Method for manufacturing organic el element and method for setting focal point of laser

一种制造方法、焦点位置的技术,应用在有机半导体器件、半导体/固态器件制造、电气元件等方向,能够解决短寿命、变形或变质、有机EL元件发光效率下降等问题,达到提高利用率、高效率修复的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0065]

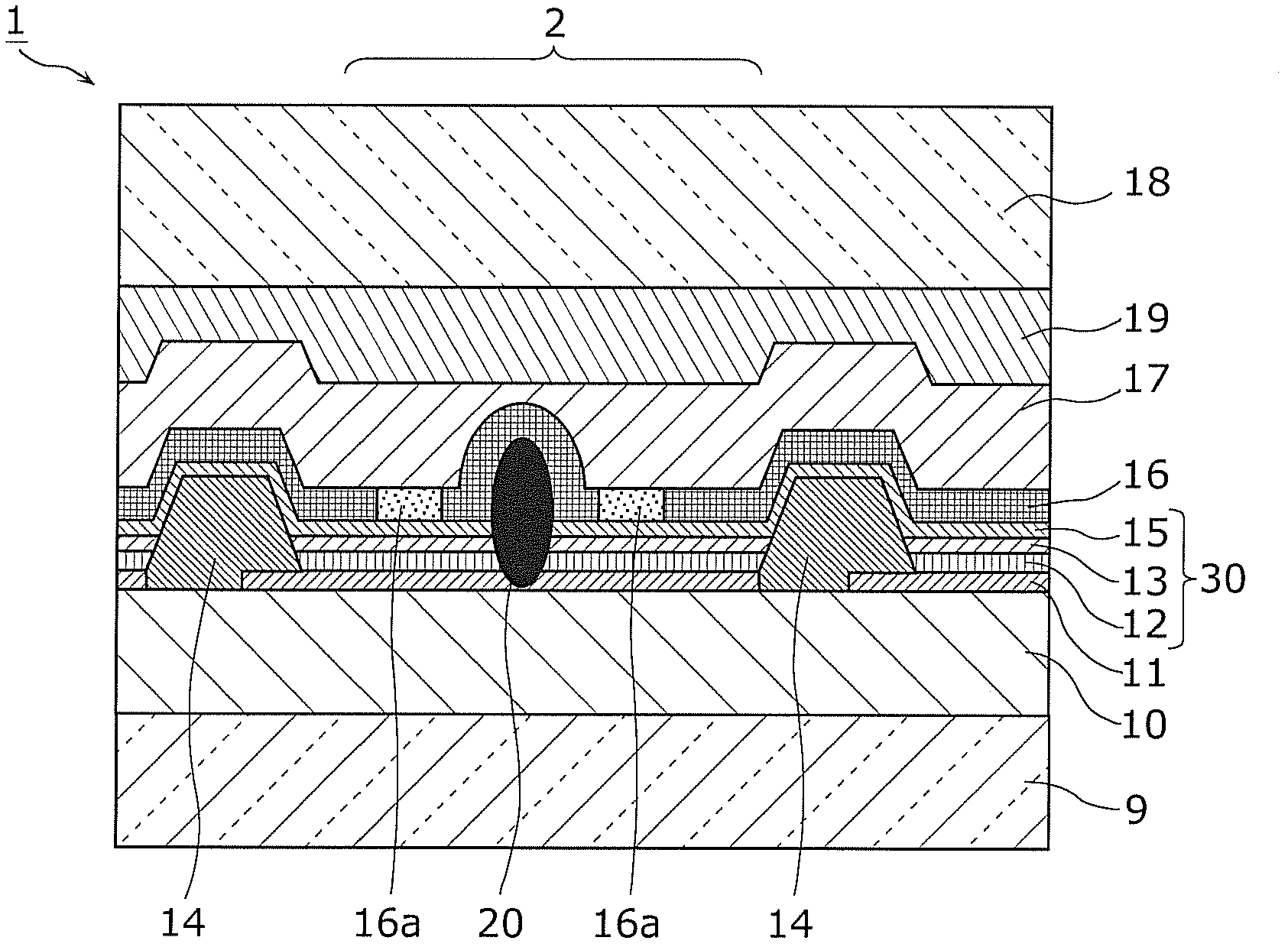

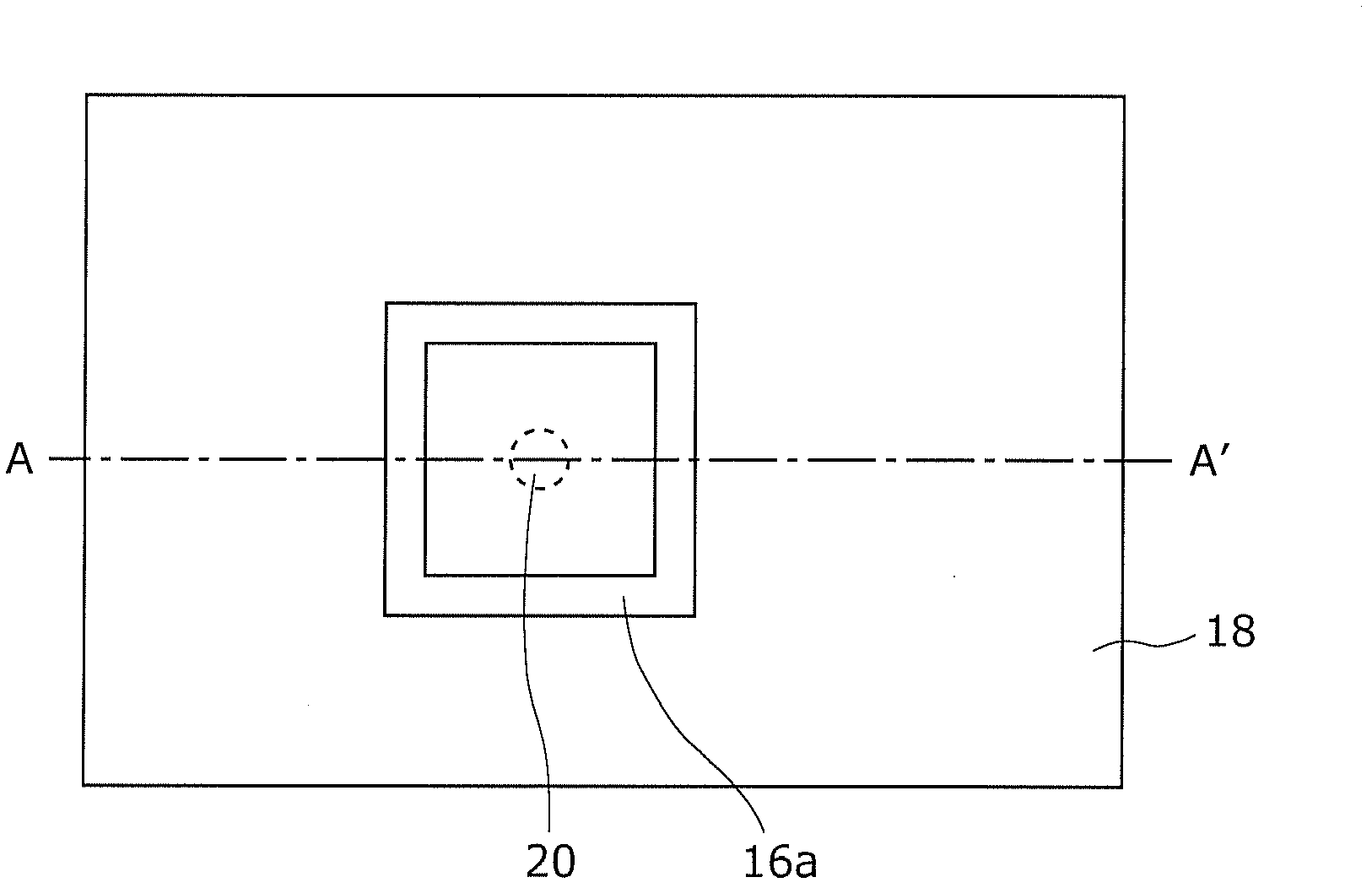

[0066] figure 1 It is a schematic cross-sectional view of the organic EL element 1 according to Embodiment 1 of the present invention. figure 1 The organic EL element 1 shown in is an organic functional device having an anode, a cathode, and an organic layer including a light-emitting layer sandwiched between the anode and the cathode.

[0067] Such as figure 1 As shown, in the organic EL element 1, a planarizing film 10, an anode 11, a hole injection layer 12, a light emitting layer 13, a partition wall 14, an electron injection layer 15, a cathode 16, a thin film sealing layer 17, The resin layer 19 and the transparent glass 18 are used for sealing.

[0068] The anode 11 and the cathode 16 correspond to the lower electrode layer and the upper electrode layer in the present invention, respectively. In addition, the hole injection layer 12, the light emitting layer 13, and the electron injection layer 15 correspond to the organic layer in this invention.

[0069...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com