Entrained-flow bed gasifier

A gasifier and entrained bed technology, which is applied in the details of the gasification unit, the feeding tool of the gasification unit, and the gasification of granular/powder fuels, etc., can solve the problems of huge investment, complicated operation and high requirements for safety interlocking system , to achieve the effect of improving volumetric efficiency, uniform temperature distribution, and improving unit volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The cooling walls of the entrained-bed gasification furnace in this embodiment are all in the form of cooling jackets, and the radiant waste pot is used in combination with the gasification chamber.

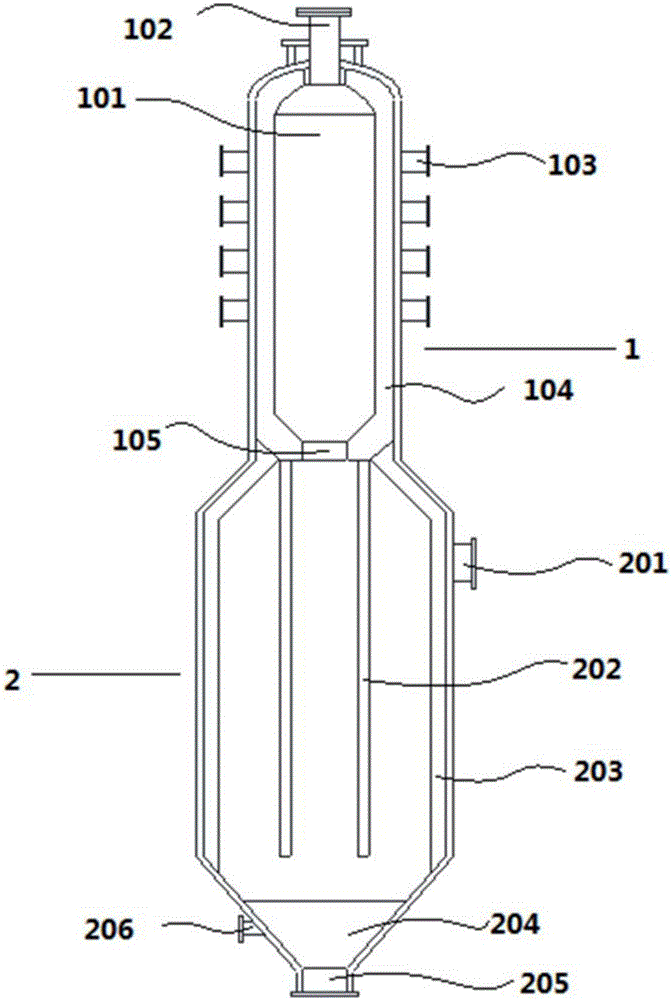

[0047] The entrained-bed gasification furnace of this embodiment comprises a gasification chamber 1 and a radiation waste pot 2 detachably connected to the bottom of the gasification chamber 1, and a main process burner 102 is arranged on the top of the gasification chamber 1, so that The gasification chamber 1 has a furnace body, and several rows of auxiliary process burners 103 are vertically pierced on the outer wall of the furnace body. A furnace 101 is arranged in the furnace body. Gasification chamber cooling jacket 104, the bottom of the furnace 1 is provided with a gasification chamber outlet 105; the radiant waste pot 2 includes a feed inlet, a slag water outlet 205 and an industrial gas outlet 201, the feed inlet, the The slag water outlet 205 and the industrial ...

Embodiment 2

[0060] The entrained-bed gasifier of this embodiment adopts the structure of Embodiment 1.

[0061] Taking a certain coal-to-gas industrial gas project as an example, the project adopts the gasifier of the present invention to produce industrial gas with medium calorific value by using pulverized coal and oxygen-enriched raw materials, and the coal processing capacity of the gasifier is 200t (dry basis coal) / d.

[0062] In this embodiment, the gasification raw material and 50% of the gasification agent enter the gasification chamber 1 from the main process burner 102 , and 50% of the gasification agent enters the gasification chamber from the auxiliary process burner 103 .

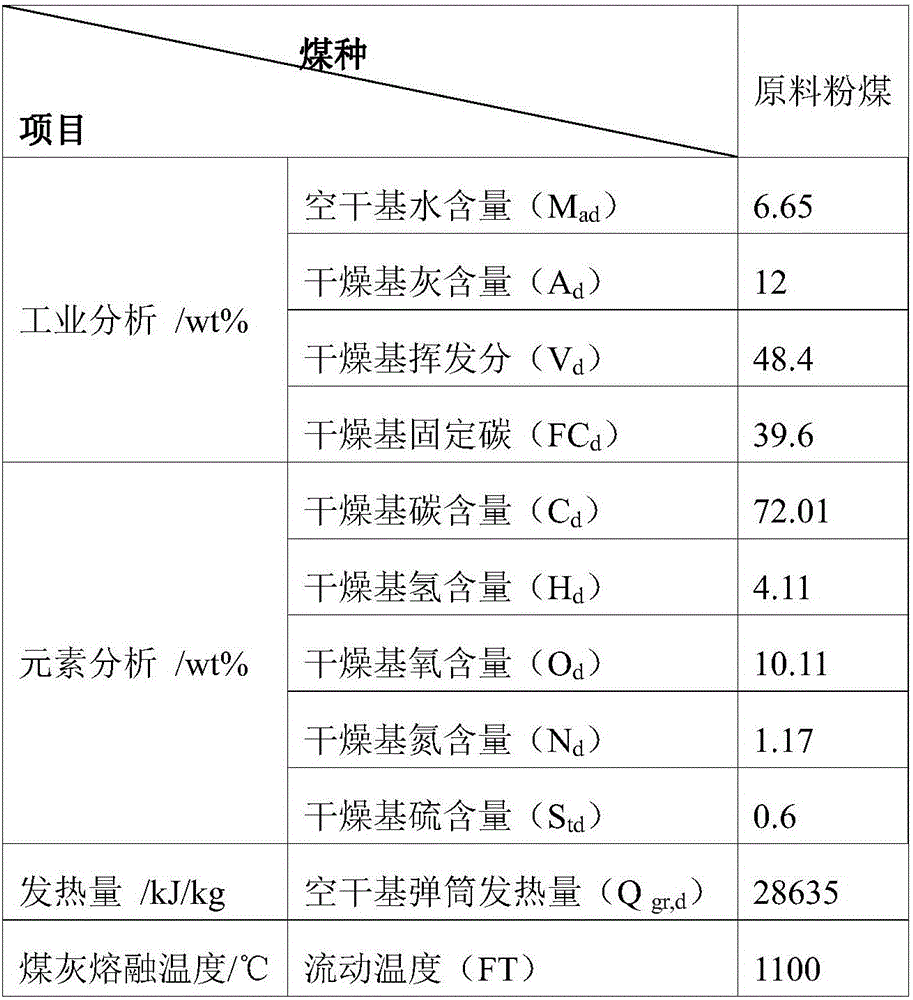

[0063] The coal quality analysis results of the raw pulverized coal used are shown in Table 1. The average particle size of the pulverized coal is 100 μm.

[0064] Table 3 shows the gasification conditions, industrial gas composition and device process performance of this embodiment.

[0065] Table 3 Gasi...

Embodiment 3

[0069] The entrained-bed gasifier of this embodiment adopts the structure of Embodiment 1.

[0070] Taking a petroleum coke industrial gas project as an example, the project adopts the gasifier of the present invention to produce industrial gas with medium calorific value by using petroleum coke and 95% pure oxygen as raw materials. The petroleum coke processing capacity of the gasifier is 200t (dry basis) / d.

[0071] In this embodiment, gasification raw materials and more than 90% of the gasification agent enter the gasification chamber 1 from the main process burner 102 , and less than 10% of the gasification agent enters the gasification chamber from the auxiliary process burner 103 .

[0072] The analysis results of the raw petroleum coke used are shown in Table 4, and the average particle size of the petroleum coke powder is 100 μm.

[0073] Table 4 Petroleum coke analysis results

[0074]

[0075]

[0076] Table 5 shows the gasification conditions, industrial ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com