A kind of preparation method of porous carbon heat insulation composite material

A composite material and porous carbon technology, applied in ceramic products, other household utensils, household utensils, etc., can solve the problems of low thermal conductivity of materials, large volume shrinkage, and large safety hazards, and achieve low thermal conductivity and excellent preparation process. The effect of simplicity and short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

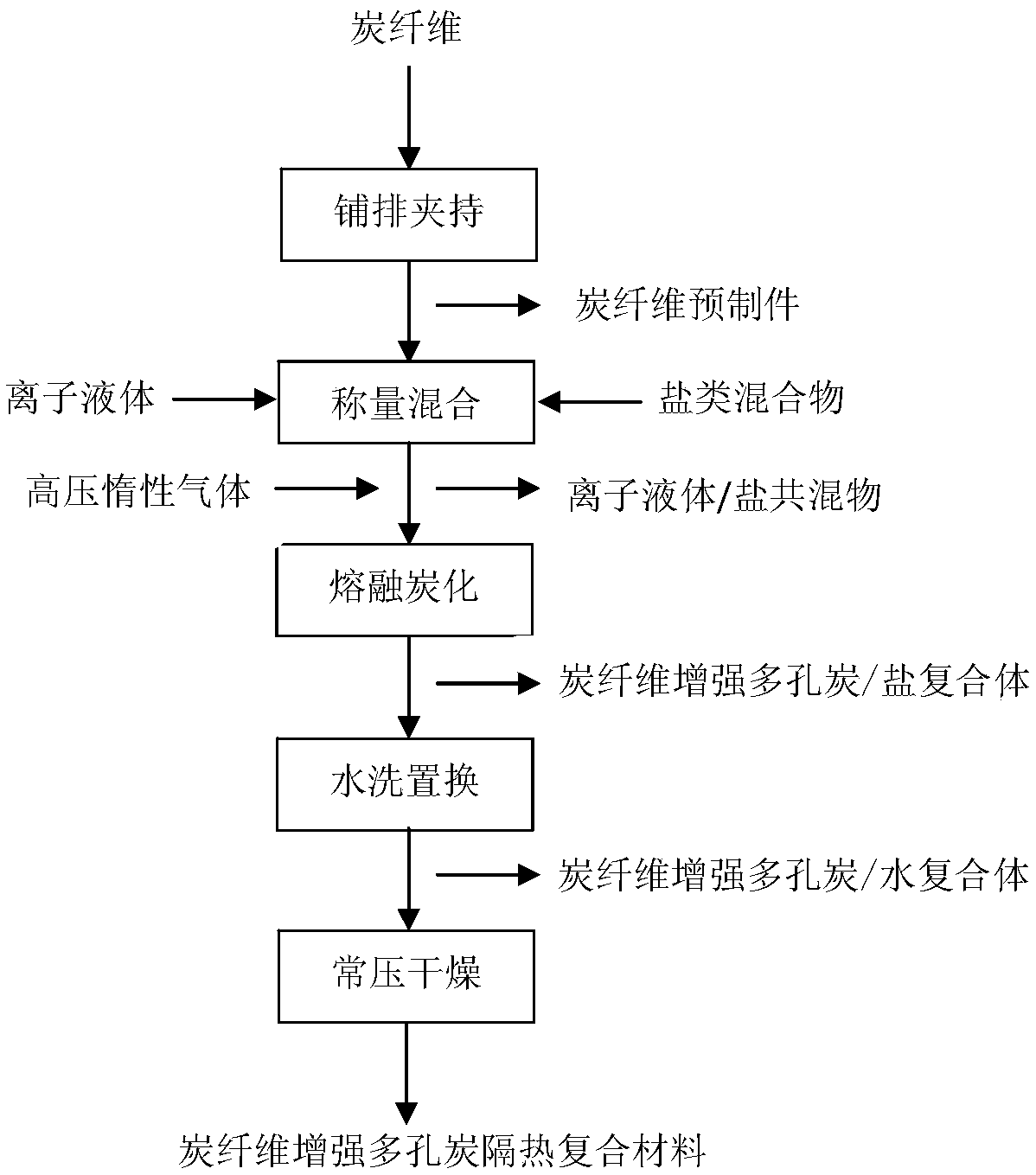

Method used

Image

Examples

Embodiment 1

[0044] (1) Prepare carbon fiber prefabricated parts by arranging and clamping carbon fibers: the designed carbon fiber prefabricated parts have an apparent density of 0.13g / cm 3 , according to the volume of the carbon fiber prefabricated part and the apparent density of the carbon fiber prefabricated part, the mass of the required carbon fiber is calculated by mass = density × volume. The perforated graphite fixture clamps and fixes the arranged carbon fiber to obtain a carbon fiber prefabricated part;

[0045] (2) Weighing and preparing 1-ethyl-3-methylimidazolium dicyanamide / KCl / ZnCl 2 Blends:

[0046] 2.1 Weigh the eutectic salt mixture KCl / ZnCl as the porogen of the porous carbon thermal insulation composite material 2 : Using KCl / ZnCl 2 This eutectic salt mixture consists of KCl and ZnCl 2 Two salt compositions, according to KCl and ZnCl 2 The mass ratio at the eutectic point of the binary phase diagram is 47:100 and weighed to prepare KCl / ZnCl 2 Deep eutectic salt ...

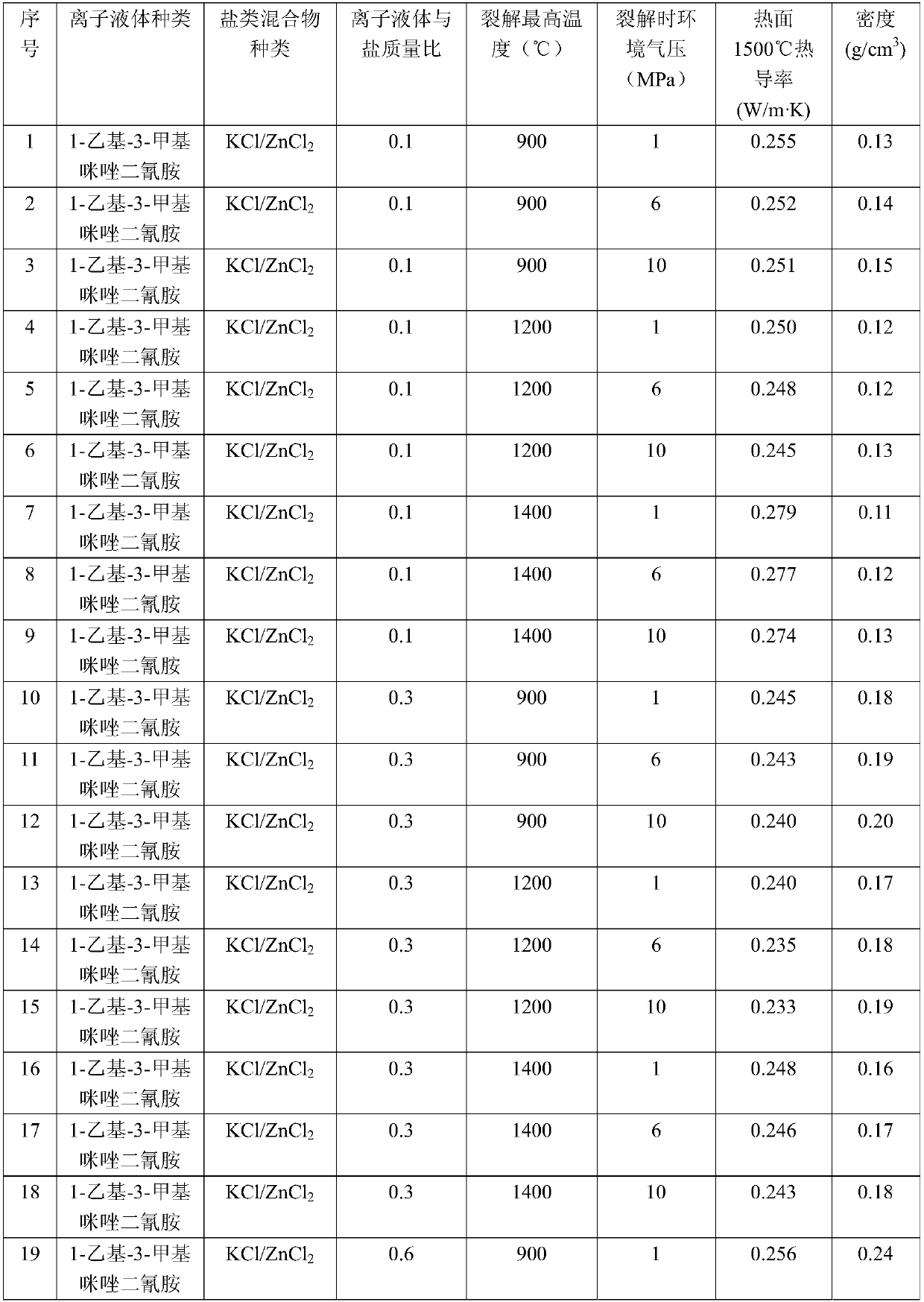

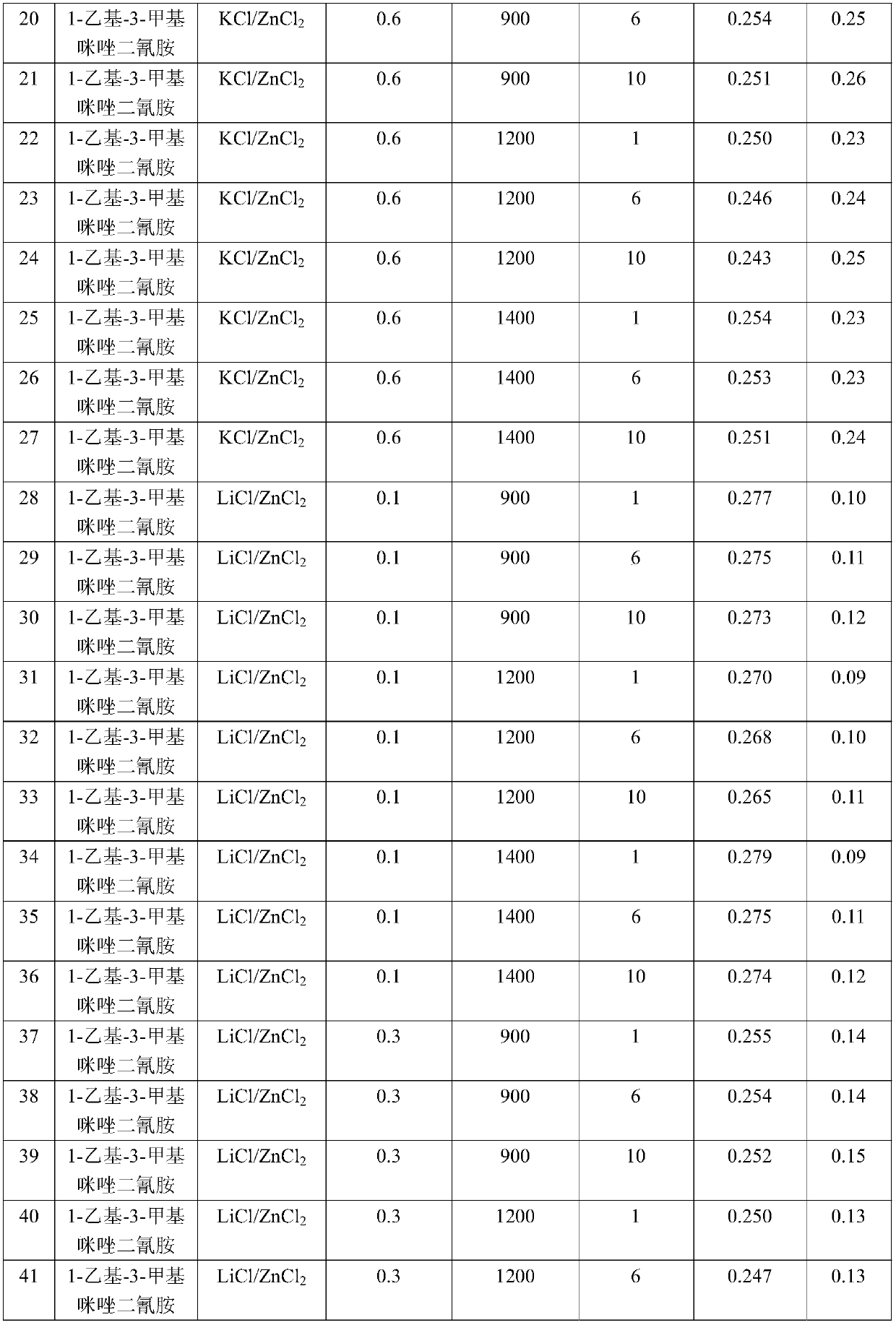

Embodiment 2~243

[0054] When preparing the eutectic salt mixture in the second step, the mass ratio of the two salts is the mass ratio of the binary phase diagram of the two salts at the eutectic point, which is determined to remain unchanged. In the third step of heating, the inert The gas provides a protective atmosphere when the ionic liquid / salt blend is heated, melted and carbonized. The use of different inert gases has no obvious effect on the performance of the composite material. In the third heating process, the heating program is determined by the ionic liquid. Different ions Liquids react violently at different temperature stages. In order to obtain high-performance carbon fiber-reinforced porous carbon insulation composites, it is necessary to slowly raise the temperature at the stage of intense reaction of ionic liquids to slow down the severity of carbonization and cracking of ionic liquids. Different ionic liquids require The temperature stage of slow heating can be obtained by d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com