Quick dry adhesive for corrugated paper box and preparation method of quick dry adhesive

An adhesive and carton technology, applied in the directions of adhesive additives, adhesive types, starch-derived adhesives, etc., can solve the problems of slow drying speed, reduced production efficiency, difficult storage, etc., and achieves fast natural drying speed, The effect of short reaction time and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

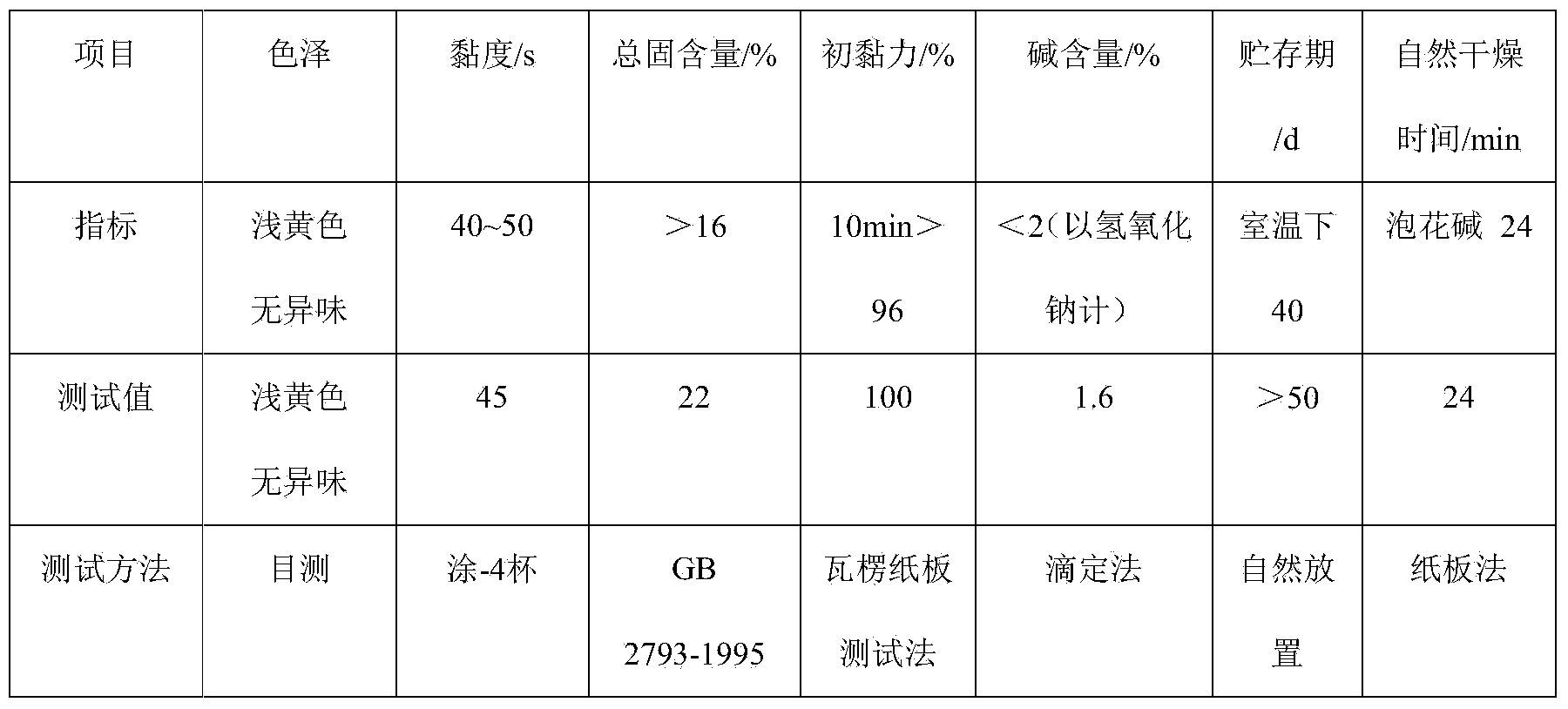

Image

Examples

Embodiment 1

[0015] A quick-drying adhesive for corrugated cartons of the present invention comprises the following components in parts by weight: 90 parts of cornstarch, 5 parts of bentonite, 6 parts of sodium hypochlorite, 0.1 part of sodium pyrosulfate, 0.1 part of ferrous sulfate, 0.15 parts of dry agent, 5 parts of sodium hydroxide solution with a volume concentration of 3%, 0.6 parts of borax, 0.5 parts of sodium sulfite, 200-280 parts of clear water and 0.5 parts of defoamer.

[0016] The defoamer in this embodiment is tributyl phosphate.

[0017] The invention also discloses a preparation method of a quick-drying adhesive for corrugated boxes, comprising the following steps:

[0018] (1) Stir the water and cornstarch weighed in parts by weight in the reactor for 5 minutes at room temperature,

[0019] (2) Then add sodium hypochlorite and ferrous sulfate solution and adjust the pH value of the mixture to 9~10 with sodium hydroxide solution, add sodium sulfite solution and stir for ...

Embodiment 2

[0023] A quick-drying adhesive for corrugated cartons of the present invention comprises the following components in parts by weight: 110 parts of cornstarch, 7 parts of bentonite, 10 parts of sodium hypochlorite, 0.2 parts of sodium pyrosulfate, 1 part of ferrous sulfate, 0.25 parts of dry agent, 8 parts of sodium hydroxide solution with a volume concentration of 3%, 1.6 parts of borax, 1.0 part of sodium sulfite, 280 parts of clear water and 1.5 parts of defoamer.

[0024] The defoamer in this embodiment is tributyl phosphate.

[0025] The preparation method is the same as in Example 1.

Embodiment 3

[0027] A quick-drying adhesive for corrugated cartons of the present invention comprises the following components in parts by weight: 95 parts of cornstarch, 5.5 parts of bentonite, 6.6 parts of sodium hypochlorite, 0.12 parts of sodium pyrosulfate, 0.13 parts of ferrous sulfate, 0.17 parts of dry agent, 5.5 parts of sodium hydroxide, 0.7 parts of borax, 0.6 parts of sodium sulfite, 210 parts of clear water and 0.6 parts of defoamer.

[0028] The defoamer used in this example is tributyl phosphate.

[0029] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com