Determination method of total aluminum content in steel and alloy

A determination method and technology for aluminum content, applied in the field of chemical detection, to achieve the effects of less environmental pollution, less matrix effect and high analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

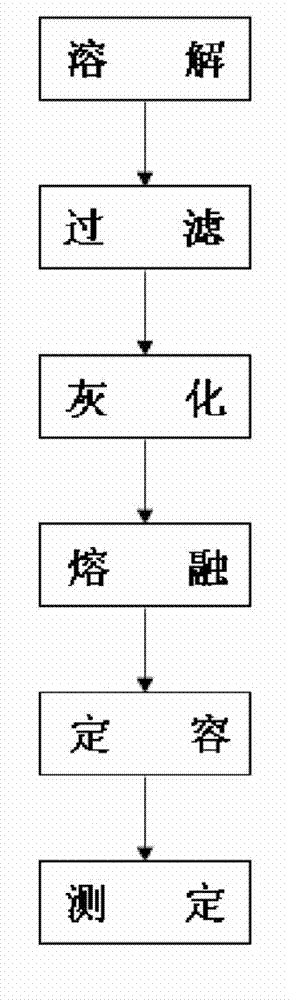

Method used

Image

Examples

Embodiment 1

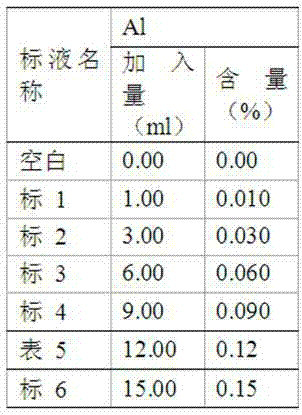

[0045] Prepare the following standard solutions as usual:

[0046] 1. Preparation of aluminum standard solution:

[0047] 1A. Put 1.0000g of pure commercially available metallic aluminum in a 400 mL beaker, add hydrochloric acid at an amount of 200mL / g metallic aluminum, dissolve in a water bath at 85°C (1-3 days), and cool to room temperature after dissolving ;

[0048] 1B. Transfer the solution in step 1A into a 1000mL volumetric flask, dilute to 1000mL with distilled water, and shake well to obtain a 1mg / mL aluminum standard stock solution;

[0049] 1C. Pipette 20mL of the solution in step 1B into a 100mL volumetric flask, add 10mL of hydrochloric acid (1+1), dilute to 100mL with water, and shake well to obtain a 200.0ug / mL aluminum standard solution.

[0050] 1D. Pipette 25mL of the solution in step 1C into a 100mL volumetric flask, add 10mL of hydrochloric acid (1+1), dilute to 100mL with water, and shake well to obtain a 50.0ug / mL aluminum standard solution.

[0051] ...

Embodiment 2

[0062] Preparation of all-aluminum sample solution in steel and alloy to be tested:

[0063] 1A. Add 10mL of distilled water to 0.5000g of steel and alloy samples to be tested, according to the amount of 20mL / g sample, to obtain a mixed solution;

[0064] 1B. In the mixed solution obtained in step 1A, add 8 mL of hydrochloric acid in an amount of 15 mL / g sample to obtain a mixed solution;

[0065] 1C. Add 3 mL of nitric acid to the mixed liquid obtained in step 1B according to the amount of 6 mL / g sample, heat and dissolve on a 100°C electric heating plate at low temperature, cool to room temperature, filter with slow filter paper with a small amount of pulp added, and precipitate Move all into filter paper, wash the filter paper and precipitate with hydrochloric acid (5+95) for 7 to 8 times, and wash with hot water for 2 to 3 times to obtain the filtrate, residue and filter paper;

[0066] 1D. Put the residue and filter paper obtained in step 1C in a platinum crucible, dry a...

Embodiment 3

[0073] Preparation of all-aluminum sample solution in steel and alloy to be tested:

[0074] 1A. Add 13mL of distilled water to 0.5000g of steel and alloy samples to be tested, according to the amount of 25mL / g sample, to obtain a mixed solution;

[0075] 1B. In the mixed solution obtained in step 1A, add 10 mL of hydrochloric acid in an amount of 20 mL / g sample to obtain a mixed solution;

[0076] 1C. Add 4 mL of nitric acid to the mixed liquid obtained in step 1B, according to the amount of 8 mL / g sample, heat and dissolve on a hot plate at 120 °C at low temperature, cool to room temperature, filter with slow filter paper with a small amount of pulp added, and precipitate Move all into filter paper, wash the filter paper and precipitate with hydrochloric acid (5+95) for 7 to 8 times, and wash with hot water for 2 to 3 times to obtain the filtrate, residue and filter paper;

[0077] 1D. Put the residue obtained in step 1C and filter paper in a platinum crucible, dry and ash,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com