Clamping and positioning device for steel pipe punching

A technology of clamping positioning and positioning device, applied in positioning device, clamping, boring/drilling, etc., can solve problems such as deviation of drill bit, damage to steel pipe and drill bit, deformation of steel pipe, etc., to achieve convenient processing , avoid offset, improve the effect of punching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

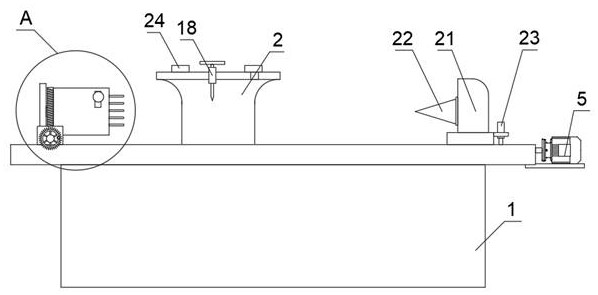

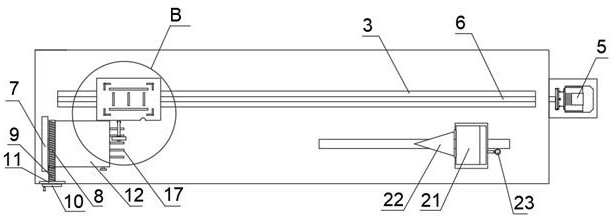

[0034] see Figure 1-9 , a clamping and positioning device for steel pipe drilling, including a workbench 1, and also includes:

[0035] The mobile seat 2, the upper surface of the workbench 1 is provided with a T-shaped slot 3, and a slide block 4 is slidably connected in the T-shaped slot 3, the side wall of the slide block 4 is provided with a threaded hole, and the slide block 4 The upper surface is fixedly connected with the moving seat 2, and one side of the workbench 1 is fixedly connected with a first servo motor 5, and the output end of the first servo motor 5 is fixedly connected with a screw rod 6, and the screw rod 6 runs through the working The side wall of the table 1 extends into the T-shaped slot 3 and is set, and the screw rod 6 is screwed to the threaded hole, and a positioning device 18 is fixedly connected to one side of the moving base 2 .

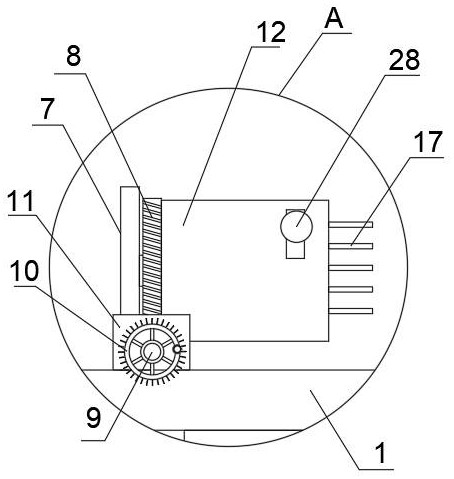

[0036] Steering mechanism, the steering mechanism includes a support plate 7, the side wall of the support plate 7 ...

Embodiment 2

[0044] Based on Example 1, such as Figure 10 , the positioning device 18 includes a connecting rod 187, the connecting rod 187 is slidingly connected to the moving base 2, and the end of the connecting rod 187 away from the moving base 2 is fixedly connected to a bearing 188, and a positioning ring is placed on the bearing 188 189. When drilling, first select positioning rings 189 with different inner diameters according to the outer diameter of the drilling bit and put them in the center of the bearing 188, then slide the connecting rod 187 up and down to make the lower surface of the bearing 188 offset against the upper surface of the steel pipe , then when punching, the drill bit of the drilling equipment passes through the positioning ring 189, thereby avoiding the offset when the drill bit contacts the arc surface of the steel pipe, improving the stability of the drill bit, and by setting the bearing 188, the positioning ring 189 and the drilling bit can be lowered. and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com