Method for producing adiponitrile through acrylonitrile electrolysis dimerization method

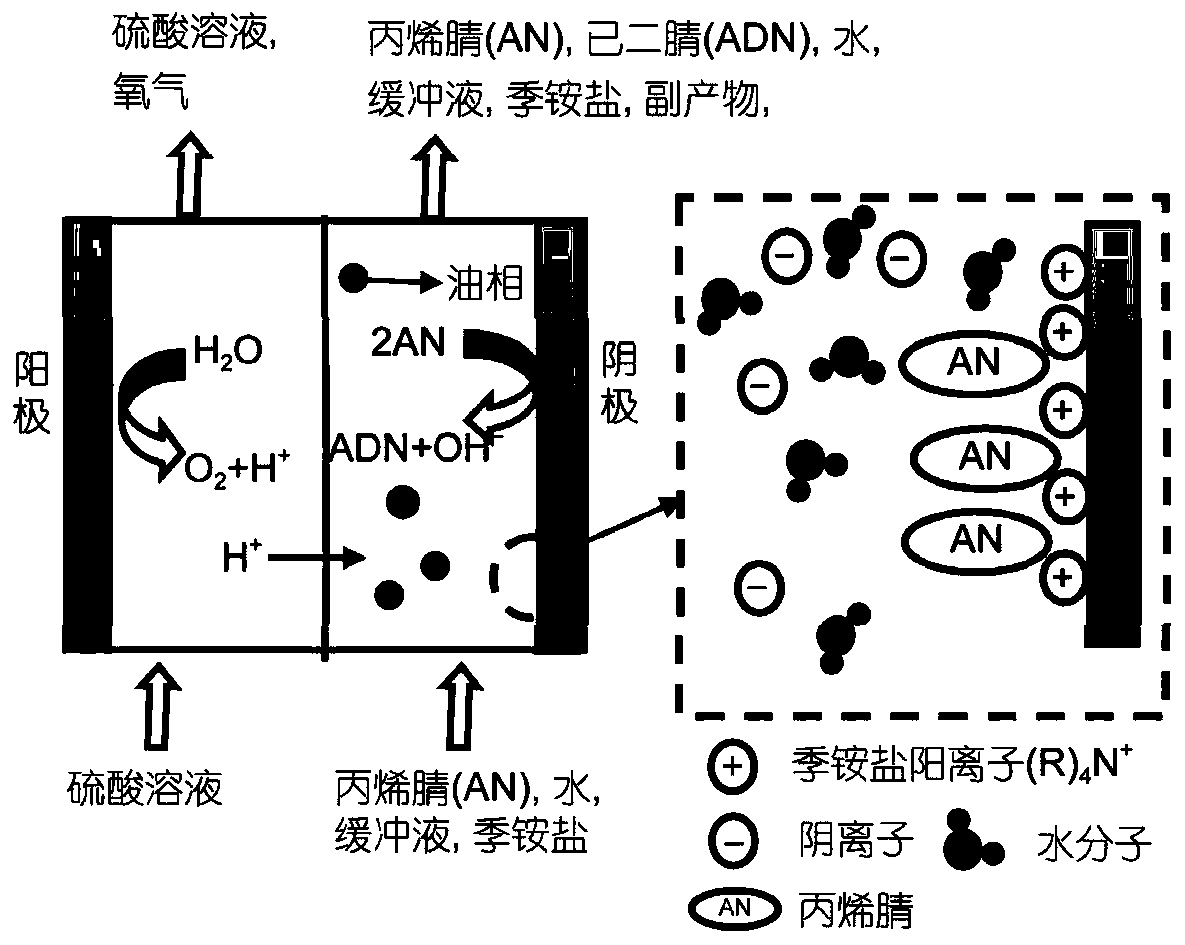

A technology of acrylonitrile and adiponitrile, which is applied in the field of electrolytic preparation of adiponitrile, which can solve the problems of small investment and achieve the effects of improving mass transfer, reducing concentration polarization, and good degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

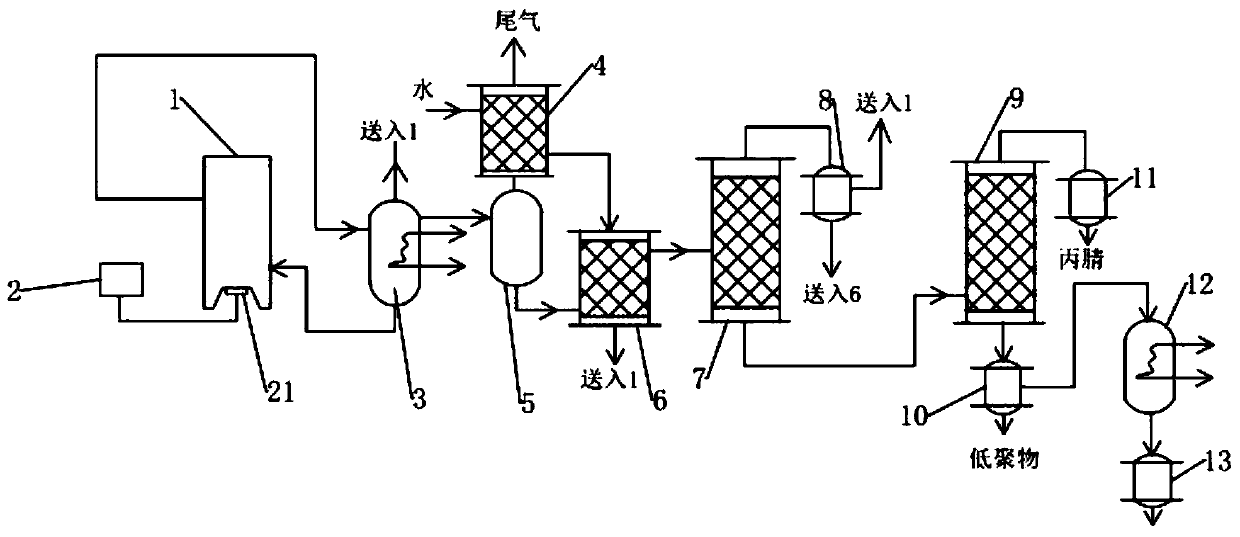

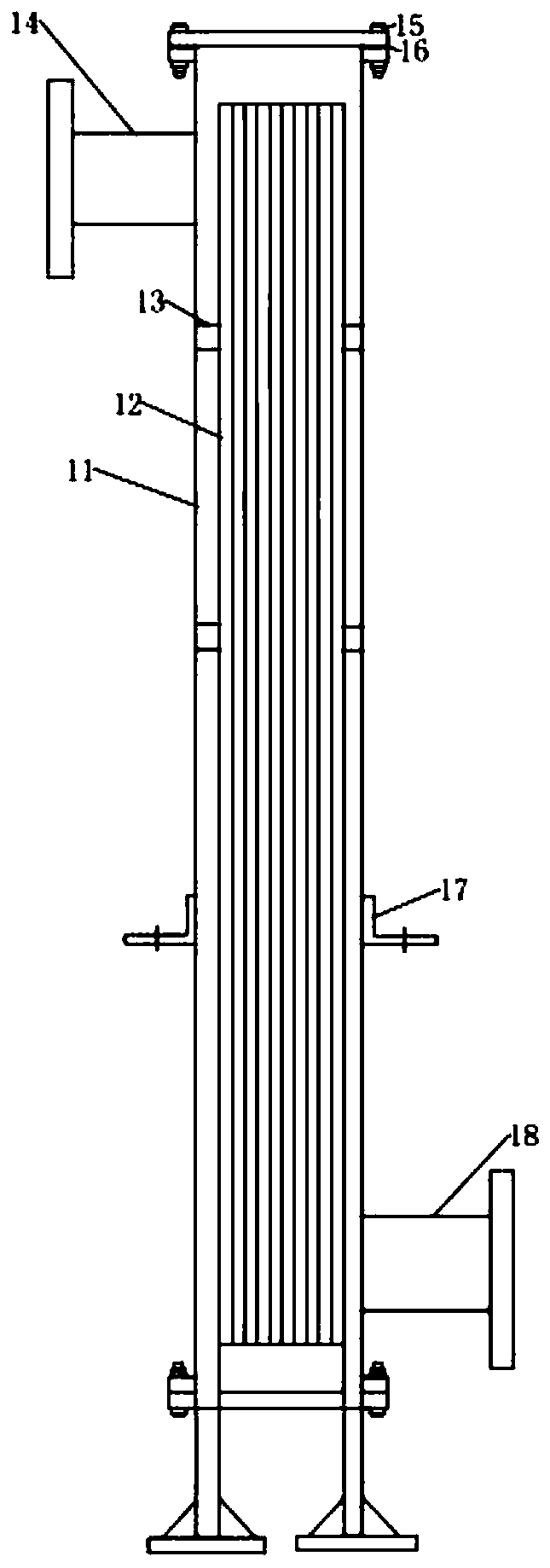

[0040] A method for producing adiponitrile by electrolytic dimerization of acrylonitrile, comprising adding an electrolytic solution in an electrolytic cell 1 without a diaphragm, in the range of pH 6 to 9, at a temperature of 20 to 60°C and an electrolysis voltage of 3~7V, current density 500~3000A·m -2 Continuous electrolysis under the condition of continuous electrolysis, start the ultrasonic generator 2 at the same time of electrolysis, the electrolyte solution after electrolysis is cooled by the first cooler 3 and then enters the phase separator 5, and the water phase electrolyte is separated from the lower water phase outlet after being coalesced and stratified Go out and enter the second washing tower 6 and then return to the electrolytic tank 1, and the crude product of the oil phase enters the first washing tower 4 and washes with water to separate the double quaternary ammonium salt, the latter returns to the electrolytic tank 1, and then flows into the second washing...

Embodiment 2

[0047] The components of the electrolyte and their mass percentages are: 3% acrylonitrile, 6% adiponitrile, 5% sodium hydrogen phosphate, 5% sodium dihydrogen phosphate, 1% dipotassium EDTA, 5% Borax, 3% N, N, N, N', N', N'-hexaethylhexamethylenediamine hydrogen phosphate, 1.5% sodium pyrosulfate, 1.5% 1-butyl-3-methylimidazole Monobasic phosphate, 3% sodium 2,3-dihydroxysuccinate, balance water.

[0048] Electrolysis conditions: pH 7, temperature 40°C, electrolysis voltage 5V, current density 1500A m -2 , the ultrasonic frequency is 50kHz, and the ultrasonic intensity is 0.5W·cm -2 , the electrolysis time is the theoretical electrolysis time.

[0049] After electrolysis, the yield of adiponitrile was 91.2%, and the current efficiency was 92.1%.

[0050] All the other are with embodiment 1.

Embodiment 3

[0052] The components of the electrolyte and their mass percentages are: 5% acrylonitrile, 10% adiponitrile, 15% potassium phosphate, 2% disodium EDTA, 10% borax, 2% N, N '-Diethyl-N,N,N',N'-tetrabutylhexamethylenediamine sulfate, 3% of N,N'-diethyl-N,N,N',N'-tetrabutyloctyl Diamine sulfuric acid, 3% sodium pyrosulfate, 2% 1-butyl-3-methylimidazolium dihydrogen phosphate, 4% sodium 2,3-dihydroxysuccinate, and the rest is water.

[0053] Electrolysis conditions: pH 9, temperature 60°C, electrolysis voltage 7V, current density 3000A m -2 , the ultrasonic frequency is 80kHz, and the ultrasonic intensity is 1W·cm -2 , the electrolysis time is the theoretical electrolysis time.

[0054] After electrolysis, the yield of adiponitrile was 91.4%, and the current efficiency was 92.6%.

[0055] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com