Treatment process for edge of coated-type alkaline accumulator pole piece and auxiliary edge-covering equipment

A treatment process and storage battery technology, which is applied to the electrodes of alkaline storage batteries, etc., can solve problems such as tiny burrs on the edge of pole pieces, shedding of fine powder, and short-circuiting of batteries, and achieve the goals of eliminating short-circuit and low-voltage problems, simplifying production processes, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

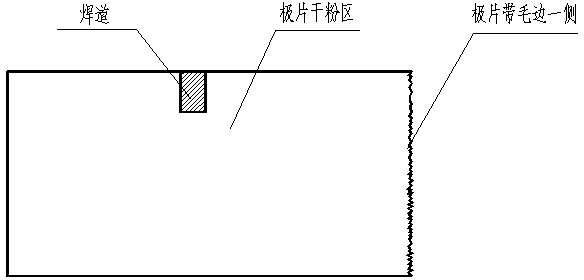

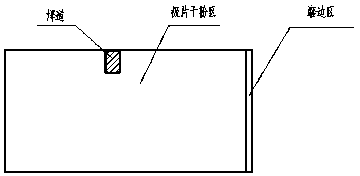

[0049] The treatment process for the edge of the coated alkaline battery pole piece is as follows: before filling the active material into the raw material of the battery pole piece - foamed nickel, use an automatic edge wrapping machine to insulate the alkali-resistant steel plate with a width of 2~10mm The material is wrapped around the edge of the foamed nickel, and the thickness of the foamed nickel covered by the alkali-resistant insulating material is compressed to less than 1.5mm, and finally the wrapped nickel foam is filled with active substances.

[0050] The alkali-resistant insulating material can be selected according to needs: such as PVC, PP, special paper tape, etc.

[0051] The process method see Figure 12 hint. After the edge-wrapped nickel foam is filled with active materials, it enters the four-stage drying kiln for drying, and then proceeds to the subsequent pole piece treatment.

[0052] The voltage standard deviation of the battery using this scheme i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com