Cutting equipment and cutting method of flexible thin film solar cell

A technology for solar cells and flexible films, applied in the field of solar cells, can solve problems such as cell efficiency decline, and achieve the effects of simple equipment, simple cutting process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the purpose, technical solution and advantages of the present invention clearer, the cutting method and equipment of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0072] In this embodiment, cutting a flexible compound thin film solar cell is taken as an example, and the substrate of the compound thin film solar cell is a metal foil.

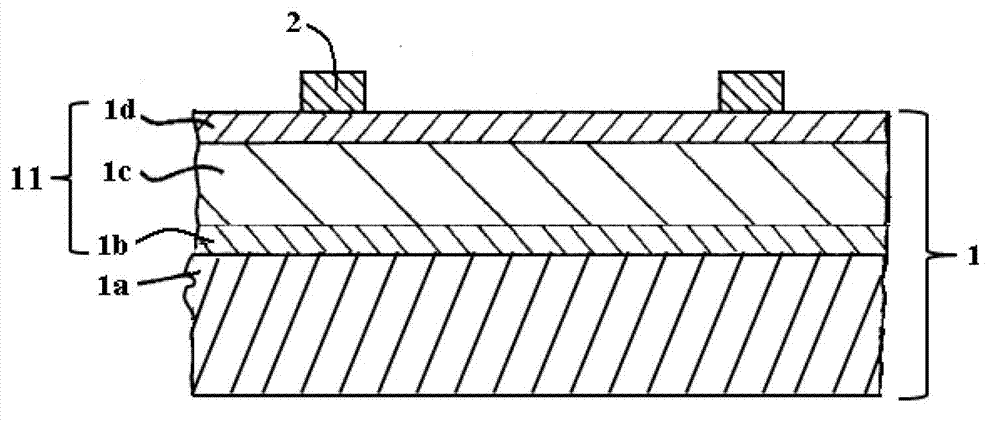

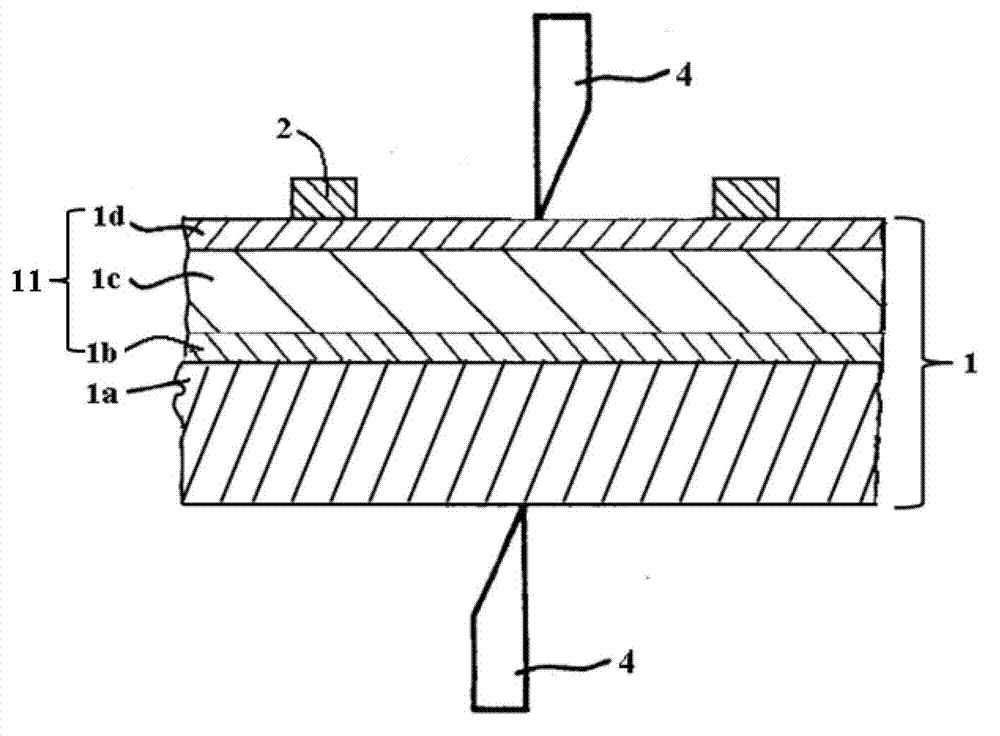

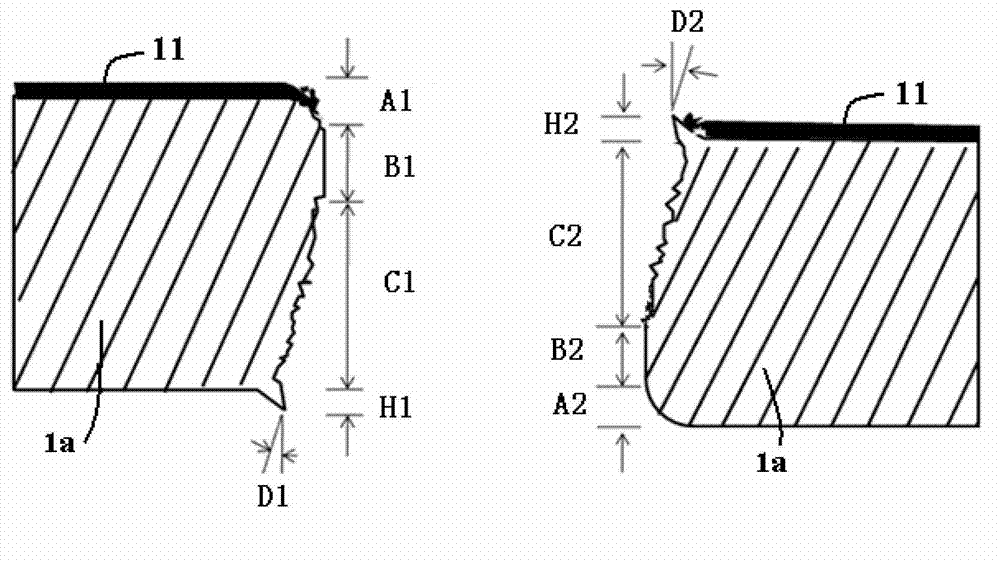

[0073] Such as figure 1 Shown is a schematic structural view of a compound thin film solar cell 1 to be cut in the embodiment of the present invention, including a metal substrate 1a, a metal back electrode film layer 1b, a semiconductor base film layer 1c, a TCO material film layer 1d and a gate Pole 2.

[0074] Unwinding process: such as figure 1 , Figure 7 with Figure 8 As shown, the battery roll 11a with the protective film 12a lined between the roll layers is placed on the support 73 of the unwinding mechanism 7, and under the action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com