Laser processing apparatus, laser processing method, manufacturing method of wiring substrate, manufacturing method of display apparatus and wiring substrate

一种激光加工方法、激光加工的技术,应用在激光焊接设备、金属加工设备、制造工具等方向,能够解决长生产周期、工艺复杂等问题,达到提高制造产量、改善特性、简单和可靠激光加工的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0097] An example (detection result) of a wiring substrate (array substrate) manufacturing method is described below as a specific example of a laser processing method according to an embodiment of the present invention.

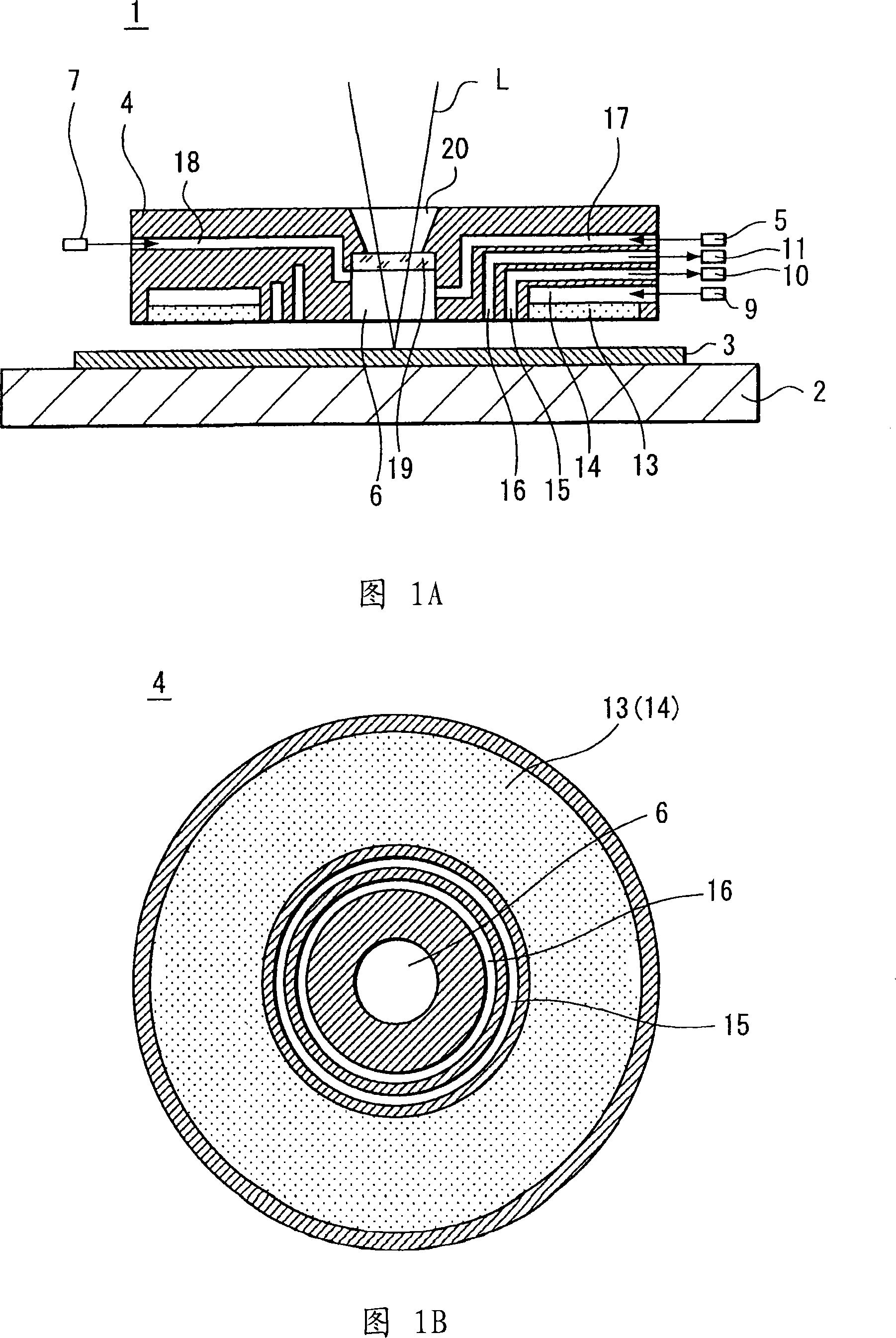

[0098] With the apparatus shown in FIGS. 1A and 1B , a thin film transistor (TFT) substrate was used as a processing object and laser processing was performed.

[0099] First, the inert gas argon (Ar) or nitrogen (N 2 ) is injected into the support table 2 through the porous gas permeable membrane 13 inside the local exhaust 4. The local exhaust device 4 is raised above the thickness of the processed object 3 , for example, 100 μm away from the support table 2 . Therefore, even when the processing object 3 is slightly bent or shaken, the local exhaust device 4 and the processing object 3 can avoid contacting each other in the next process.

[0100] Next, the support table 2 is moved in the horizontal direction and the processing object 3 is inserted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com