Filling tailing curing agent containing copper smelting slag

A technology of copper smelting slag and curing agent, which is applied in the field of metal mines, can solve the problems of unsatisfactory curing effect, high cost and low early strength of ultra-fine tailings, and achieve good economic and social effects, high early strength and working performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 A tailings solidifying agent containing copper smelting slag, which is prepared by mixing the following raw materials uniformly and then drying to a moisture content of 0.5%: 60 kg of copper smelting slag fine powder, 20 kg of S95 mineral powder kg, 10 kg of desulfurized gypsum, 9 kg of Portland cement clinker powder, and 1 kg of Yuanming powder.

[0031] Among them: S95 ore powder comes from Hanzhong Iron and Steel Plant, and its specific surface area is 450 m 2 / kg.

[0032] The Portland cement clinker forms a powder material after grinding, and its specific surface area is 410m 2 / kg.

[0033] The desulfurized gypsum was taken from a nearby power plant, and it was determined that calcium sulfate dihydrate CaSO 4 2H 2 The O content is 93.6%.

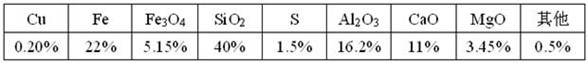

[0034] The copper smelting slag originated from a copper smelter in Gansu, and its chemical composition is shown in Table 1 below.

[0035] Table 1 Composition of copper smelting slag

[0036]

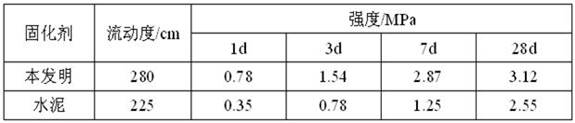

[0037] Apply ...

Embodiment 2

[0046] Example 2 A tailings solidifying agent containing copper smelting slag, which is prepared by mixing the following raw materials uniformly and then drying to a moisture content of 0.5%: 66 kg of copper smelting slag fine powder, 15 kg of S95 mineral powder kg, 10 kg of desulfurized gypsum, 8 kg of Portland cement clinker powder, and 1 kg of Yuanming powder.

[0047] Among them: S95 ore powder comes from Xuanhua Iron and Steel Plant, and its specific surface area is 465 m 2 / kg.

[0048] The Portland cement clinker forms a powder material after grinding, and its specific surface area is 405m 2 / kg.

[0049] The desulfurized gypsum was taken from a nearby power plant, and it was determined that calcium sulfate dihydrate CaSO 4 2H 2 O content is 94%.

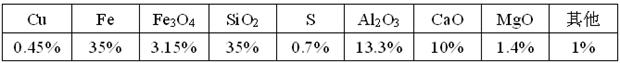

[0050] The copper smelting slag originated from a copper smelter in Hebei, and its chemical composition is shown in Table 3 below.

[0051] Table 3 Composition of copper smelting slag

[0052]

[0053] Apply the obtai...

Embodiment 3

[0062] Example 3 A tailings solidifying agent containing copper smelting slag, which is prepared from the following raw materials: 50 kg of fine powder of copper smelting slag, 15 kg of S95 ore powder, 20 kg of desulfurized gypsum, and Portland cement clinker 13 kg of fine powder, 2 kg of Yuanming powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com