Spray drying tower

A technology of spray drying tower and drying tower, which is applied in the direction of spray evaporation and evaporator accessories, which can solve the problems of fire and other problems, and achieve the effects of cost saving, energy consumption reduction and tower diameter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

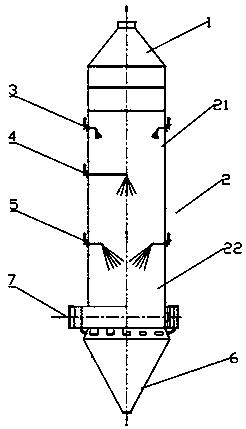

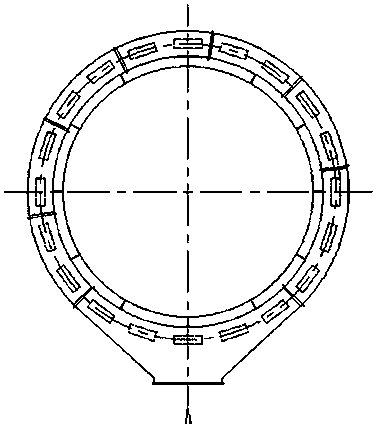

[0023] refer to Figure 1-2 , a spray drying tower, hot gas is input from the air inlet at the bottom of the drying tower, passes through the hot gas distributor 7, and is evenly output to the top of the drying tower, and the material to be dried is sprayed from the side of the drying tower through the atomizer Into the tower, after drying, it will be output in powder form from the bottom of the drying tower. The drying tower includes an upper tower body 1, which is a conical cylinder with an outlet on the top that shrinks upwards. After drying, the gas flows from the top of the upper tower body 1. Exit discharge. The drying tower of the present invention is a counter-flow type, that is, the direction of movement of the drying medium (hot air) is opposite to that of the atomized material liquid, and the atomized droplets move from top to bottom, while the hot air moves from bottom to top. The movement direction of the hot air in the drying tower is opposite to that of the ato...

Embodiment 2

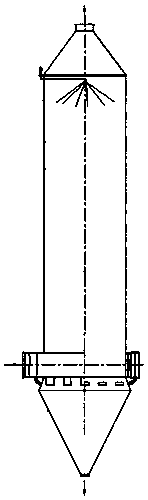

[0031] refer to image 3 , this embodiment is the drying tower before the improvement, and the main technical parameters of the drying tower, the drying tower before the improvement, the spray gun is located at the top of the drying tower, the material droplets are sprayed from top to bottom, and the hot air is from the bottom of the drying tower upwards, as Countercurrent drying tower. The height of the straight section of the drying tower is 25 meters, and the diameter of the straight section is 7 meters. Taking drying laundry powder as an example, the evaporation capacity of the drying tower is 13500kg / h, the initial mass fraction of laundry powder is 63~65%, the feed temperature is 55~60 ℃, and the air volume of the inlet air is 84440m 3 / h (under standard conditions), inlet air temperature: 380-400 ℃; exhaust air volume: 103040 m3 / h (under standard conditions); exhaust air temperature: 105-120 ℃; powder mass fraction: 97.2%. At this time, the hourly energy supply is abo...

Embodiment 3

[0033] This embodiment is the drying tower of the present invention, and the main technical parameters of the drying tower. There are 3 short spray guns evenly distributed on the upper part of the first straight barrel section, a central spray gun is distributed in the middle of the straight barrel section, and the upper part of the second straight barrel section is evenly distributed. Distributed with 3 long spray guns. The material droplets are sprayed from top to bottom, and the hot air is from the bottom of the drying tower upwards, which is a countercurrent drying tower. The height of the straight section of the drying tower is 21 meters, and the diameter of the straight section is 6 meters. Taking dry laundry powder as an example, the evaporation capacity of the drying tower is 13,500kg / h, the initial mass fraction of laundry powder is 63~65%, the feed temperature is 55~60 ℃, and the air intake volume: 65,790 m3 / h (under standard conditions) , Inlet air temperature: 420...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com