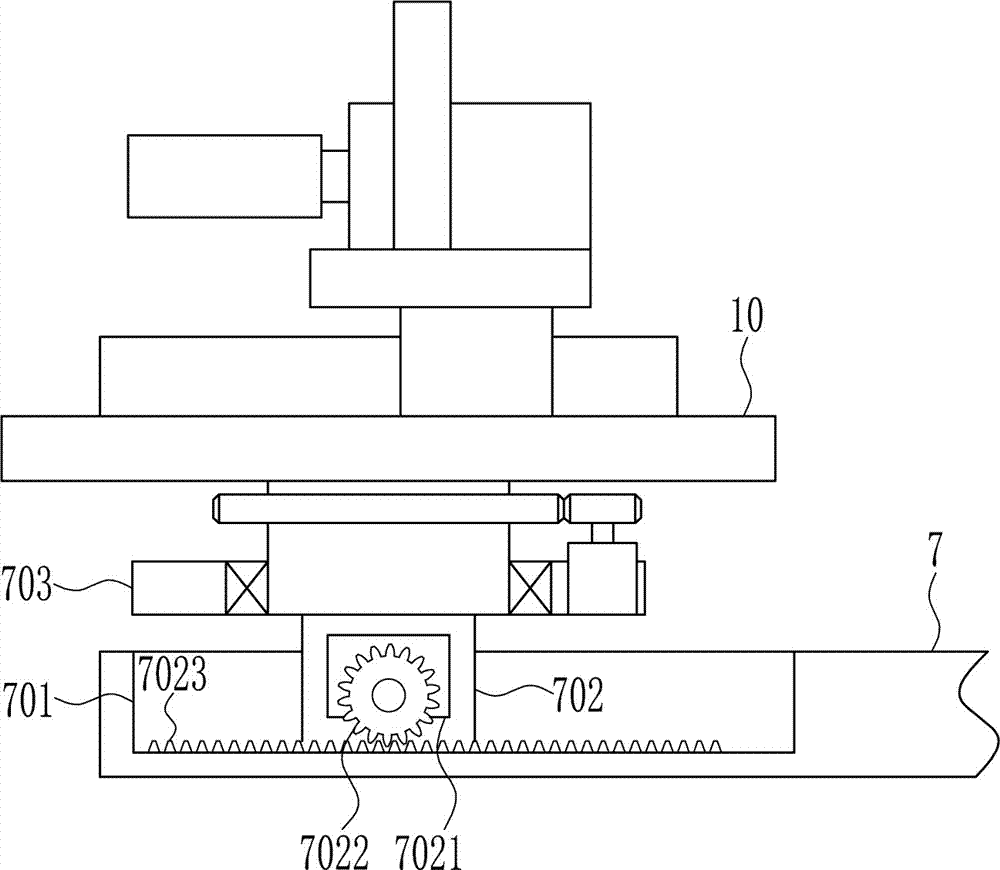

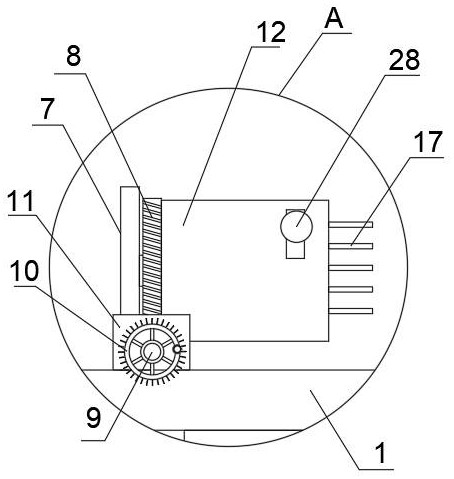

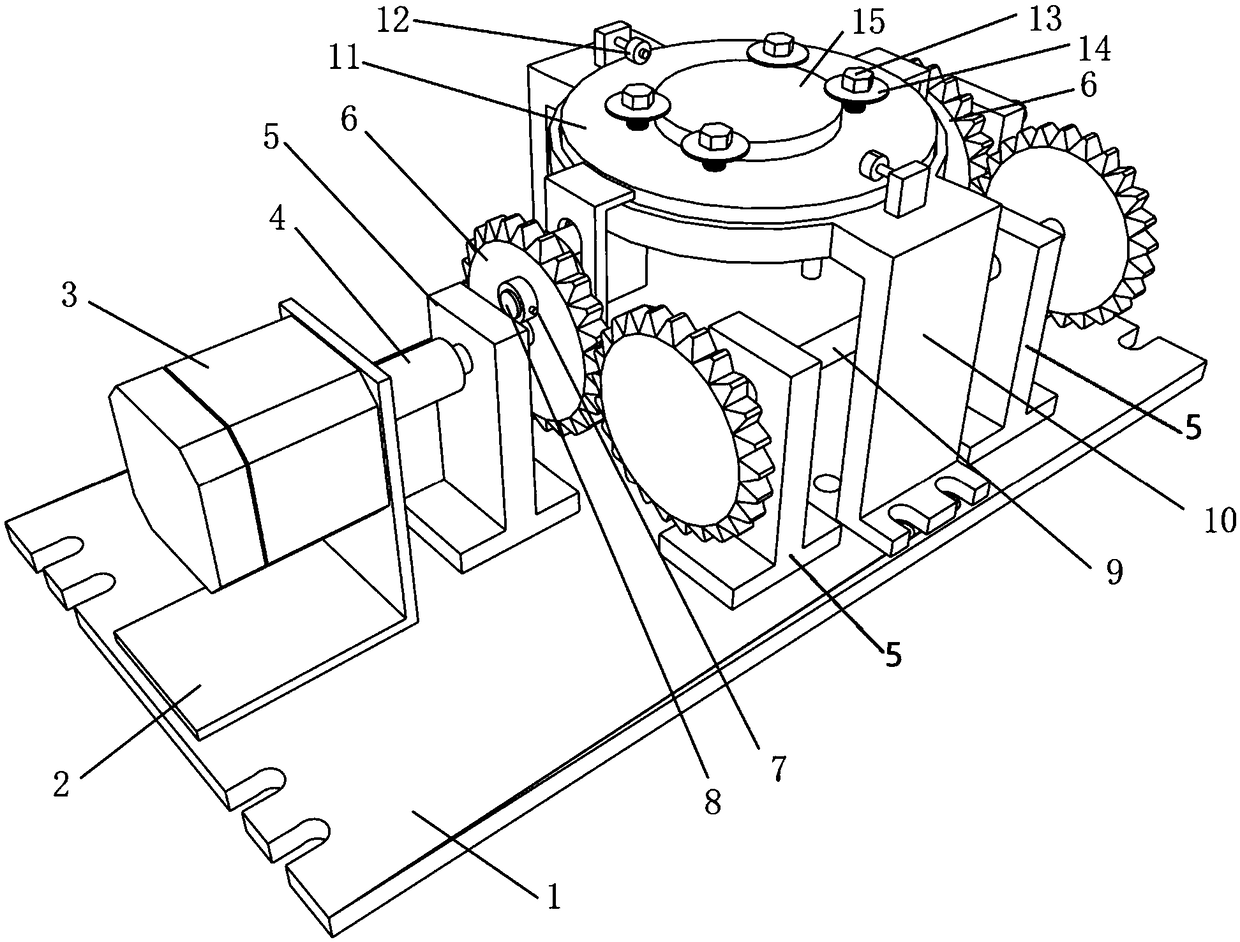

Synchronous adjustable multiple shaft machine

InactiveCN101372045APrecise drillingDrilling safetyBoring/drilling componentsBoring/drilling machinesGear wheelEngineering

A synchronous adjustable multi-axis machine is designed aiming at workpieces with pitch-row reference circle of different sizes and uniformly distributed angle, such as a shell of a small and medium motor and the drilling of an end closure. The synchronous adjustable multi-axis machine comprises a multi-axis machine shell, regulating cylinders, a drill pipe, a locknut, a drive gear, and a synchronous regulating mechanism, and the like. The multi-axis machine has a plurality of regulating cylinders which are internally provided with transition gears. One side of the transition gears is engaged with a drive gear, and the other side drives a drill pipe gear to lead the drill pipes to rotate; one end of axle of the transition gear is fixed in the multi-axis machine shell, and the other end is matched with the locknut which fixes the regulating cylinder; loosing the locknut so that the the regulating cylinder can rotate to lead the drill pipe locate on the needed position. In order to regulate the needed pitch-low synchronously, a linkage mechanism is arranged among a plurality of regulating cylinders; when the pitch-row of the drilling is adjusted, the regulating cylinders are rotate simultaneously to ensure that the distance of the drill pipe is evenly distributed along the circumference. The excircle of the regulating cylinder is cut with a value cue mark of the diameter (D) or the radius (R) of the drilling reference cycle.

Owner:吴为国

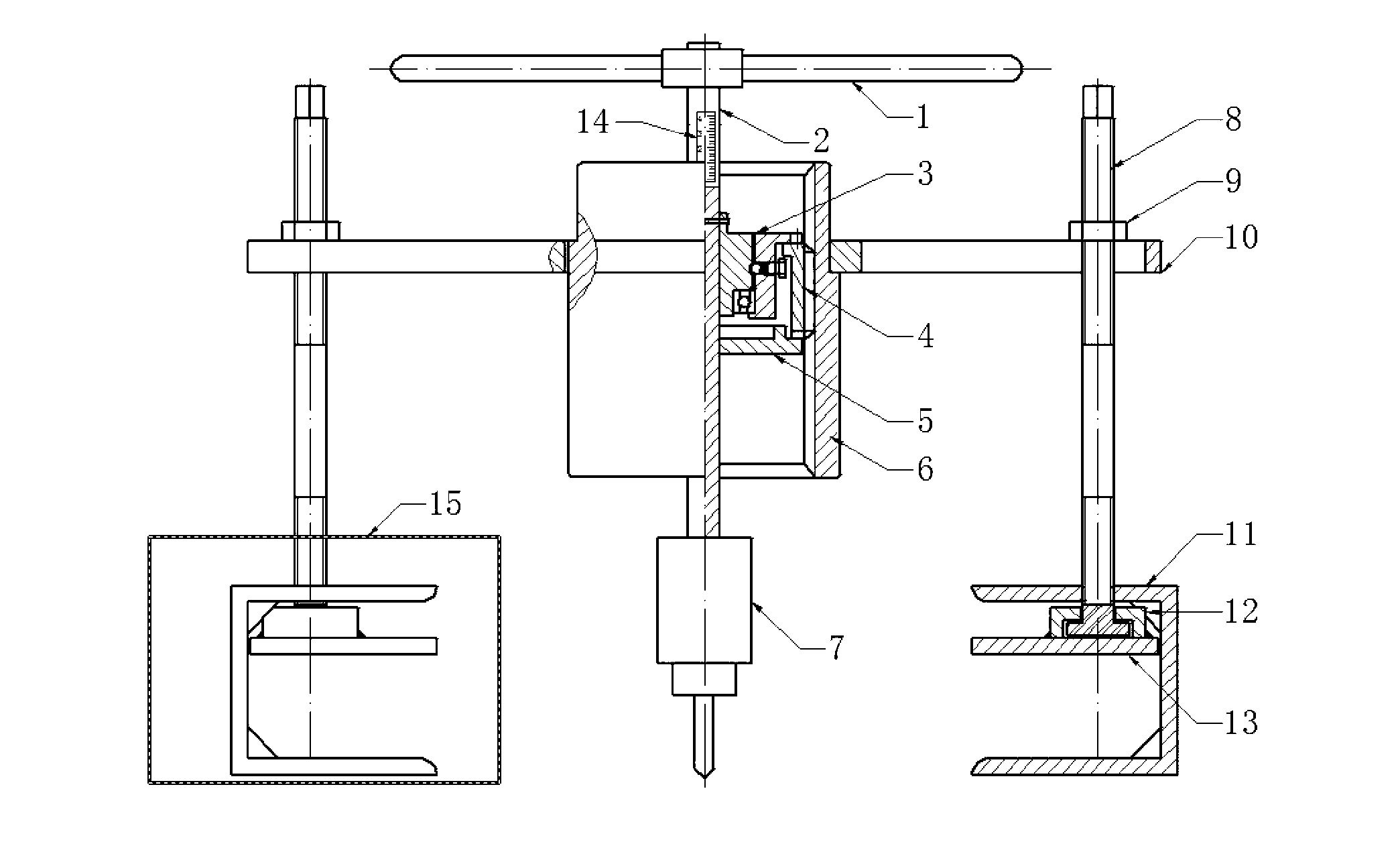

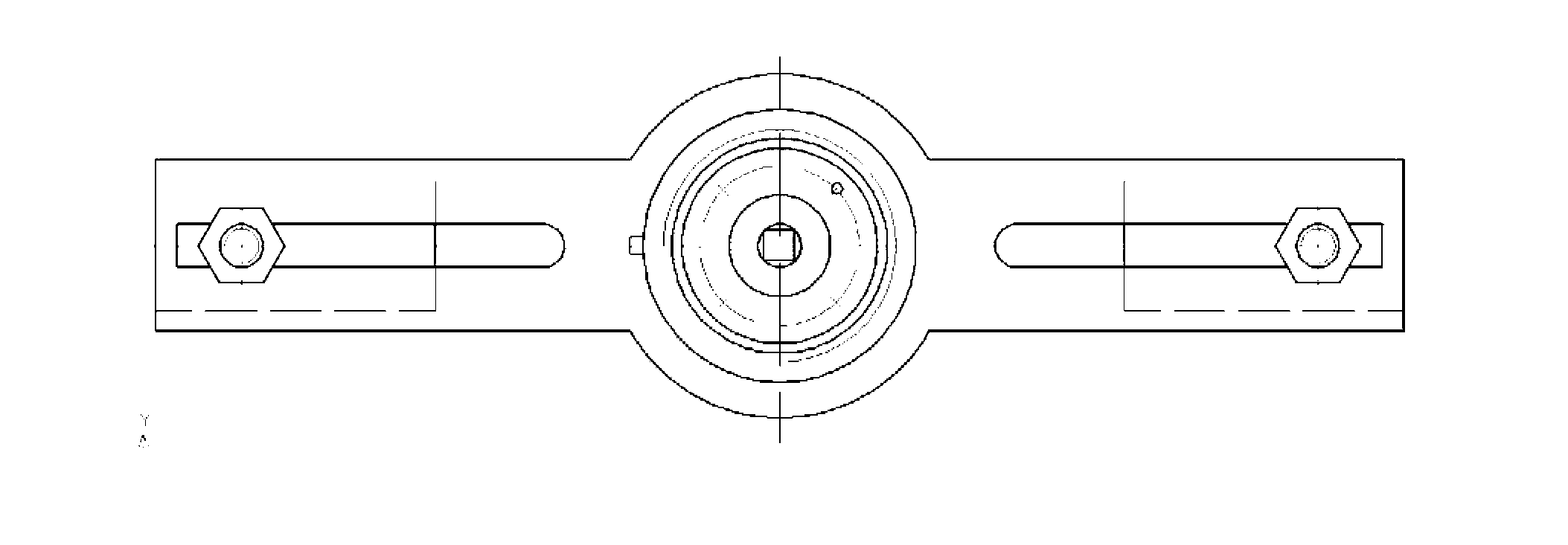

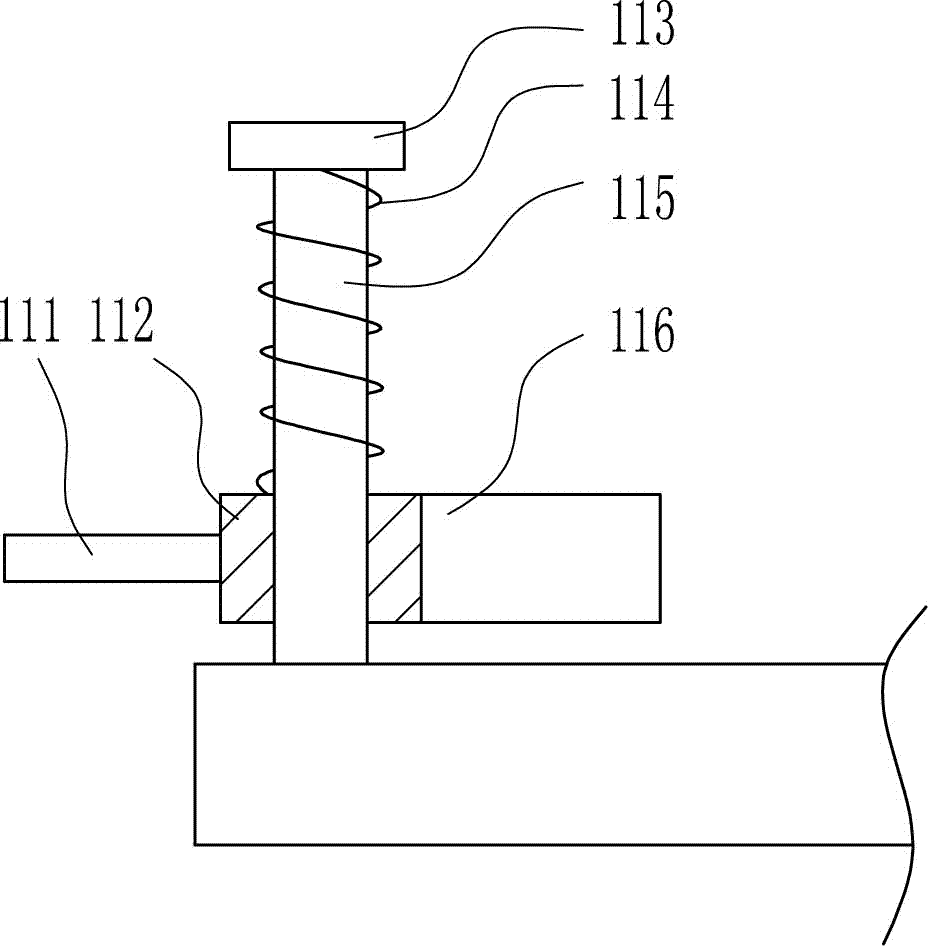

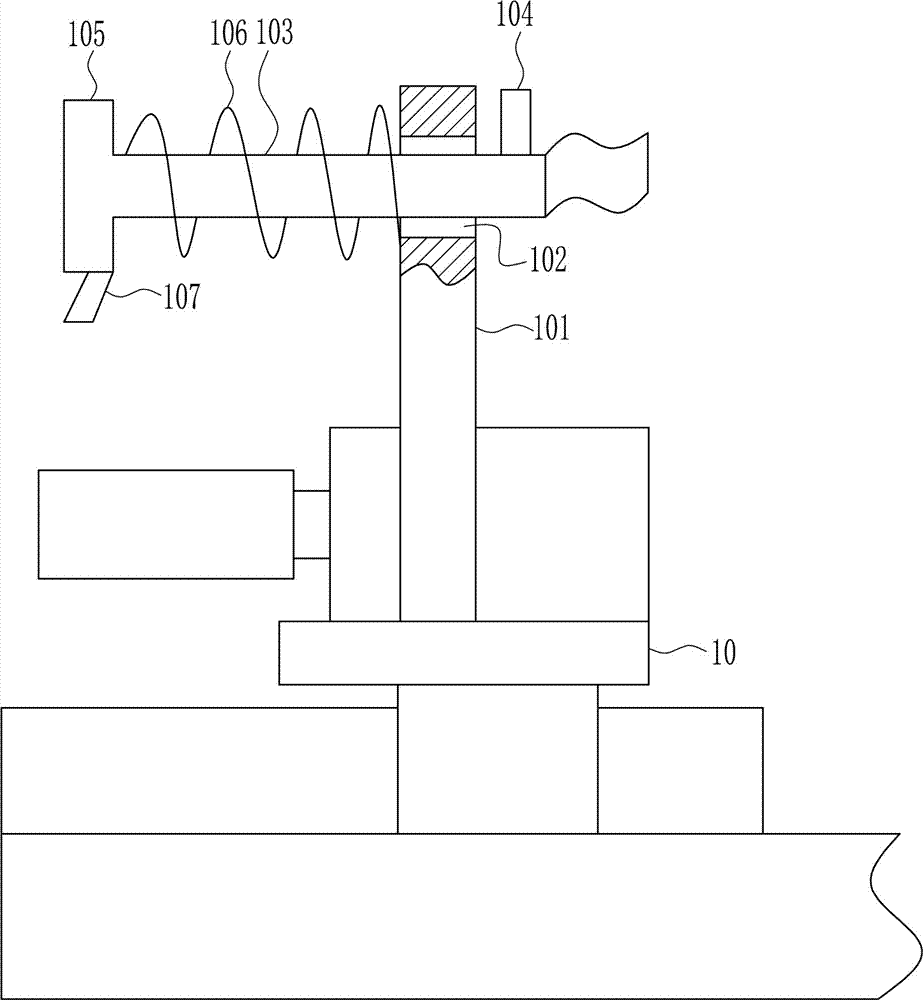

Manual multi-purpose drilling device

InactiveCN103212734APrecise drillingMetal working apparatusPortable drilling machinesCouplingScrew thread

The invention relates to a manual multi-purpose drilling device which is characterized in that a handle and a drill pipe are connected, the drill pipe (2) is connected with a safety coupler through a flat key, the upper edge of an internal spiral rotating drum is connected with the safety coupler through a flange, and the inner spiral rotating drum is connected with an outer sleeve through threads. An annular retainer ring is arranged between the drill pipe and the internal spiral rotating drum, wherein a center hole of the annular retainer ring is sleeved on the drill pipe in a fixed-connection mode, the annular retainer ring makes contact with the lower edge of the internal spiral rotating drum in a sliding mode, and the drill pipe is connected with a drill bit chuck through threads. Two double-head screw rods (8) are arranged in sliding chutes in the two ends of a supporting plate (10) respectively, the lower ends of the double-head screw rods are connected with frame-shaped clamping plates (11) through threads, and bosses at the lower ends of the double-head screw rods are arranged in bowel-shaped sleeves. The supporting plate (10) and the outer sleeve (6) are arranged coaxially and movably connected through flat keys. By using of the device, in the whole process of manual drilling, only one action of rotating the drill pipe is needed to finish the manual drilling, through reference to scale marks on the drill pipe, the accurate drilling can be achieved, and replaceable clamping frames can be flexibly used in kinds of drilling places.

Owner:EAST CHINA UNIV OF SCI & TECH

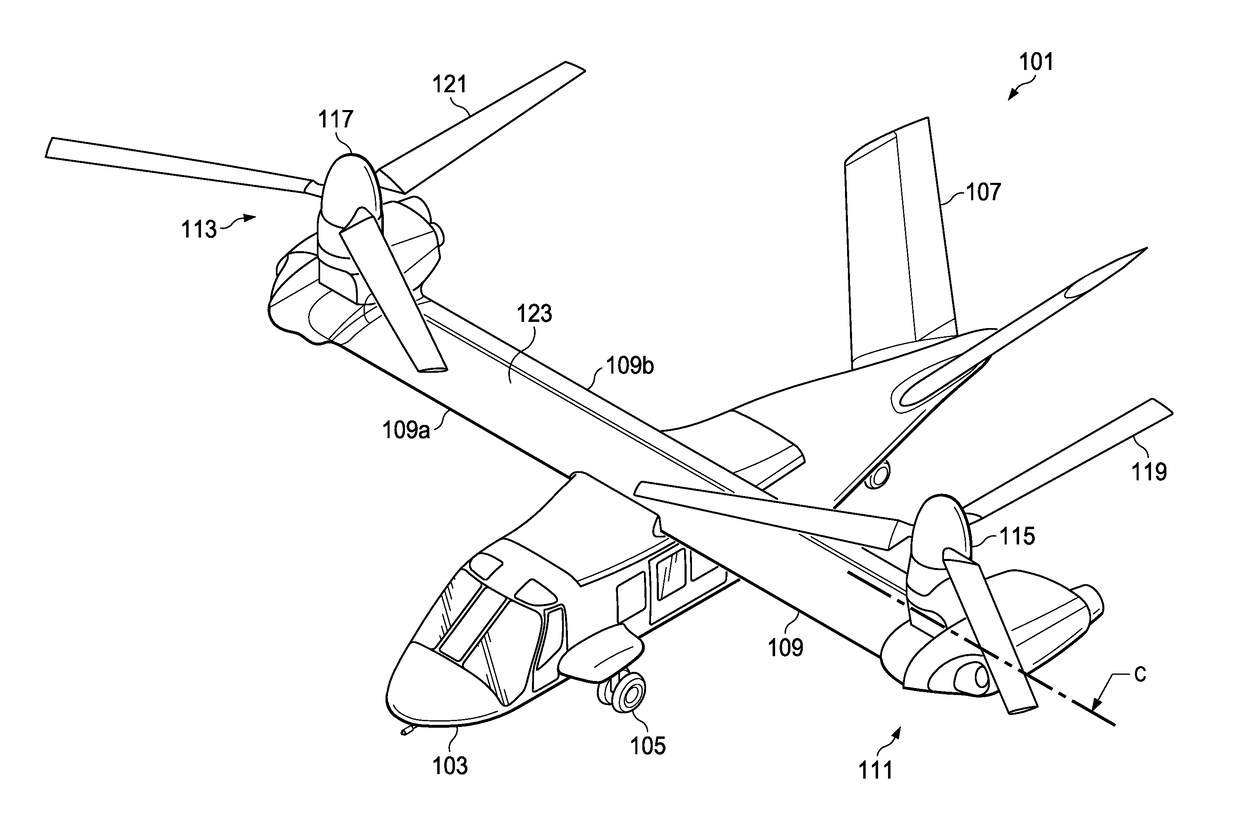

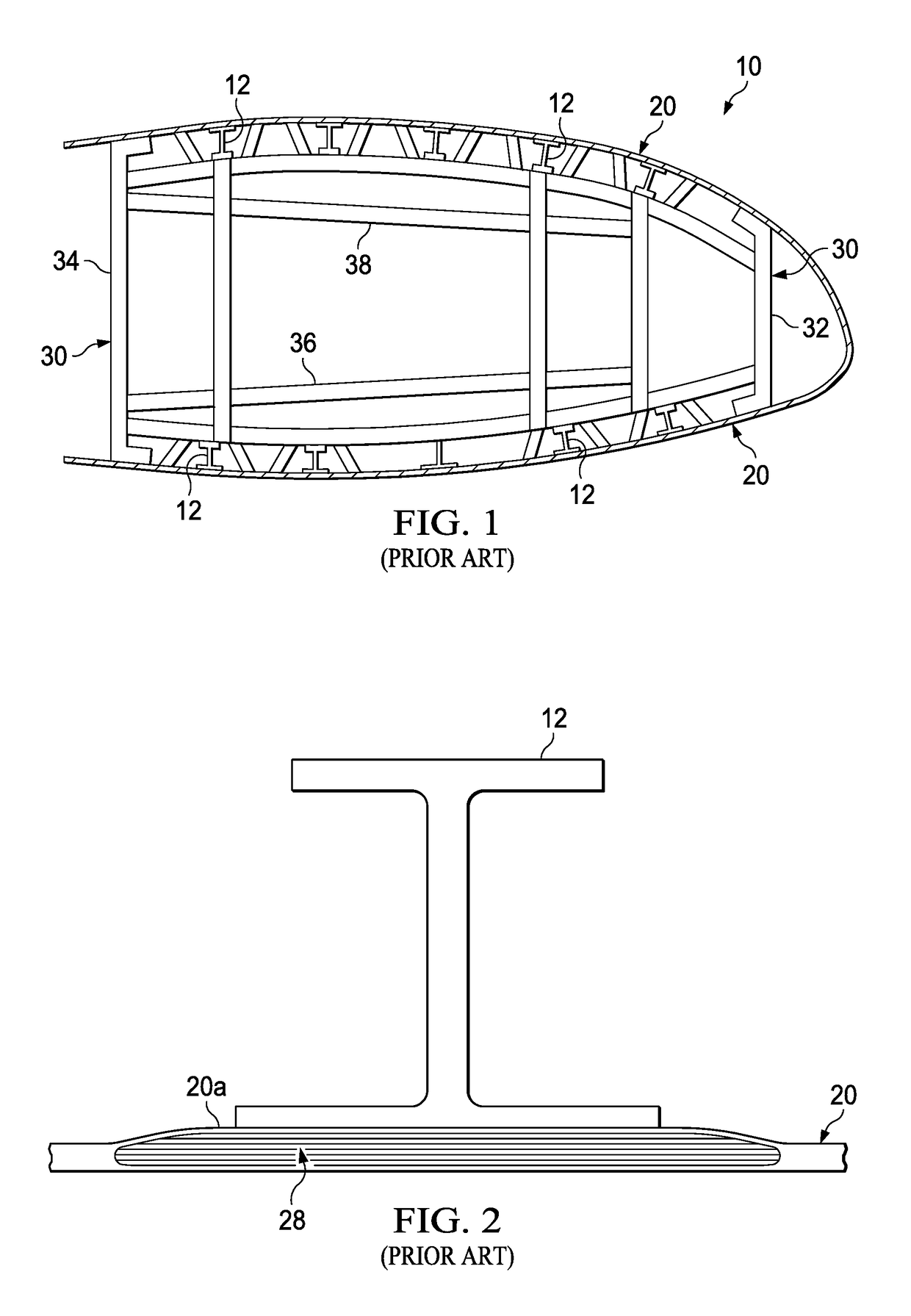

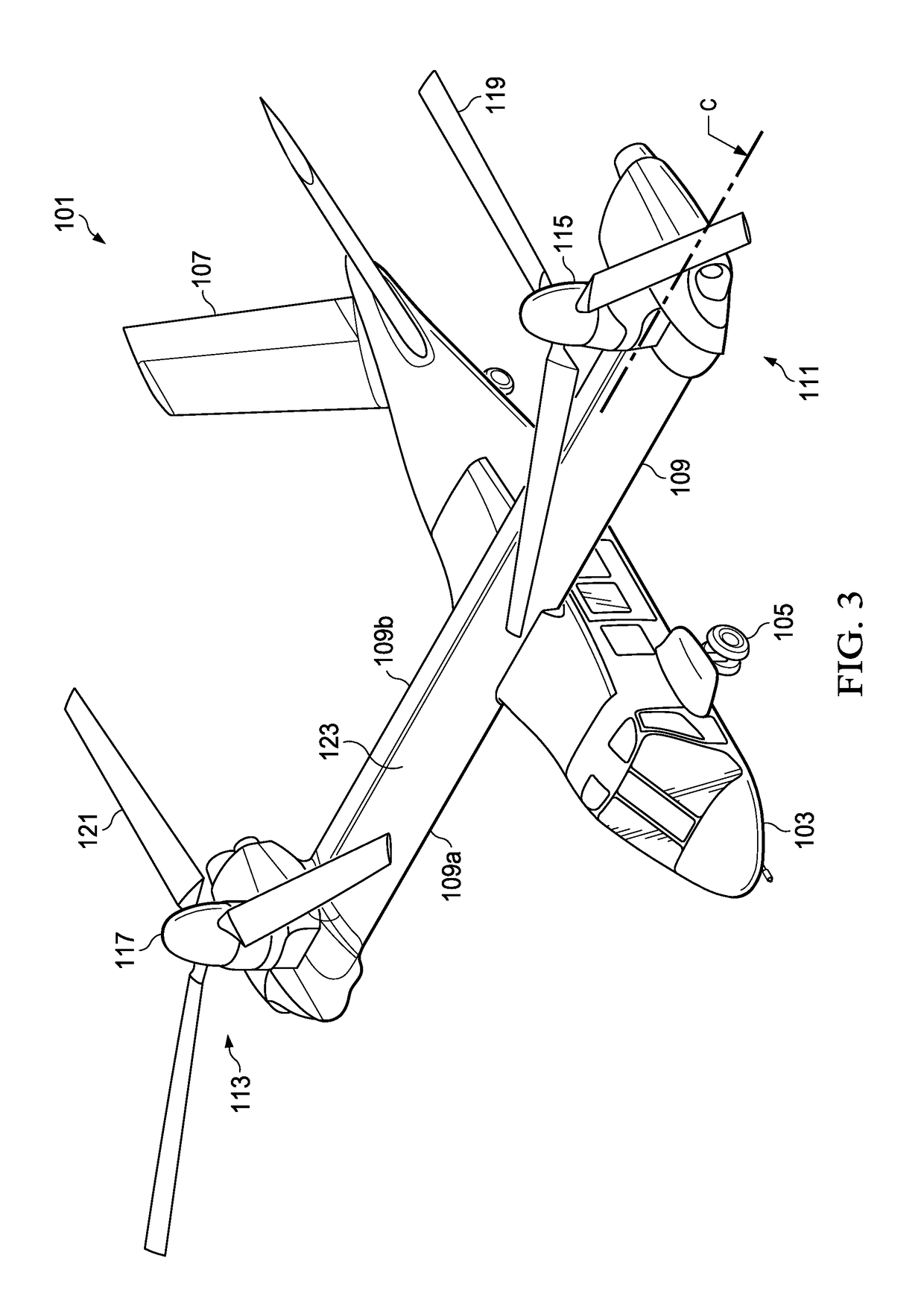

Composite wing structure and methods of manufacture

ActiveUS20170225769A1Precise drillingLayered productsSpars/stringersMechanical engineeringHelicopter rotor

Owner:BELL HELICOPTER TEXTRON INC

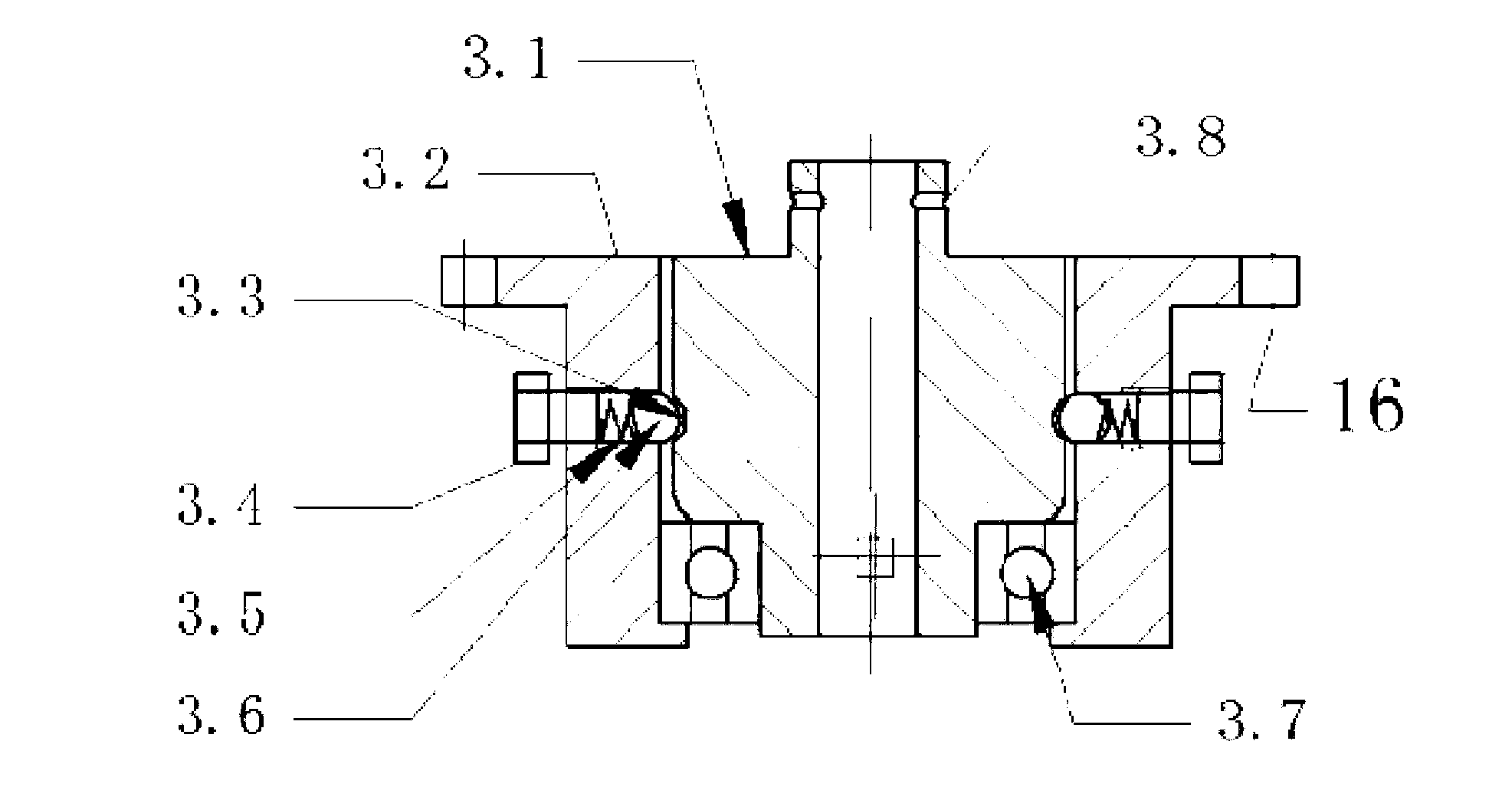

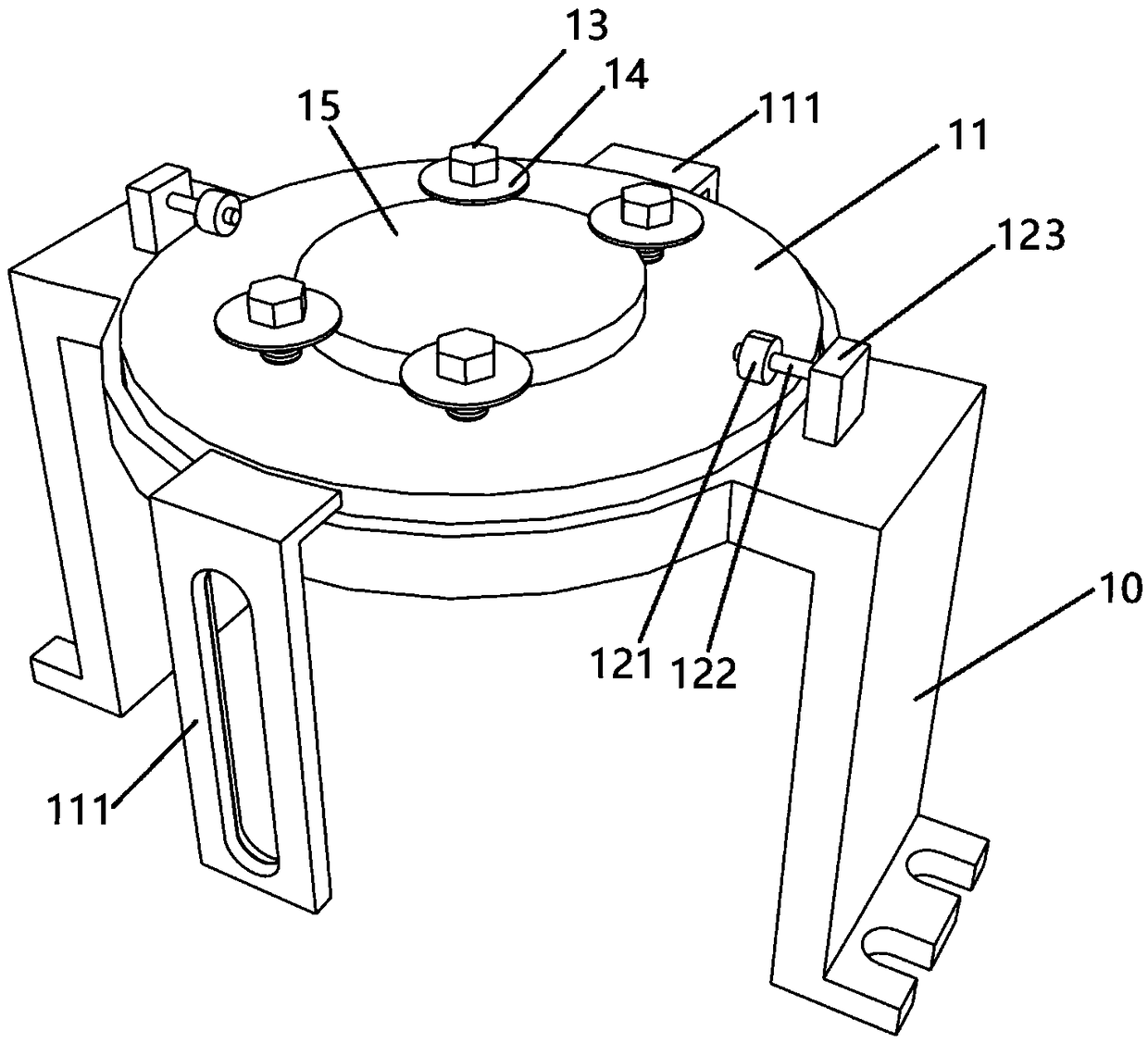

A centering clamping device for crystal material processing

ActiveCN102294761AImprove work efficiencyGrinding evenlyWorking accessoriesGrinding work supportsCrystalline materialsRocker arm

The invention relates to a fixture for a crystal material, in particular to a centering and clamping device used for processing the crystal material. The fixture is characterized in that the opposite faces of the upper parts of a rocker arm (2) at one side and a rocker arm (4) at the other side are respectively fixedly connected with a big clamping piece (1) and a small clamping piece (5), the opposite faces of the big clamping piece and the small clamping piece are respectively provided with slots (16), the lower part at a hinge joint of rocker arm support plates (7) on the bases of the rocker arm at one side and the rocker arm at the other side is respectively connected with the two ends of an elastic body; a corresponding lower part between the rocker arm at one side and the rocker arm at the other side is provided with a wedge-shaped block (8) which is small at the top and big at the bottom, and the lower part of the wedge-shaped block (8) is provided with a power mechanism which moves up and down. In the invention, by virtue of the big clamping block on the rocker arm at one side and the small clamping block on the rocker arm at the other side, stable positioning on a silicon core is realized, and accurate drilling or grooving or grinding on the silicon core is realized; and the defect that a hole or grinding groove on a transverse or vertical silicon core is non-standard due to the traditional manual operation mode is overcome by using the fixture provided by the invention.

Owner:LUOYANG JINNUO MECHANICAL ENG

Medical drilling machine

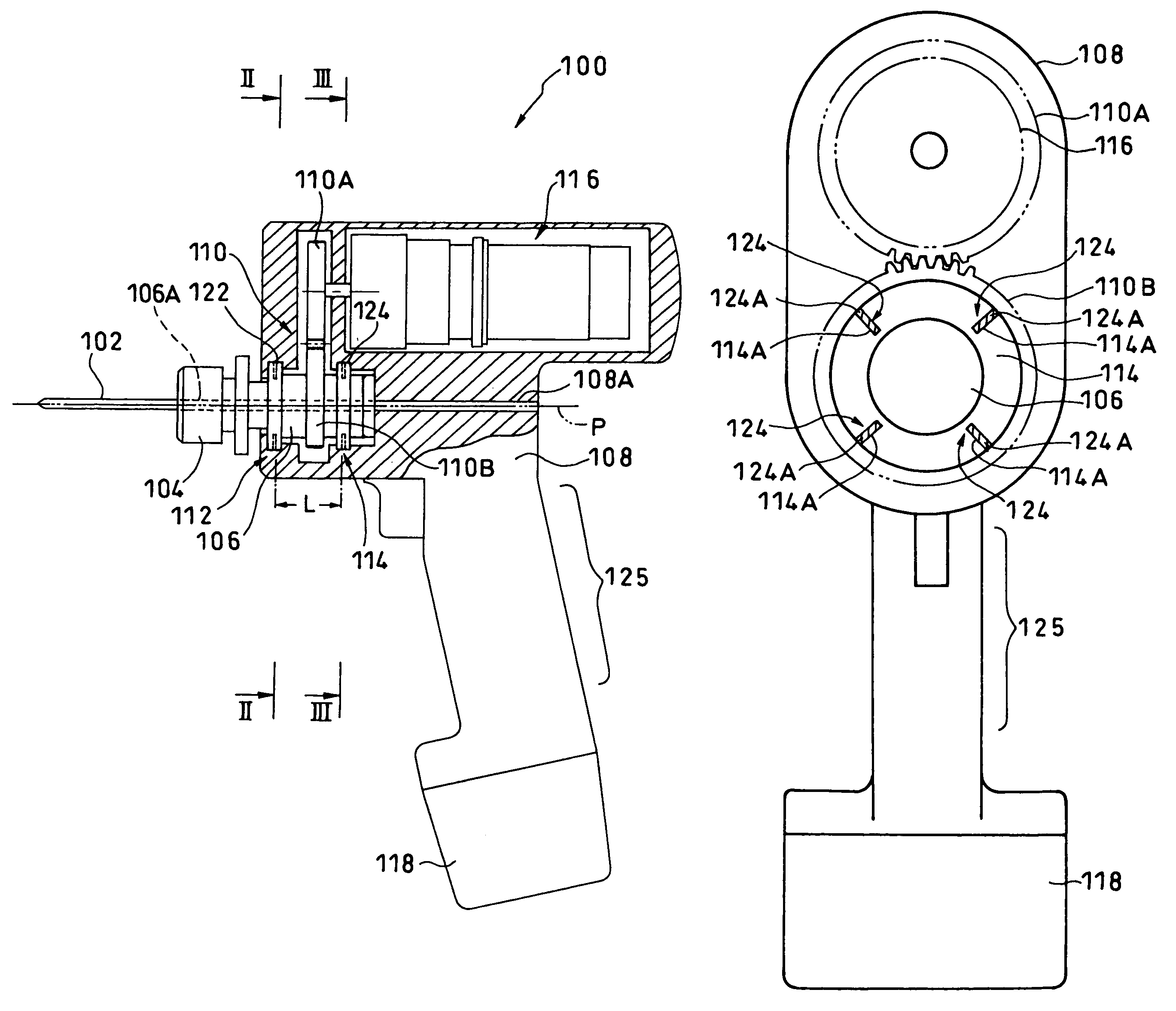

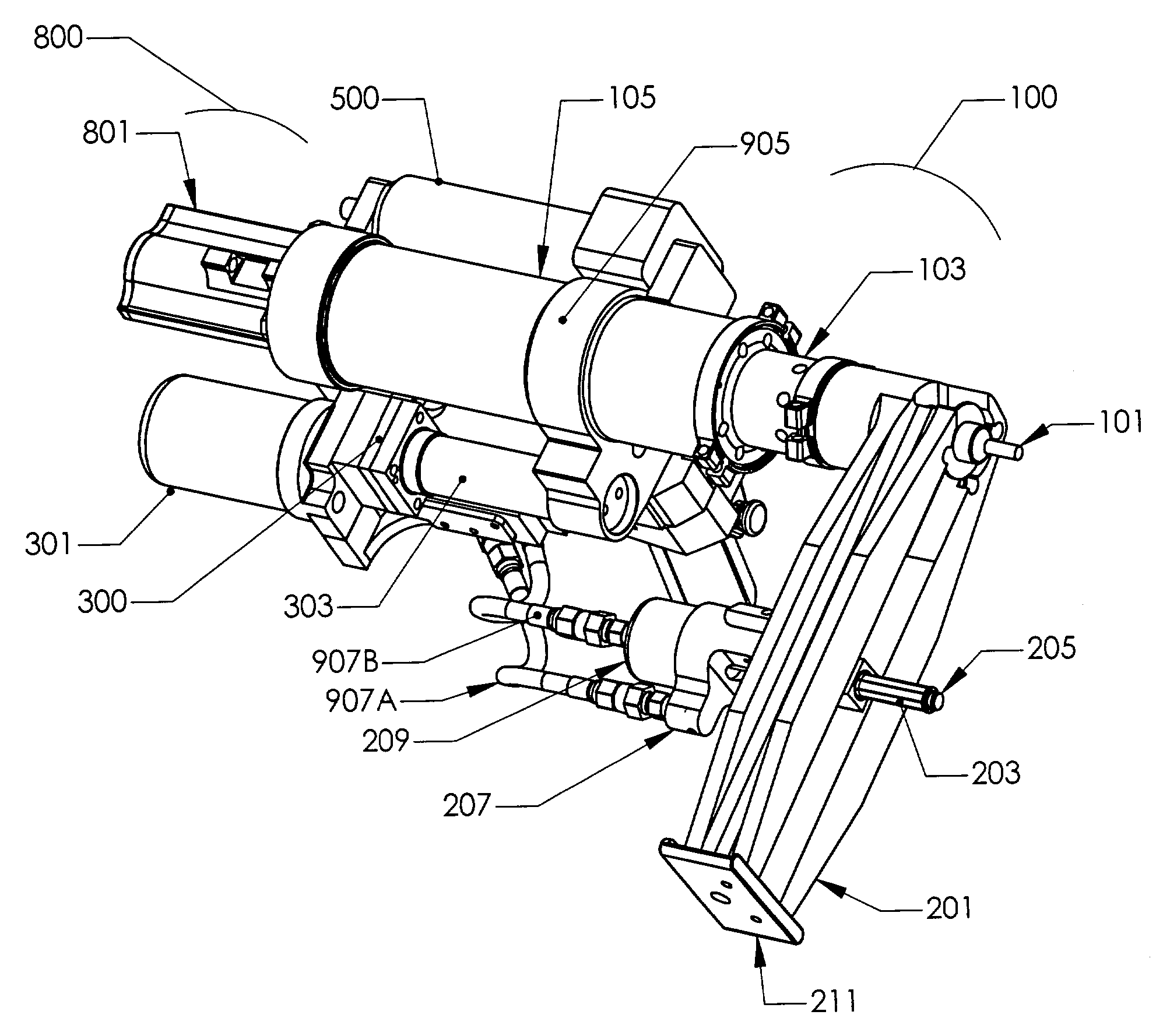

InactiveUS7074225B2Reduce user burdenPrecise drillingProsthesisOsteosynthesis devicesDrive shaftX-ray

To facilitate positioning of a drill bit and alleviate burden to a user, a medical drill machine including a drive shaft gripping a drill bit, a casing constituted of X-ray transparent material and capable of housing the drive shaft, and a force transferring mechanism for transferring rotational force to the drive shaft is provided. In this medical drill machine, a first guide and a second guide constituted of X-ray opaque material are fixed at given positions along an axial direction of the drive shaft in the casing. Both guides are arranged coaxially with the axis of the drive shaft, and are formed in mutually different shapes. A slant direction of the drill bit can be recognized from any relative misalignment of the mutually different shapes of the guides included in an X-ray image along the ideal axial line.

Owner:HOYA TECHNOSURGICAL CORP

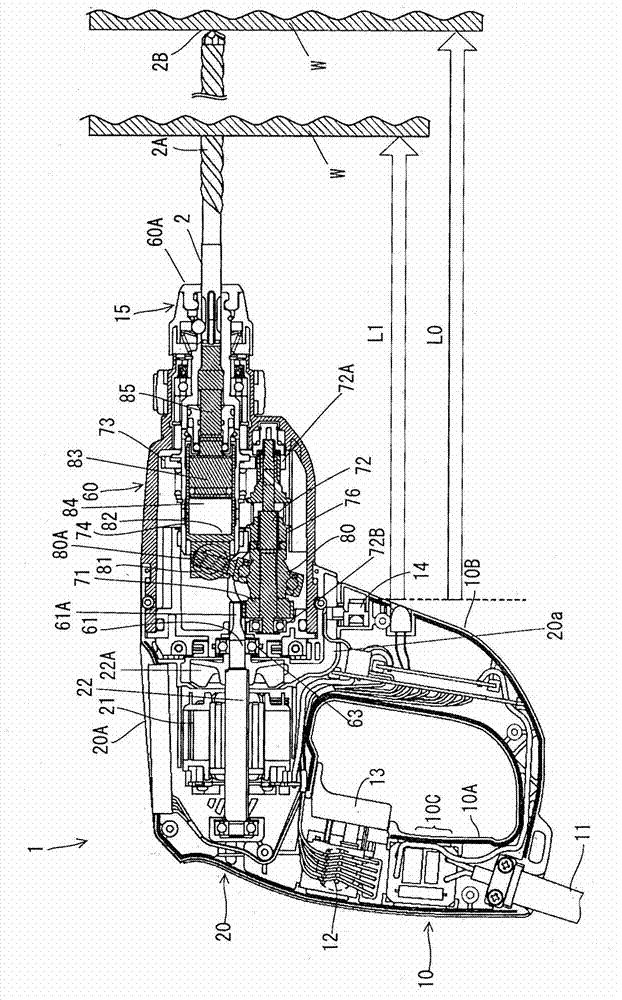

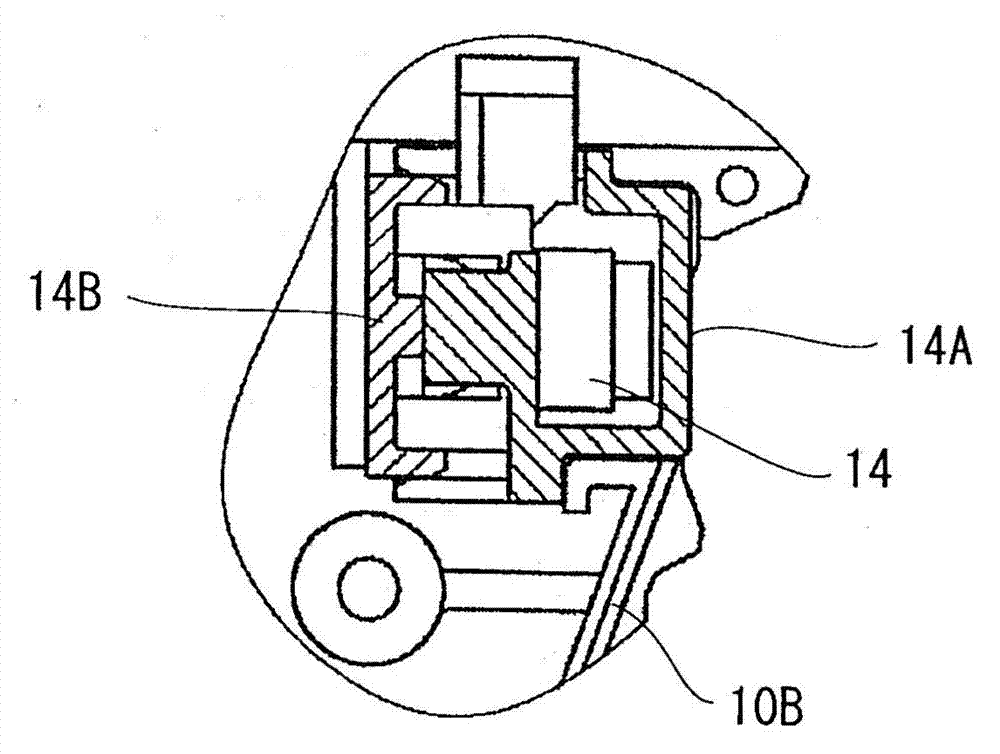

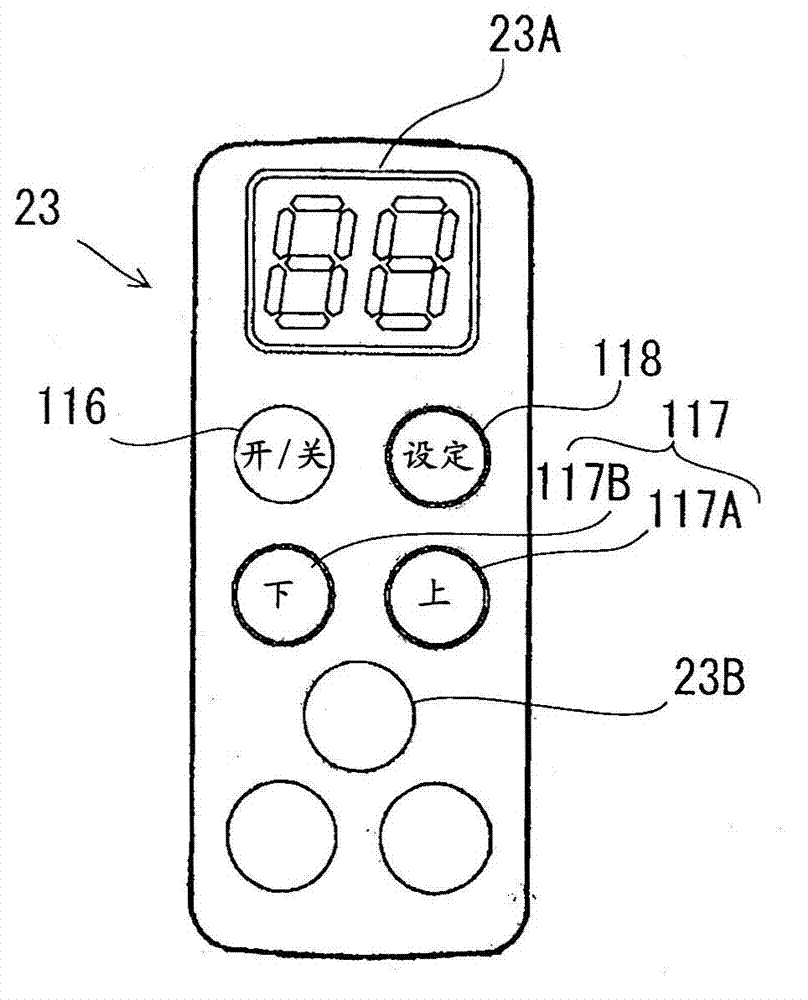

Power tool

InactiveCN103097084APrecise drillingDrilling/boring measurement devicesMeasurement/indication equipmentsMotor driveEngineering

A power tool includes: a motor driving an end bit; a housing accommodating the motor; a distance measuring sensor provided at the housing; and a controlling section connected to the distance measuring sensor. The controlling section is configured to exclude an abnormal value from measurement value measured by the distance measuring sensor.

Owner:HITACHI KOKI CO LTD

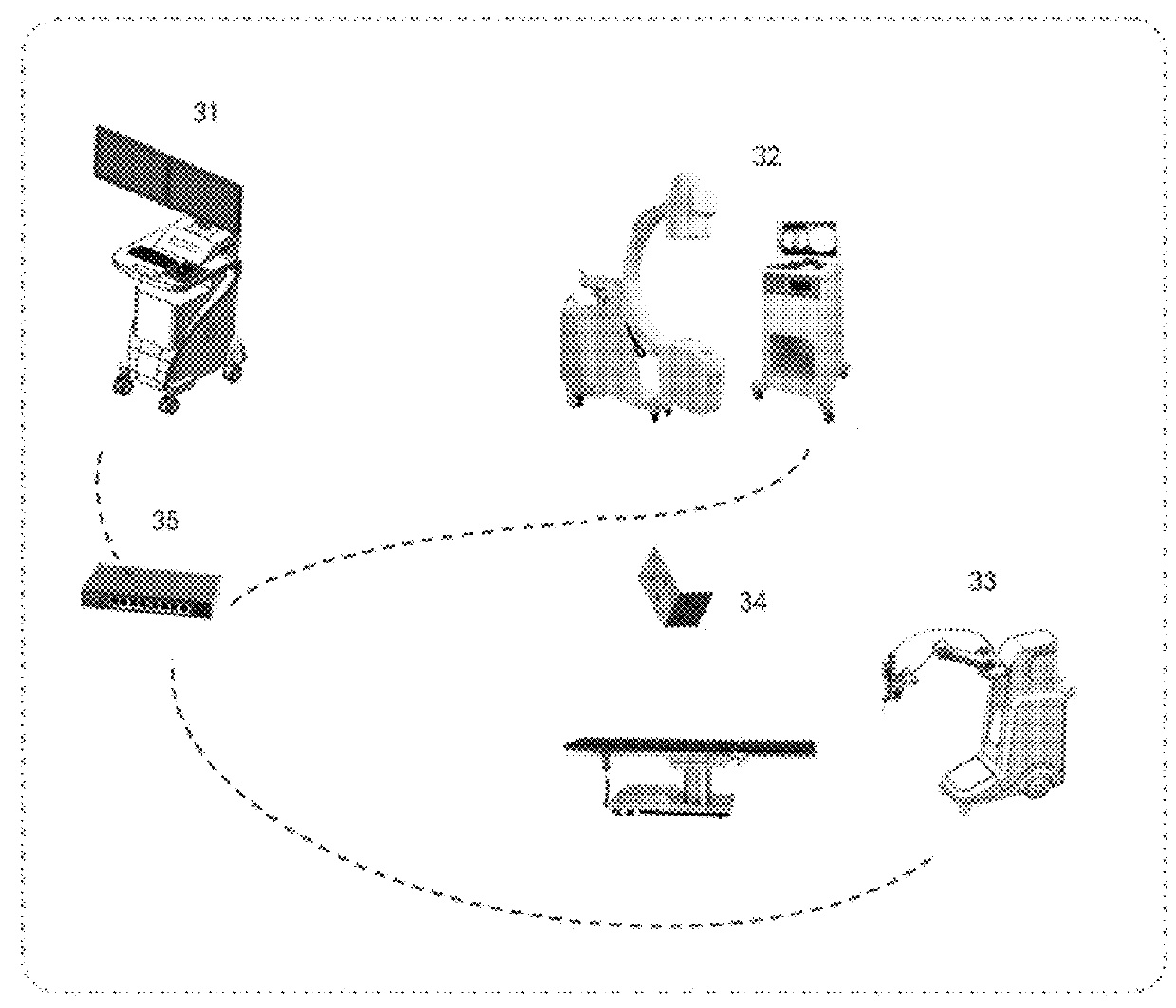

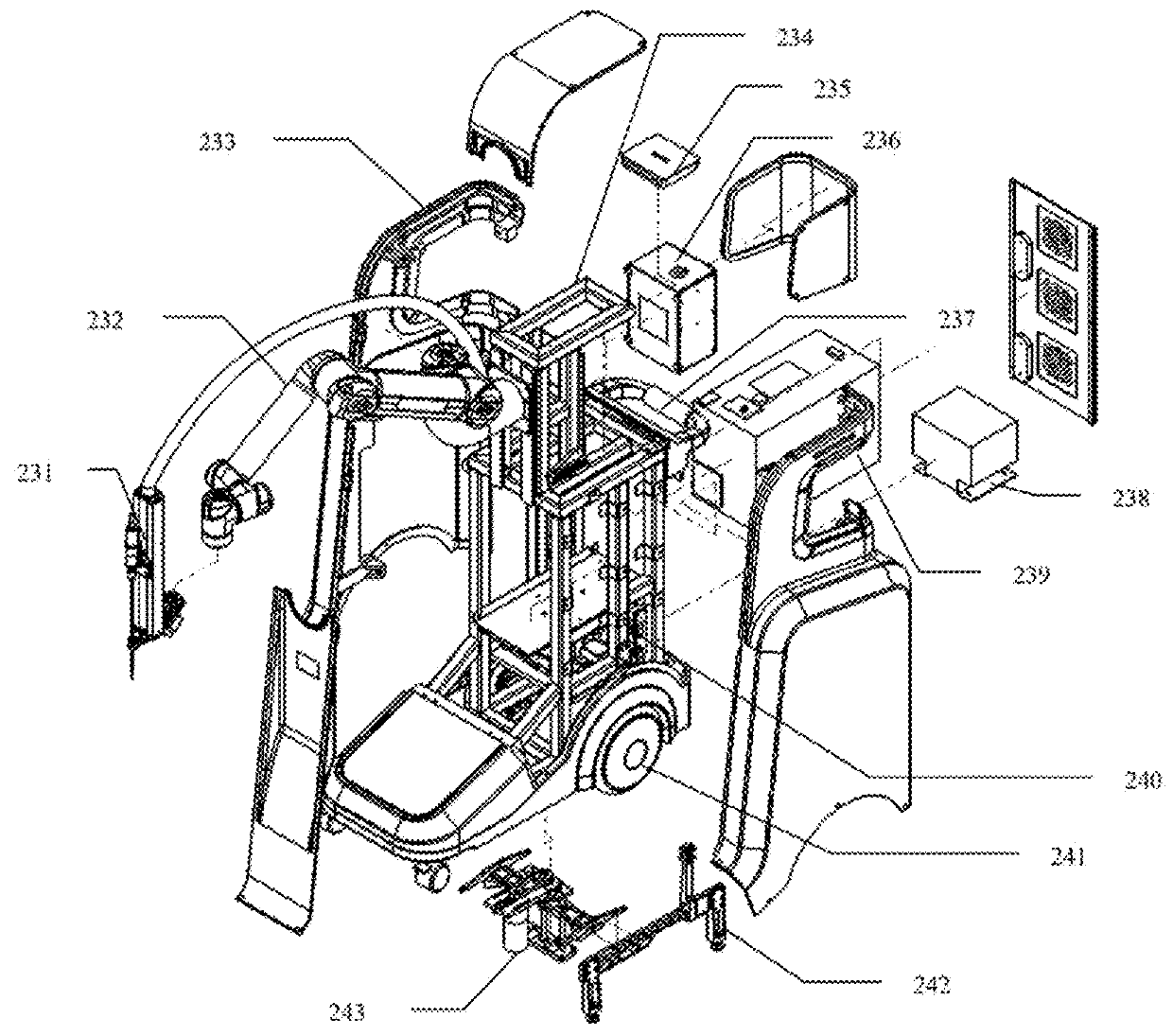

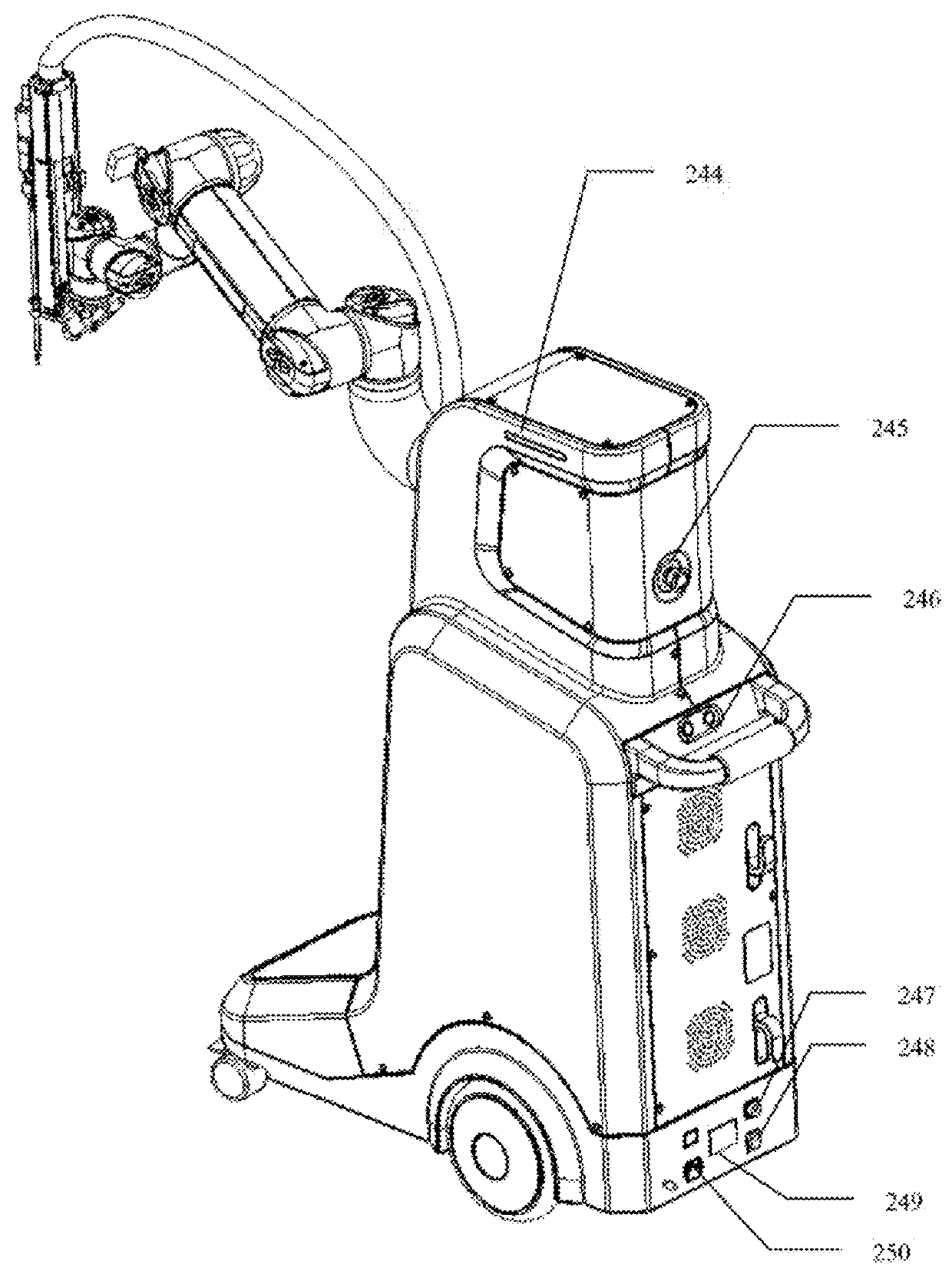

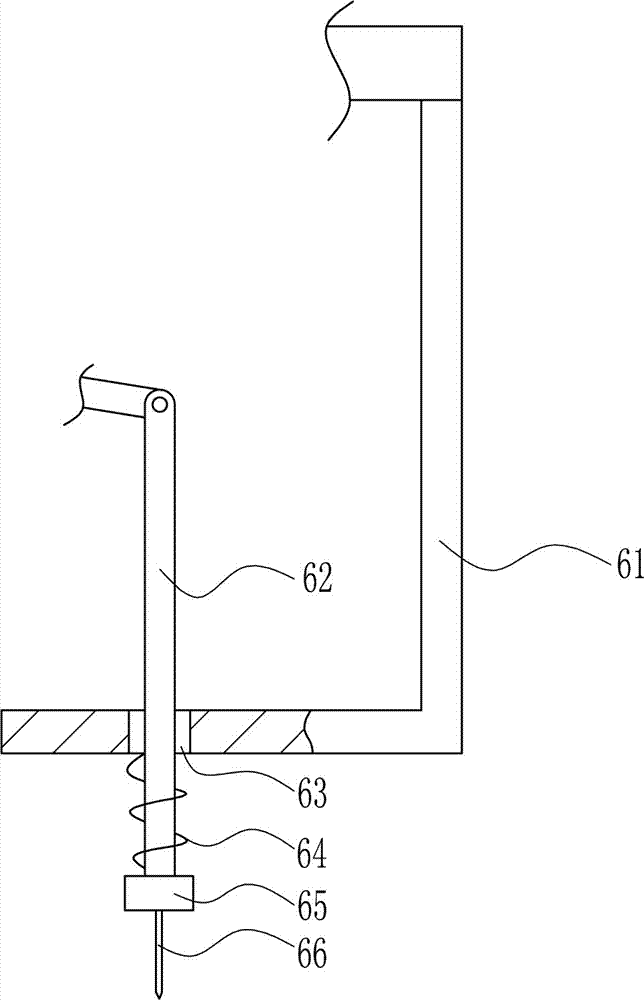

Intelligent orthopedic surgical system

ActiveUS20180092648A1Improve accuracyImprove stabilitySurgical navigation systemsSurgical systems user interfaceSurgical robotElectrical control

An intelligent orthopedic surgical system comprises a switcher, a surgical location device, a surgical planning and monitoring device connected to the switcher, a C-arm X-ray apparatus and an orthopedic surgical robot. The orthopedic surgical robot comprises a robot body, a robot arm fixed to the robot body, an intelligent bone drill fixed to the robot arm, a communication module, a robot arm control module, an intelligent bone drill control module and a surgical robot electrical control module. The intelligent bone drill comprises a surgery electric drill, a guide mechanism for an electric drill head, a pushing mechanism, a visual identification system, a pressure sensor and a bone drill controller. The orthopedic surgical robot of the present system can perforate accurately under the navigation control and improve the accuracy and stability of the operation.

Owner:SHENZHEN XINJUNTE SMART MEDICAL EQUIP CO LTD

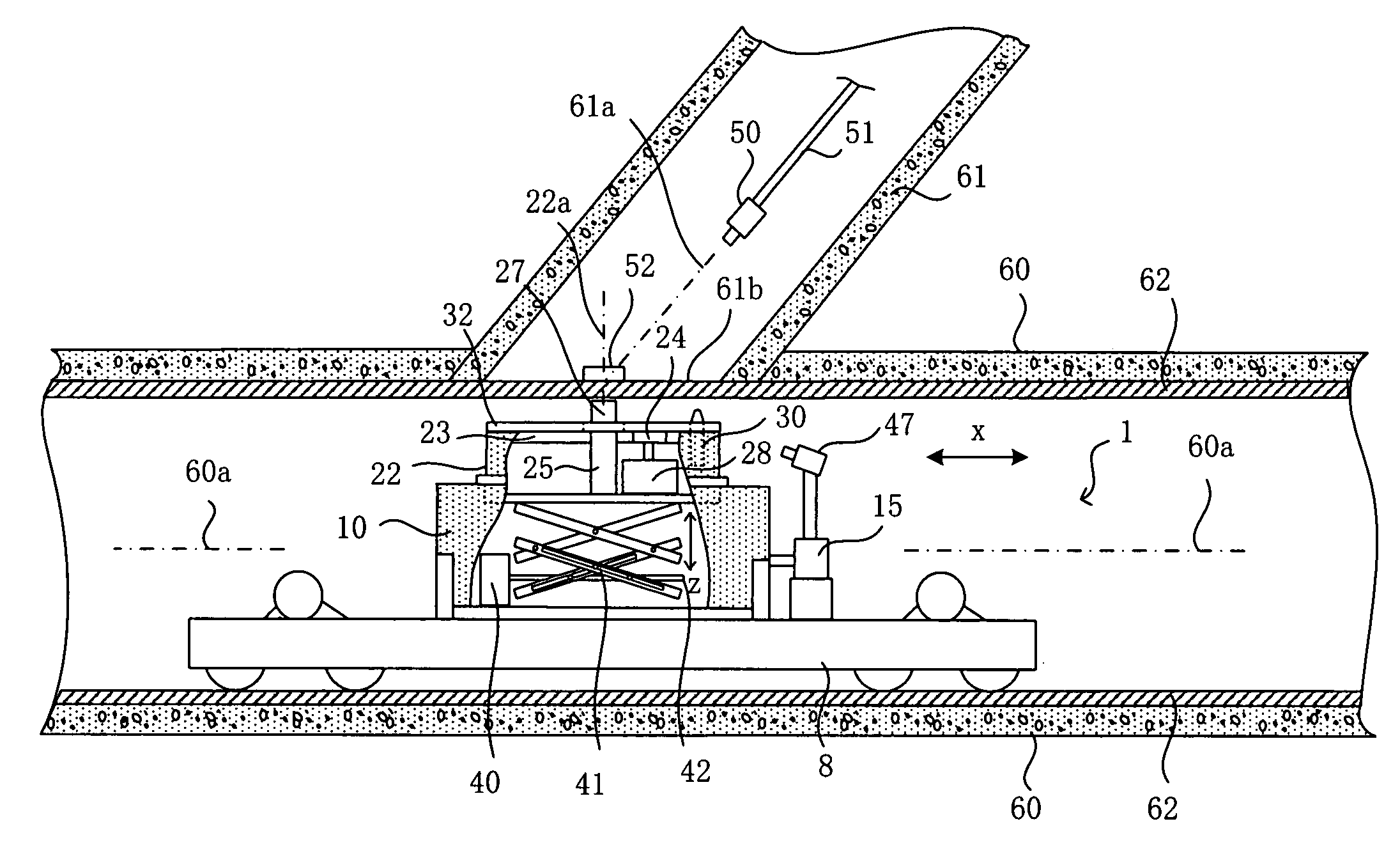

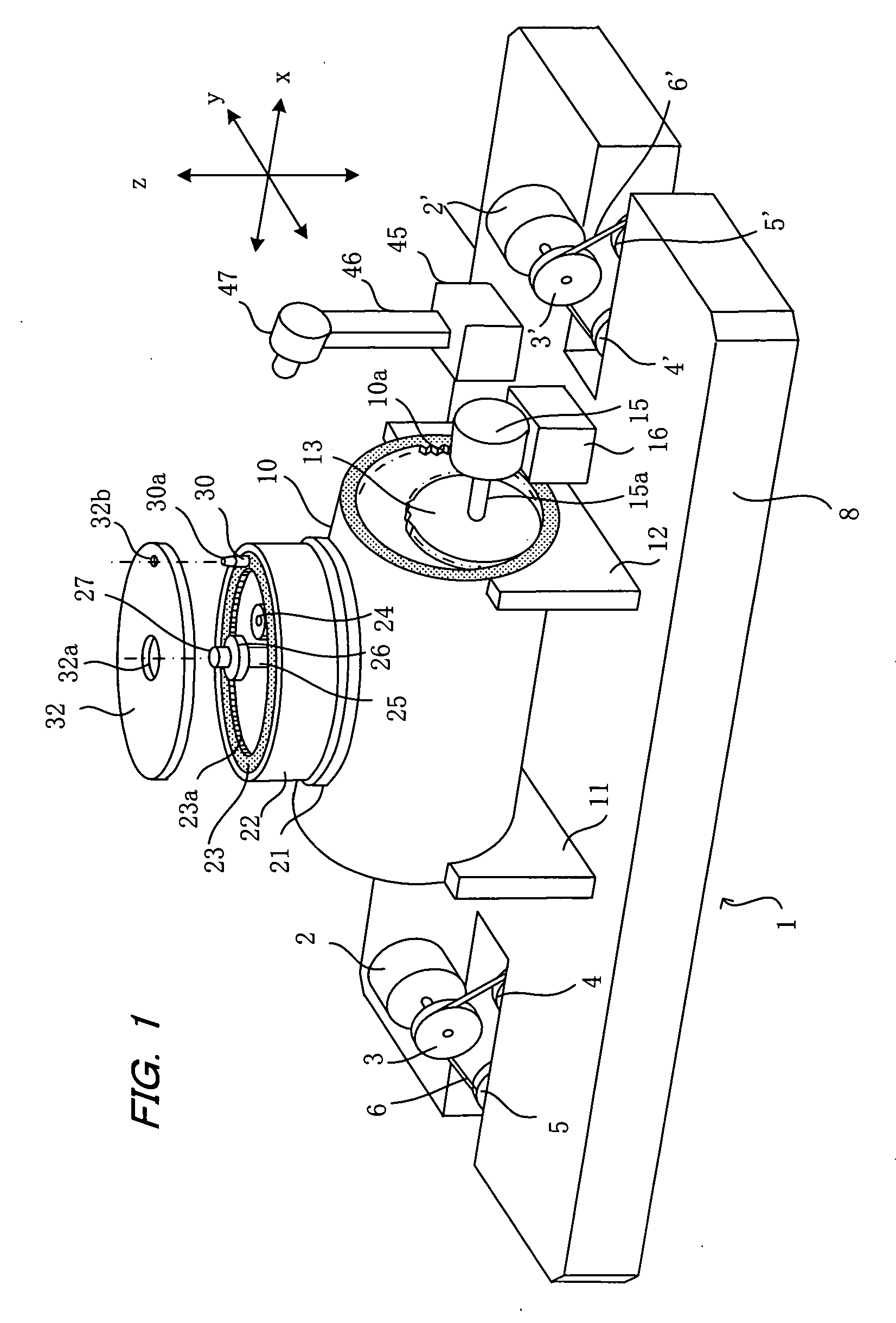

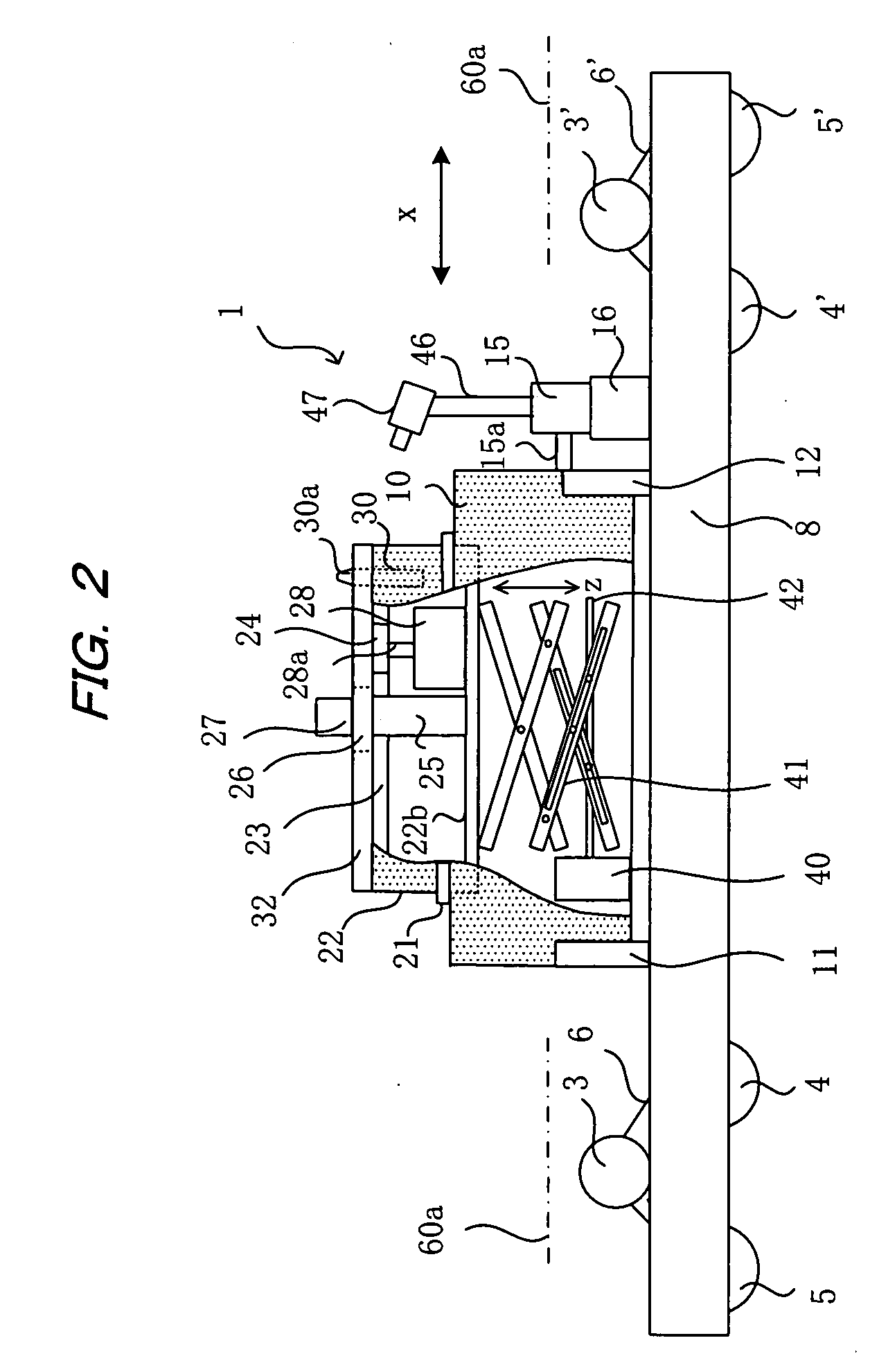

In-pipe work robot

A main pipe is lined using a pipe lining material that blocks the opening of a lateral pipe branching from the main pipe. An in-pipe work robot is provided with a cutting nozzle for spraying a pressurized fluid material or pressurized granular material onto the pipe lining material of the main pipe. The cutting nozzle is moved to a predetermined position inside the main pipe and rotated about a vertical axis by a rotary mechanism to cut the lining material between the first and second pipes by the pressurized fluid material or pressurized granular material sprayed from the cutting nozzle in order to form an opening for communicating the main pipe with the lateral pipe. The cutting nozzle can be moved in desired positions to drill holes accurately without damaging the internal peripheral surface of the lateral pipe.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

Drill

ActiveUS7344341B2Avoid malfunctioningInhibit wearThread cutting machinesThread cutting auxillary apparatusTool bitGear pump

A portable power drill having an automatic drilling cycle for feeding a rotating tool bit to a workpiece to effect the desired operation. The drill uses a rotary gerotor pump to pump hydraulic fluid used in its system, and pressurized air to operate the hydraulic pump. The drill has a clamping assembly which clamps the unit on a workpiece before the drill bit is advanced toward the workpiece. The drill also has an integral drill spindle-planet carrier area which adds to its operability and reliability.

Owner:WEST COAST INDS

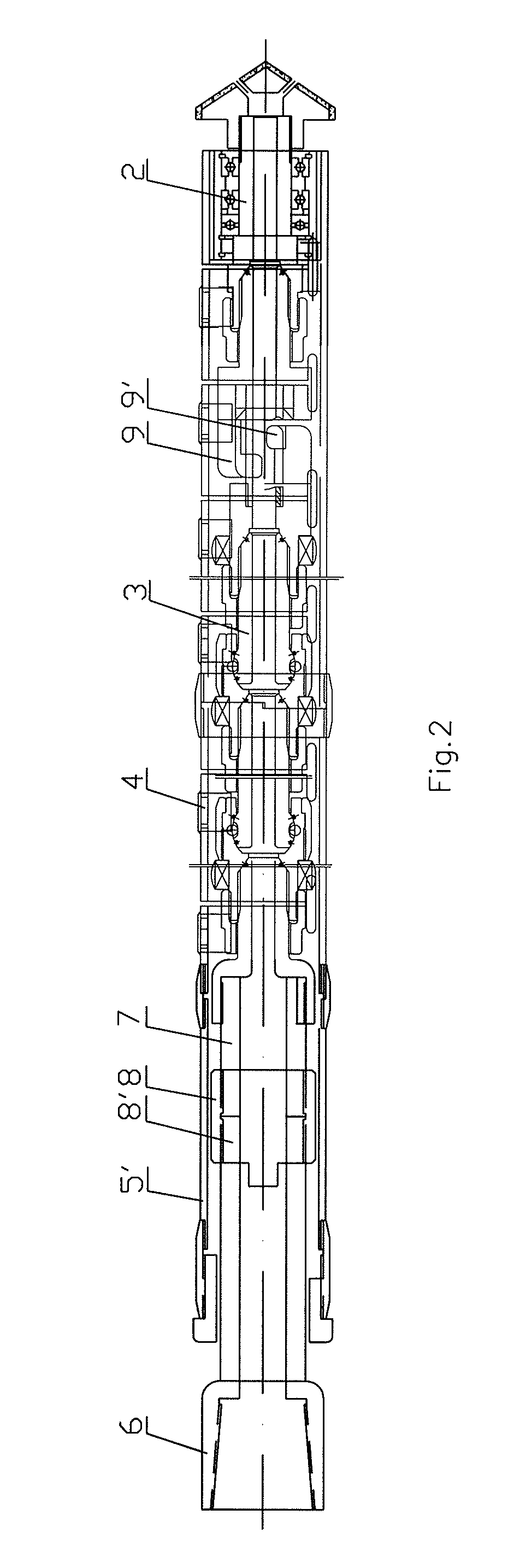

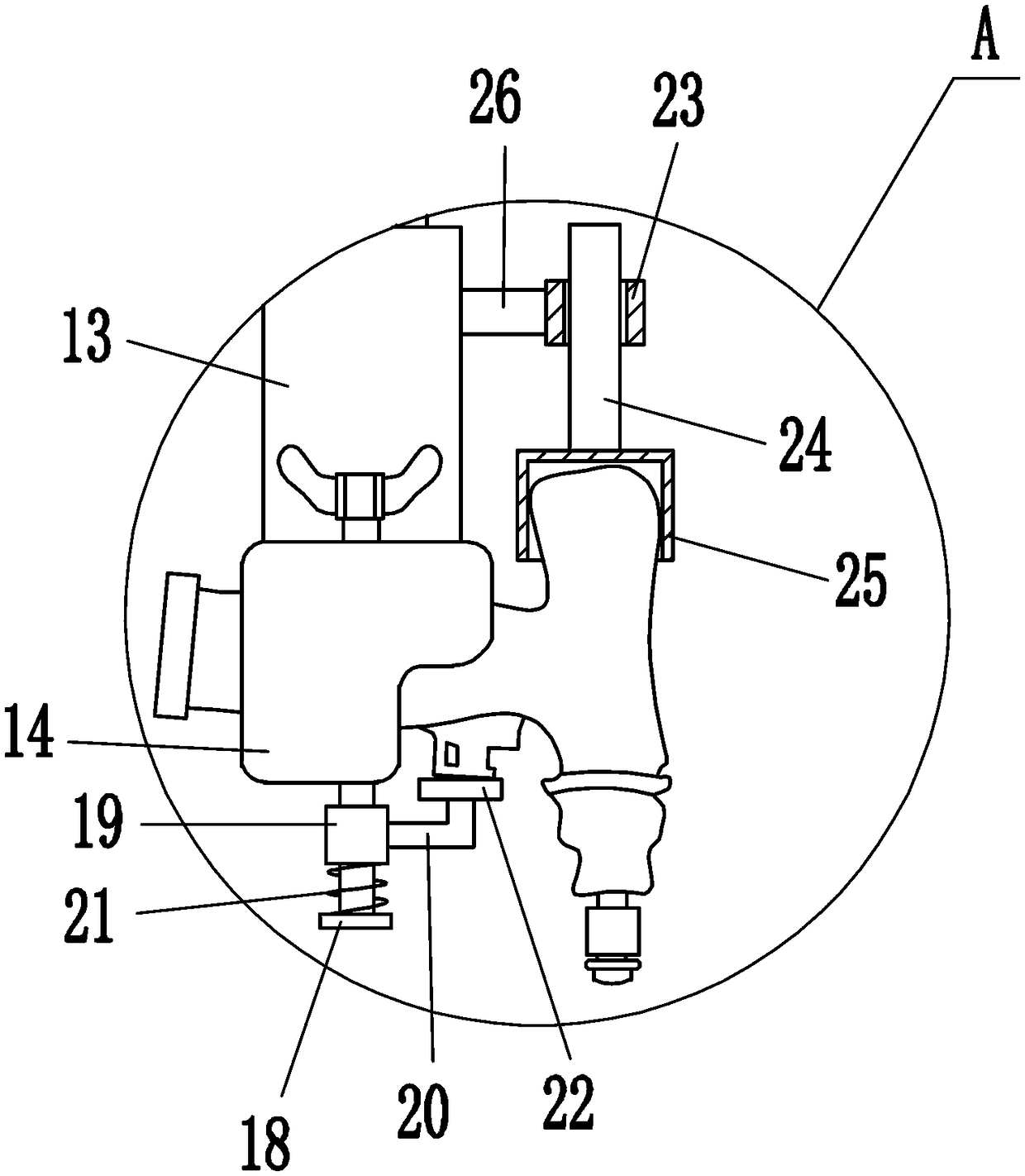

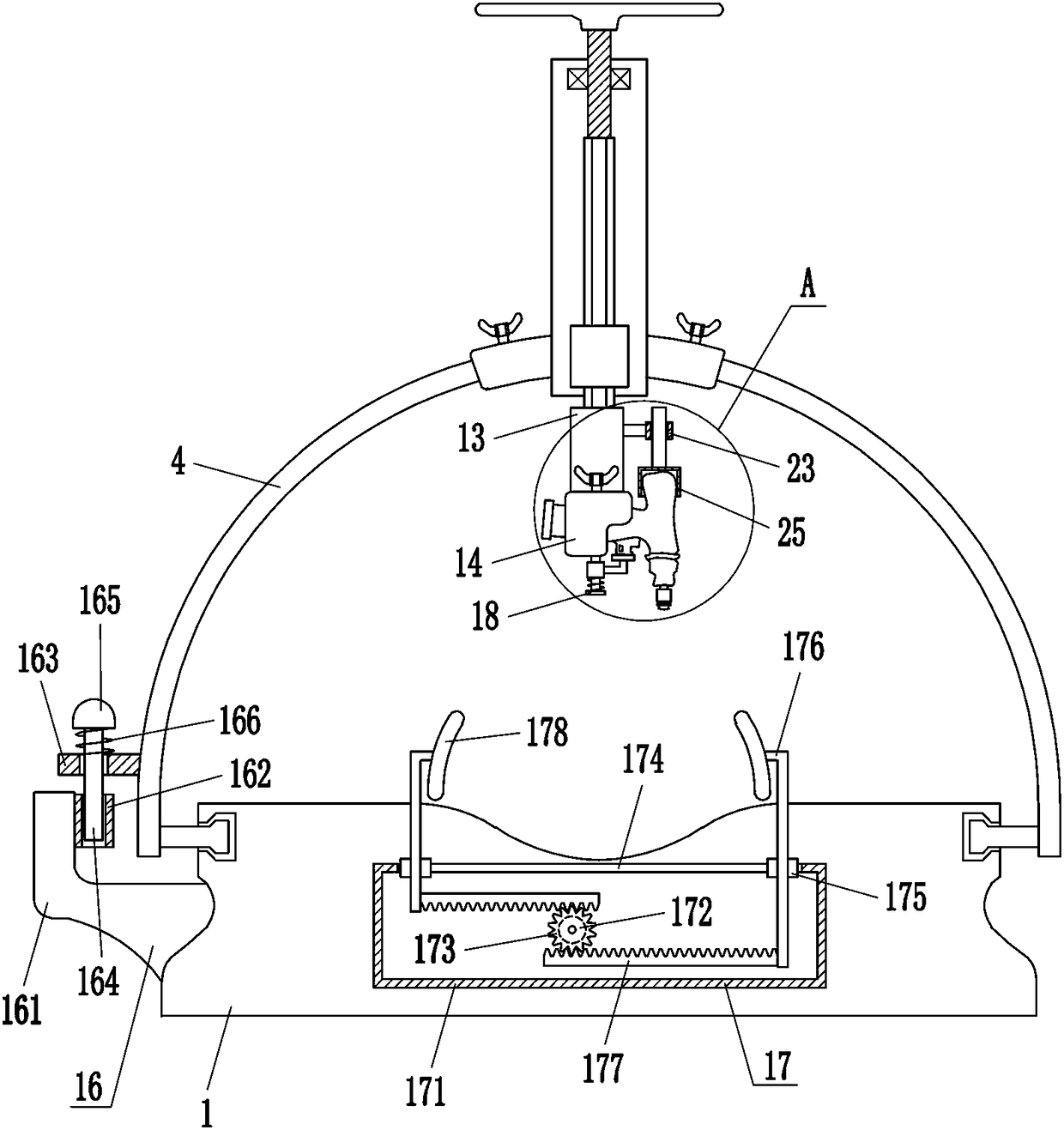

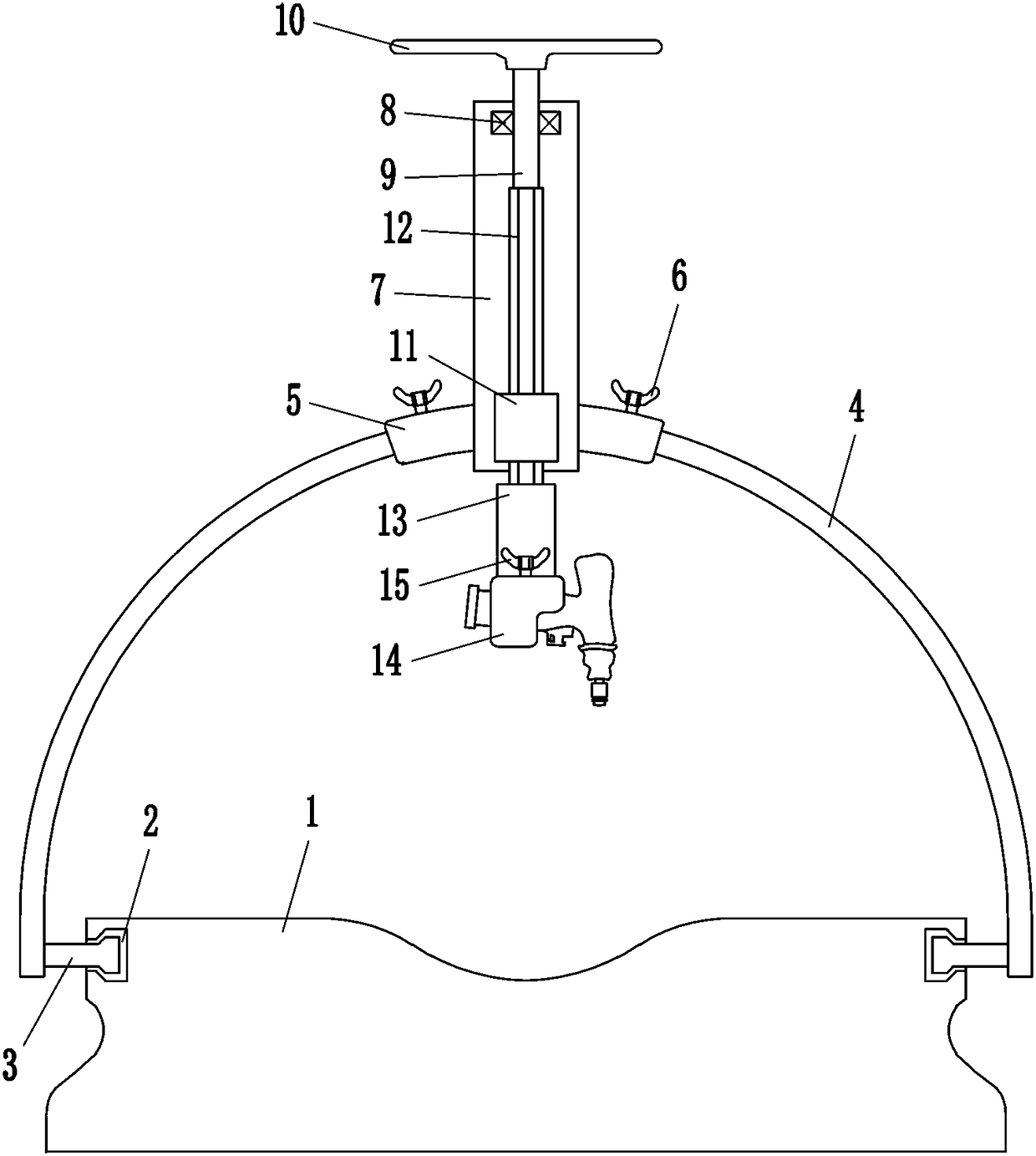

Tools and technology of radical and level drilling/well completion under ultra-short radius

Owner:BEIJING WANWEI YITONG TECHNOLOGICAL DEV

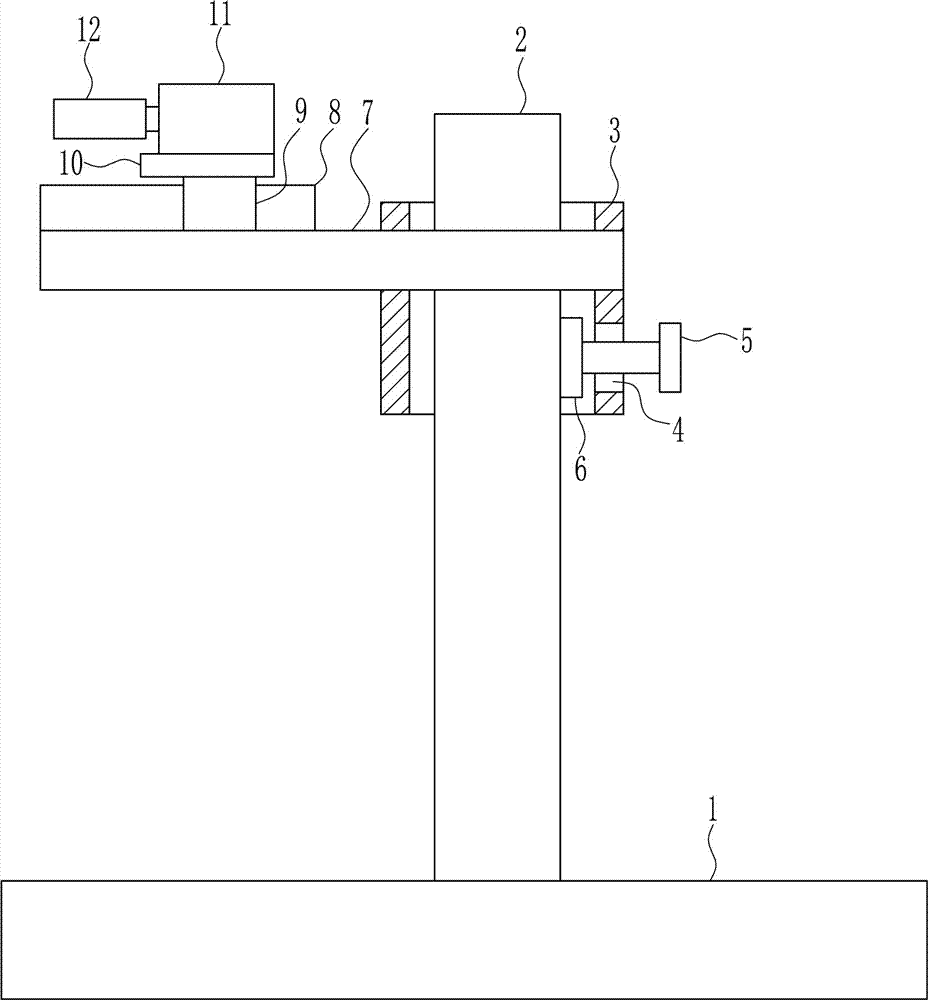

Electric drill fixing device for orthopedic department

The invention relates to a fixing device, in particular to an electric drill fixing device for the orthopedic department. The technical purpose is to provide the electric drill fixing device which isaccurate in drilling, can reduce workload of orthopedists and is for the orthopedic department. According to the technical scheme, the electric drill fixing device for the orthopedic department comprises a base, first slide blocks, an arc rod, an arc guide sleeve, first fastening bolts, a mounting plate, a bearing base, a screw, a rotary rod, a first guide sleeve, a hexagonal sleeve and the like;first slide grooves are formed in the left side and the right side of the upper portion of the base, the first slide blocks are slidably arranged in the two first slide grooves, the arc rod is connected to the outer sides of the two first slide blocks, and the arc guide sleeve is arranged on the arc rod. According to the fixing device, by screwing up a second fastening bolt, an electric drill forthe orthopedic department can be fixed, and thus drilling is more accurate; by clockwise rotating the rotary rod, the electric drill for the orthopedic department can be driven to move downwards for drilling, in this way, the orthopedists do not need to hold the electric drill for the orthopedic department by the hands for drilling, and thus the workload of the orthopedists can be reduced.

Owner:THE AFFILIATED HOSPITAL OF SHANDONG UNIV OF TCM

Upper precise drilling device for shoe manufacturing

InactiveCN106974371AImprove eye drilling accuracyExtended service lifeFasteningsDrillPetroleum engineering

The invention relates to a drilling device, in particular to a high-efficiency drilling device for uppers of shoes. The technical problem to be solved by the present invention is to provide a high-efficiency drilling device for shoe uppers for shoe manufacturing with precise drilling positions and high drilling efficiency. In order to solve the above technical problems, the present invention provides such a high-efficiency perforating device for shoe uppers for shoe manufacturing, which includes a bottom plate, a support seat, a moving mechanism, a first side plate, a second side plate, a first lifting mechanism, etc.; the support seat and The top of the bottom plate is fixed, the support platform is fixed on the top of the support seat, the moving mechanism for moving the upper of the shoe left and right is fixed on the top of the support platform, and the clamping mechanism is used to clamp the upper of the shoe to punch holes; The direction is fixed on one side of the bottom plate. The present invention adjusts the positions of the second lifting mechanism and the punching mechanism through the first lifting mechanism, punches the upper of the shoe through the second lifting mechanism and the punching mechanism, and drives the upper of the shoe to move left and right through the moving mechanism.

Owner:谢英

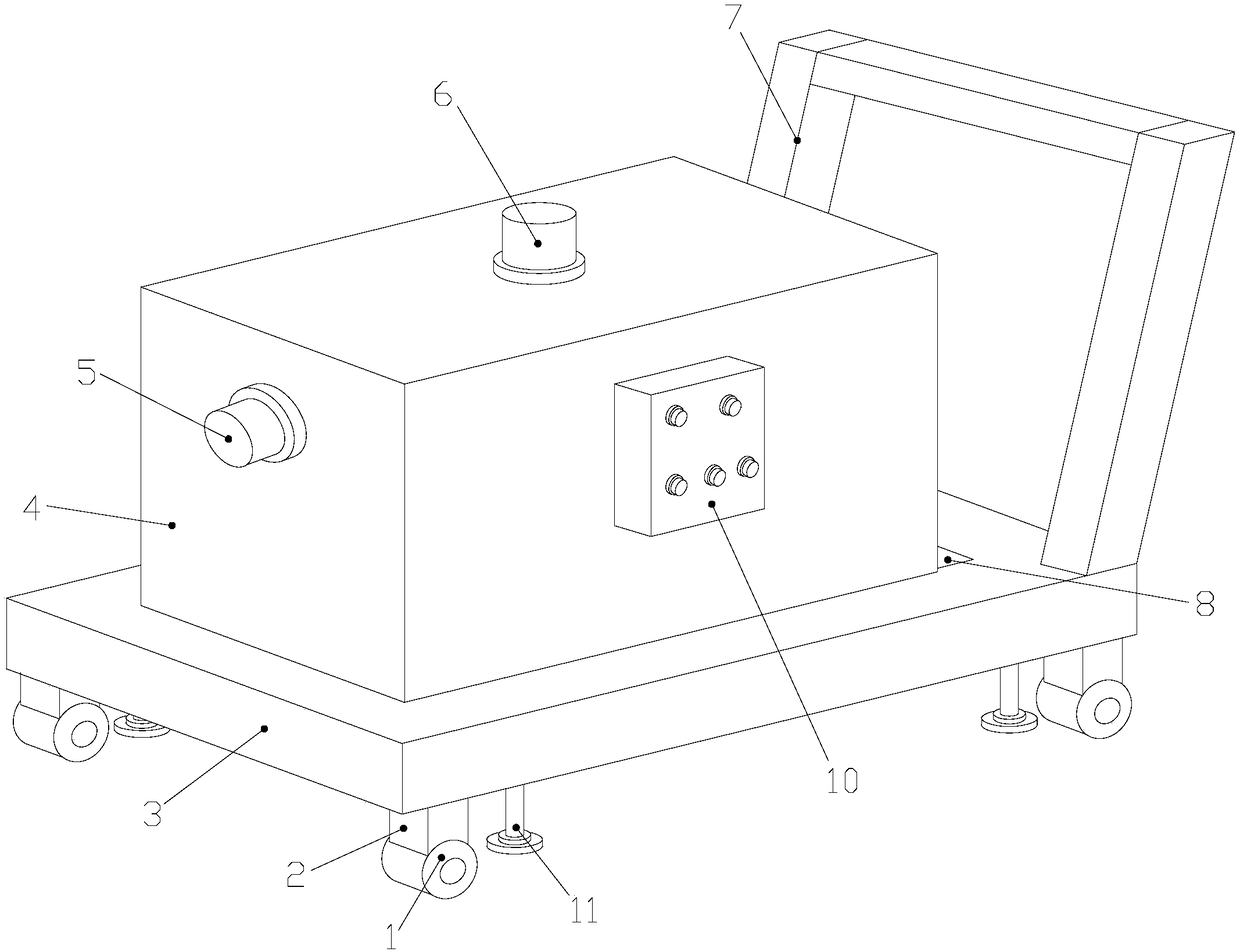

Novel traffic engineering road drilling machine

PendingCN108374638APrecise drillingAvoid punching deviationsDrilling rodsConstructionsElectric machineryOperation mode

The invention discloses a novel traffic engineering road drilling machine which structurally comprises movable wheels, supporting legs, a base, a shell, a first motor, a second motor, a handle, a square groove, a drilling mechanism, a control cabinet and lifting leg cups. The movable wheels are matched with the bottoms of the supporting legs, the tops of the supporting legs are vertically welded at the bottom of the base, the supporting legs are perpendicularly arranged at four corners of the bottom of the base, and the square groove is formed in the middle of the base. According to the structure of the drilling machine, a positioning plate is mounted at the bottom of the shell, a positioning hole is formed in the positioning plate and aligned to a portion needing to be drilled before a hole is drilled, a motor is started to drive a spiral drilling rod to rotate, a drilling bit on the spiral drilling rod is aligned to the positioning hole to drill, the hole is accurately drilled by theaid of an operation mode, drilling deviation is avoided, and working efficiency is improved.

Owner:曾淑敏

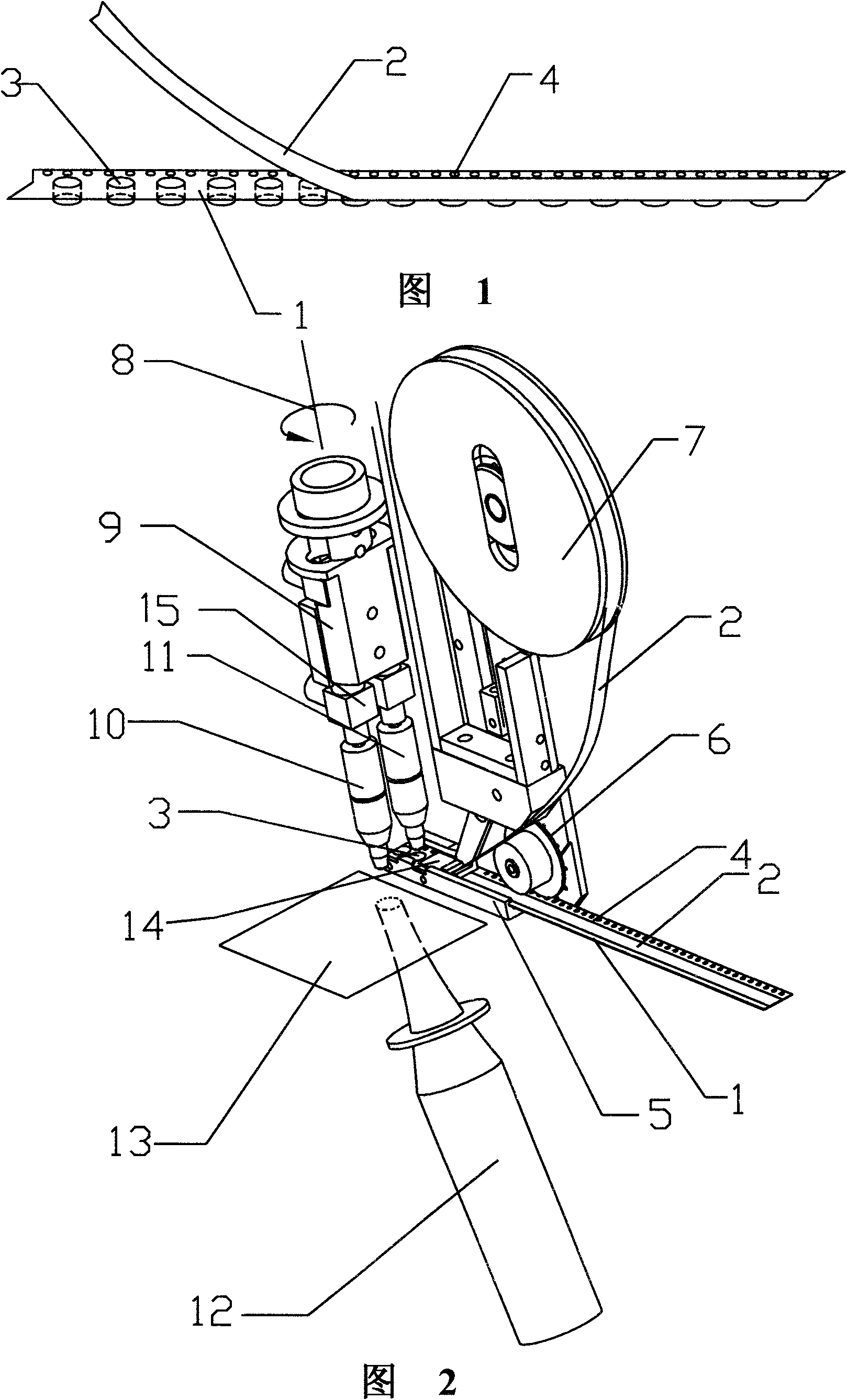

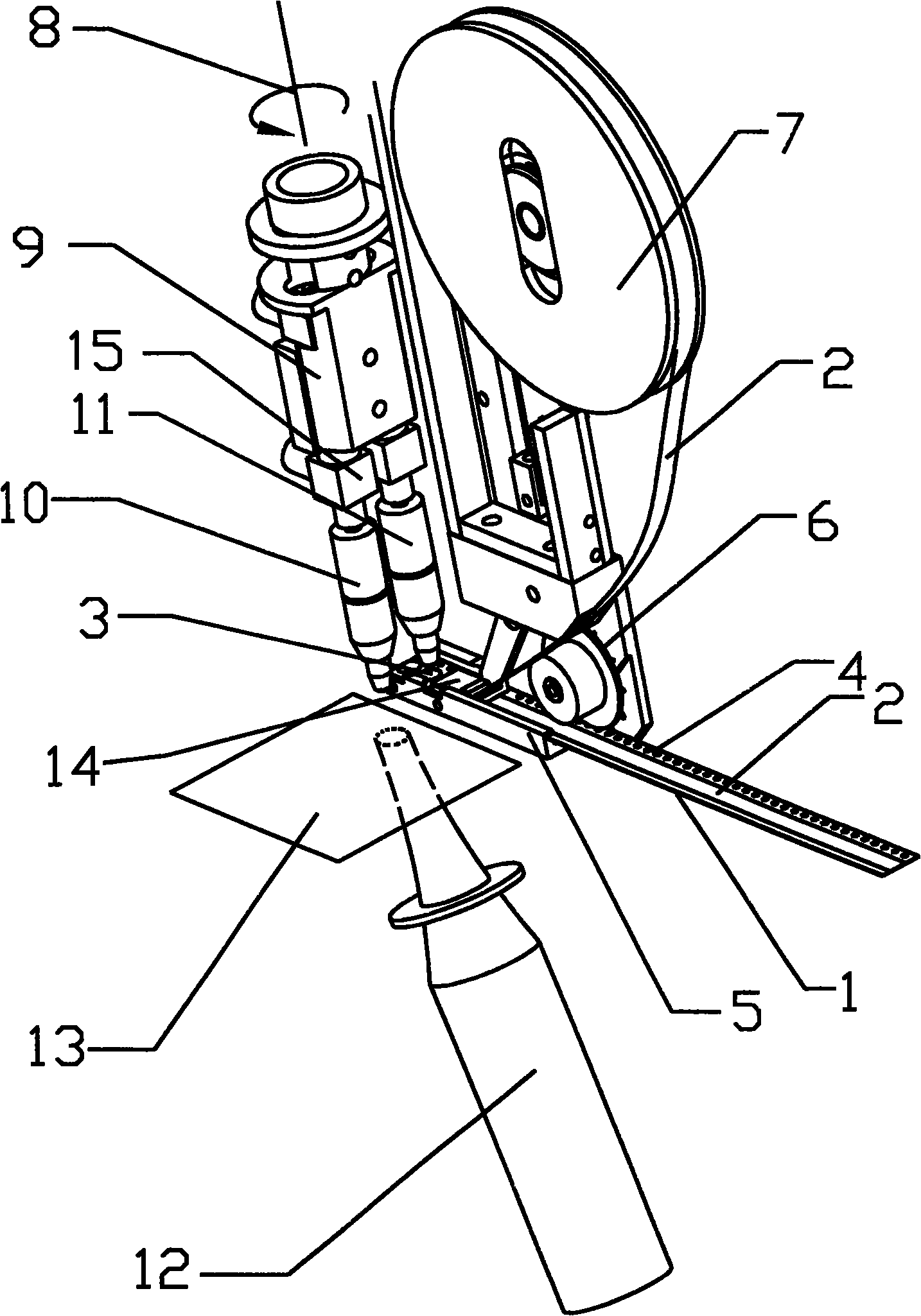

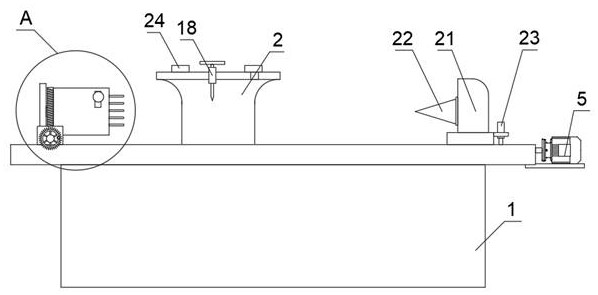

Carrier tape for rhinestone machine and rhinestone method applying same

The invention relates to a carrier tape for a rhinestone machine and a rhinestone method applying the same. The invention is characterized in that the carrier tape (1) is band-shaped and is covered with a covering tape (2); grooves (3) for loading rhinestones are arranged on the carrier tape (1) at equal intervals; rhinestones with bottom down are loaded in the grooves (3); ratchet wheel holes (4) are arranged at one side of the carrier tape (1) close to edges at equal intervals; and when the covering tape (2) can be adhered to the carrier tape (1), the notches of the grooves (3) are covered completely after adhesion. The rhinestone method applying the carrier tape comprises the steps of: putting the rhinestones in the grooves (3) on the carrier tape (1) by using a special machine; installing the rhinestone carrier tape; starting the rhinestone machine; actuating a rhinestone suction machine (9) alternately; and melting thermosol at the bottoms of the rhinestones by using an ultrasonic generator (12), and the like. When in use, the invention ensures accurate rhinestone picking, fast rhinestone processing speed and high stability and is suitable to a multi-head rhinestone machine; in addition, because of small space, rhinestone switching among different specifications or colors can be realized on each head of the multi-head rhinestone machine.

Owner:WUHAN NORTH PHENIX JIAMEI COMPIZED EMBROIDERYMACHINE MFG

Novel wall drilling equipment for construction site

ActiveCN106891446APrecise drillingReduce riskWorking accessoriesStone-like material working toolsDrill holeDrill bit

The invention relates to drilling equipment, in particular to novel wall drilling equipment for a construction site. The novel wall drilling equipment for the construction site is provided for achieving the technical effects that the equipment can conduct accurate drilling, damage is small in the drilling process, and time and labor are saved in the drilling process. In order to achieve the technical effects, the novel wall drilling equipment for the construction site, provided by the invention, comprises a bottom plate, a first guide rail, a first guide sleeve, a screw rod, a pressing block, a supporting plate, a first slide rail and the like. The first guide rail is mounted in the middle of the upper side of the bottom plate in a welded mode. The first guide sleeve is connected to the first guide rail in a sliding mode. A threaded hole is formed in the lower portion of the right side of the first guide sleeve. The screw rod is arranged in the threaded hole. The novel wall drilling equipment for the construction site achieves the effects that the equipment can conduct accurate drilling, danger is small in the drilling process, and time and labor are saved in the drilling process. The novel wall drilling equipment for the construction site can move a drill bit automatically by adopting a rotating device and a feeding device.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD +2

Clamping and positioning device for steel pipe punching

InactiveCN112405056APrecise drillingMeet different needsPositioning apparatusMetal-working holdersPunchingClassical mechanics

The invention relates to a clamping and positioning device for steel pipe punching. The clamping and positioning device comprises a workbench and further comprises a movable base, a T-shaped groove isformed in the upper surface of the workbench, a sliding block is slidably connected into the T-shaped groove, a threaded hole is formed in the side wall of the sliding block, and the upper surface ofthe sliding block is fixedly connected with the movable base; and one side of the workbench is fixedly connected with a first servo motor. The clamping and positioning device for steel pipe punchingrelates to the technical field of steel pipe machining equipment; the movable base is arranged to be matched with a screw rod and the first servo motor, punching equipment such as a bench drill is installed on the movable base and can be matched with the clamping and positioning device to punch a steel plate, and the first servo motor is used for driving the punching equipment to move, so that punching operation can be accurately conducted on the side wall of a steel pipe; and a steering mechanism is arranged, and a hand wheel can be used for driving a worm wheel to rotate, so that a clampingdevice drives the steel pipe to rotate, and punching is conducted at different positions of the side wall of the steel pipe.

Owner:潍坊维润金属科技有限公司

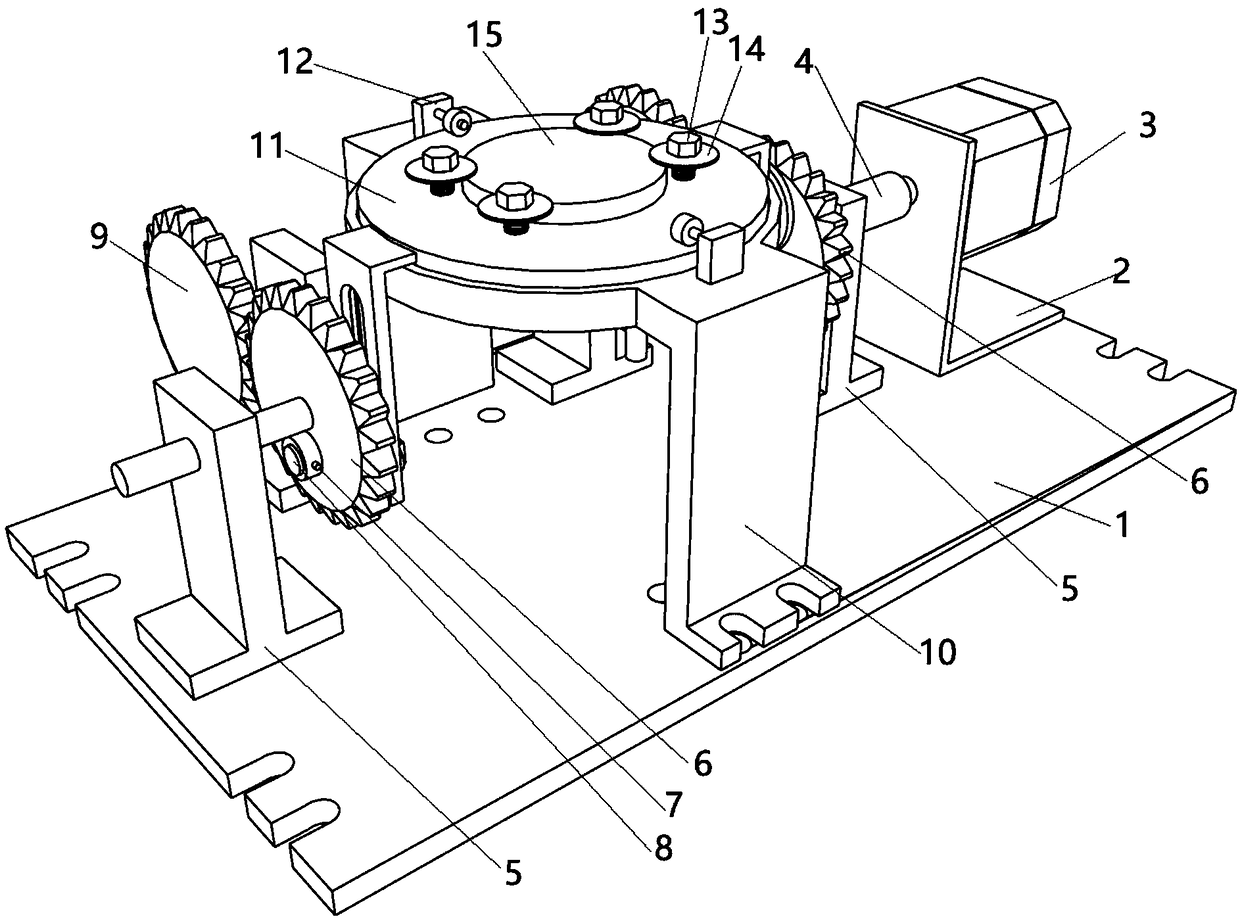

Mechanical torsional vibration table based on double-eccentric-wheel module

ActiveCN109333652ASimple structureEasy to operateMetal working apparatusElectric machineryTorsional vibration

The invention provides a mechanical torsional vibration table based on a double-eccentric-wheel module. The mechanical torsional vibrator comprises a torsional vibration table surface and two eccentric wheel assemblies. The two eccentric wheel assemblies are respectively located on two sides of the torsional vibration table surface, and are connected with the torsional vibration table surface. Thetwo eccentric wheel assemblies apply homodromous torque to the torsional vibration table surface, and the torque changes in a sinusoidal mode. Torsional vibration with adjustable amplitude and frequency can be superposed to a workpiece in the hole drilling and hole expanding process. The structure is simple, and operation is easy. The mechanical torsional vibration table is suitable for vibrationassisted drilling machining technology. The torsional vibration effect is good, and therefore hole drilling and hole expanding are more accurate. Independent amplitude and frequency adjusting is achieved. The frequency can be adjusted by adjusting the rotating speed of a driving serve motor. The amplitude can be adjusted by adjusting the angle of eccentric subwheels. Convenience, rapidness and stability are achieved.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com