A kind of fast-setting impact-resistant composite thin plate and its preparation method

A composite sheet, impact-resistant technology, applied in the field of building materials, can solve the problems of unstable performance in the later stage, limited effective application, single component, etc., achieve good mechanical properties and dimensional stability, inhibit crack generation and expansion, and environmental adaptation. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

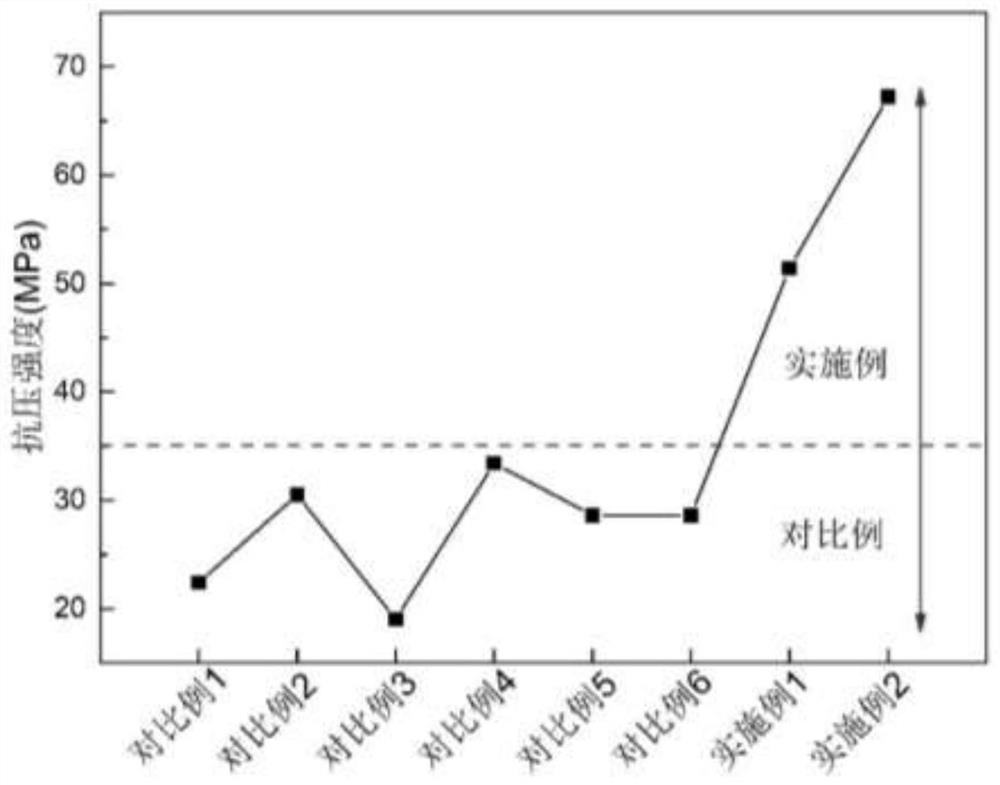

[0046] The formula of phosphate-based fast-hardening gelling powder is optimized. Weigh each raw material according to the formula conditions described in Table 1, mix the weighed phosphate, magnesium oxide and boric acid evenly, add water to mix evenly, and maintain in natural environment. Hydration products of different phosphate-based fast-hardening gelling powders.

[0047] The mixing ratio of the phosphate-based fast-hardening cementitious materials described in the comparative examples and examples in Table 1

[0048]

[0049]

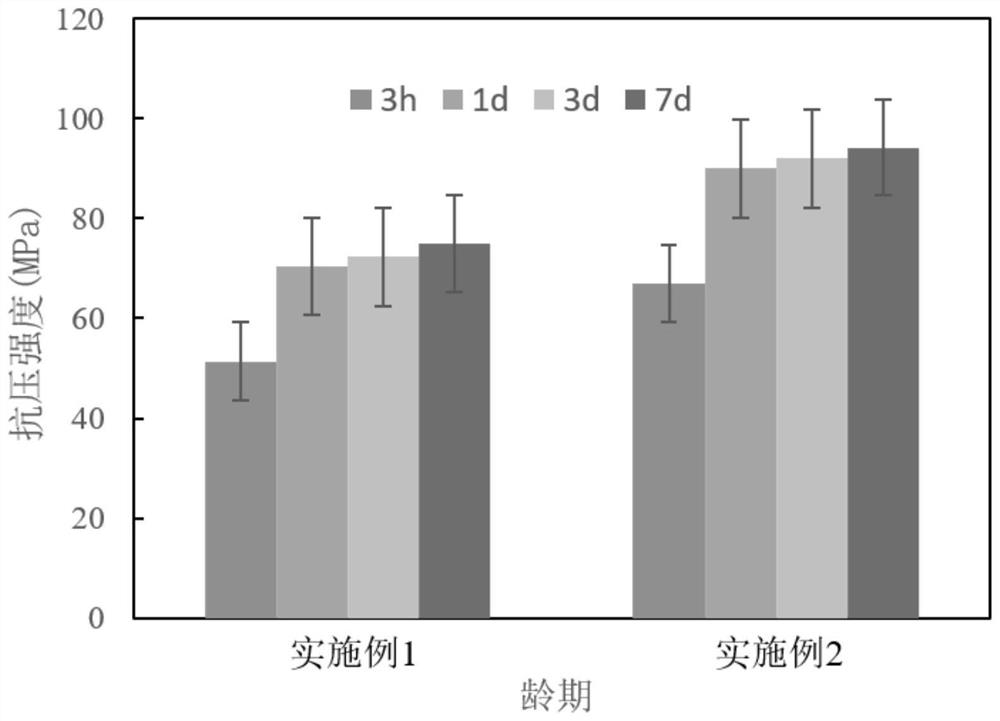

[0050] The hydration products obtained in Examples 1-2 and Comparative Examples 1-6 were respectively subjected to performance tests such as gel time and compressive strength, as follows:

[0051] 1) coagulation time

[0052] Using the instruments and appliances specified in GB / T1346-2011 "Water Consumption, Setting Time, and Stability Test Methods for Standard Consistency of Cement", during the setting time test process, it is measured ev...

Embodiment 3~4

[0061] A fast-setting impact-resistant composite sheet, the preparation method of which comprises the following steps:

[0062] 1) Preparation of phosphate-based quick-hardening gelling powder; weigh each component according to the ratio described in Table 3, and mix the weighed phosphate, magnesium oxide and boric acid to obtain phosphate-based quick-hardening gelling powder body;

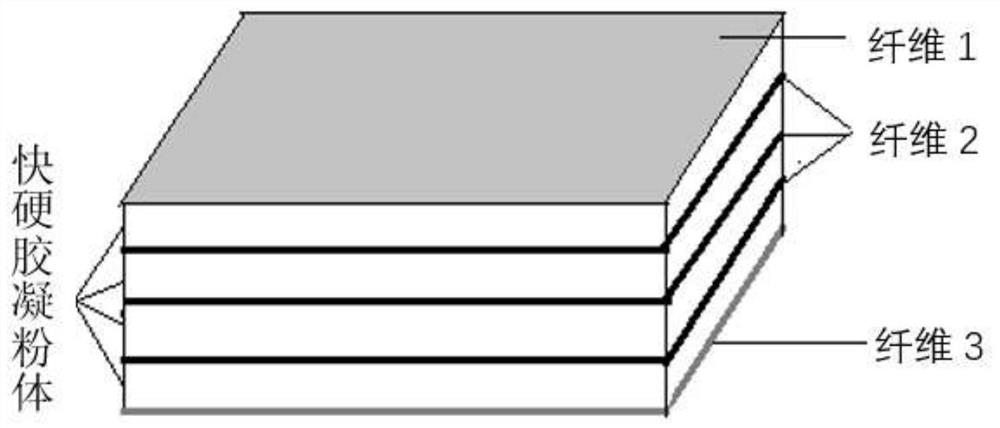

[0063] 2) Using an edge-sealing mold, mix the phosphate-based fast-hardening gelling powder with the composite fiber fabric layer by layer according to the volume ratio described in Table 4, and perform ultrasonic vibration to ensure the filling uniformity and compactness of the powder; press figure 1 The structure shown is for material preparation, wherein fiber 1 selects hemp fiber, fiber 2 selects cotton fiber, fiber 3 is basalt fiber, and Table 5 is the composite fiber fabric structure composition; wherein, the thickness of the single-layer cementitious powder of Example 3 is 3mm , the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com