Control circuit of inverter welding machine

A technology for controlling circuits and inverter welding machines, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of welding rods sticking together, threatening personal safety, affecting welding efficiency, etc., and achieves the reduction of welding interruption and reduction Equipment damage and the effect of ensuring welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

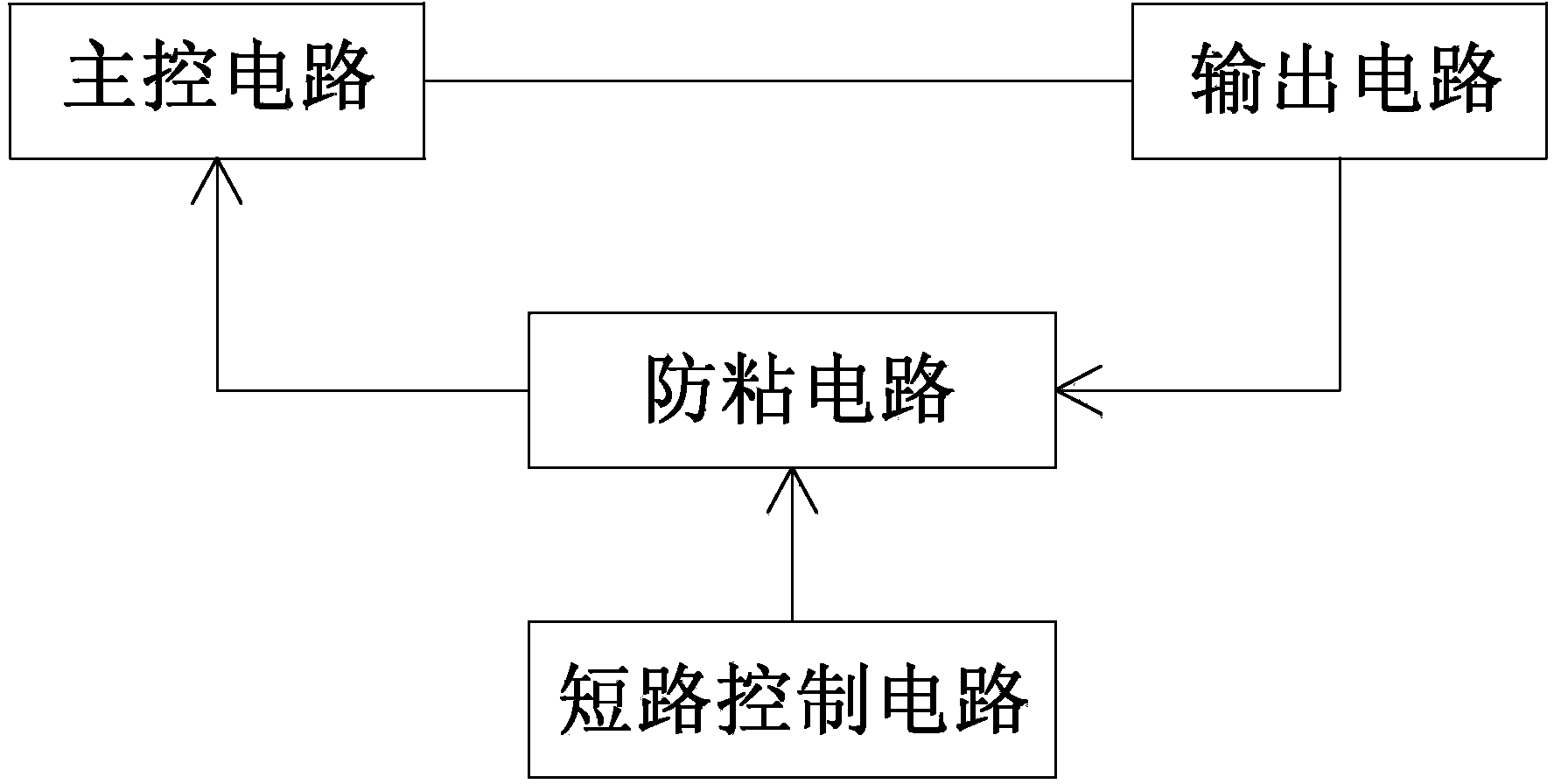

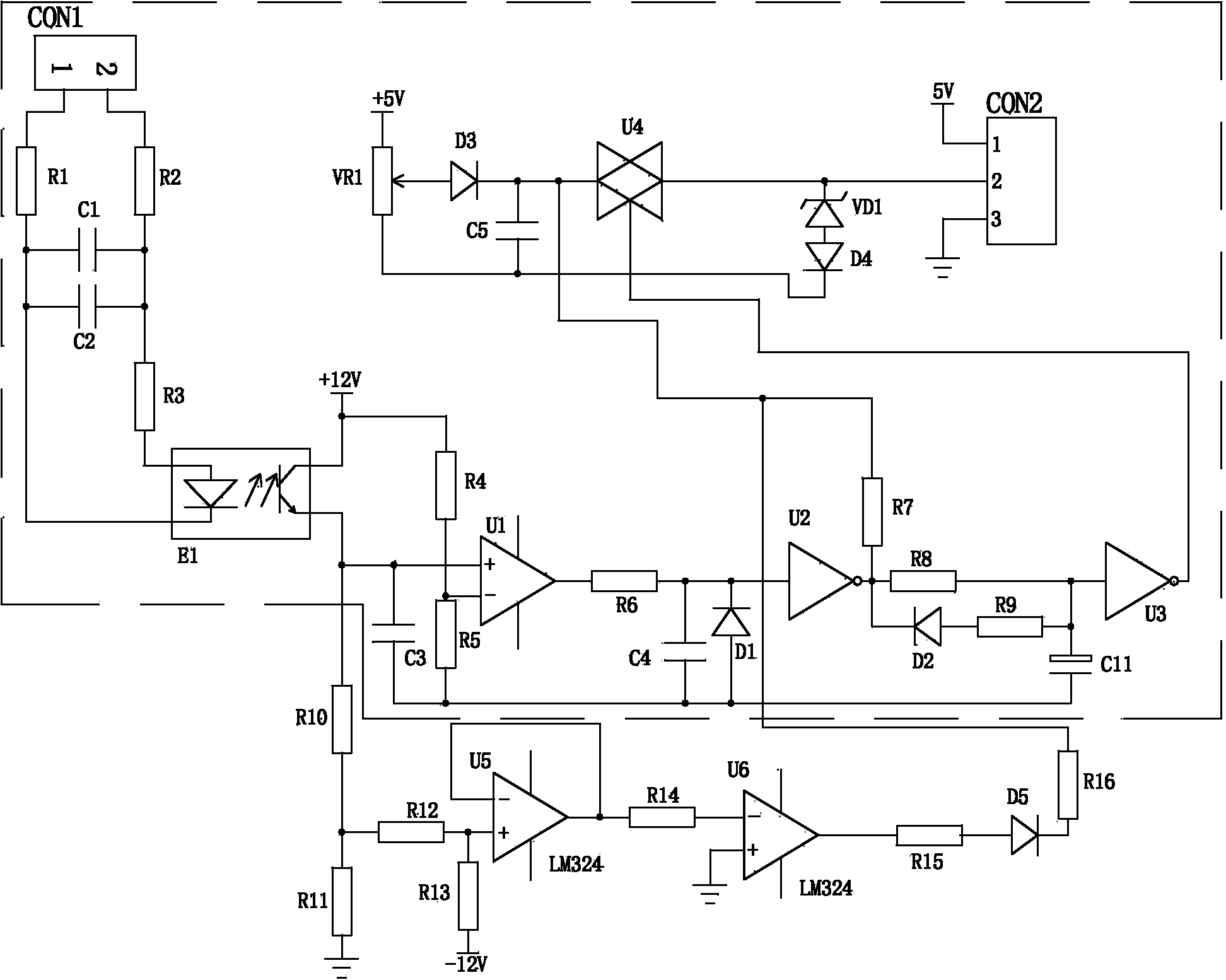

[0012] Such as figure 1 , figure 2 As shown, an inverter welding machine control circuit of the present invention includes a main control circuit and an output circuit, the main control circuit is connected to the output circuit, the above is the prior art; the inverter welding machine control circuit also includes -Anti-adhesive circuit to prevent the welding rod from sticking to the workpiece (e.g. figure 2 The structure in the middle box), the anti-sticking circuit includes resistors R1, R2, R3, R4, R5, R6, R7, R8, R9, capacitors C1, C2, C3, C4, C5, diodes D1, D2, D3 , D4, Zener diode VD1, rheostat VR1, electrolytic capacitor C11, photocoupler E1, comparator U1, inverter U2 and U3, electronic switch U4; one end of the resistor R1 and one end of the resistor R2 are respectively connected to the output circuit The positive and negative po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com