Frequency varying driven washer

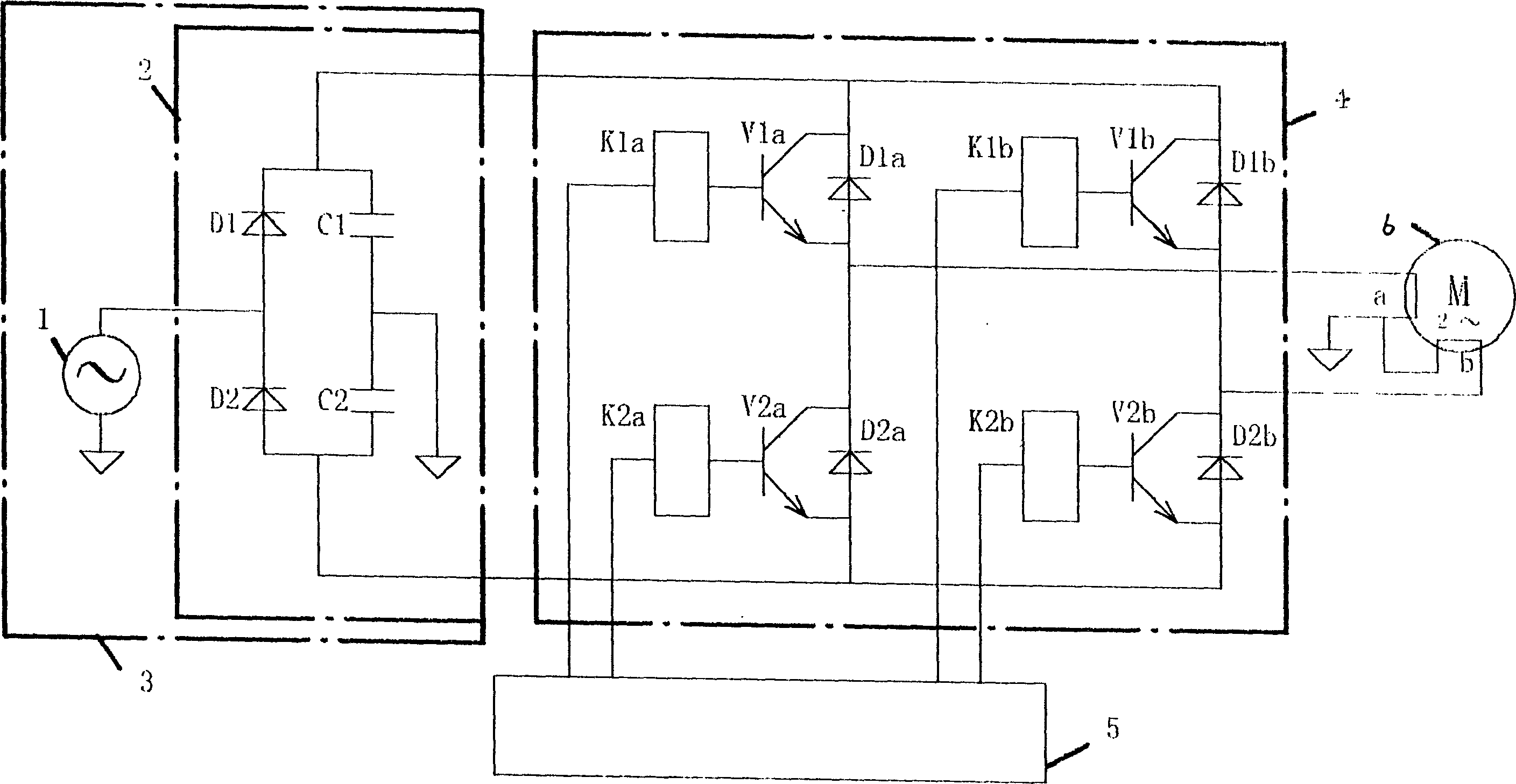

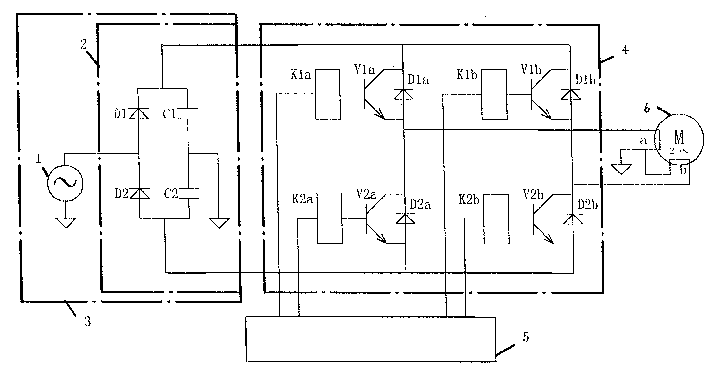

A variable frequency drive, washing machine technology, applied in the direction of DC motor speed/torque control, output power conversion device, AC power input conversion to AC power output, etc., can solve the problem of large number of inverter circuit units, complex embedded wires, and Cost and other issues, to achieve the effect of eliminating short-circuit low impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The tub is rotatably provided with a washing tub and dehydration tub rotatably provided with a pulsator at the inner bottom, and is suspended in the main body of the washing machine by a suspension member. The deceleration mechanism is arranged at the bottom of the water tank, and the power is transmitted to the pulsator, the washing bucket and the dehydration bucket. The lower part of the reduction mechanism is provided with a motor. The water supply system supplies water to the washing bucket and dehydration bucket, and the drain valve system discharges the washing water and the like in the washing and dehydration bucket. This is a typical composition of a pulsator washing machine. However, it is not limited to a pulsator type washing machine, and may also be an agitator type washing machine and a drum type washing machine. In addition, it is not limited to the structure that requires a deceleration mechanism or / and the coaxial transmission of the motor and each rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com