Setups modus of short-circuit-proof spiral baffle plate shell-and-tube heat exchanger draw rod

A technology of shell-and-tube heat exchangers and spiral baffles, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., and can solve the problems affecting the heat exchange efficiency of equipment and the number of tie rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

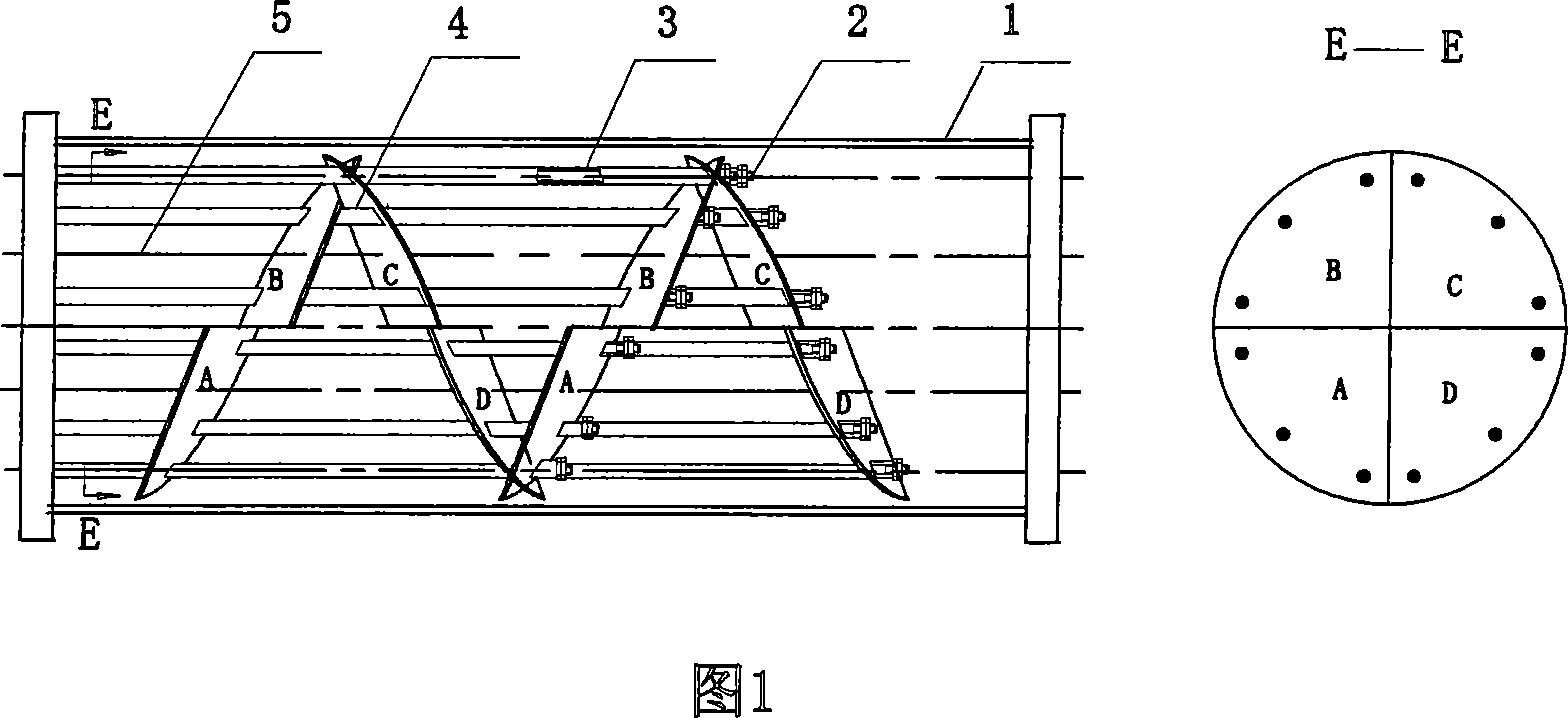

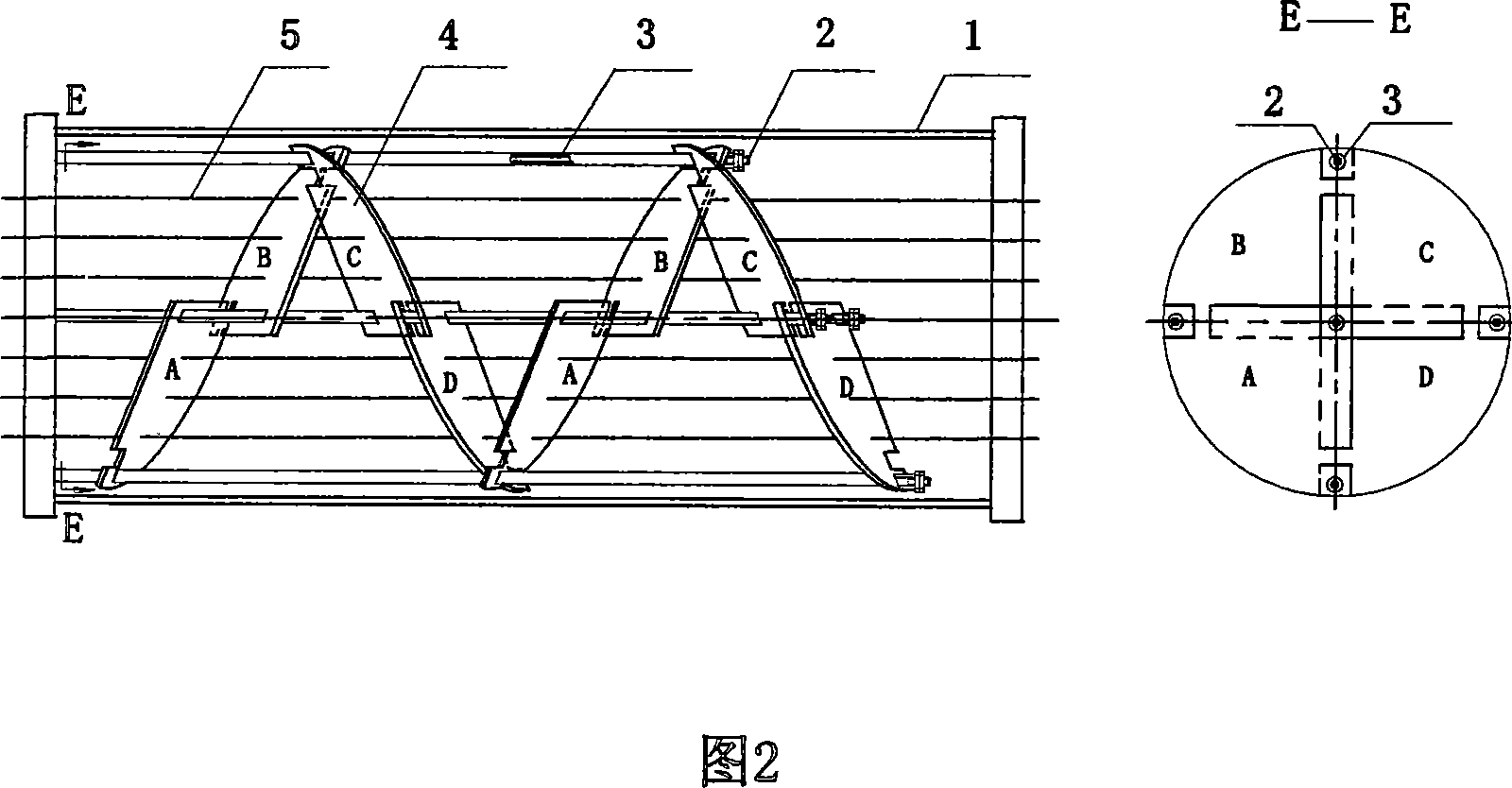

[0006] A pitch of the helical propulsion of the shell channel is composed of four fan-shaped baffles with the same number of quadrants, and the straight side of each baffle is increased by 10mm to 100mm in width, and the widening width depends on the diameter of the equipment and the angle of the baffles. When assembling, the widened part of the straight side of the baffle is overlapped, and the tie rod is used to pass through the overlapping part of the baffle on the axis of the shell and the vertical line passing through the center of the shell, and the distance tube is set on the pull rod to fix the adjacent quadrant folds A baffle and a baffle behind the same quadrant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com