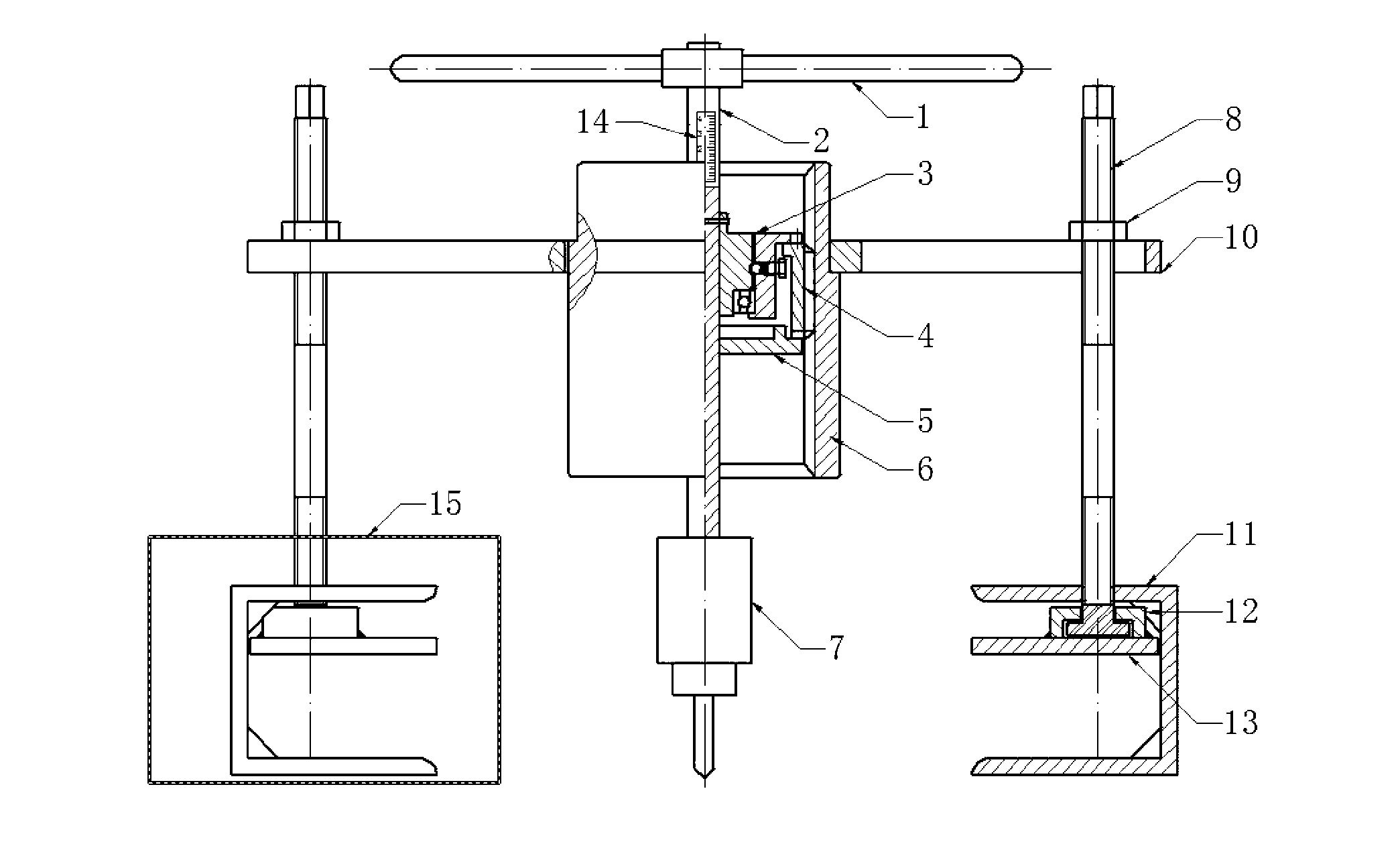

Manual multi-purpose drilling device

A drilling device and multi-purpose technology, applied in the direction of drilling/drilling equipment, portable drilling machine, boring machine/drilling machine components, etc., can solve the problem of different workpiece clamping, inability to realize drilling, large pressing force, etc. problem, to achieve the effect of precise drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

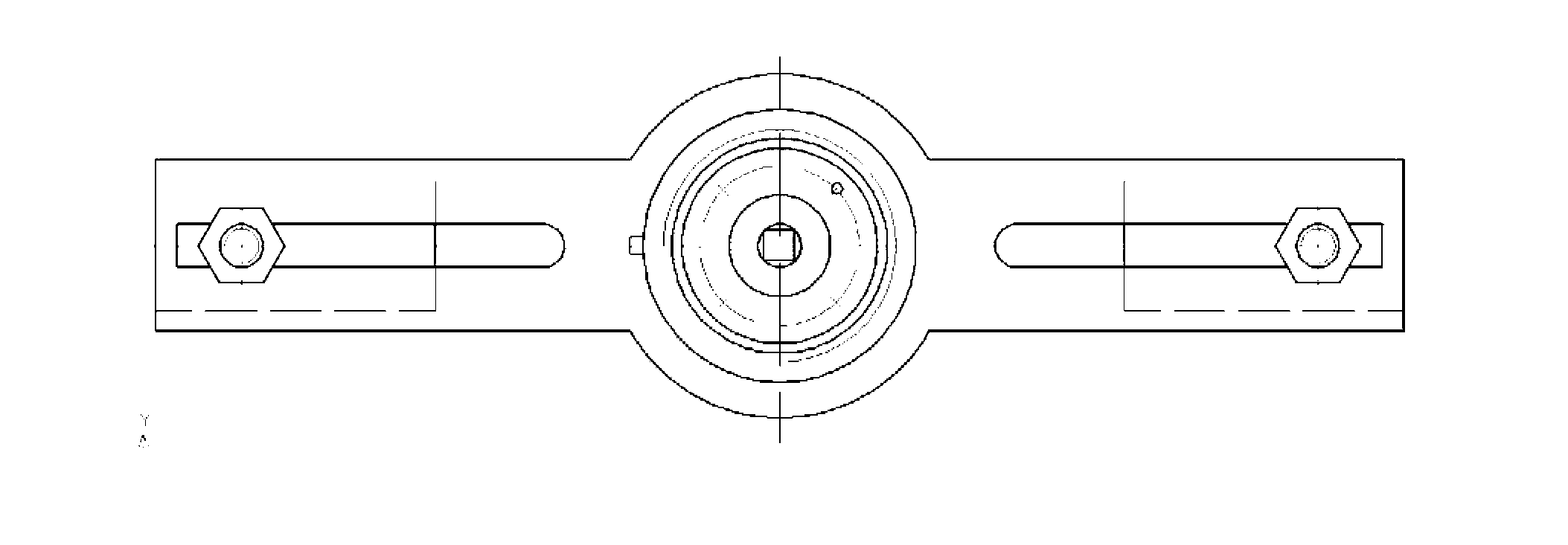

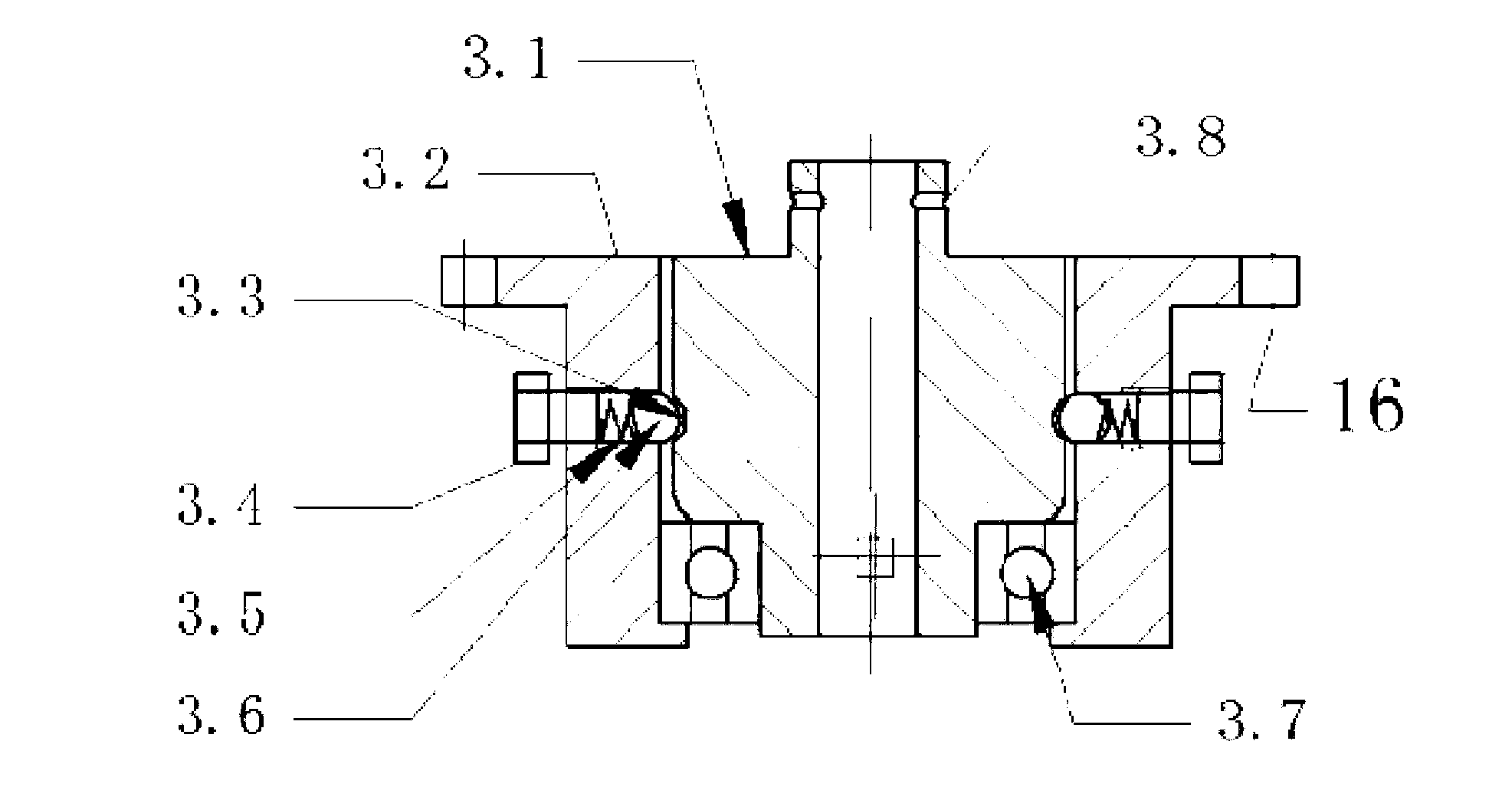

[0035] Drill a piece of material into a No. 45 steel plate with a length of 1000 mm, a width of 250 mm, and a thickness of 10 mm. Before operation, first clamp the 8mm machine drill bit, and reset the scale mark 14 on the drill rod to zero, and then adjust the nut 9 so that when the drill bit is on the upper surface of the steel plate, the clamping frame 15 can just hold it from the side Steel plate, then the handle 1 is loaded onto the upper end of the double-ended screw rod 8, and the handle 1 is turned so that the movable splint 13 tightens the steel plate. Then the handle 1 is moved to the upper end of the drill rod 2, and the handle 1 is rotated to start the drilling operation until the end. The whole process takes about 5 minutes from preparation to completion. In order to drill other holes along the same line as the first hole on the board, just reverse the handle 1 to move the drill bit 8 out of the first hole, and then move the bracket 10 so that the double-ended scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com