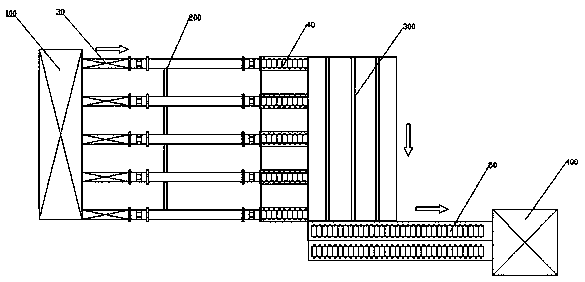

Continuous production system and production method for bamboo flattened plates

A production system and production method technology, applied in reed/straw treatment, wood compression, wood processing appliances and other directions, can solve the problems of long bamboo transportation distance, bamboo temperature loss, difficulty in flattening operation, etc., to optimize the production process, improve the The effect of utilization and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

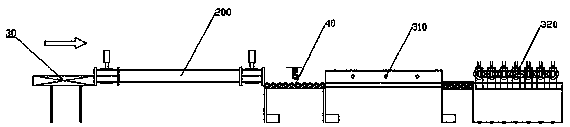

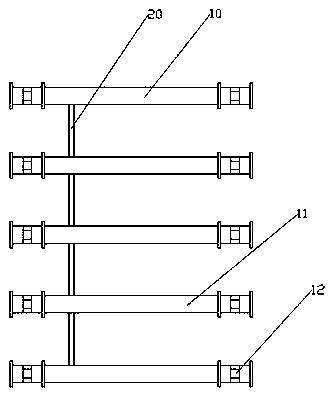

[0054] Embodiment 1 provides a kind of continuous production method of bamboo expansion plate, described production method uses the continuous production system of above-mentioned bamboo expansion plate to carry out bamboo expansion flat plate production, comprises the steps:

[0055] Step S1, bamboo pretreatment: first cut the original bamboo that has been felled for 15 days into a bamboo tube with a length of 2000mm, remove the green from the bamboo tube, and use a bamboo splitter to cut it into 1 / 4 arc-shaped bamboo slices, and measure the thickness of the arc-shaped bamboo slices Sort and stack.

[0056] Step S2, softening of bamboo slices: the arc-shaped bamboo slices output from the cutting end of the bamboo cutting machine with the yellowish side facing upwards, are loaded into the pressure tubes of the bamboo softening device through the automatic feeding device in the way of pushing the bamboo through the bamboo, Close the high-temperature steam pressure electric ball...

Embodiment 2

[0060] Embodiment 2 provides a kind of continuous production method of bamboo expansion board, comprises the steps:

[0061] Step S1, bamboo pretreatment: first cut the original bamboo that has been felled for 5 days into a bamboo tube with a length of 1200mm, and use a milling cutter to perform floating cutting on the bamboo tube to remove the 0.5mm thick bamboo green layer, and then use a circular saw blade to determine the width Form the curved bamboo slices with a width of 100 mm, and stack them according to the thickness of the curved bamboo slices.

[0062]Step S2, softening of bamboo slices: the arc-shaped bamboo slices output from the cutting end of the bamboo cutting machine with the yellowish side facing upwards, are loaded into the pressure tubes of the bamboo softening device through the automatic feeding device in the way of pushing the bamboo through the bamboo, Close the high-temperature steam pressure electric ball valve and each joint on the pipe body to carry...

Embodiment 3

[0066] Embodiment 3 provides a kind of continuous production method of bamboo expansion board, comprises the steps:

[0067] Step S1, bamboo pretreatment: first cut the original bamboo that has been felled for 10 days into a bamboo tube with a length of 800 mm, remove the green from the bamboo tube, and use a bamboo splitter to cut it into 1 / 3 arc-shaped bamboo slices, and measure the thickness of the arc-shaped bamboo slices Sort and stack.

[0068] Step S2, softening of bamboo slices: the arc-shaped bamboo slices output from the cutting end of the bamboo cutting machine with the yellowish side facing upwards, are loaded into the pressure tubes of the bamboo softening device through the automatic feeding device in the way of pushing the bamboo through the bamboo, Close the high-temperature steam pressure electric ball valve and each joint on the pipe body to carry out continuous heating and softening treatment of the arc-shaped bamboo slices. The bamboo softening device is fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com