Patents

Literature

38 results about "Sodium pyrosulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium pyrosulfate is an inorganic compound with the chemical formula of Na₂S₂O₇. It is a colorless salt.

Method for regenerating positive electrode active material in LiNi1/3Co1/3Mn1/3O2 waste lithium ion battery

ActiveCN104466295AImprove performanceReduce recycling costsWaste accumulators reclaimingBattery recyclingHydrogen SulfateSodium bisulfate

The invention discloses a method for regenerating a positive electrode active material in a LiNi1 / 3Co1 / 3Mn1 / 3O2 waste lithium ion battery. The method includes the steps that the waste lithium ion battery is subjected to discharging and dismantling or positive pole leftover materials and positive electrode fragments are collected to obtain waste positive plates, and the waste positive plates are subjected to roasting, water dissolving and filtering to obtain waste LiNi1 / 3Co1 / 3Mn1 / 3O2 powder; the waste LiNi1 / 3Co1 / 3Mn1 / 3O2 powder and sodium pyrosulfate are roasted after being mixed according to a certain proportion, roasted products are leached by water, then a sodium carbonate solution is added into liquor, filtering is conducted, after the proportion of Li, Ni, Co and Mn in carbonate modulation filter residues is supplemented, the Li, Ni, Co and Mn are subjected to ball milling, compressing and roasting, and accordingly the LiNi1 / 3Co1 / 3Mn1 / 3O2 positive electrode material is obtained again. Components of filter liquor are adjusted through sulfuric acid, crystallization processing is carried out, and then sodium hydrogen sulfate is obtained.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Inorganic ferrous sulfide passivation abluent

ActiveCN102373122ASolve environmental problems of emissionsEfficient removalInorganic non-surface-active detergent compositionsTreatment apparatus corrosion/fouling inhibitionSodium bicarbonateHypochlorite

The invention relates to an inorganic ferrous sulfide passivation abluent which is characterized in that: the inorganic ferrous sulfide passivation abluent is composed of components of, by mass: 5 to 15% of sodium pyrosulfate, 15 to 35% of hypochlorite, 0.5 to 10% of trisodium phosphate, 0.1 to 5% of sodium bicarbonate, and 35 to 79% of water. The pH value of the product is controlled at 11 to 12. With the inorganic ferrous sulfide passivator, FeS and oil stains on refining equipments can be effectively and quickly removed; and gases such as H2S, micro-molecular sulfur and alcohol in equipments such as towers and containers can be absorbed. Indexes such as COD of the abluent satisfy an oil refinery sewage discharging standard. With the inorganic ferrous sulfide passivation abluent, environment protection problems such as a FeS passivation problem and an abluent waste liquid discharging problem can be well solved.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly composite ferrous sulfide passivator and preparation method thereof

InactiveCN104263408AStable in natureFast passivationTreatment apparatus corrosion/fouling inhibitionSodium bicarbonateSpontaneous combustion

The invention discloses an environment-friendly composite ferrous sulfide passivator which is composed of the following components in percentage by mass: 5-10% of sodium pyrosulfate, 10-25% of sodium hypochlorite, 1-10% of trisodium phosphate, 0.5-7% of sodium hydrogen carbonate, 20-35% of sodium hydroxide, 1-2% of potassium ferrate and 30-60% of water; and the environment-friendly composite ferrous sulfide passivator is prepared by uniformly mixing the components according to a specific step order. The environment-friendly composite ferrous sulfide passivator disclosed by the invention is efficient, is free of toxicity, corrosive property and secondary pollution and is capable of quickly passivating ferrous sulfide and effectively preventing spontaneous combustion of ferrous sulfide; the passivator has a good cleaning effect on such malodorant as hydrogen sulfide, ferrous sulfide passivation time is 8-10h and more than 98% of ferrous sulfide is removed, and shutdown time of a device is correspondingly shortened; and a protective film is formed on the surface of passivated metal, so as to effectively prevent metal surface from being further corroded.

Owner:JINAN RUIDONG IND

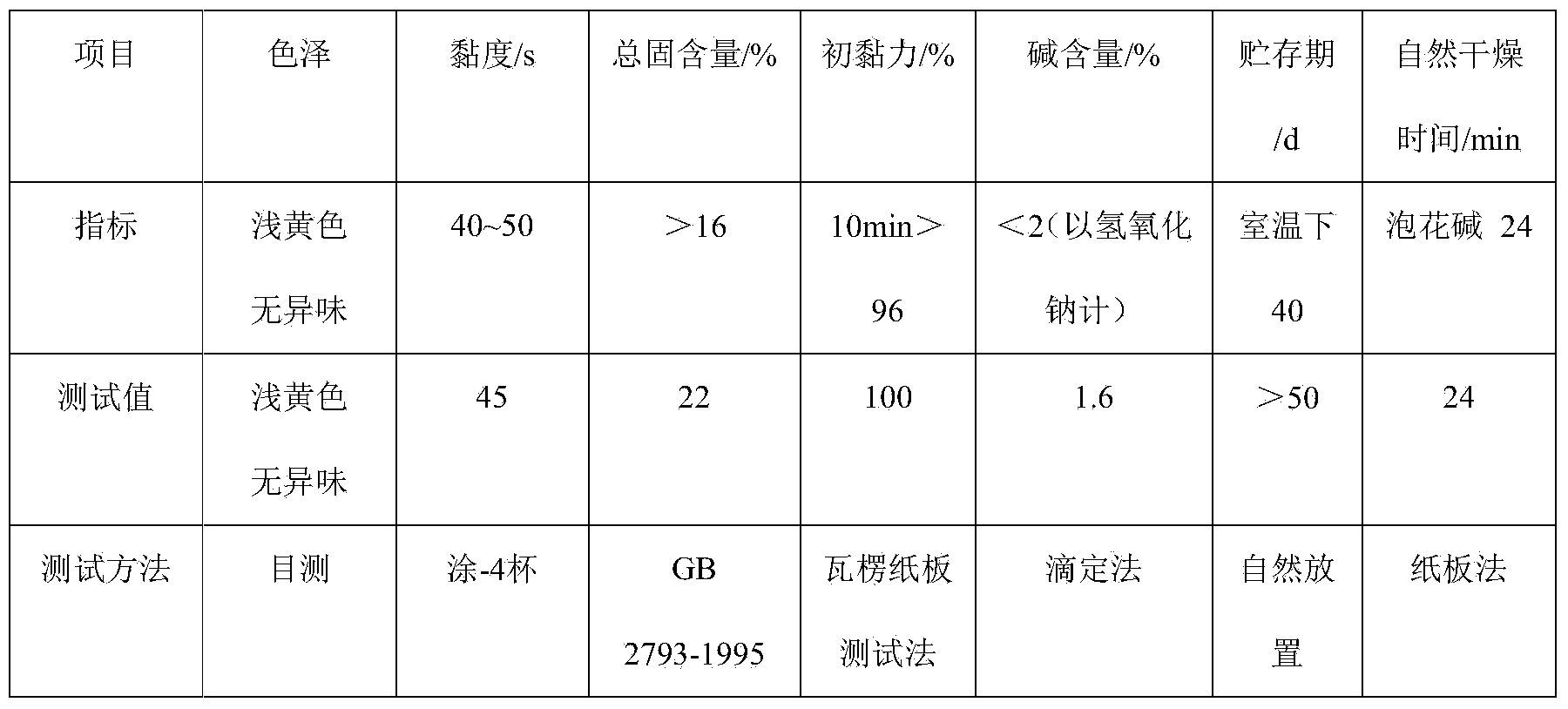

Quick dry adhesive for corrugated paper box and preparation method of quick dry adhesive

InactiveCN104231973AQuality improvementShort reaction timeNon-macromolecular adhesive additivesStarch derivtive adhesivesPtru catalystAdhesive

The invention discloses a quick dry adhesive for a corrugated paper box. The quick dry adhesive is prepared from the following components: corn starch, bentonite, sodium hypochlorite, sodium pyrosulfate, ferrous sulfate, a drier, a 3% (volume concentration) sodium hydroxide solution, borax, sodium sulfite, clean water and a defoamer. The adhesive disclosed by the invention is stable in quality, short in reaction time, fast in natural drying speed, simple in process and easy to operate. A catalyst used in the quick dry adhesive disclosed by the invention is low in cost, stable in performance and can be stored for a long time, and gelation and stratification phenomena cannot be easily caused.

Owner:JURONG GEILI PACKAGING PROD FACTORY

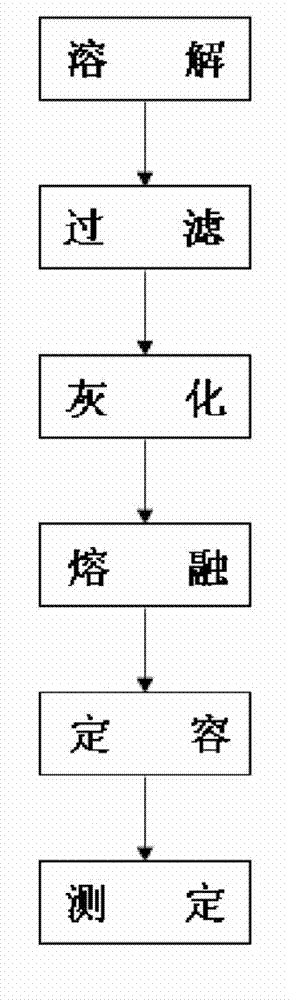

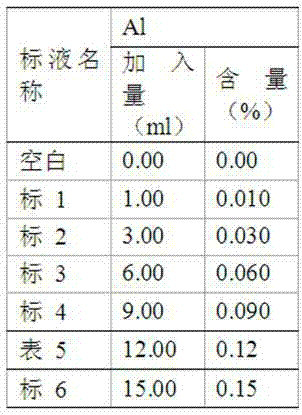

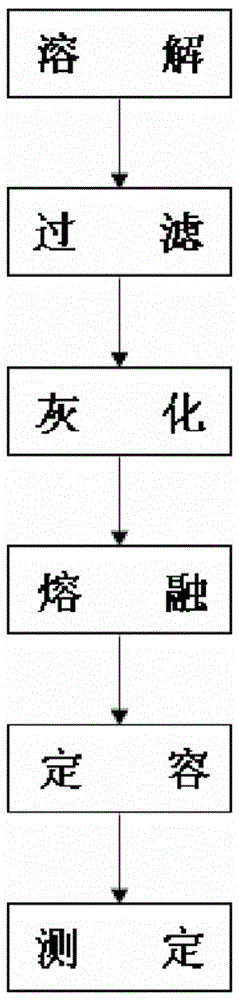

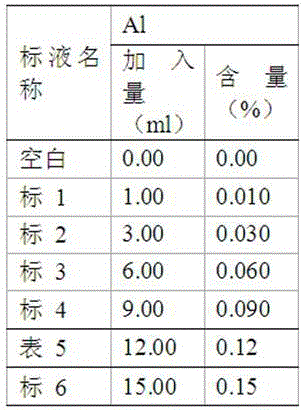

Determination method of total aluminum content in steel and alloy

ActiveCN103698176AReduce dosageReduce pollutionPreparing sample for investigationAnalysis by thermal excitationSpectrographAlloy

The invention discloses a determination method of total aluminum content in steel and alloy. The method comprises the steps of pretreatment and determination, and particularly comprises the following steps: adding distilled water, hydrochloric acid and nitric acid to a sample to be determined to heat and dissolve at low temperature; filtering by slow speed filter paper; taking filtrate as main liquid, fusing the residue by using sodium pyrosulfate, leaching by hydrochloric acid, and merging the main liquid; fixing the volume by using the distilled water, so as to obtain a sample solution to be determined; and determining by using a spectrograph, so as to obtain the target content data. By adopting the determination method, the defects that the wet-process analysis operation process is complicated, the operation is not easy to grasp, more interference elements exist, more chemical reagents are used and the like are avoided, and the characteristics that a plasma emission spectrum is low in detection limit, good in accuracy, small in matrix effect and the like are fully and effectively utilized. The determination method disclosed by the invention is simple and convenient to operate, less in reagent dosage, high in analysis accuracy, short in detection period, and small in environmental pollution, and the determination requirements of total aluminum content in daily steel and alloy can be met.

Owner:WUKUN STEEL

Novel special derusting and rust-preventing paint

InactiveCN104098986AImprove bindingAnti-rust and long lifeRosin coatingsAnti-corrosive paintsBenzoic acidPolyvinyl chloride

The invention discloses a novel special derusting and rust-preventing paint. According to the formula, the paint is prepared from the following raw materials in parts by weight: 5-8 parts of polyvinylpyrrolidone, 10-12 parts of rosin resin, 8-10 parts of polyester resin, 10-12 parts of epoxy resin, 6-8 parts of ethyl orthosilicate, 5-8 parts of polyacrylamide, 5-6 parts of silica, 5-8 parts of polypropylene, 3-5 parts of polyvinyl chloride, 6-8 parts of acetic acid, 3-5 parts of diethyl ether, 3-5 parts of ephedrine, 2-4 parts of ethyl acetate, 3-5 parts of benzoic acid, 3-6 parts of carboxylic acid, 3-6 parts of sodium citrate, 2-3 parts of potassium sorbate, 1-3 parts of sodium pyrosulfate, 2-3 parts of diatom ooze, 3-6 parts of titanium dioxide, 3-6 parts of calcium carbonate, 2-4 parts of sodium bicarbonate, 3-5 parts of ferroferric oxide, 3-5 parts of magnesium oxide, 2-3 parts of alumina, 3-5 parts of zinc phosphate, 4-5 parts of sodium dichromate, 2-3 parts of vanadium pentoxide, 1-3 parts of phosphorus pentoxide and 25-30 parts of deionized water. The paint is excellent in adhesion with the metal surface, long in service life for rust prevention, quick in drying, low in cost and good in high-temperature resistance, and can be directly sprayed or coated on the surface of rusting steel.

Owner:司徒建辉

Composite sludge deep dehydration agent and preparation method and use method thereof

InactiveCN111875231AReduce moisture contentImprove dehydration effectSludge treatmentIron sulfateAluminium chloride

The invention discloses a composite sludge deep dehydration agent, and a preparation method and a use method thereof. The composite sludge deep dehydration agent comprises a modifier, the modifier ispowder, the effective content is more than 90%, and the passing rate of the modifier with fineness of 100 meshes is more than 85%; wherein the main component of the modifier is a combination of multiple of magnesium sulfate, magnesium chloride, aluminum sulfate, magnesium oxide, ammonium chloride, sodium gluconate, ferric chloride, ferric sulfate, ammonium sulfate, aluminum chloride, sodium aluminate and sodium pyrosulfate. The method includes steps of: carrying out mechanical dehydration on the sludge to be treated to obtain plastic sludge with the water content of 75-85%; mixing the modifierwith water to prepare a modifier solution, wherein the mass ratio of the modifier to the water is 1:1-1:5; adding the modifier solution into the plastic sludge, wherein the adding amount of the modifier solution is 0.5-2% of the mass of the plastic sludge; and carrying out re-dehydration treatment through high-pressure deep dehydration equipment, so that the water content of the sludge with the water content of 75-85% can be reduced to 45-70%.

Owner:北京首创污泥处置技术有限公司

Preparation method of chlorine dioxide

The invention discloses a preparation method of chlorine dioxide. The preparation method comprises the following steps of dropwise adding water in a mixture of chlorate, an acidic substance, an activating agent and a reducing agent, and reacting, thus obtaining the chlorine dioxide, wherein the reducing agent is sodium sulphite, potassium sulphite, oxalic acid, sodium oxalate, potassium oxalate or urea, the acidic substance for providing an acid environment is sodium hydrogen sulphate, potassium hydrogen sulphate, calcium hydrogen sulphate, sodium pyrosulphate, potassium pyrosulphate, the oxalic acid, citric acid or tartaric acid, and the activating agent is anhydrous calcium sulphate, anhydrous calcium chloride, anhydrous aluminium sulphate, anhydrous aluminium chloride, anhydrous ferric sulphate, anhydrous ferric chloride, anhydrous magnesium chloride or anhydrous magnesium sulphate. The preparation method of the chlorine dioxide, disclosed by the invention, is high is security, low in cost, less in loss of the chlorine dioxide and simple in operation.

Owner:山东华实药业有限公司

Water purifying and disinfection effervescent tablets and preparation method thereof

InactiveCN106629899ASuitable for disinfectionSimple preparation processBiocideSpecific water treatment objectivesEffervescent tabletChlorine dioxide

The invention discloses water purifying and disinfection effervescent tablets and a preparation method thereof. The water purifying and disinfection effervescent tablets contain the following components in parts by mass: 4-6 parts of chlorine dioxide powder, 1-3 parts of sodium chloride, 4-6 parts of sodium pyrosulfate, 4-6 parts of food-grade chitosan, 3-5 parts of citric acid, 5-7 parts of NaHCO3, 4-6 parts of polyvinylpyrrolidone, 5-7 parts of sesame oil, 4-8 parts of ethanol solution, 1-3 parts of catalyst, 3-5 parts of active halogen preparation, 2-4 parts of polyhexamethylene biguanidine and 0.8-1 part of flavoring agent. The purifying agent disclosed by the invention has the advantages of simplicity in preparation technology, low cost and good purifying effect and is suitable for disinfecting the drinking water for military personnel, field workers, tourists and residents in regions without tap water and the industrial drinking water.

Owner:钦州市高新技术产业服务中心

Nutrient-rich monascus blueberry wine and preparation method thereof

InactiveCN105969570AProlong fermentation timeAvoid harmAlcoholic beverage preparationBiotechnologyAdditive ingredient

The invention discloses nutrient-rich monascus blueberry wine, which is characterized by comprising the following ingredients (by weight): 100-120 parts of blueberry, 4-5 parts of monascus, 4-6 parts of maltose, 5.8-8.2 parts of aroma-producing yeast, 1-2 parts of pectase, 2.3-3.2 parts of yeast cell wall, 2-3 parts of konjac glucomannan, 1-2 parts of beta-glucanase, 1-2 parts of alkaline amino acid, 0.3-0.4 part of sodium pyrosulfate and 3-5 parts of 600 DEG C heating modified attapulgite. With the nutrients of monascus, the product is enriched. According to the production technology, two kinds of yeasts, namely aroma-producing yeast for promoting fermentation and aroma-producing yeast for inhibiting fermentation, are adopted during the main fermentation stage to conduct cooperative fermentation at 16-20 DEG C; in the late fermentation stage, konjac glucomannan is hydrolyzed to generate sugar for aroma-producing yeast, then fermentation time of aroma-producing yeast is prolonged, and nutrition and taste of the fermented final product are more optimized; and with addition of attapulgite, the blueberry wine can be clarified. The technology is simplified.

Owner:经雷

Water clarifying agent capable of flocculating fast

InactiveCN105753129AGood biocompatibilityStable playWater contaminantsWater/sewage treatment by flocculation/precipitationOxygenPolyacrylamide

The invention discloses a water clarifying agent capable of flocculating fast.The water clarifying agent comprises, by weight, 25-35 parts of brewer's grain, 5-6 parts of wheat gluten flour, 2.1-2.3 parts of sodium pyrosulfate, 3-4 parts of xanthan gum, 3-4 parts of polyacrylamide, 3-4 parts of activated carbon powder, 68-70 parts of sunflower head, 1.8-2.2 parts of ferroferric oxide powder, 29-30 parts of 0.1mol / L ferrous oxalate solution, an appropriate amount of acetic acid solution and an appropriate amount of water.The water clarifying agent has the advantages that the water clarifying agent is capable of flocculating fast in water by adding raw materials such as the xanthan gum and the polyacrylamide, the suspended matter, harmful heavy metal and the like in the water can be absorbed in a short time, the visibility of the water can be improved, sunlight transmission is promoted, the photosynthesis of aquatic plants is intensified, oxygen release of the water is increased, and good economic value and environment protection value are achieved.

Owner:FEIDONG KEWENBIN FAMILY FARM

Nectarine antistaling agent

InactiveCN105532853AFruit and vegetables preservationInorganic compound food ingredientsVitamin CPotassium permanganate

The invention relates to a fruit antistaling agent, in particular to an antistaling agent special for nectarines. The antistaling agent comprises: edible salt, sodium pyrosulfate, sodium benzoate, vitamin C, vitamin B, zinc oxide and citric acid, wherein the vitamin C can also be replaced by oxalic acid, and potassium permanganate, calcium chloride and chitosan with a deacetylation degree of greater than or equal to 90% can also be added. Compared with previous antistaling agents, the antistaling agent has the advantages of high efficiency, convenience, no toxicity and no pollution.

Owner:张家港市金阳生态农业科技有限公司

Novel municipal sewage treatment method

InactiveCN108358396ASolve the problem of C-N ratio imbalanceProcessing speedWater/sewage treatment by irradiationSpecific water treatment objectivesWater qualityMunicipal sewage

The invention relates to a novel municipal sewage treatment method. The method comprises the following steps: firstly, performing adsorption treatment on sewage; then adding hydrogen peroxide and sodium pyrosulfate into the sewage to carry out ultraviolet optical irradiation treatment; then adding a processing agent for treatment; performing biological degradation treatment; finally sterilizing byadopting chlorine to carry out processing of the sewage. According to the novel municipal sewage treatment method disclosed by the invention, the problem of unbalance of C-N ratio of the municipal sewage can be effectively solved, so that processing speed of the sewage is higher, the efficiency is higher, the effect is better and the quality of effluent water is good; in a whole processing procedure, harmful gas and sludge are basically not produced, so that the water treatment cost is lower.

Owner:北京华禹清源水务科技有限公司

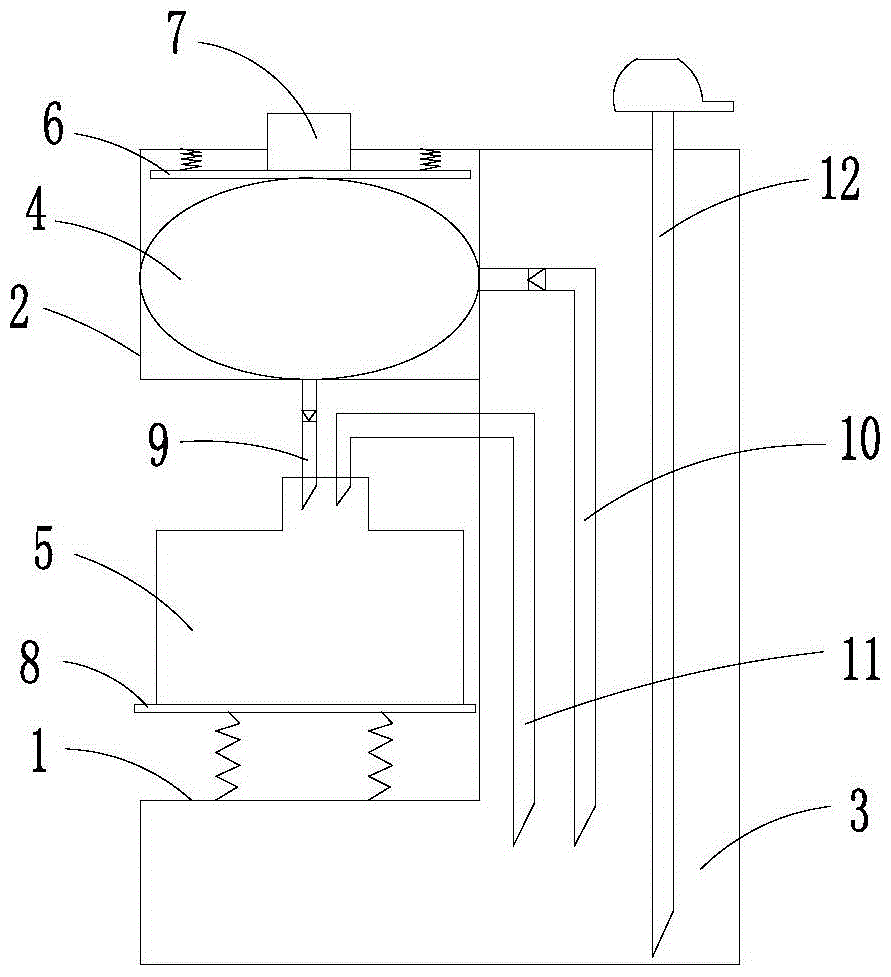

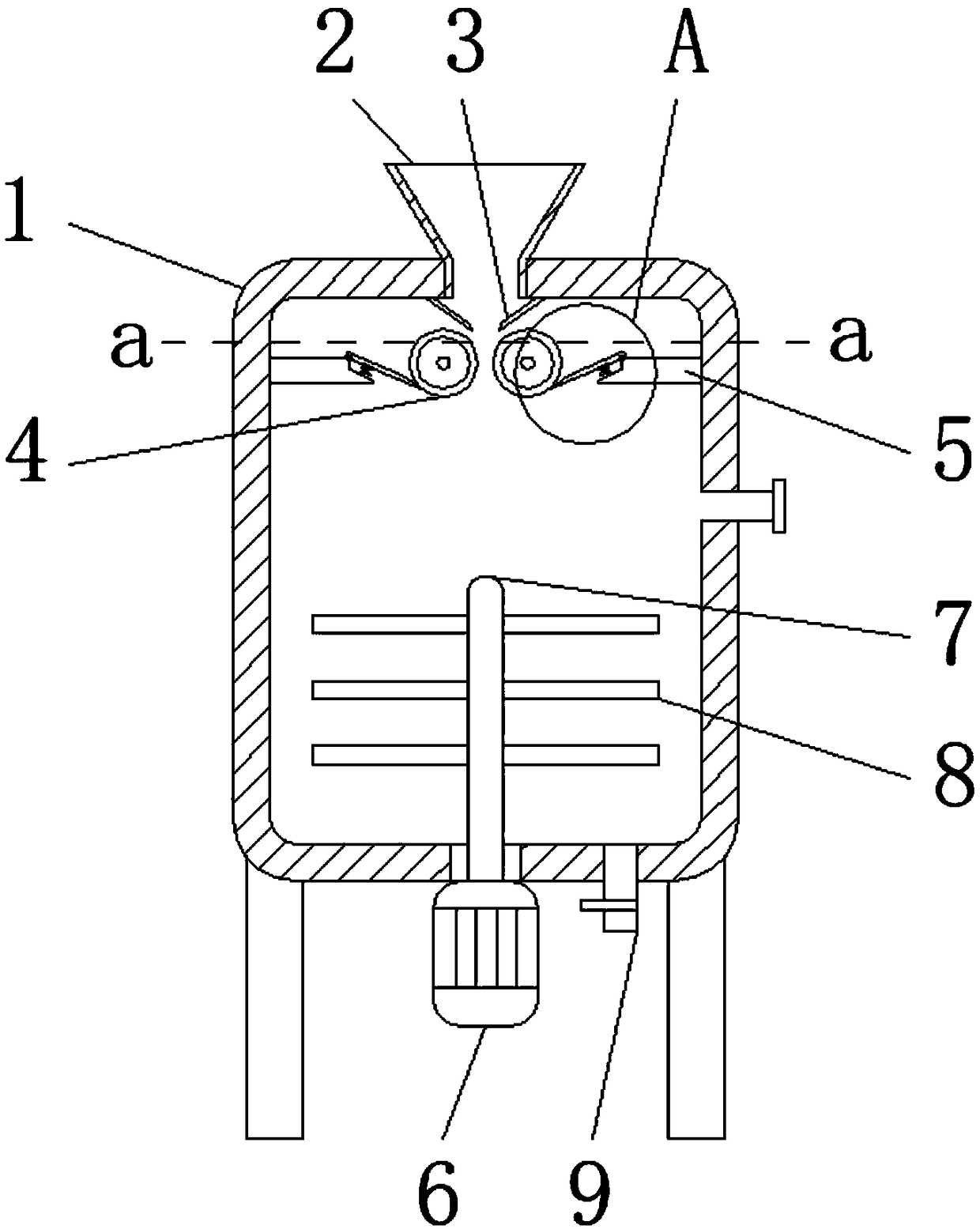

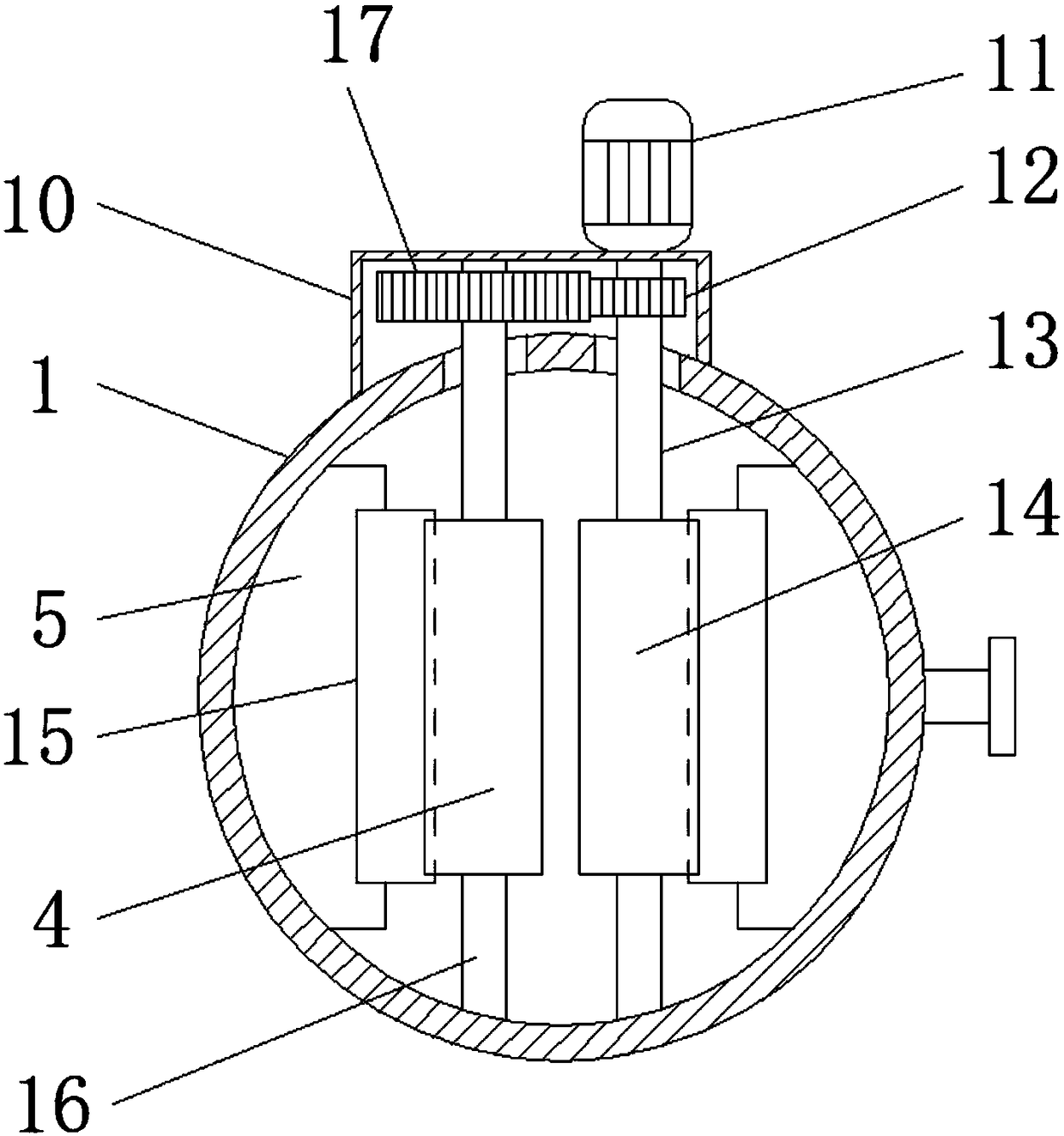

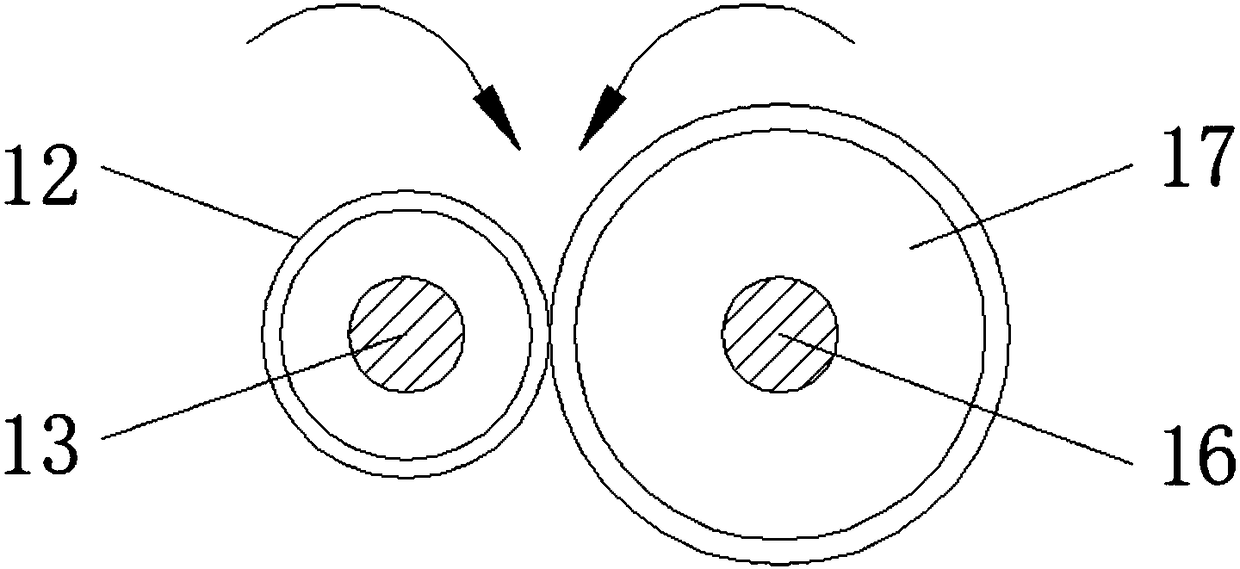

Reaction kettle with smashing function for sodium pyrosulfate production

InactiveCN108380166APlay the role of crushingPlay a tight roleChemical/physical/physico-chemical stationary reactorsGrain treatmentsDrive shaftPulp and paper industry

The invention discloses a reaction kettle with a smashing function for sodium pyrosulfate production. The reaction kettle comprises a reaction kettle body, a driven roller, a fixing plate, a stirringmotor, stirring blades, a discharging outlet, a smashing motor and a driving roller; a feeding inlet is formed above the reaction kettle body, a guide plate is arranged below the feeding inlet, the driven roller and the driving roller are arranged below the guide plate through the driven shaft and the driving shaft respectively, the fixing plate is welded to the interior of the reaction kettle body, the stirring motor is arranged at the lower end of the reaction kettle body, the stirring blades are welded to the outer side of a stirring shaft, the discharging outlet is formed in the lower endof the reaction kettle body, and the smashing motor is arranged on the outer side of a protective outer shell through a driving shaft. According to the reaction kettle with the smashing function for sodium pyrosulfate production, the lower portions on the outer sides of the driven roller and the driving roller are each provided with an anti-sticky plate, the effect of scraping away raw materials attached to the surfaces of the driven roller and the driving roller is achieved, and raw materials can fall into the reaction kettle body conveniently.

Owner:贵州开阳川东化工有限公司

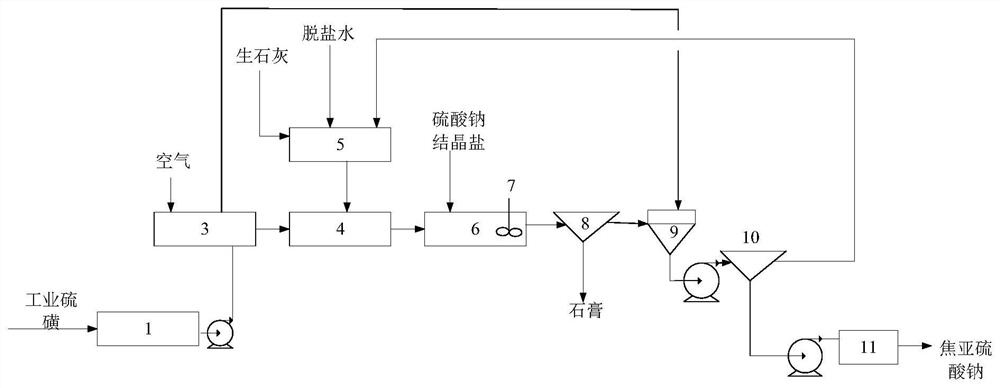

Method and system for preparing sodium pyrosulfite by using sodium sulfate crystal salt byproduct of coal chemical industry wastewater

PendingCN113830794AImprove efficiencySave dosing costDispersed particle separationSolution crystallizationSodium bisulfateSodium sulfate

The invention relates to the technical field of coal chemical industry, and concretely relates to a method and a system for preparing sodium pyrosulfite by using sodium sulfate crystal salt. The method comprises the following steps: (1) contacting the sodium sulfate crystal salt with a calcium hydrogen sulfite solution to carry out first reaction to obtain a first mixed system, and carrying out centrifugal separation on the first mixed system to obtain a gypsum precipitate and a sodium hydrogen sulfite solution; and (2) introducing furnace gas containing sulfur dioxide into the sodium hydrogen sulfite solution to form a sodium hydrogen sulfite supersaturated solution, and separating out sodium pyrosulfite crystals in the sodium hydrogen sulfite supersaturated solution to obtain a second mixed system. Sodium pyrosulfate is produced by replacing sodium carbonate with the byproduct sodium sulfate crystalline salt of the coal chemical industry wastewater, so that the adding cost of sodium carbonate can be effectively saved, and sodium pyrosulfate meeting the national standard is produced for downstream markets to use; and the byproduct gypsum can be used as a building material and a cement raw material, so that the resource utilization efficiency and the economic benefit of the byproduct crystal salt are improved.

Owner:CHINA SHENHUA COAL TO LIQUID & CHEM CO LTD +1

Foamed polystyrene resin with high flame retardancy and preparation method thereof

The invention relates to a foamed polystyrene resin with high flame retardancy and a preparation method thereof. The method for preparing the foamed polystyrene resin with high flame retardancy comprises the following steps of: in a reaction kettle at 69-71 DEG C, mixing and dissolving 0.3-1 weight parts of sodium pyrosulfate or cellulose, 0.25-0.6 weight parts of calcium phosphate, 0.02-0.05 weight parts of sodium dodecylbenzenesulfonate and 180-300 weight parts of deionized water to obtain a first mixture; adding a fire retardant and 100 weight parts of styrene monomers into the first mixture, and allowing the reaction to take place at 89-91 DEG C for 3-5 hours to obtain a second mixture; when the second mixture becomes hard, heating up to 95 DEG C and curing for 30 min to obtain polystyrene resin particles; and performing foaming treatment on the polystyrene resin particles to obtain foamed polystyrene resin with high flame retardancy. The foamed polystyrene resin with high flame retardancy, prepared by the method, has good flame retardancy, low thermal conductivity and high strength.

Owner:胥明

Method for reclaiming cobalt lithium aluminum from scrapped lithium ion battery cathode sheet

ActiveCN104103870BHigh recovery rateReduce recycling costsWaste accumulators reclaimingBattery recyclingOxalateLithium carbonate

The method for recovering cobalt-lithium-aluminum from the positive electrode sheet of the scrapped lithium ion battery comprises the following steps: discharging and dismantling the spent lithium ion battery, roasting the spent positive electrode sheet in a box-type resistance furnace, dissolving in water, and filtering to obtain waste cobalt acid Lithium powder and aluminum foil, waste lithium cobaltate powder and sodium bisulfate or sodium pyrosulfate are mixed in a certain proportion and then placed in a ball mill for ball milling. The ball-milled mixture is put into a box-type resistance furnace for roasting at low temperature, and the roasted product is leached with water. Cobalt oxalate and lithium carbonate are obtained from the leaching solution through cobalt precipitation and lithium precipitation operations.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Fruit preservation powder and preparation method thereof

InactiveCN104304438ARespiratory suppressionPrevent evaporationFruit and vegetables preservationSulfateSodium propionate

The invention discloses fruit preservation powder and a preparation method thereof. The preservation powder comprises the following components in percentage by weight: 50-60% of light calcium carbonate, 10-20% of calcium sulfate, 15-25% of talcum powder, 5-7% of sodium propionate and 6-8% of sodium pyrosulfate. The preparation method comprises steps of mixing the light calcium carbonate, the calcium sulfate, the talcum powder, the sodium propionate and the sodium pyrosulfate according to proportions, heating to 70-100 DEG C for 10-15min and stirring to obtain a finished product. The preservation powder disclosed by the invention is excellent in sterilization and preservation functions, the preparation method is scientific and reasonable, simple and easy to implement, and the preservation powder has the advantages of good preservation effect, low cost, etc.

Owner:烟台朗博商贸有限公司

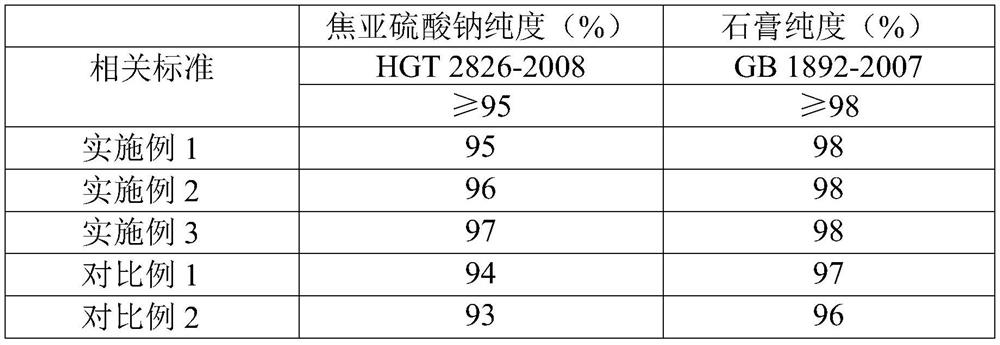

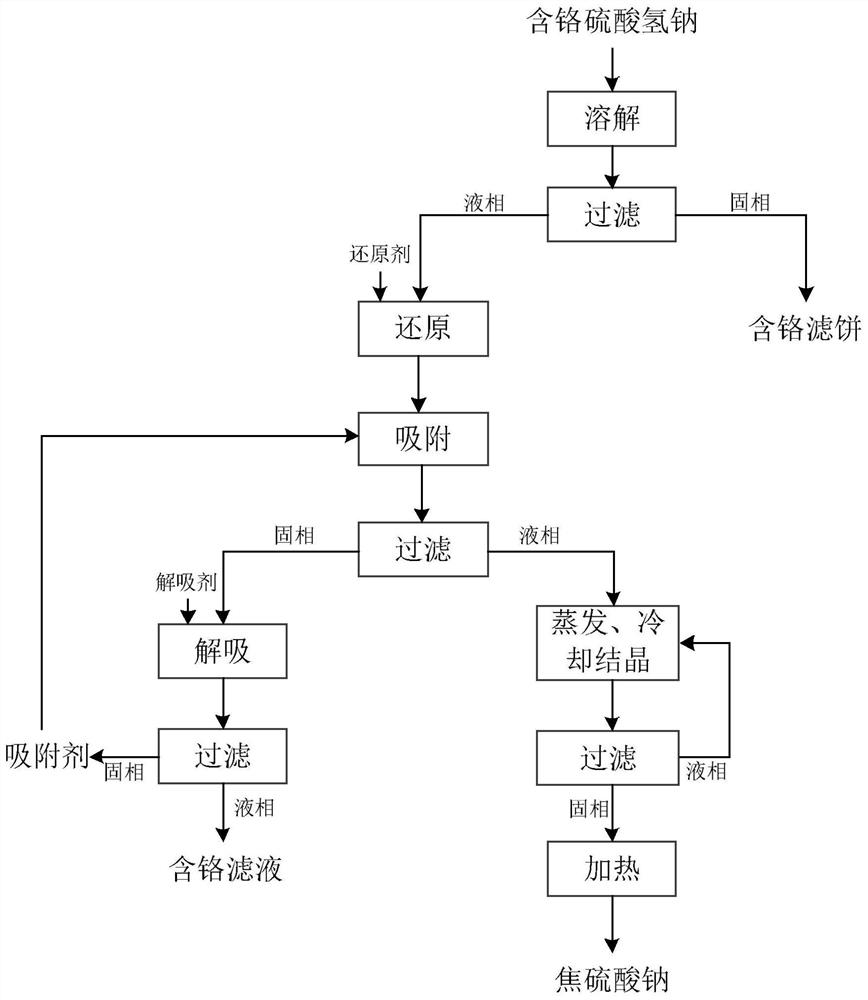

Method for resource utilization of chromium-containing sodium hydrogen sulfate

PendingCN112142073ASolve poisoningAchieve separationAlkali metal sulfite/sulfate purificationHydrogen SulfateFluid phase

The invention provides a method for resource utilization of chromium-containing sodium hydrogen sulfate, which comprises the following steps: dissolving chromium-containing sodium hydrogen sulfate, carrying out solid-liquid separation, and adding a reducing agent into the obtained liquid phase for reaction; and mixing the reacted solution with an adsorbent for adsorbing, carrying out solid-liquidseparation, and and evaporating, cooling and crystallizing the obtained liquid phase to obtain anhydrous sodium hydrogen sulfate. According to the method, chromium in the chromium-containing sodium hydrogen sulfate is reduced and selectively adsorbed, so that components in the chromium-containing sodium hydrogen sulfate are separated, chromium is subjected to harmless treatment, sodium hydrogen sulfate salt is purified, and the purity of the anhydrous sodium hydrogen sulfate product can reach 98% or above, the purity of the further prepared sodium pyrosulfate reaches 95% or above, and the added value of the products is high; and the method is simple in process, the adsorbent can be regenerated and recycled, the operation and raw material cost is low, and good economic benefits and application prospects are achieved.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD +1

Concrete waterproof agent

PendingCN110028264ASolve the disadvantages of producing unhelpful Fe(OH)3 colloidsClogged osmotic migration channelsAcetic acidAging resistance

The invention provides a concrete waterproof agent, which is prepared from the following raw materials by weight: 1-60 parts of ammonium ferric sulfate, 1-30 of glacial acetic acid, 1-40 parts of 8-hydroxyquinoline, and 1-50 parts of sodium pyrosulfate. According to the present invention, the waterproof agent has good adaptability to concrete, has advanced and reasonable waterproof mechanism, andcan generate iron hydroxide colloid at the appropriate timing of cement hydration, wherein the colloid can be generated at the micro-gap, and block the gap, and has characteristics of good waterproofand anti-crack performance, good aging resistance, high anti-penetration strength and environmental protection.

Owner:张郁文

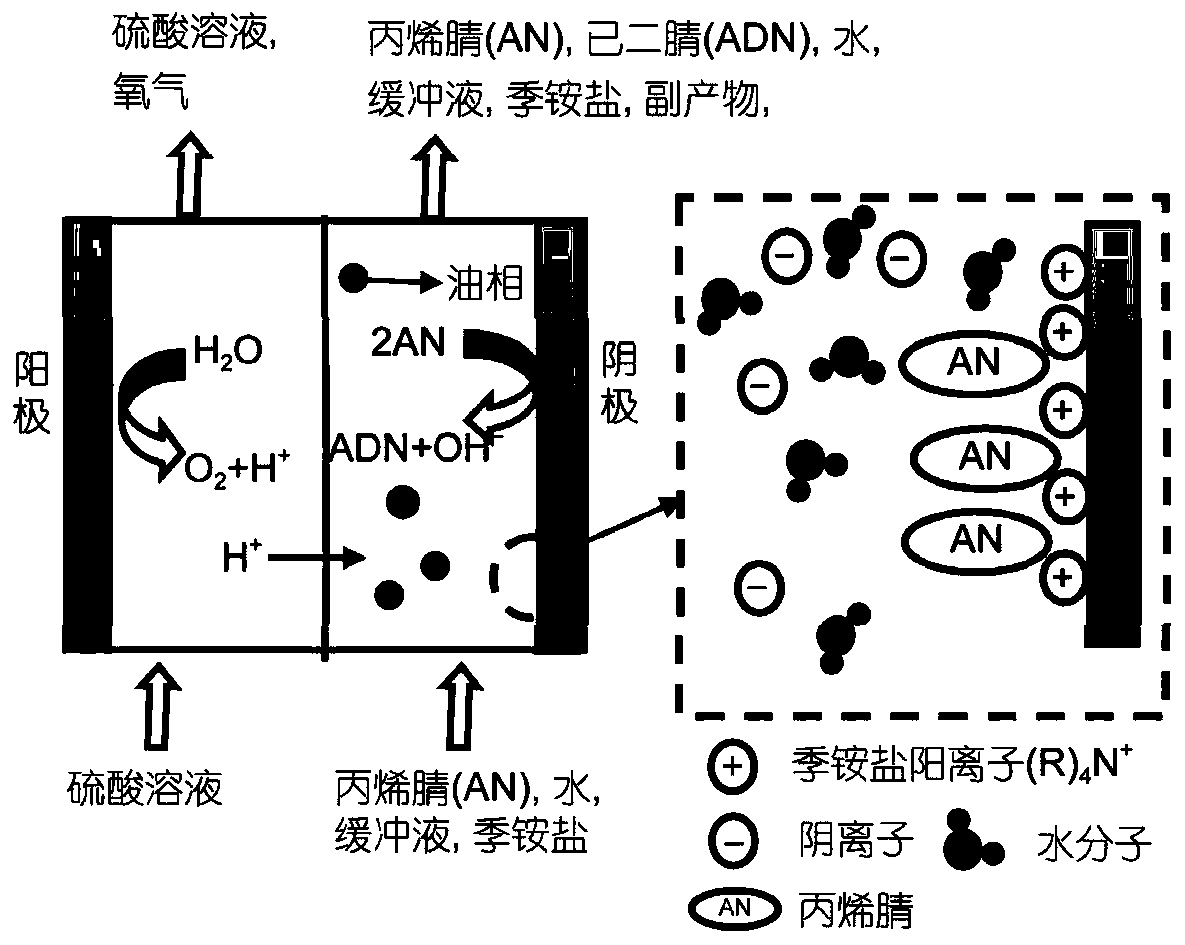

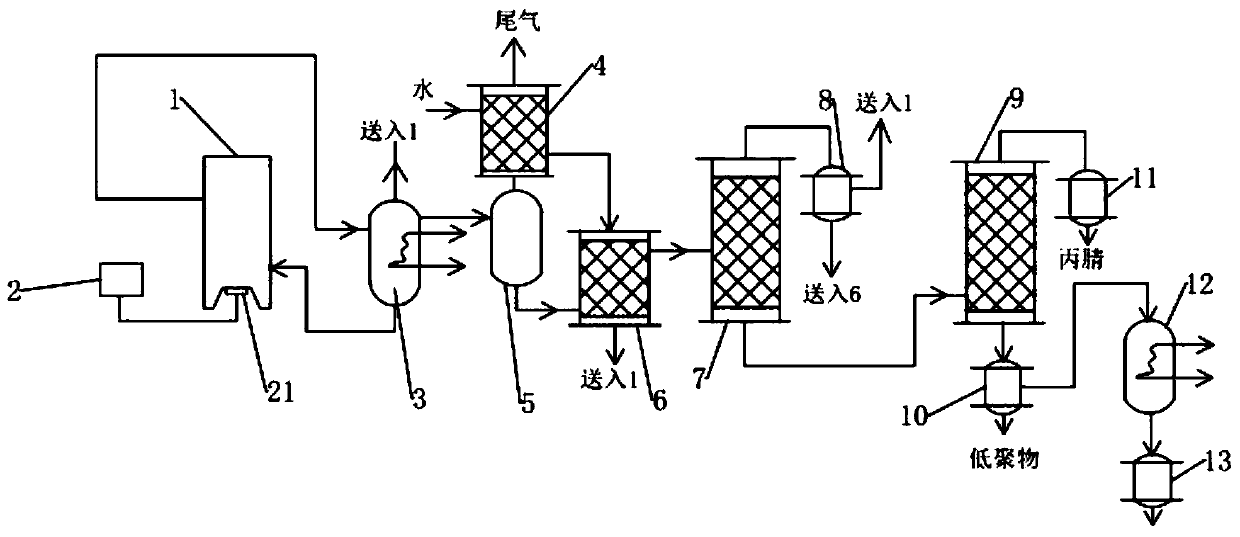

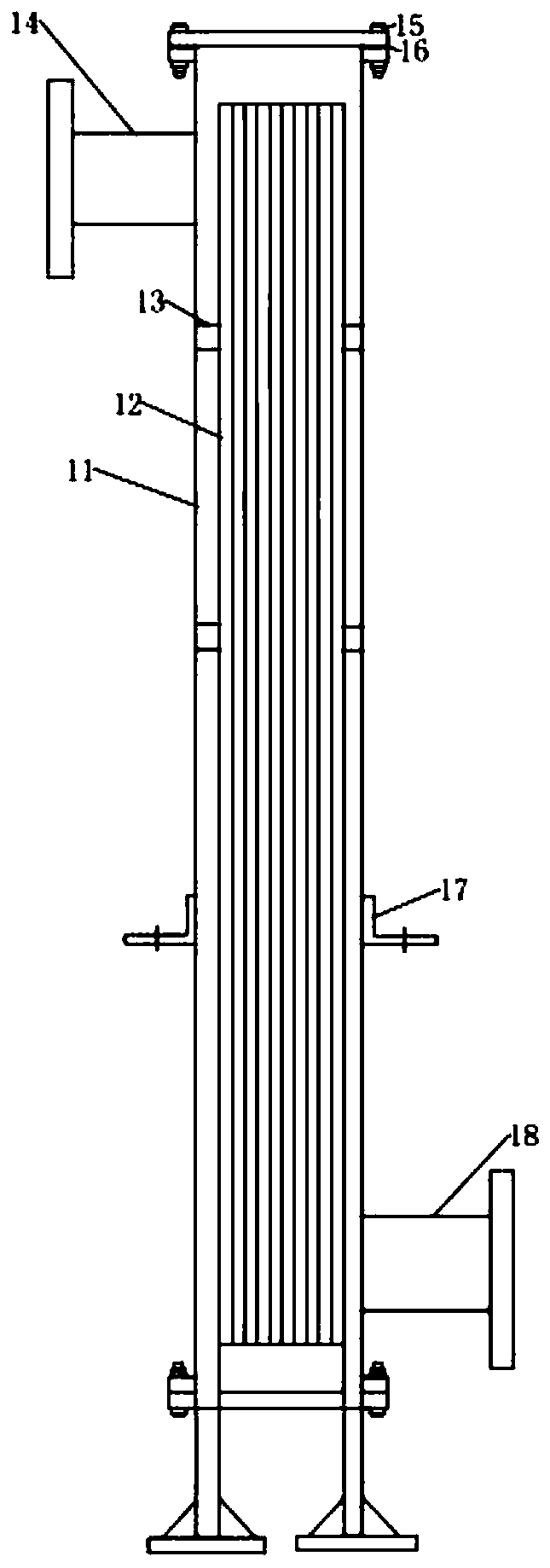

Method for producing adiponitrile through acrylonitrile electrolysis dimerization method

InactiveCN110042422AHigh yieldImprove current efficiencyElectrolysis componentsElectrolytic organic productionPhosphateAcrylonitrile

The invention provides a method for producing adiponitrile through an acrylonitrile electrolysis dimerization method. The method comprises the following steps: adding electrolyte into a diaphragm-freeelectrolytic cell and continuously electrolyzing; in an electrolyzing process, starting an ultrasonic generator; cooling, washing and rectifying an oil-phase crude product to obtain the high-purity adiponitrile, wherein the electrolyte is prepared from the following components in percentage by mass: 0.5 to 5 percent of acrylonitrile, 0 to 10 percent of the adiponitrile, 8 to 15 percent of phosphate, 0.1 to 2 percent of EDTA (Ethylene Diamine Tetraacetic Acid) or EDTA salt, 1 to 10 percent of borax, 0.1 to 5 percent of bis-quaternary ammonium salt, 0.1 to 3 percent of sodium pyrosulfate, 1 to2 percent of 1-butyl-3-methylimidazole dihydrogen phosphate, 2 to 4 percent of sodium 2,3-dihydroxysuccinate and the balance of water. The invention further provides the electrolytic cell used for themethod. According to the method provided by the invention, an electrolysis process is strengthened by ultrasonic sounds and the electrolyte is improved and optimized, so that the yield of the adiponitrile and the current efficiency are higher; the yield of the adiponitrile is 90 percent or more and the current efficiency is 92 percent or more.

Owner:青岛中石恒润化工技术有限公司

Banana preservative

InactiveCN108552305APrevent spoilageExtend freshnessFruit and vegetables preservationFood ingredient for microbe protectionPreservativeChitin formation

The invention discloses a preservative suitable for the fresh-keeping of bananas. The banana preservative is characterized in that the finished product comprises the following components: sodium benzoate, sodium pyrosulfate, sodium chloride, citric acid, edible salt, tartaric acid, chitin, lignin and deionized water. The fruit and vegetable preservative of the invention uses the sodium benzoate and the sodium pyrosulfate as fresh keeping agents which can prevent the deterioration of fruits and vegetables and prolong the fresh-keeping time. The citric acid can effectively prevent discolorationand prevent bacterium breeding, and plays a good protective and fresh-keeping effect on fruits and vegetables. The preservative is simple in formula and convenient to use.

Owner:LIUZHOU SHENGJU AGRI TECH CO LTD

Inorganic ferrous sulfide passivation abluent

ActiveCN102373122BSolve environmental problems of emissionsEfficient removalInorganic non-surface-active detergent compositionsTreatment apparatus corrosion/fouling inhibitionSodium bicarbonateHypochlorite

The invention relates to an inorganic ferrous sulfide passivation abluent which is characterized in that: the inorganic ferrous sulfide passivation abluent is composed of components of, by mass: 5 to 15% of sodium pyrosulfate, 15 to 35% of hypochlorite, 0.5 to 10% of trisodium phosphate, 0.1 to 5% of sodium bicarbonate, and 35 to 79% of water. The pH value of the product is controlled at 11 to 12. With the inorganic ferrous sulfide passivator, FeS and oil stains on refining equipments can be effectively and quickly removed; and gases such as H2S, micro-molecular sulfur and alcohol in equipments such as towers and containers can be absorbed. Indexes such as COD of the abluent satisfy an oil refinery sewage discharging standard. With the inorganic ferrous sulfide passivation abluent, environment protection problems such as a FeS passivation problem and an abluent waste liquid discharging problem can be well solved.

Owner:CHINA PETROLEUM & CHEM CORP

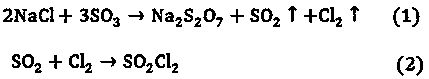

Method for co-producing sodium pyrosulfate and sulfuryl chloride

PendingCN110540175ARealize cleaner productionImprove qualitySulfuryl chlorideAlkali metal sulfites/sulfatesRefluxSulfite salt

The invention discloses a method for coproducing sodium pyrosulfate and sulfuryl chloride. The method comprises the following steps: reacting the industrial byproduct sodium chloride with sulfur trioxide-containing gas at a high temperature to prepare sodium pyrosulfate, carrying out condensation reflux treatment on generated tail gas to recover sulfur trioxide, and introducing the tail gas into asulfuryl chloride synthesis device to synthesize sulfuryl chloride. The method is not reported at home and abroad, and is a pioneering technology; and the method prepares the high-content sodium pyrosulfate, overcomes the problems of accumulation and high treatment cost of the byproduct sodium chloride at present, converts the low-value byproduct sodium chloride into a high-value product which can be directly used for downstream production, and truly realizes the comprehensive utilization of resources.

Owner:SHANDONG WEIFANG RAINBOW CHEM

A kind of determination method of total aluminum content in steel and alloy

ActiveCN103698176BReduce dosageReduce pollutionPreparing sample for investigationAnalysis by thermal excitationAlloyWet analysis

The invention discloses a determination method of total aluminum content in steel and alloy. The method comprises the steps of pretreatment and determination, and particularly comprises the following steps: adding distilled water, hydrochloric acid and nitric acid to a sample to be determined to heat and dissolve at low temperature; filtering by slow speed filter paper; taking filtrate as main liquid, fusing the residue by using sodium pyrosulfate, leaching by hydrochloric acid, and merging the main liquid; fixing the volume by using the distilled water, so as to obtain a sample solution to be determined; and determining by using a spectrograph, so as to obtain the target content data. By adopting the determination method, the defects that the wet-process analysis operation process is complicated, the operation is not easy to grasp, more interference elements exist, more chemical reagents are used and the like are avoided, and the characteristics that a plasma emission spectrum is low in detection limit, good in accuracy, small in matrix effect and the like are fully and effectively utilized. The determination method disclosed by the invention is simple and convenient to operate, less in reagent dosage, high in analysis accuracy, short in detection period, and small in environmental pollution, and the determination requirements of total aluminum content in daily steel and alloy can be met.

Owner:WUKUN STEEL

Reagent for detecting formaldehyde in food and preparation method thereof

InactiveCN108760726AWide variety of sourcesSource satisfiesMaterial analysis by observing effect on chemical indicatorSolubilityDisodium Edetate

The invention discloses a reagent for detecting formaldehyde in food. The reagent is prepared from the following raw materials in parts by weight: sodium periodate, potassium hydroxide, petroleum ether, sodium benzoate, sodium pyrosulfate, sodium thiosulfate, anhydrous ethanol, methyl dihydrojasmonate, tea polyphenol, carzenide, disodium edetate, acetylacetone, disodium hydrogen phosphate dodecahydrate, luminol, chalcanthite, oxalic acid, lauryl sodium sulfate, ginkgo leaf, polyacrylamide, diatomaceous earth, cetyltrimethylammonium chloride, lead acetate, fuchsin sulfite, and distilled water.The raw materials are widely available, the preparation process is simple, and the reagent can be used to effectively detect formaldehyde in food and to determine the content of formaldehyde in food very simply and fast with low cost, can be operated by non-professionals, has the characteristics of high reaction speed, high sensitivity and stable water solubility and meets the usage requirements of people.

Owner:SHANDONG WUZHOU DETECTION

Method for preparing zirconium oxide powder from zircon

This invention relates to a method for preparing zirconium oxide. The preparation method is: mixing zircon and soda, reaction under high temperature, cooling the product, adding water and acid; regulation its pH value, filtering, washing and drying the obtained product; the above mentioned product is then added with sodium pyrosulfate, reaction under temperature of 700-800deg.C, cooling, adding water, filtering, washing and drying, obtaining product of powder of mixture of zirconium oxide and silicon oxide; above mentioned mixture is added with solution of sodium hydroxide, reacting under proper pressure and temperature for 2-3hrs, then cooling, separation, washing, drying to obtain the inventive product. This invention has advantages of: low cost, short process, simple operation. And the product is of high pureness, with regular octahedron particles, its size is 1-3um. The power of the inventive product has well dispersiveness, no blocking problem.

Owner:PUYANG REFRACTORIES GRP CO LTD

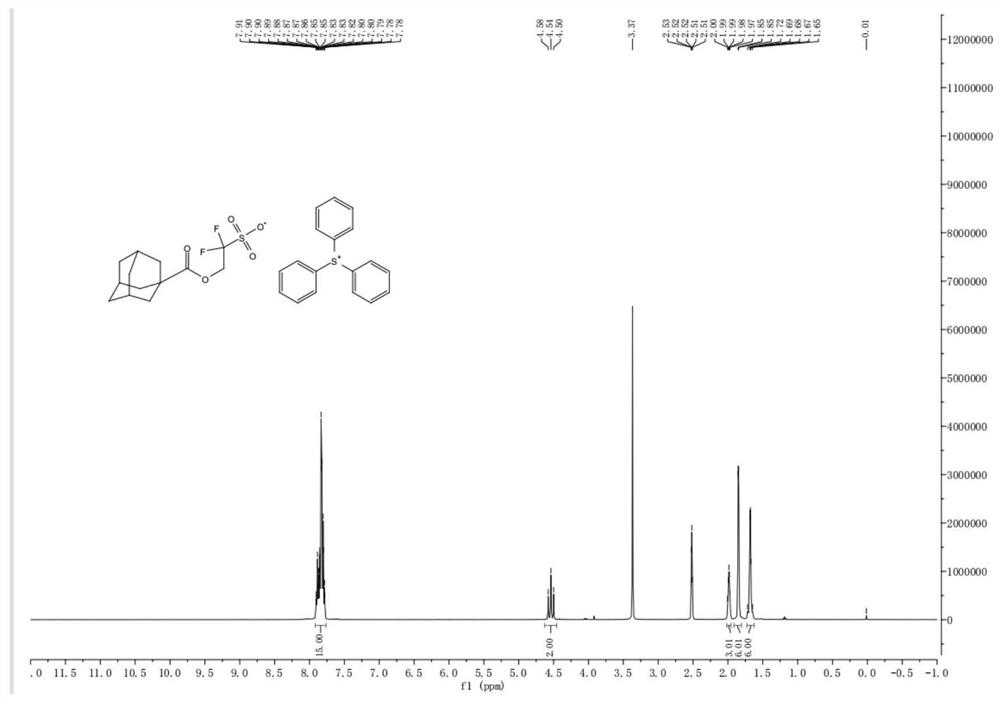

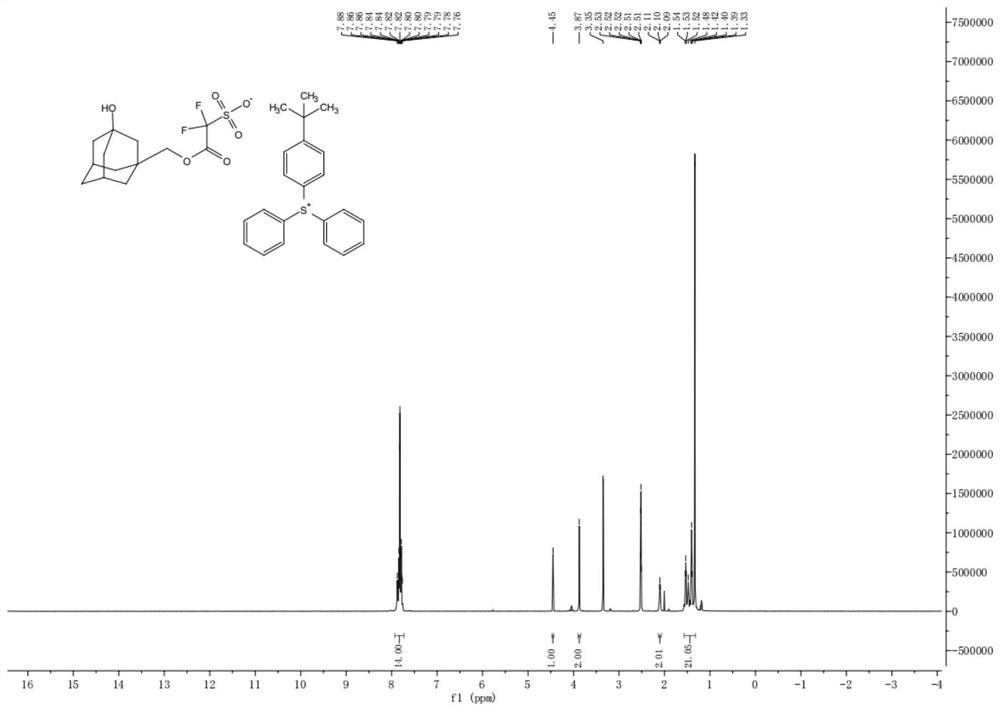

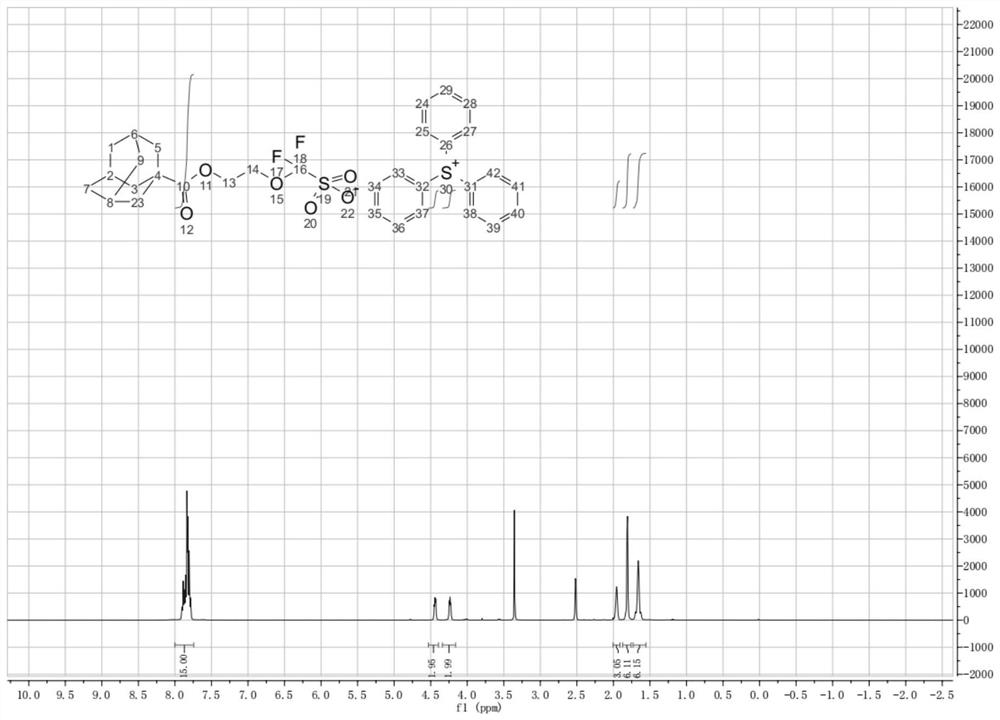

Preparation method and application of photoinitiator triphenyl sulfonium salt for ArF photoresist

PendingCN114736120ALow priceEasy to operateOrganic compound preparationCarboxylic acid esters preparationPolymer scienceOrganic synthesis

The invention relates to the field of organic synthesis, and particularly provides a preparation method of triphenyl sulfonium salt, which is characterized by comprising the following steps: step 1, taking difluorobromoacetic acid and alcohol as raw materials, and carrying out condensation reaction to obtain difluorobromoacetate; 2, carrying out a substitution reaction on the bromo difluoroacetate and sodium pyrosulfate to obtain sodium sulfonate; and 3, reacting the sodium sulfonate with triphenyl sulfur chloride to obtain the triphenyl sulfonium salt. The invention aims to provide a novel synthesis method which has the advantages of simplicity in operation, safety, high yield, easiness in purification and convenience in industrial production.

Owner:安徽秀朗新材料科技有限公司

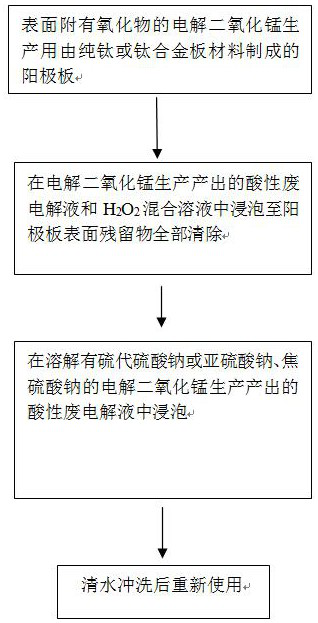

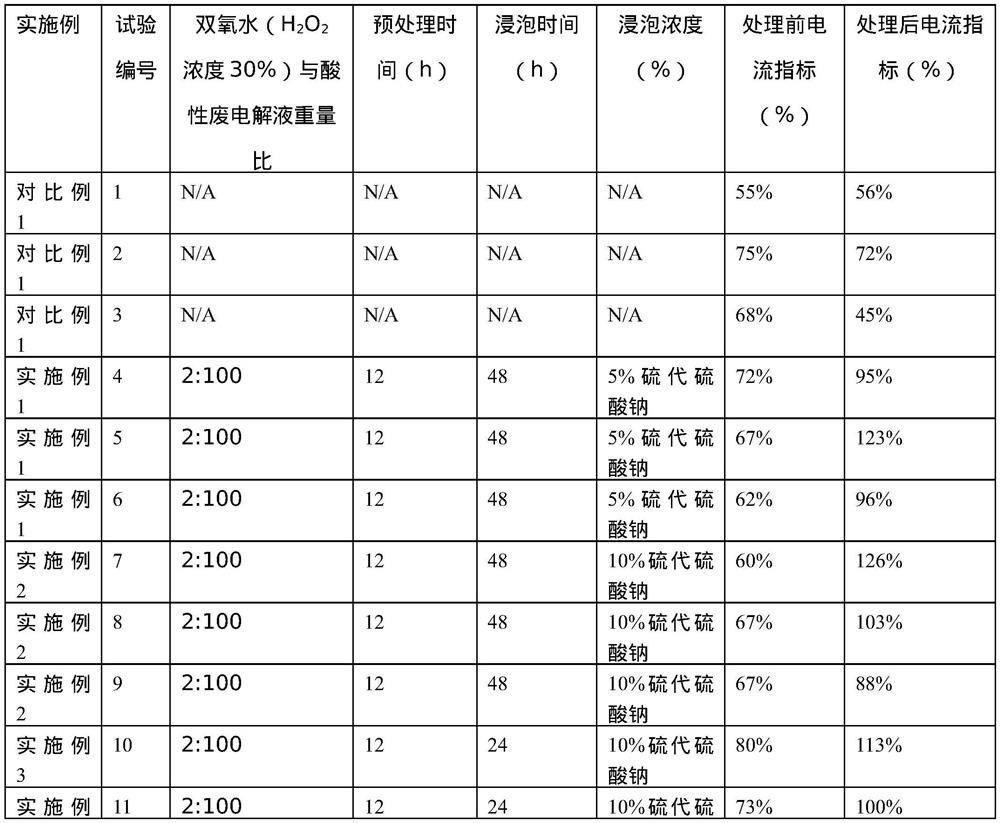

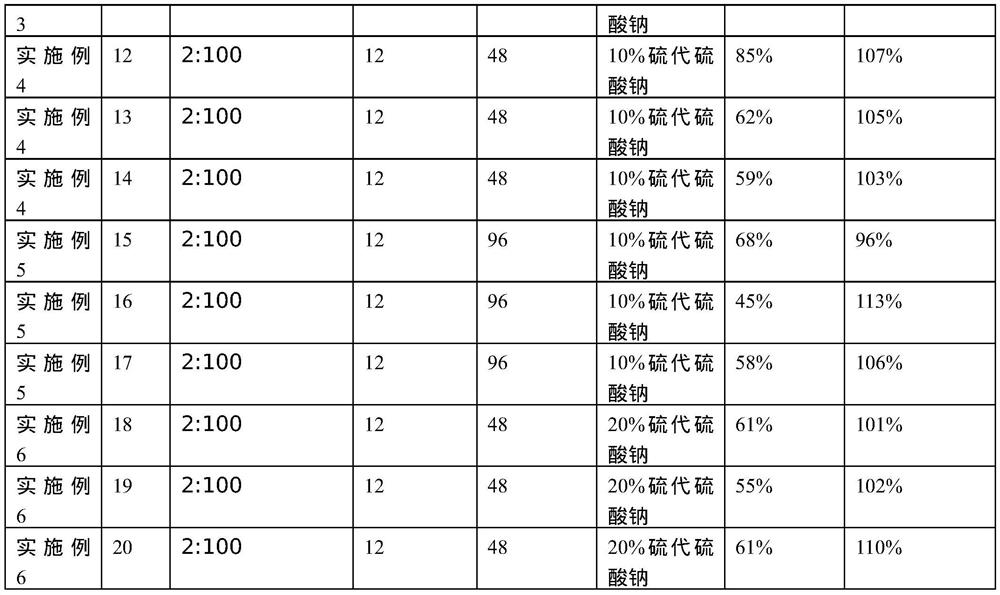

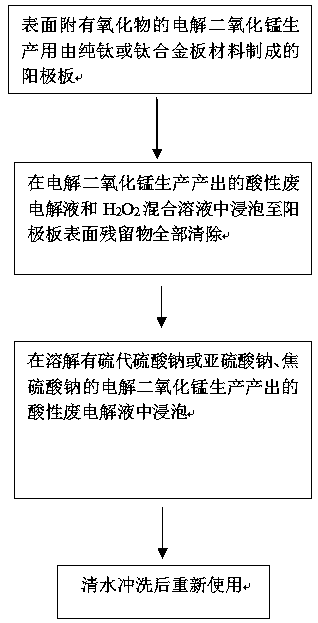

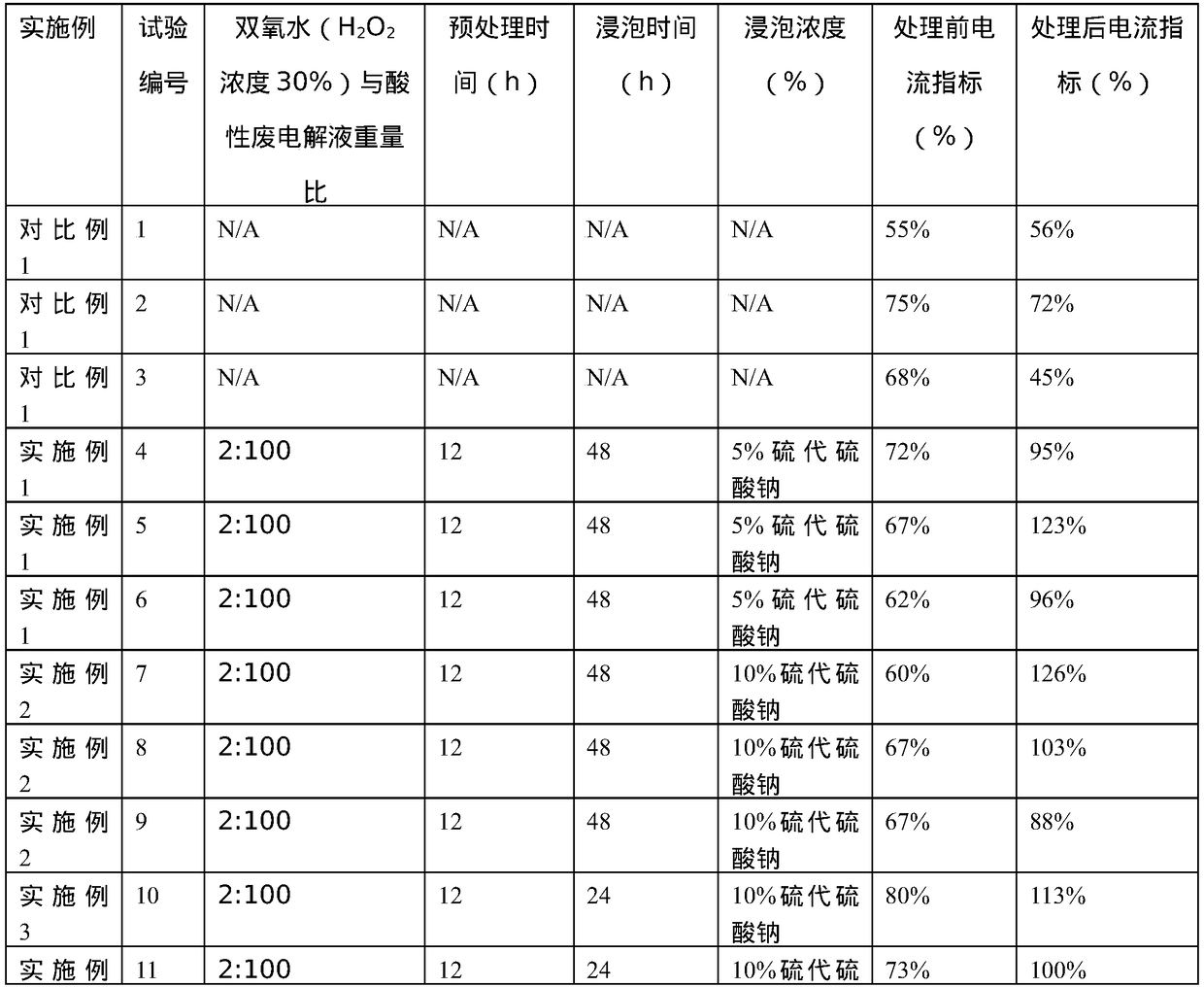

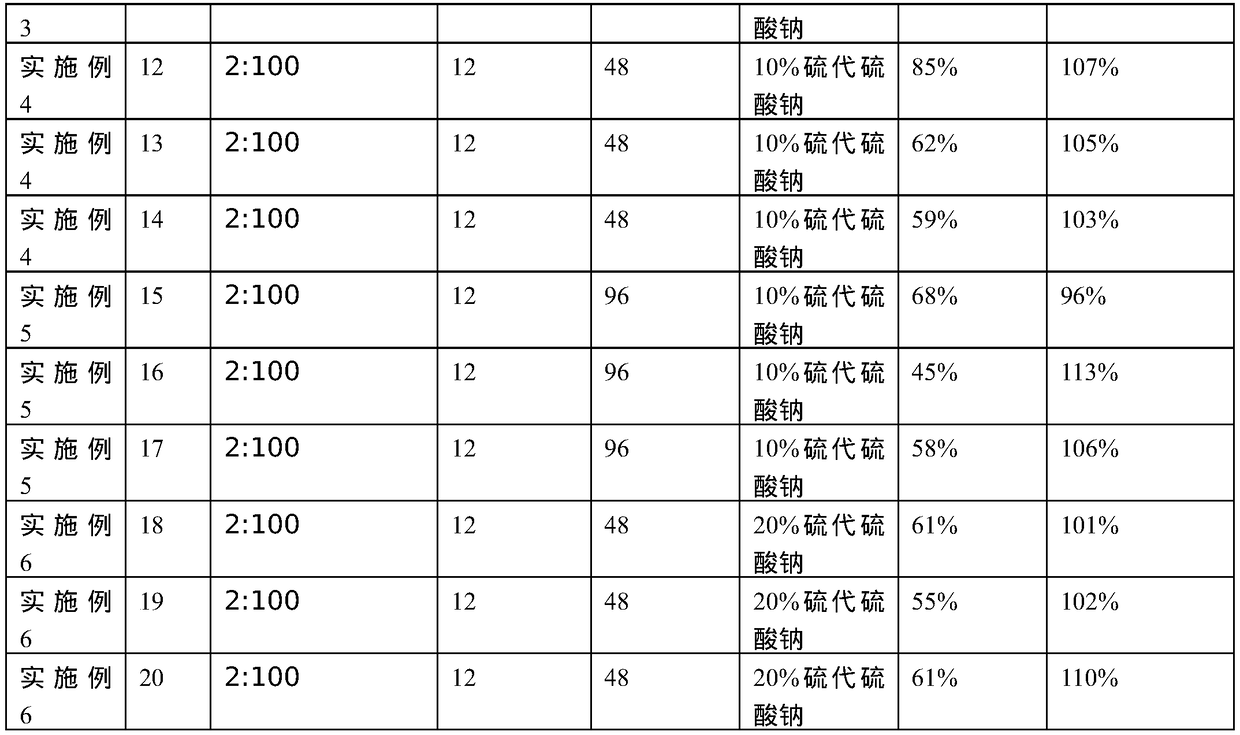

A treatment method for improving the conductivity of anode plates for electrolytic manganese dioxide

ActiveCN109385645BImprove conductivityNo damageNon-noble metal oxide coatingsMetallic material coating processesElectrolytic agentSulfite salt

The invention discloses a treatment method for improving the conductivity of an anode plate for electrolytic manganese dioxide, which comprises the following steps: (1) injecting the acid waste electrolyte produced in the production process of electrolytic manganese dioxide into treatment tank 1 and treatment tank respectively In the second process, after adding hydrogen peroxide in the treatment tank 1, the anode plate with poor conductivity is pretreated to remove the residual electrolytic manganese dioxide on the surface of the anode plate; (2) Add sodium thiosulfate to the acidic waste electrolyte in the treatment tank 2 , Sodium sulfite or sodium pyrosulfate, redox immersion treatment is carried out on the pretreated anode plate; (3) After the immersion treatment is completed, the anode plate is taken out, and it can be reused after washing with clean water. The invention can remove the oxide layer on the surface of the anode plate used for electrolytic manganese dioxide production without causing damage to the anode body, and can prolong the service life of the anode plate.

Owner:GUANGXI ERAMET COMILOG CHEM

Treatment method for improving conductivity of anode plate for electrolytic manganese dioxide production

The invention discloses a treatment method for improving the conductivity of an anode plate for electrolytic manganese dioxide production. The treatment method comprises the following steps: (1), injecting an acid waste electrolyte produced during the electrolytic manganese dioxide production into a treating tank 1 and a treating tank 2 respectively, adding hydrogen peroxide into the treating tank1, and then pretreating the anode plate with poor conductivity, so as to remove residual electrolytic manganese dioxide on the surface of the anode plate; (2), adding sodium thiosulfate, sodium sulfite or sodium pyrosulfate into the acid waste electrolyte in the treating tank 2, and then performing redox soaking treatment to the pretreated anode plate; (3), after completion of the soaking treatment, taking out the anode plate and washing with clear water for reuse. With the treatment method, an oxide layer on the surface of the anode plate for the electrolytic manganese dioxide production canbe removed without damage to an anode body, and the service life of the anode plate can be prolonged.

Owner:GUANGXI ERAMET COMILOG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com