Circuit board automatic drilling machine

A drilling machine and circuit board technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problem of unbearable high-priced drilling equipment, inaccurate manual positioning, and the efficiency of drilling low cost, low cost, simple structure and fast drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

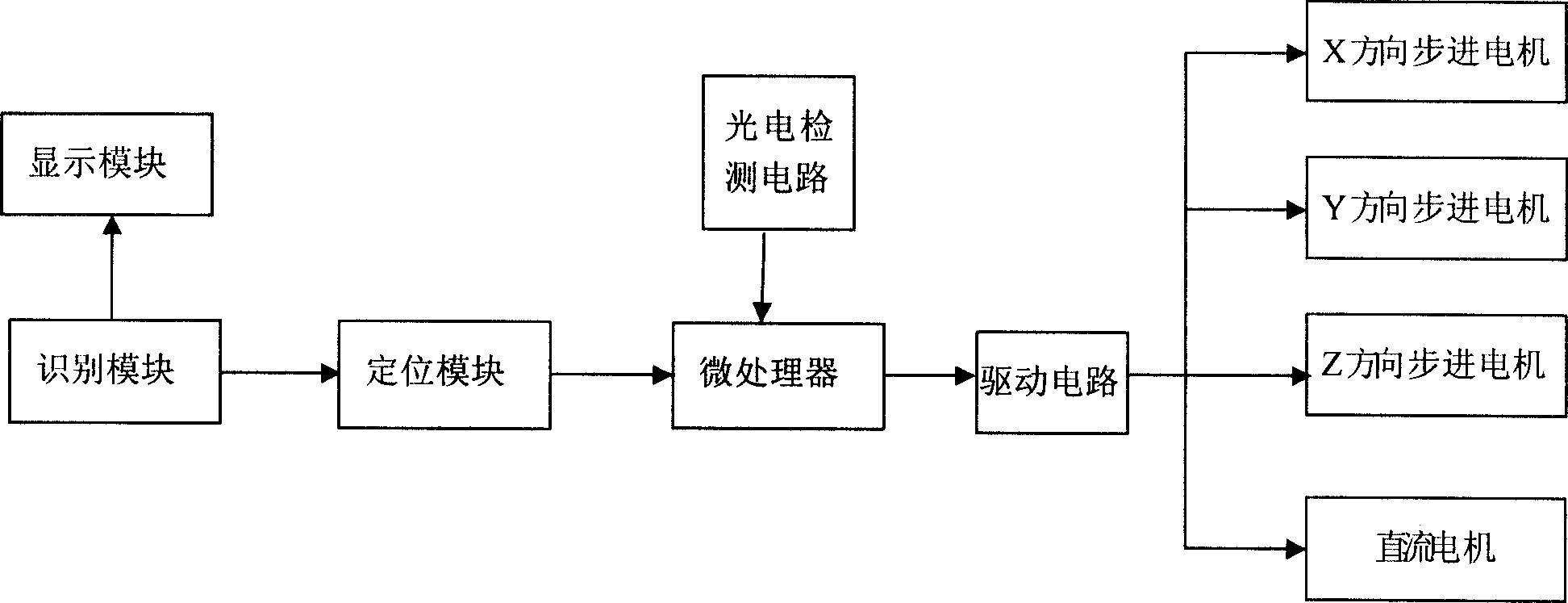

[0012] Such as figure 1 as shown, figure 1 It is a structural diagram of the control part of the present invention, the identification module is connected with the display module, the storage module, and the positioning module respectively, and the identification module reads and identifies the PCB file, on the one hand, obtains and processes the PCB file circuit and drilling data, and processes the processed circuit and the drilling data are displayed by the display module; on the other hand, the data related to the hole is obtained from the PCB file and sent to the positioning module. The positioning module processes the relevant data of the hole, obtains the drilling data of the hole, and sends it to the micro The processor and the microprocessor respectively control the driving circuit according to the drilling data of the hole, and drive the DC motor, the x-axis stepping motor, and the z-axis stepping motor to complete the drilling work. The photoelectric detection circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com