Efficient production method of small-diameter-log composite wood

A production method and technology of small-diameter timber, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of cumbersome processing, high requirements for log straightness, low material utilization rate, etc., and achieve good quality and stable size Good performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

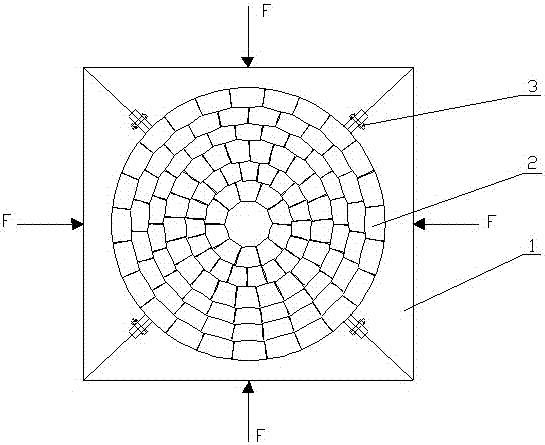

[0017] Embodiment 1, the method for manufacturing cylindrical composite material, is made up of following steps:

[0018] a) Small-diameter wood pretreatment: first peel off the outer skin of the small-diameter wood, polish the scars, cut it to a fixed length, control the moisture content at 20%, 30% or 40%, and heat the small-diameter wood with too much curvature Straighten, tie a certain volume of small-diameter timber with steel wire or string between the head and the tail, and measure its volume by water immersion method. The small-diameter timber in the outer layer requires high strength, less scarring, and small diameter grade. It is recommended to place the timber with a diameter grade greater than 35mm in the middle of the composite material;

[0019] b) Saturated steam is heated and softened. Put the bundled small-diameter timber into a closed pressure tank, and pass high-temperature saturated steam into it. Start timing when the temperature reaches 150°C, and the ti...

Embodiment 2

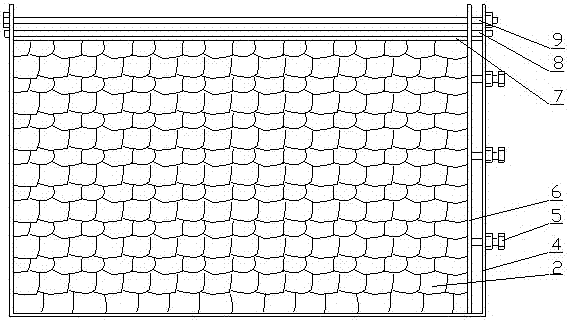

[0022] Embodiment 2, the method for manufacturing rectangular column type composite material, is made up of following steps:

[0023] a) Small-diameter wood pretreatment, first peel off the outer skin of the small-diameter wood, polish the scars, cut it to a fixed length, and control the moisture content at 20%, 30%, 40% or 60%, and the small diameter with too much curvature The wood is straightened by heating, and a certain volume of small-diameter wood is tied tightly with steel wires or strings alternately between the head and the tail, and its volume is measured by the water immersion method. The small-diameter timber in the outer layer requires high strength, less scarring, and small diameter grade. It is recommended to place the timber with a diameter grade greater than 35mm in the middle of the composite material;

[0024] b) Saturated steam heating and softening: put the bundled small-diameter timber in a closed pressure tank, and pass high-temperature saturated steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com