Preparation method of chlorine dioxide

A chlorine dioxide and activator technology, applied in the direction of chlorine dioxide, chlorine oxide, etc., can solve the problems of losing the superiority of chlorine dioxide in treating tap water, high price, and drug failure, and achieves simple structure, convenient operation, and prevention of emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 prepares chlorine dioxide solution

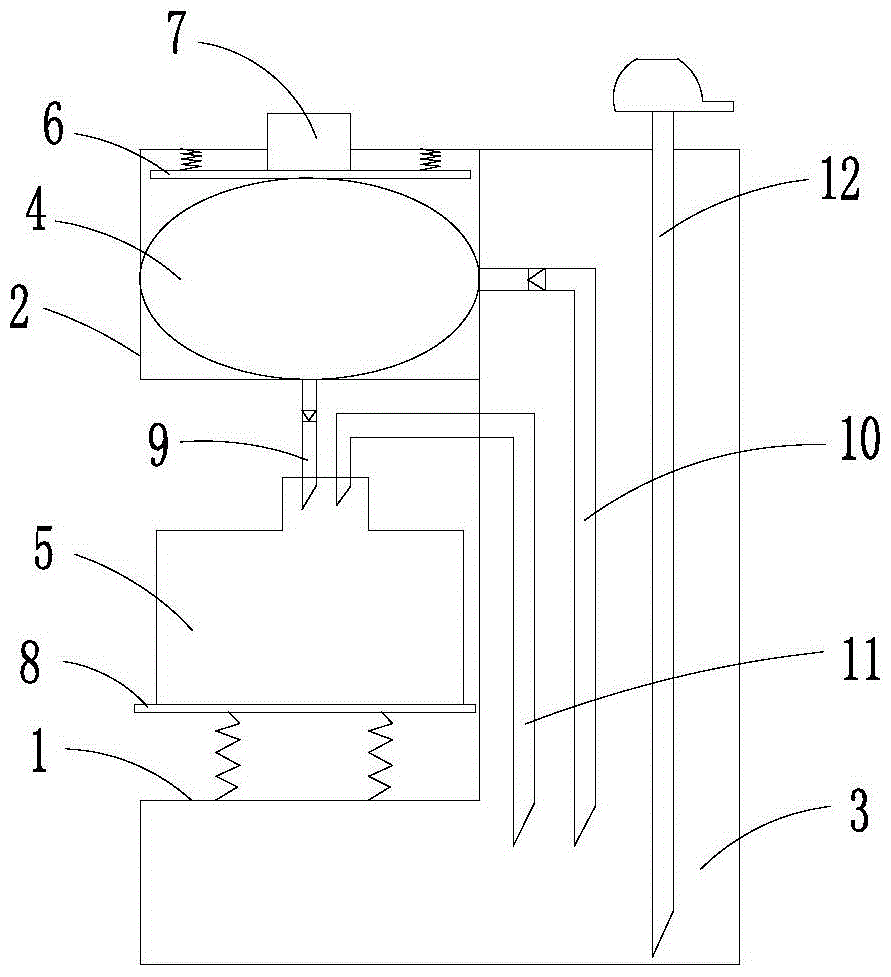

[0020] use figure 1 The chlorine dioxide reaction apparatus shown prepares chlorine dioxide solution. The raw materials in the kit 5 are powdery, containing: 12.06g (0.11mol) of sodium chlorate, 4.41g (0.049mol) of oxalic acid dihydrate, 5.28g (0.044mol) of sodium bisulfate, 24.4g (0.044mol) of anhydrous calcium chloride ( 0.22mol).

[0021] Follow the steps below:

[0022] Step 1: Unload the outlet tap 12 of the chlorine dioxide absorption bottle 3 or open the bottle cap of the chlorine dioxide absorption bottle 3, and add 1L of tap water to it to ensure that the liquid level is higher than the second conduit 10 in the chlorine dioxide absorption bottle 3 And the conduit port of the first water outlet tap 12, but lower than the conduit port of the third conduit 11 above the medicine box 5, preventing water from flowing backwards. Usually, the mass ratio of the chlorate in the kit 5 to the water added in the absorpti...

Embodiment 2

[0029] Embodiment 2 prepares chlorine dioxide solution

[0030] Chlorine dioxide is prepared according to the same method in Example 1, but the raw materials in the kit 5 are different, and the raw materials contain: potassium chlorate 12.25g (0.1mol), oxalic acid 10.8g (0.12mol), potassium pyrosulfate 40.7g ( 0.16mol), 5.33g (0.04mol) of anhydrous aluminum chloride.

[0031] After reacting for 12 minutes, the absorption solution in the absorption bottle 3 was taken for inspection, and the chlorine dioxide concentration recorded was 438ppm, and the chlorine gas concentration was 26ppm.

Embodiment 3

[0032] Embodiment 3 prepares chlorine dioxide solution

[0033]Chlorine dioxide is prepared according to the same method in Example 1, but the raw materials in the kit 5 are different, and the raw materials contain: sodium chlorate 10.64g (0.1mol), sodium sulfite 12.6g (0.1mol), oxalic acid 9.0g ( 0.1mol), anhydrous magnesium chloride 9.5g (0.1mol).

[0034] After reacting for 12 minutes, the absorption solution in the absorption bottle 3 was taken for inspection, and the chlorine dioxide concentration recorded was 316 ppm, and the chlorine gas concentration was 32 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com