Treatment method for improving conductivity of anode plate for electrolytic manganese dioxide production

A technology of electrolytic manganese dioxide and treatment methods, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of increased possibility, damage to the anode plate body, thinning of the anode plate, etc., to achieve easy acquisition, improved electrical conductivity, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

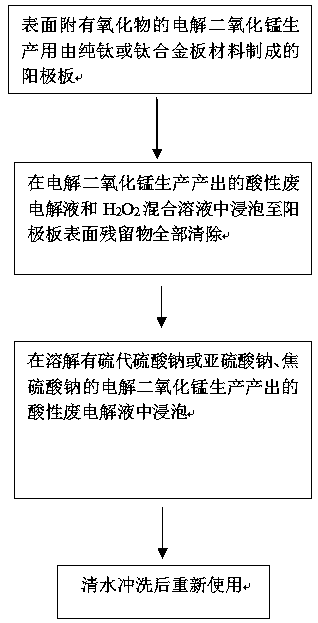

Method used

Image

Examples

Embodiment 1

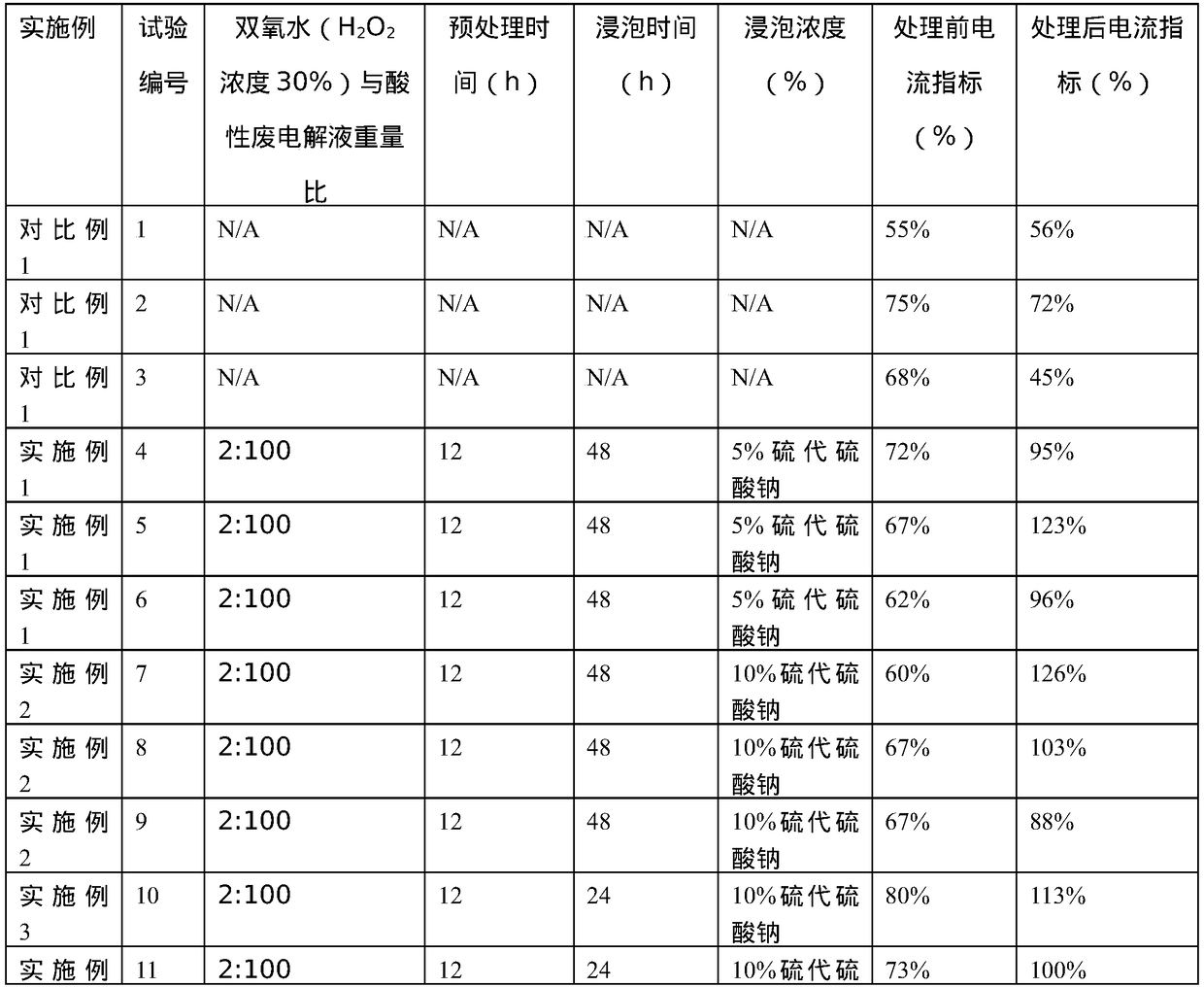

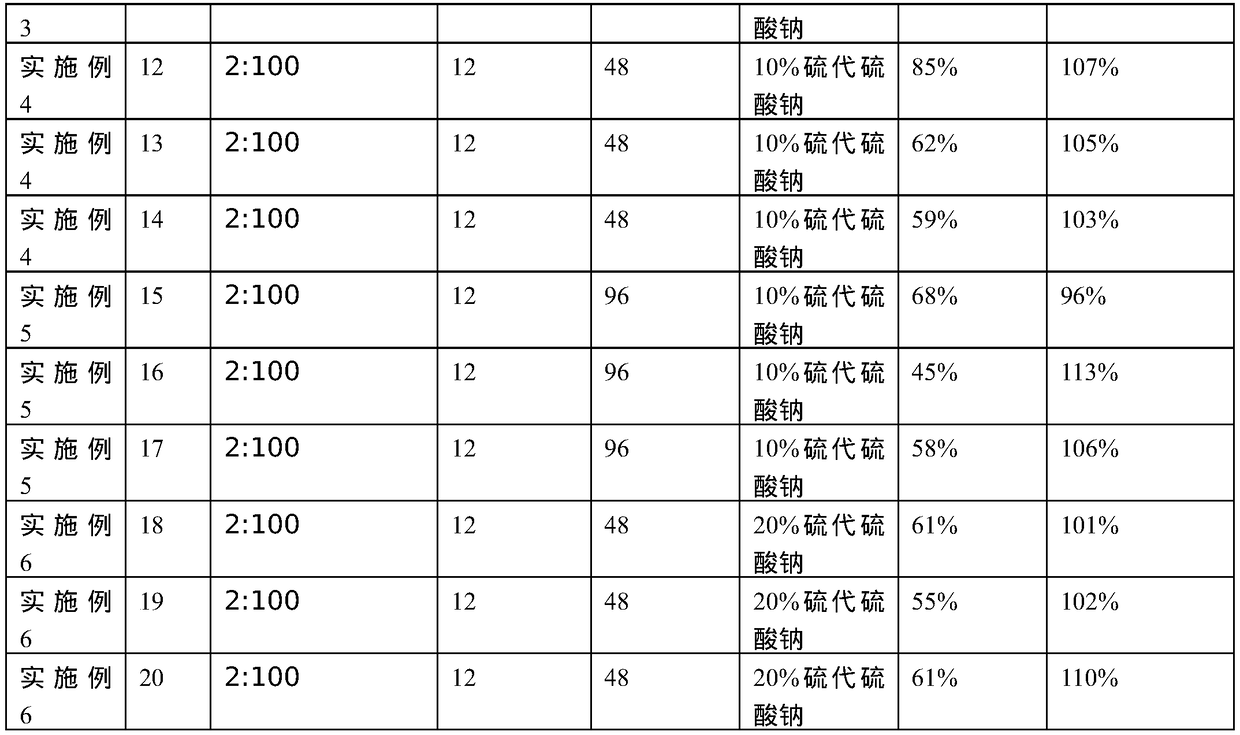

[0036] Embodiment 1 (No. 4, 5, 6)

[0037] The electrolytic manganese dioxide production anode plates selected during the production process with poor conductivity and low overcurrent are put back into the normal production electrolytic manganese dioxide electrolytic cell for electrolytic production, and the FLUKE current clamp meter is used to measure through each anode plate Anode plate current. After the measurement, the anode plate is taken out from the electrolytic cell, pretreated and soaked, and then put back into the normal production electrolytic manganese dioxide electrolytic cell for electrolytic production. The current passing through each anode plate is measured with a FLUKE current clamp meter. Taking the measured current as the numerator and the normal current of the unpassivated and normal plate as the denominator, the measured current is converted into a percentage as the current index and compared with the normal current index of the unpassivated plate. In t...

Embodiment 2

[0042] Embodiment 2 (No. 7, 8, 9)

[0043] Part of the process of this embodiment is the same as that of Embodiment 1.

[0044] The weight ratio of hydrogen peroxide and acid waste electrolytic solution in the pretreatment step of the present embodiment is 2:100; Contain sulfuric acid 30g / L, manganese sulfate 80g / L in the acid waste electrolytic solution, the processing time of pretreatment step is 12 hours; The temperature is room temperature;

[0045] Soaking conditions of the present embodiment: add 10% sodium thiosulfate in the acidic waste electrolyte; soak for 48 hours, contain 30 g / L of sulfuric acid and 100 g / L of manganese sulfate in the acidic waste electrolyte, and the treatment temperature is room temperature;

[0046] Results: The average veneer before treatment was 65%, and the average veneer after treatment was 106%.

Embodiment 3

[0047] Embodiment 3 (No. 10, 11)

[0048] Part of the process of this embodiment is the same as that of Embodiment 2.

[0049] The weight ratio of pretreatment step hydrogen peroxide and acid waste electrolyte is 2:100; Contain sulfuric acid 50g / L in acid waste electrolyte, manganese sulfate 100g / L, the treatment time of pretreatment step is 12 hours; Treatment temperature is room temperature;

[0050] Soaking conditions: add 10% sodium thiosulfate to the acidic waste electrolyte; soak for 24 hours

[0051] Results: The average veneer before treatment was 77%, and the average veneer after treatment was 107%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com