Super-long slump-retaining polycarboxylic acid pumping agent and preparation method thereof

A polycarboxylic acid-based, slump-preserving technology, applied in the field of pumping agents, can solve problems such as low strength, increased viscosity, and obvious retarding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add 56.5kg of water and 20kg of water-reducing polycarboxylate superplasticizer to the composite kettle and use a concentration of 30% liquid caustic to neutralize to pH=7, then add 15kg of slump-preserving polycarboxylate superplasticizer in order chemical agent, 2kg sodium pyrophosphate, 1kg sodium pyrosulfite, 2kg sodium pyrosulfate, 2.5kg emulsified paraffin, 0.5kg polyethylene oxide, 0.3kg calcium alginate, 0.1kg triterpene saponin and 0.1kg18-3-18 type gemini quaternary ammonium Stir the salt evenly to obtain the ultra-long slump-retaining polycarboxylate pumping agent product FPPC-1.

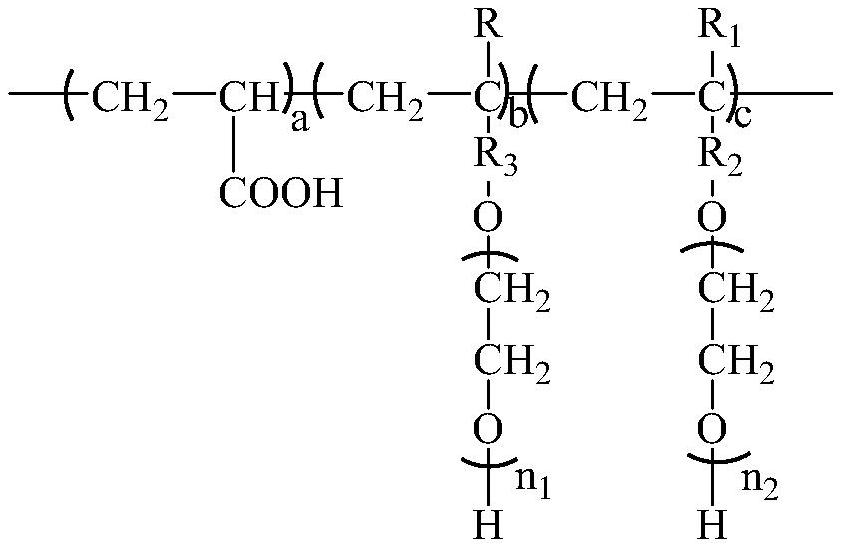

[0043] Wherein, the viscosity-average molecular weight of the water-reducing polycarboxylate superplasticizer adopted is 80020, and the mass concentration is 43%. The general structural formula of the water reducer is:

[0044]

[0045] Where a:b:c is 3.2:0.8:0.5;

[0046] where R is CH 3 , R 1 for -CH 2 CH 3 , R 2 for -CH 2 -, R 3 for-OCH 2 CH 2 CH 2 CH 2 -, n 1 =...

Embodiment 2

[0050]Add 73.19kg of water and 15kg of water-reducing polycarboxylate superplasticizer to the composite kettle with a concentration of 28% liquid caustic soda to neutralize to pH=7, then add 10kg of slump-preserving polycarboxylate superplasticizer in order Chemical agent, 0.5kg sodium metabisulfite, 0.5kg sodium carbonate, 0.5kg emulsified paraffin, 0.2kg polyethylene oxide, 0.1kg sodium alginate, 0.005kg triterpene saponin and 0.005kg12-3-12 type gemini quaternary ammonium salt are stirred evenly, The ultra-long slump-retaining polycarboxylate pumping agent product FPPC-2 was obtained.

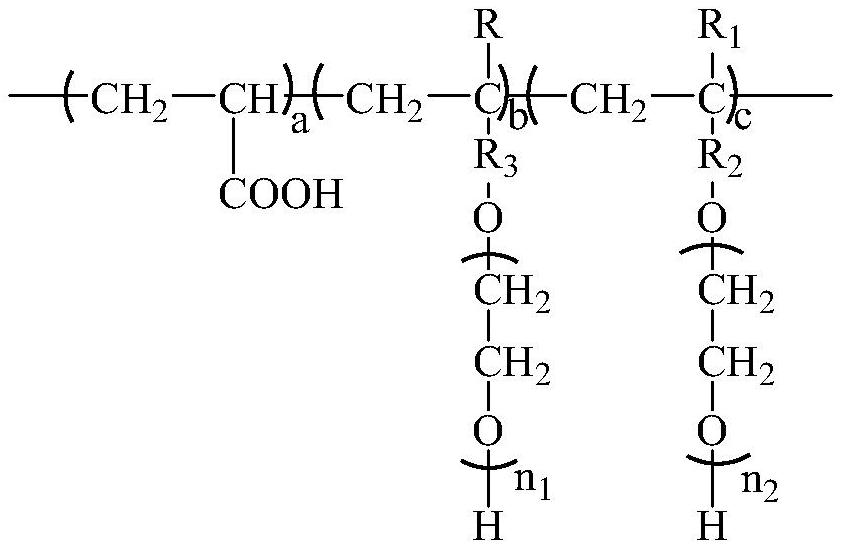

[0051] Wherein, the viscosity-average molecular weight of the water-reducing polycarboxylate superplasticizer used is 60070, and the mass concentration is 38%. The general structural formula of the water reducer is:

[0052]

[0053] In the formula, a:b:c is 2.7:0.5:0.2;

[0054] In the formula, R is H, R 1 for CH 3 , R 2 for -CH 2 -, R 3 for-OCH 2 CH 2 -, n 1 =40,n 2 =65.

[...

Embodiment 3

[0058] Add 61.9kg water and 18kg water-reducing type polycarboxylate superplasticizer to neutralize to pH value=7 with 32% liquid caustic soda in composite kettle, then add 15kg slump-preserving type polycarboxylate superplasticizer, 1kg sodium tripolyphosphate, 1kg sodium carbonate, 1kg sodium pyrosulfate, 1.5kg emulsified paraffin, 0.2kg sodium alginate, 0.3kg calcium alginate, 0.05kg triterpene saponins and 0.05kg12-3-12-3-12 type three The sub-quaternary ammonium salt was stirred evenly to obtain the ultra-long slump-retaining polycarboxylate pumping agent product FPPC-3.

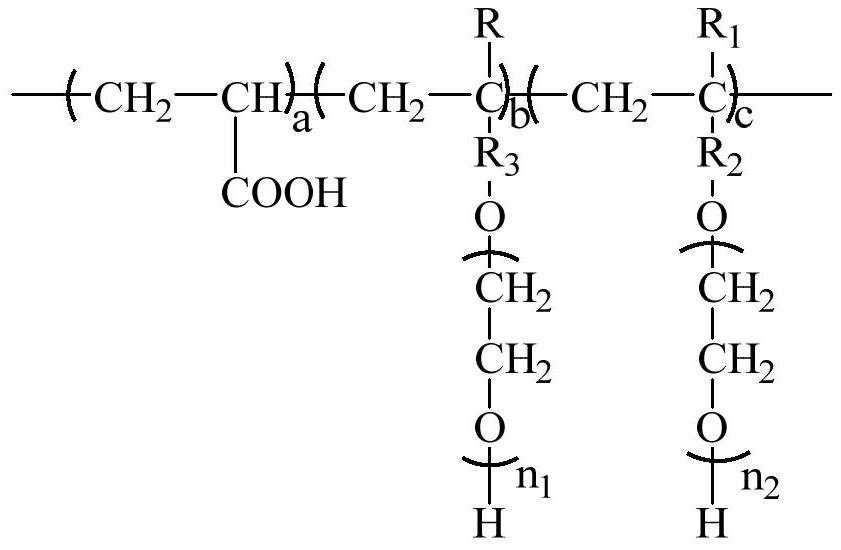

[0059] Wherein, the viscosity-average molecular weight of the water-reducing polycarboxylate superplasticizer used is 76900, and the mass concentration is 41%. The general structural formula of the water reducer is:

[0060]

[0061] Where a:b:c is 2.9:0.7:0.35;

[0062] where R is CH 3 , R 1 for -CH 2 CH 3 , R 2 for -CH 2 -, R 3 for-OCH 2 CH 2 CH 2 CH 2 -, n 1 =50,n 2 =70.

[0063] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com