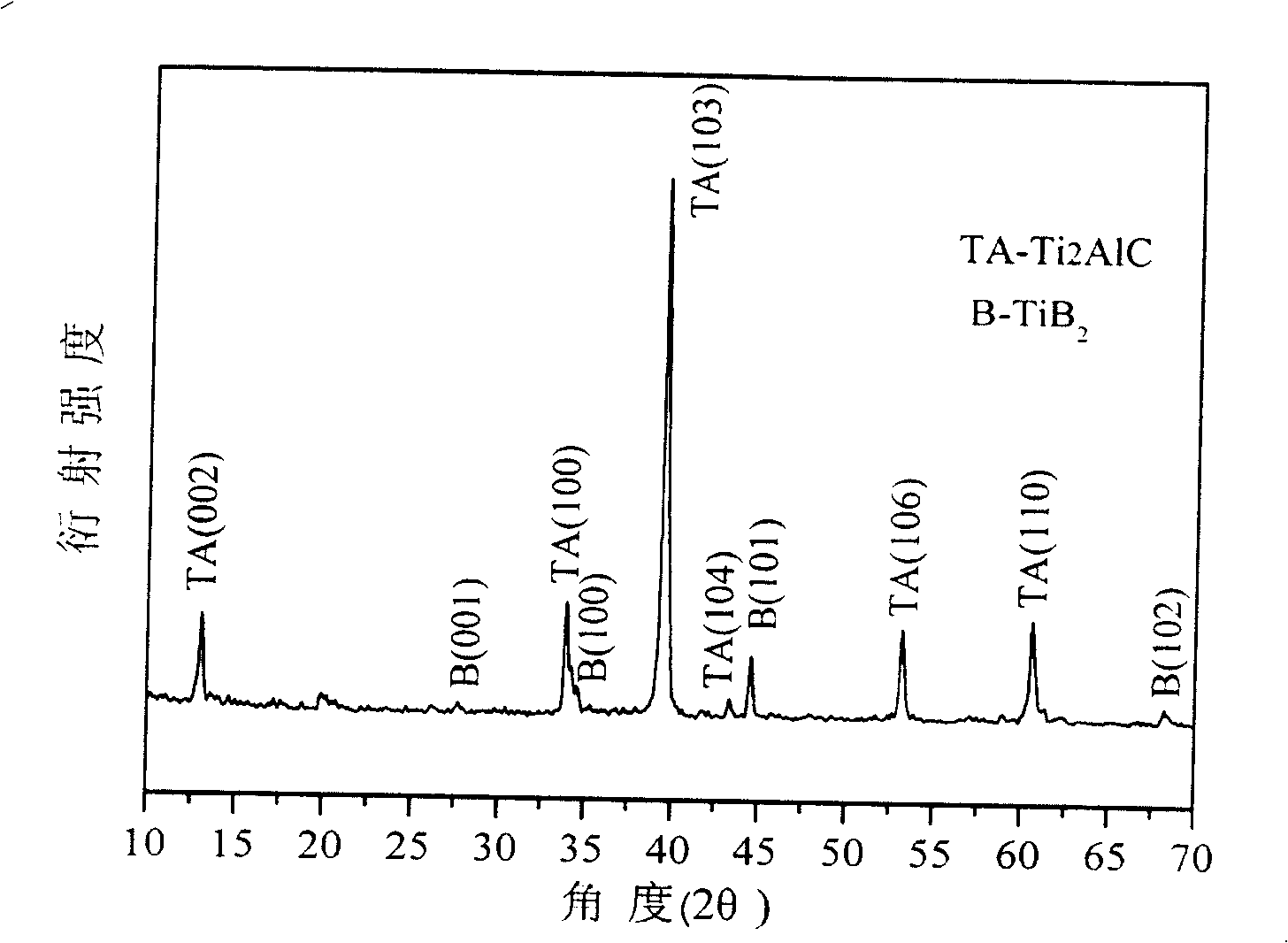

Compact Ti2AlC-TiB2 composite material and preparation method therefor

A ti2alc-tib2, composite material technology, applied in the field of new structural materials, can solve the problems of low AlC hardness and poor acid resistance, and achieve the effect of dense structure, no interface pollution, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The molar ratio of the raw material powder is Ti:Al:B:C=4.75:2.15:1:2.15; it is mixed evenly, put into a graphite mold, and sintered in a hot-press sintering system under argon protection. The heating rate is 100°C / min, the sintering temperature is 1250°C, the pressure is 30MPa, and the temperature is kept for 5 minutes. The density of the bulk material is 99.5%, Ti 2 The AlC content is 90%. Measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥800MPa, and the three-point bending strength σ b ≥600MPa, K IC ≥7MPa·m 1 / 2 , Vickers microhardness> 8GPa.

Embodiment 2

[0018] The molar ratio of the raw material powder is Ti:Al:B:C=3.15:1.35:1:1.35; it is mixed uniformly, put into a graphite mold, and sintered in a vacuum system of spark plasma sintering. The heating rate is 200°C / min, the sintering temperature is 1250°C, the pressure is 50MPa, and the temperature is kept for 10 minutes. The density of the bulk material is 99.2%, Ti 2 The AlC content is 85%. Measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥800MPa, and the three-point bending strength σ b ≥600MPa, K IC ≥7MPa·m 1 / 2 , Vickers microhardness> 8GPa.

Embodiment 3

[0020] The molar ratio of the raw material powder is Ti:Al:B:C=2.45:1.05:1:1.05; it is mixed uniformly, put into a graphite mold, and sintered in a vacuum system of spark plasma sintering. The heating rate is 200°C / min, the sintering temperature is 1200°C, the pressure is 50MPa, and the temperature is kept for 13 minutes. The density of the bulk material is 99.2%, Ti 2 The AlC content is 80%. Measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥800MPa, and the three-point bending strength σ b ≥600MPa, K IC ≥7MPa·m 1 / 2 , Vickers microhardness> 8GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

| Vickers microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com