Synchronous adjustable multiple shaft machine

A technology of a multi-axis device and an adjusting cylinder, which is applied in the field of multi-axis devices, can solve the problems of troublesome adjustment, inability to adjust the hole distance, no linkage mechanism, etc., and achieve the effect of accurate drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

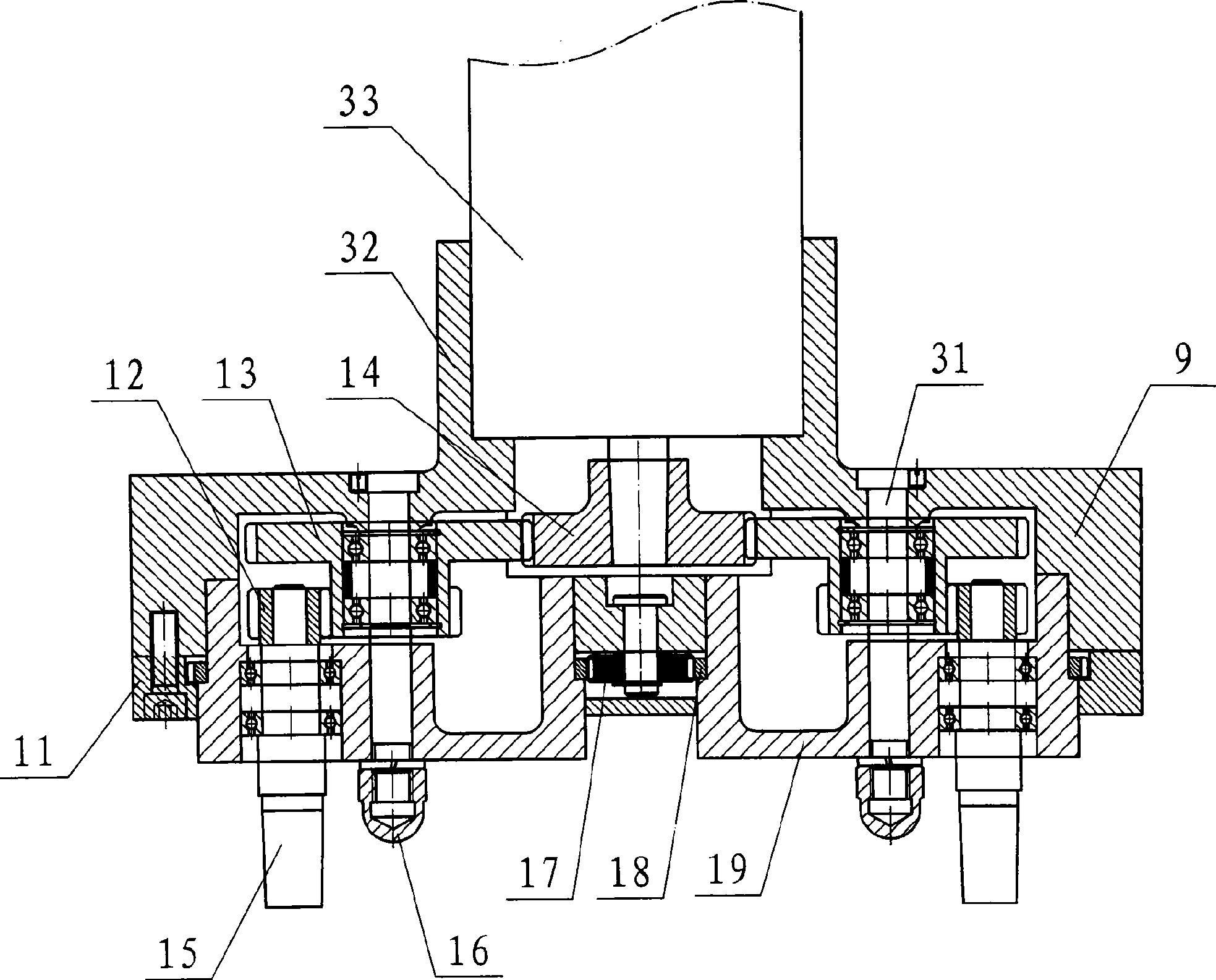

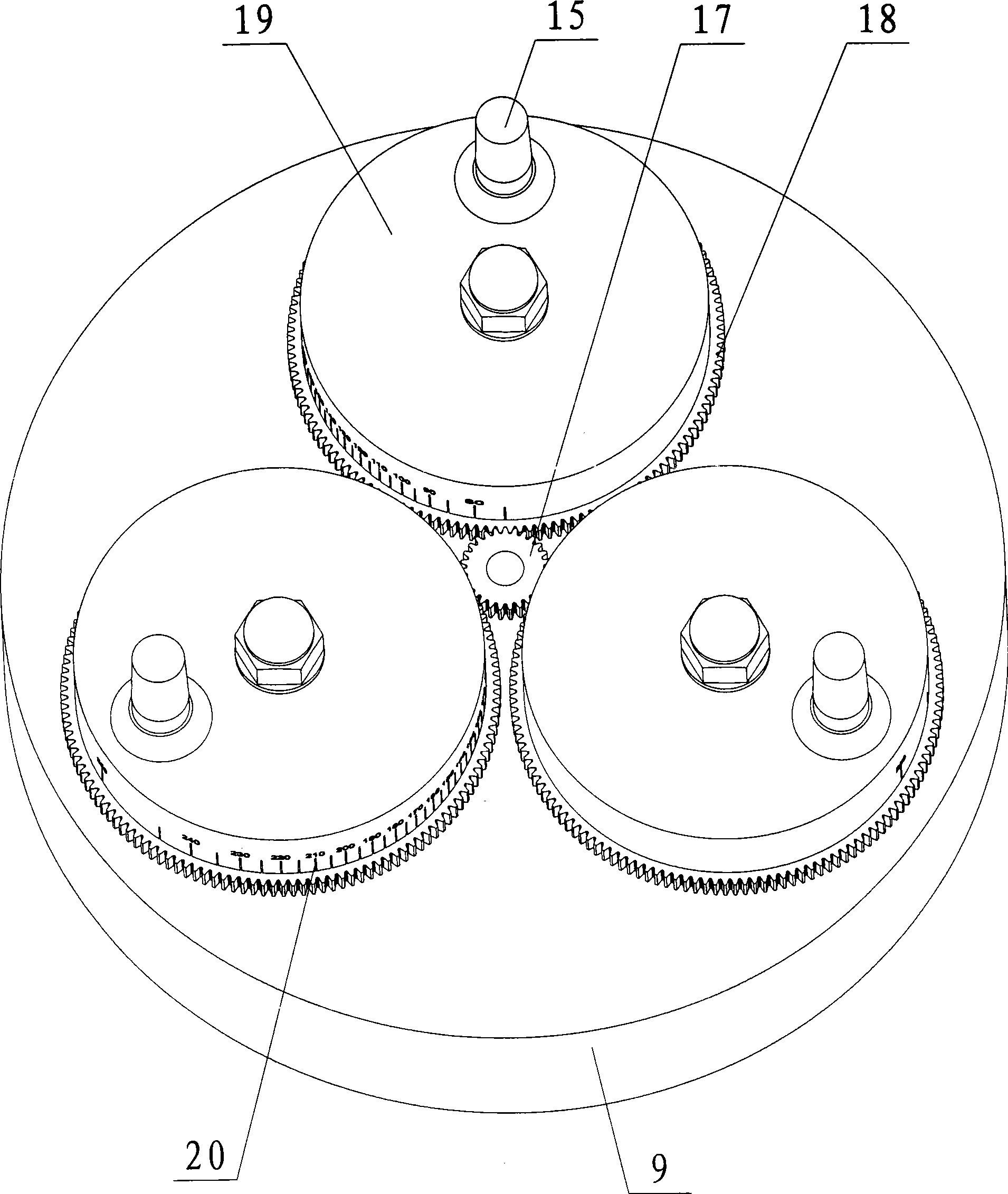

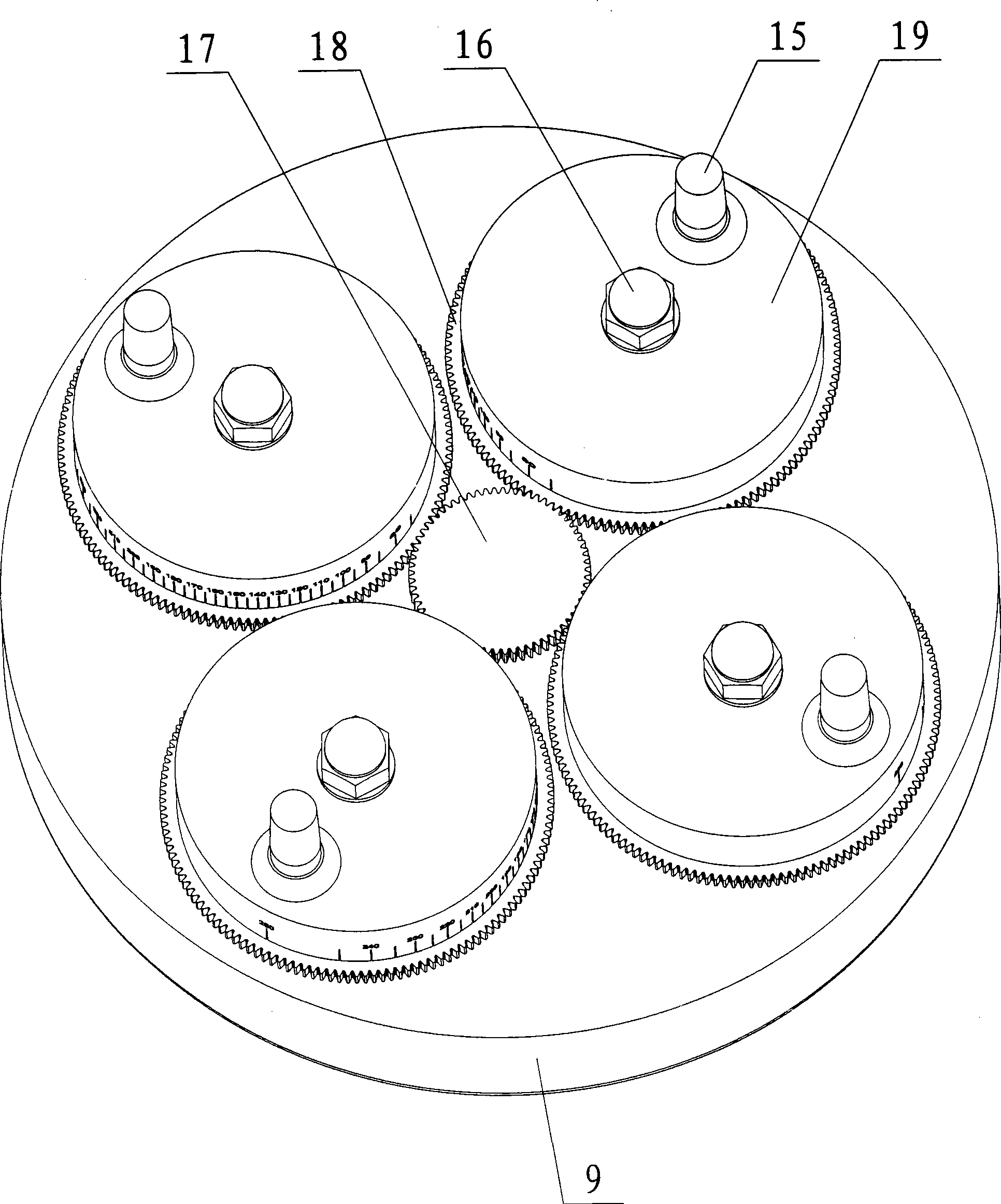

[0021] The embodiment of the synchronously adjustable multi-axis device of the present invention is designed for the drilling of casings of small and medium-sized motors, end covers and workpieces with evenly distributed holes. The synchronously adjustable multi-axis device is composed of a multi-axis device housing (9), an adjustment cylinder (19), a drill rod (15), a lock nut (16), a transmission gear, a synchronous adjustment mechanism, etc., and the multi-axis device housing The end of body (9) can be shaped on connecting sleeve (32), and connecting sleeve (32) is connected with drilling machine elevating shaft (33), and the drilling rod of driving gear (14) and drilling machine is connected. The multi-axis device has a plurality of adjustment cylinders (19), and transition gears (13) are housed in the adjustment cylinders (19), and the transition gears (13) can be made into double-linked gears to adjust the rotating speed of the drill pipe (15). (13) One side meshes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com