Arrangement for forming band loop and process and apparatus for producing tear-open lids

A technology of configuring units and belt rings, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of high cost and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

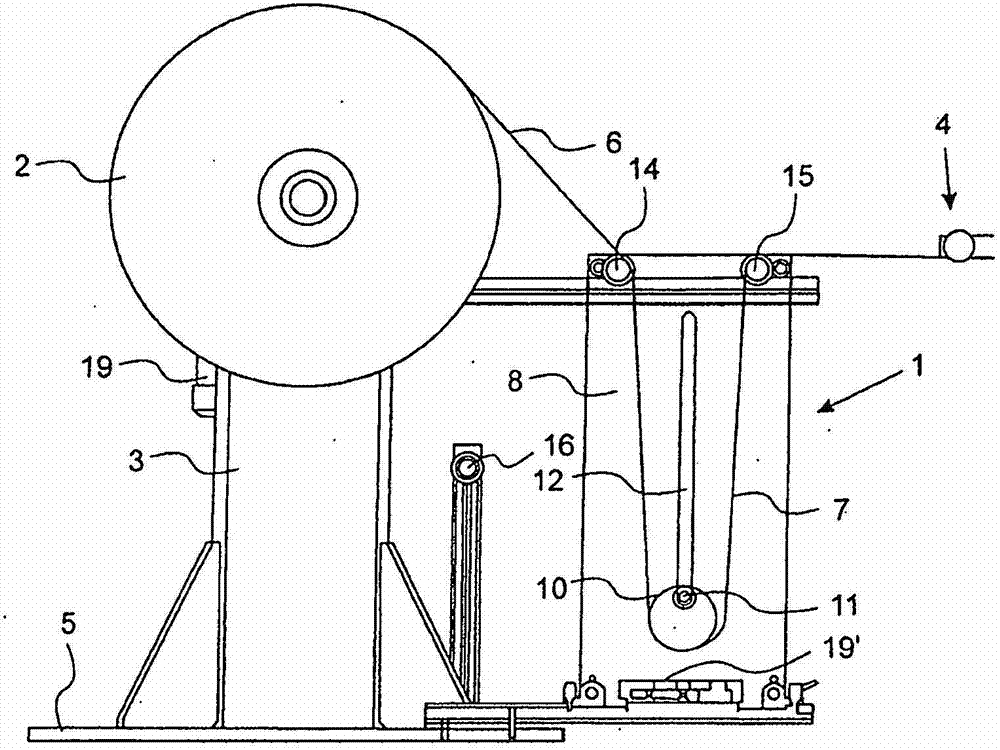

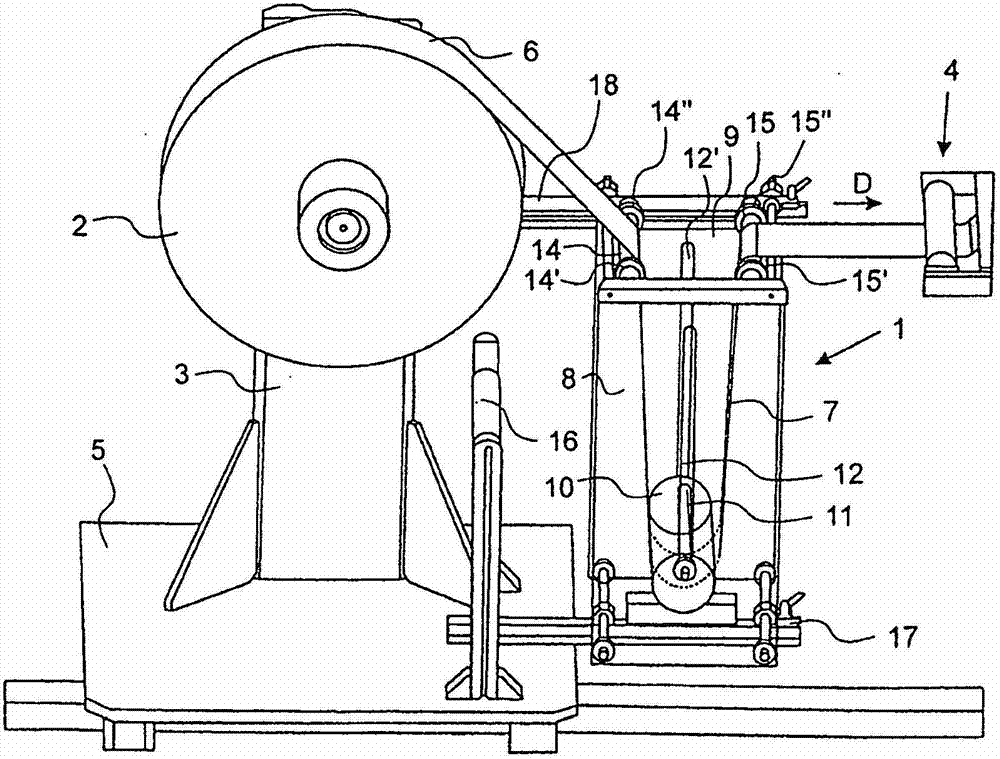

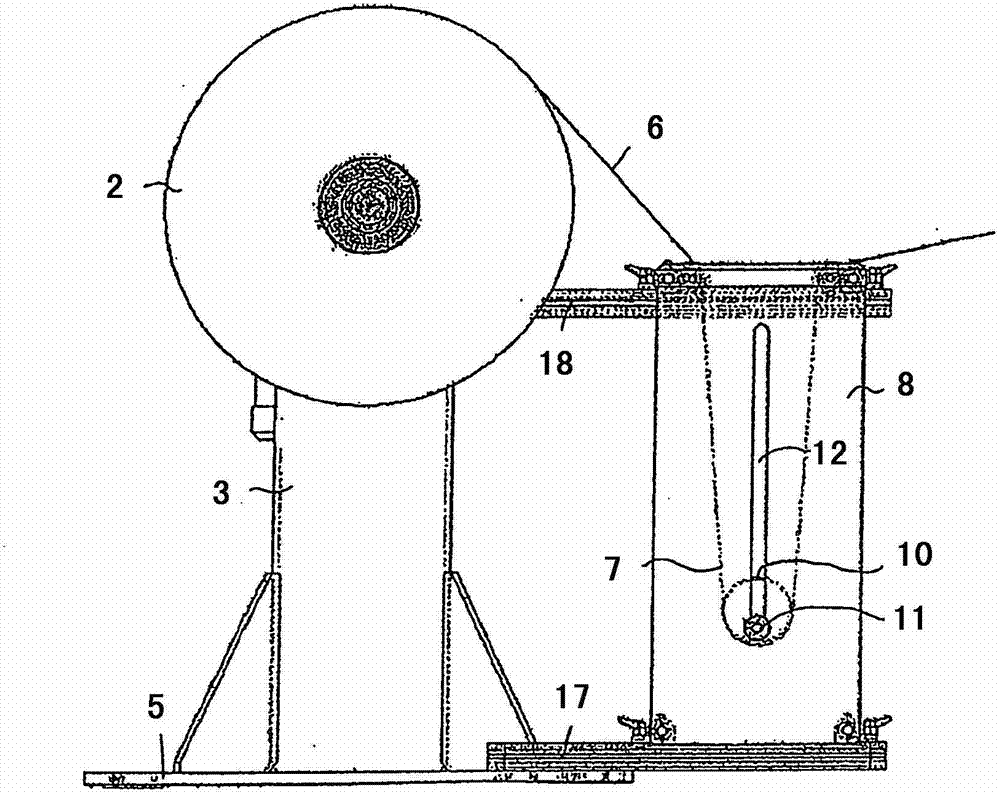

[0019] Figures 1 to 4 Shown is an embodiment of a configuration unit 1 according to the invention. The configuration unit is provided and designed to form a belt loop 7 in the belt 6 . The tape 6 is driven to unwind from the stock tape reel 2 and then into the deployment unit 1 . After this configuration unit, the strip is conveyed by a drawing device 4 belonging to the equipment for applying or processing the strip. Examples of such devices are described below. The belt running direction D is obtained from the belt transport shown. The unwinding from the supply reel generally takes place at a constant speed or can be adapted only relatively slowly by the drive 19 to the rapid speed change of the drawer 4 . In particular, the pulling device 4 can pull the tape step by step with variable pulling lengths. By forming the loop as a band material reserve which can be easily drawn, the configuration unit 1 has the purpose here of compensating for drawing fluctuations in speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com