Carrier tape for rhinestone machine and rhinestone method applying same

A technology of ironing machine and carrier tape, which is applied in application, textile decoration, clothing, etc. It can solve the problems of not being able to fully guarantee the bonding of ironing drills, difficulty in working with multiple heads at the same time, and taking up a large space, so as to achieve correct direction and accurate drilling. , the effect of running fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

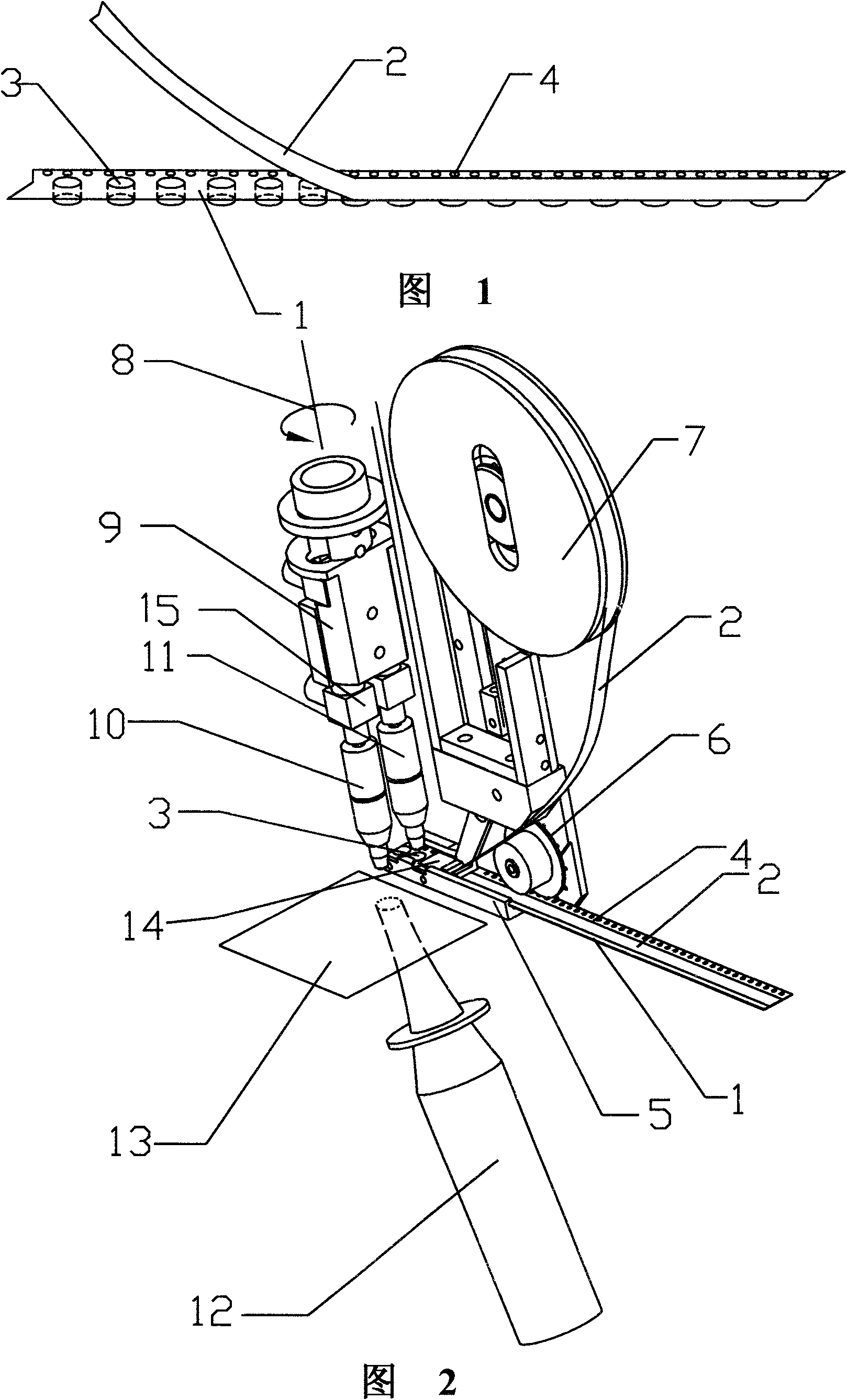

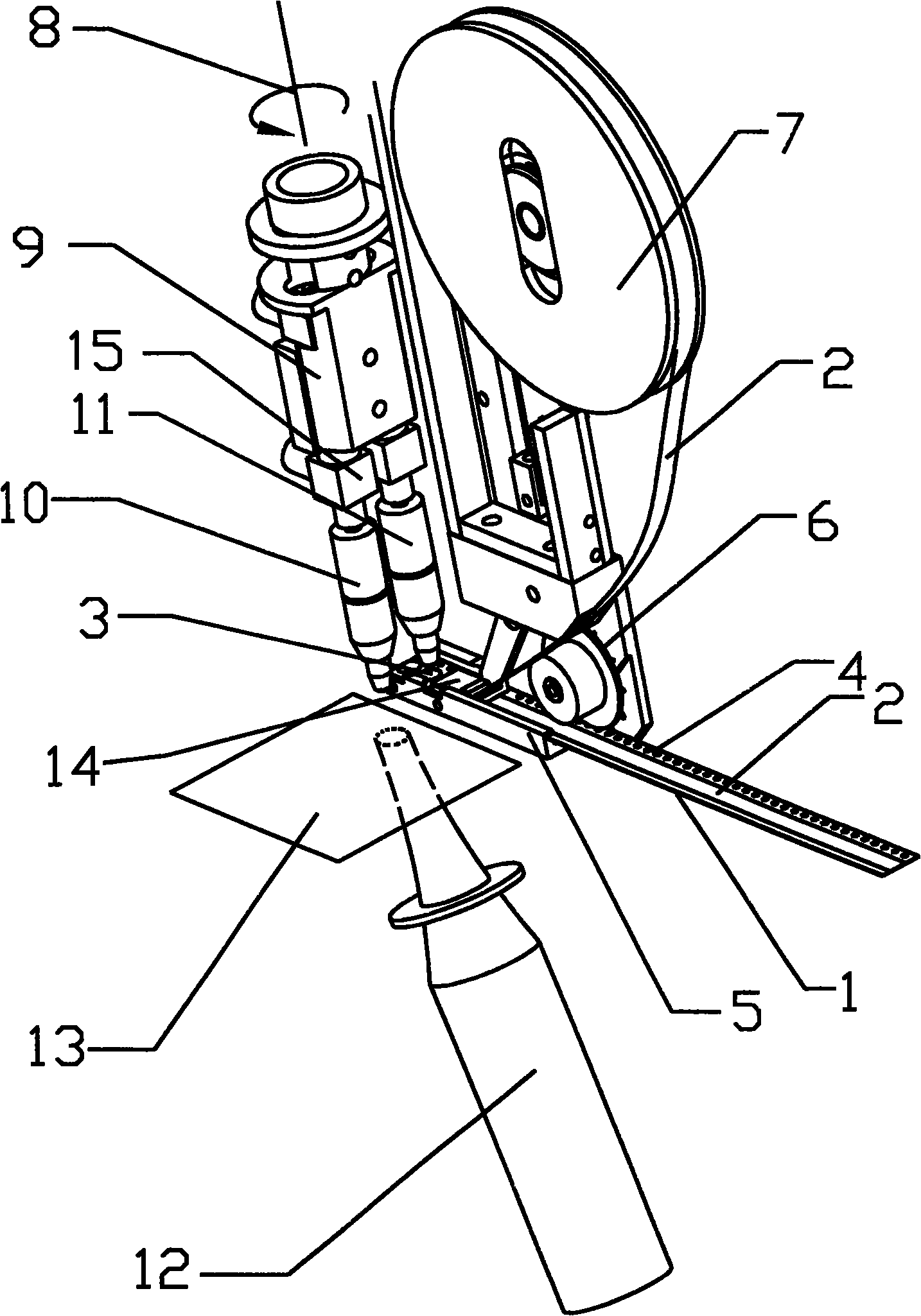

[0022] The present invention will be further described below in conjunction with accompanying drawing. figure 1 Among them, the carrier tape 1 used on the hot drill machine is in the shape of a belt, covered with a cover tape 2; on the carrier tape 1, grooves 3 for loading hot drills are equidistantly arranged, and the grooves 3 are equipped with bottom facing downwards. Hot-drilling, equidistant ratchet holes 4 are provided on one side of the carrier tape 1 close to the edge; the cover tape 2 has two forms of hot-melt bonding and self-adhesive, the two edges of the cover tape 2 can be bonded to the carrier tape 1, and the bonding The notch of rear groove 3 is completely covered, and simultaneously guarantees that cover tape 2 does not adhere to hot drilling.

[0023] figure 1 , 2 In the method of using the carrier tape for hot drilling, the hot drilling steps are:

[0024] (1) Put the ironing drill into the groove 3 on the carrier tape 1 with a special machine, with the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com