A kind of acrylate modified polyurethane emulsion type waterproof coating and preparation method thereof

A polyurethane emulsion and acrylate technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of unsatisfactory coating film performance and easy phase separation, and achieve excellent adhesion, increased water solubility, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

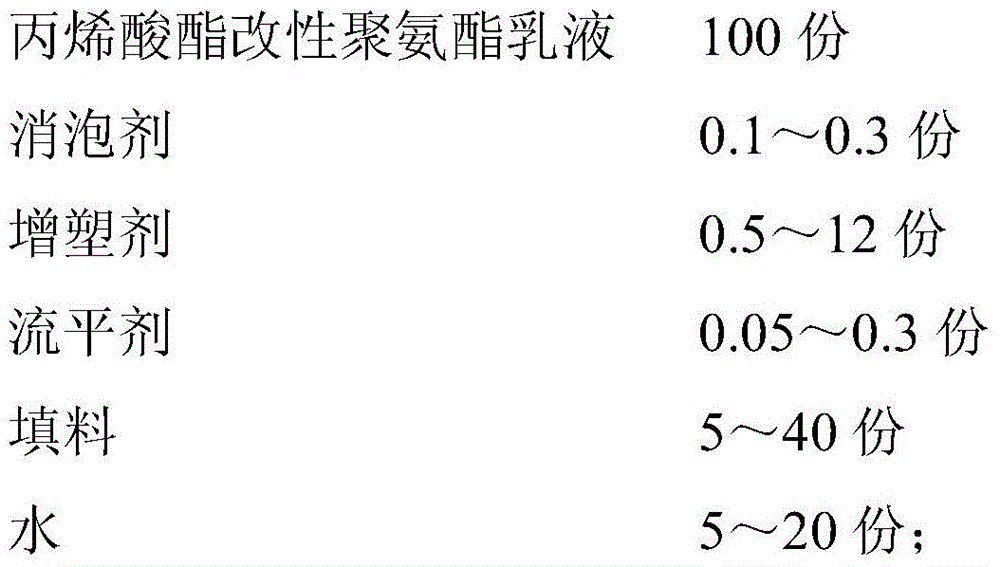

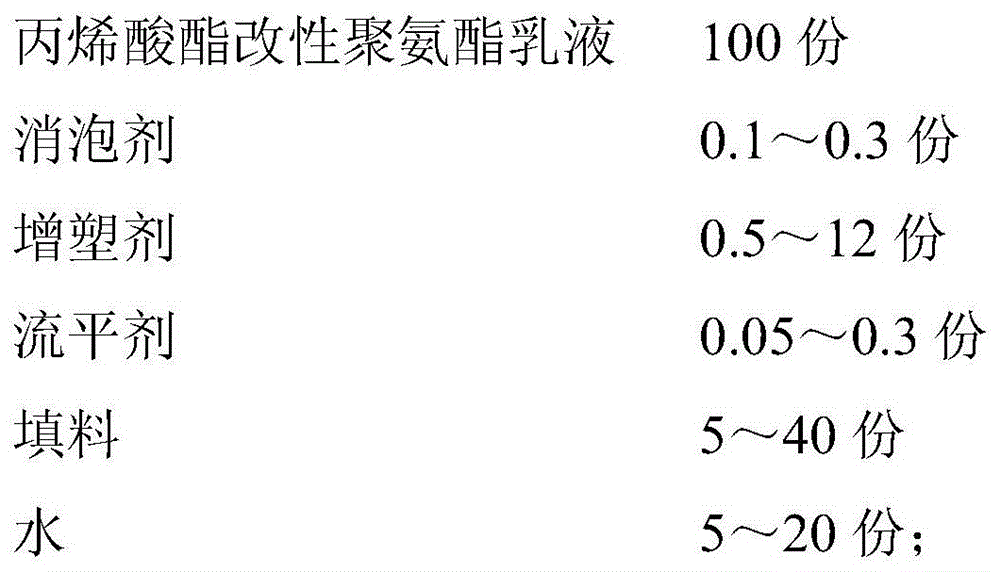

Method used

Image

Examples

Embodiment 1

[0042] Preparation of polyurethane prepolymer: Polyether PPG300 (molecular weight: 300) was vacuum-dried in a vacuum oven at 120° C. to remove water for 4 hours. According to the weight ratio, heat up 100 parts of dehydrated polyether PPG300 to 58°C, then add 20 parts of diphenylmethane diisocyanate, mix evenly under stirring conditions, heat up to 75°C, and react for 5 hours to obtain a polyurethane prepolymer PU1.

[0043] Preparation of polyacrylate prepolymer solution: by weight, 65 parts of isooctyl methacrylate, 10 parts of hydroxyethyl acrylate, 25 parts of methacrylic acid, 100 parts of ethylene glycol monomethyl ether, 2.5 parts of azo The diisobutyronitrile was stirred and mixed evenly, and the temperature was raised to 85°C for 14 hours to prepare the polyacrylate prepolymer PA1 solution.

[0044] Preparation of acrylate-modified polyurethane emulsion: Stir 35 parts by weight of PU1 and heat up to 30°C, add 110 parts by weight of PA1 solution and 0.08 parts by weig...

Embodiment 2

[0048] Preparation of polyurethane prepolymer: polyether N210 (molecular weight: 1000) was vacuum-dried in a vacuum oven at 120° C. to remove water for 4 hours. According to the weight ratio, heat up 100 parts of dehydrated polyether N210 to 60°C, then add 25 parts of toluene diisocyanate, mix evenly under stirring conditions, heat up to 70°C, and react for 6 hours to obtain polyurethane prepolymer PU2.

[0049] Preparation of polyacrylate prepolymer solution: by weight, 75 parts of isobutyl methacrylate, 5 parts of hydroxypropyl acrylate, 20 parts of acrylic acid, 100 parts of xylene, and 3 parts of azobisisovaleronitrile were stirred and mixed Evenly, after heating up to 100°C for 10 hours, the polyacrylate prepolymer PA2 solution was prepared.

[0050] Preparation of acrylate-modified polyurethane emulsion: Stir 25 parts by weight of PU2 and heat up to 40°C, add 90 parts by weight of PA2 solution and 0.08 parts by weight of dibutyltin dilaurate, stir and mix evenly, then he...

Embodiment 3

[0054] Preparation of polyurethane prepolymer: polyether PPG10000 (molecular weight: 10000) was vacuum-dried in a vacuum oven at 120° C. to remove water for 4 hours. According to the weight ratio, heat 100 parts of dehydrated polyether PPG10000 to 55°C, then add 40 parts of isophorone diisocyanate, mix evenly under stirring conditions, heat up to 78°C, and react for 4 hours to obtain a polyurethane prepolymer PU3.

[0055] Preparation of polyacrylate prepolymer solution: by weight, 80 parts of propyl methacrylate, 10 parts of hydroxyethyl methacrylate, 10 parts of acrylic acid, 100 parts of cyclohexanone, 2.8 parts of azobisisobutyronitrile Stir and mix evenly, heat up to 95° C. and react for 13 hours to prepare polyacrylate prepolymer PA3 solution.

[0056] Preparation of acrylate-modified polyurethane emulsion: Stir 25 parts by weight of PU3 and heat up to 50°C, add 100 parts by weight of PA3 solution and 0.05 part by weight of dibutyltin dilaurate, stir and mix evenly, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com